文章编号:1004-0609(2013)S1-s0738-04

熔模铸造TiAl基合金界面反应和抗氧化性能

曹守臻1,2,徐丽娟1,肖树龙1,2,贾 燚1,2,陈玉勇1,2

(1. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001)

摘 要:采用熔模铸造工艺制备ZrO2面层的型壳,离心浇注Ti-47Al和Ti-48Al-2Cr-2Nb合金,采用扫描电镜和显微硬度计研究两种合金的界面反应程度;将浇注的合金试样进行800 ℃高温氧化实验,并通过扫描电镜分析两种合金抗氧化能力的强弱。结果表明:对于Ti-48Al-2Cr-2Nb合金,其界面层处锯齿状起伏小,粘砂层较薄,反应层硬化程度较低,其在高温氧化后氧化层表面致密,氧化层较薄;Ti-48Al-2Cr-2Nb合金在界面的反应程度和抗氧化性能均优于Ti-47Al合金的。

关键词:TiAl合金;熔模铸造;界面反应;抗氧化性能

中图分类号:TG249.5 文献标志码:A

Interface reaction and oxidation resistance properties of investment casting TiAl-based alloys

CAO Shou-zhen1,2, XU Li-juan1, XIAO Shu-long1,2, JIA Yi1,2, CHEN Yu-yong1,2

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China)

Abstract: Ti-47Al and Ti-48Al-2Cr-2Nb alloys were cast in mould shells whose surface refractory material was ZrO2, and the interface reaction of these two kinds of alloys were analyzed by SEM and microhardness tester. The high temperature oxidation resistance of the cast samples at 800 ℃ was studied. The high temperature oxidation resistances of these two alloys were also analyzed by SEM. The results show that Ti-48Al-2Cr-2Nb alloy has thinner burnt-on sand layer, less ups and downs of surface and lower reaction hardening. Ti-48Al-2Cr-2Nb alloy has denser and thinner oxidation layer. Ti-48Al-2Cr-2Nb alloy has better property in interface reaction and oxidation resistance than Ti-47Al alloy.

Key words: TiAl alloy; investment casting; interface reaction; oxidation resistance

TiAl合金具有密度低、比强度高、蠕变抗性高和耐高温氧化性能好等优点,在航空航天领域具有广阔的应用前景[1-3]。但是其室温塑性不足,850 ℃以上耐高温氧化能力不足,阻碍了TiAl合金的实用化进程。添加合金化元素在TiAl合金性能的改善中具有广泛的应用,如在TiAl合金中添加Cr、Nb元素熔炼的Ti-48Al-2Cr-2Nb合金,其在室温力学性能和高温抗氧化性能上均优于一般TiAl合金的[4-5]。

熔模铸造在TiAl合金铸件的生产中应用广泛,是一种近净成形工艺,可实现小加工余量或零加工余量,且在成形形状复杂件时具有无可比拟的优势[2,6]。但TiAl合金在高温下极为活泼,几乎与所有化学元素能发生化学反应,浇注后合金与模具接触的表面会形成一层界面反应层[7-8]。在TiAl合金熔模铸造的研究中,界面反应一直是一个重要研究方向,研究者在型壳材料、浇注工艺及合金成分等方面进行研究,以降低界面反应的程度,改善铸件性能[9-10]。

本文作者采用ZrO2面层的型壳浇注Ti-47Al和Ti-48Al-2Cr-2Nb合金,研究两种合金的界面反应和抗高温氧化能力。

1 实验

实验用合金是在DHL-400非自耗电弧真空熔炼炉中熔炼制取,铸锭质量为50 g,经线切割分成均匀大小的两块用来浇注圆棒试样和片状试样。

制备型壳所选择的粘结剂为锆溶胶,面层耐火材料为粒径为45 μm的ZrO2粉(CaO稳定),背层粘结剂为硅溶胶,耐火材料则用莫来石粉和石英砂。蜡模为d10 mm×40 mm的圆棒和30 mm×50 mm×1 mm的蜡片。

浇注的试样在经过切割、磨样、抛光和喷碳处理后,采用CLEMEX全自动显微硬度计测试反应界面的显微硬度,并采用扫描电镜(SEM)对反应界面进行观察。

将由蜡片型壳浇注的试样进行喷砂处理后,切割成15 mm×15 mm×1 mm的片状在高温电阻炉中进行抗氧化实验,温度为800 ℃,采用扫描电镜(SEM)对氧化表面及剖面进行观察分析。

2 结果与分析

2.1 界面反应

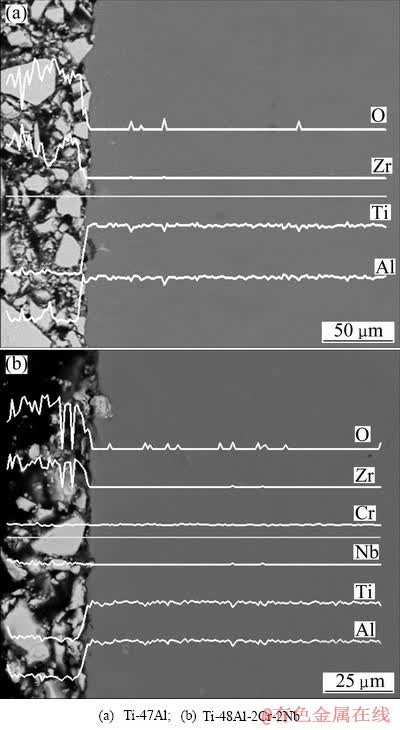

图1所示为TiAl合金界面层形貌及元素线扫分析。图中左侧区域为未参与界面反应ZrO2型壳,其中颗粒大小不均匀,大颗粒主要是由直接添加的的ZrO2组成,而小颗粒中则有相当一部分是由锆溶胶在焙烧分解时生成。由于型壳表面不是完全光滑致密的而有许多气孔,且ZrO2与TiAl合金的表面润湿性差,熔融TiAl在与型壳接触时,液体凸向型壳。故TiAl合金的界面反应不是平滑推进的,而是有强有弱,反应后界面呈锯齿状。界面反应程度越剧烈,粘砂层越厚,表面锯齿状的起伏程度也越剧烈。对比分析两种合金的界面反应层可以看出,Ti-47Al合金的界面反应层的粘砂层相对于Ti-48Al-2Cr-2Nb合金的要厚,其表面锯齿状的起伏程度也较大。

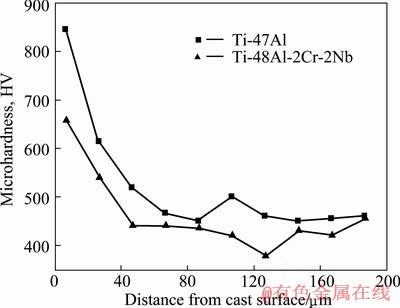

TiAl合金界面反应层会发生硬化,硬化机制主要由化学反应、元素扩散及合金浇注激冷造成。图2所示为TiAl合金界面层显微硬度变化趋势。Ti-47Al合金反应层在距离边界6.5 μm处的硬度值为846HV,Ti-48Al-2Cr-2Nb合金反应层在距离边界7 μm处的硬度值为658HV。根据硬度的变化趋势可以看出,两种合金基体内部的硬度值相近,而离边界的距离越近,合金的硬度值相差越大。分析可知,Ti-47Al合金相对于Ti-48Al-2Cr-2Nb合金界面层化学反应和元素扩散的程度要强。

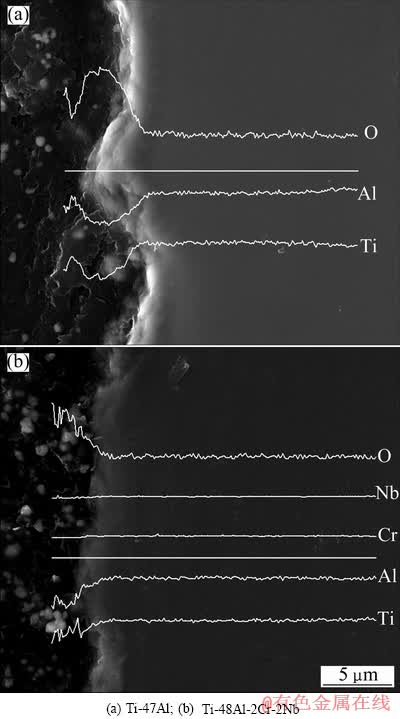

图1 TiAl合金反应界面层的SEM像及元素线扫描曲线

Fig.1 SEM images and elemental line scanning curves of interface reaction layer for TiAl alloys

图2 TiAl合金界面反应层显微硬度

Fig.2 Microhardness of interface reaction layers of TiAl alloys

2.2 高温氧化

研究表明,TiAl合金在高温条件下不能在表面形成一层致密的保护膜是其抗高温氧化性不足的主要原因。正常使用条件下TiAl合金氧化层由外及里由TiO2/Al2O3/ TiO2+Al2O3几部分组成,外层TiO2和内层混合层一般致密性较差,不能阻碍O元素的扩散,若中间的Al2O3层能形成连续致密的保护层,则能阻碍O元素的扩散,从而对合金基体起到保护作用[11]。

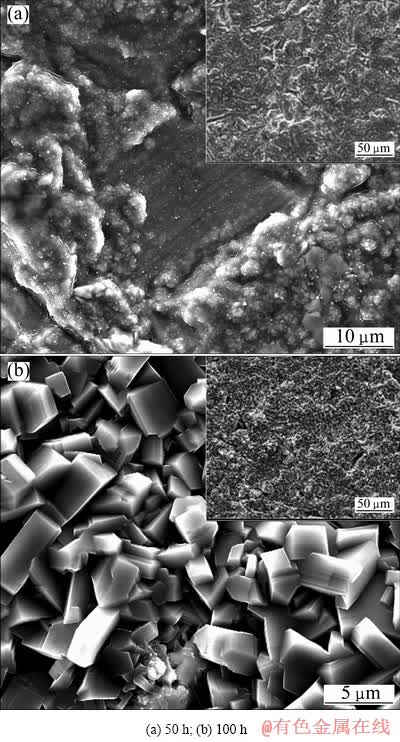

图3所示为Ti-47Al合金在800℃下氧化后氧化层的SEM像。在低倍SEM下观察,氧化50 h后,合金表面平整光亮;氧化100 h后,表面有均匀颗粒出现。在高倍SEM下观察后可明显看出,合金在氧化50 h后,其表面仍是较为光滑;氧化100 h后合,金表面由较为粗大的棱柱形氧化物组成,其截面跨度约为5 μm,各个棱柱之间并不致密,存在较大的间隙,该间隙使得大气中的O元素进入合金表面,不能起到保护基体作用。经EDS测定其成分主要有Ti与O,故其应为金红石型TiO2,微观特征为阶梯状,晶体特征为四方晶系[10]。

图3 ZrO2面层型壳浇注的Ti-47Al合金800℃氧化后氧化层的SEM像

Fig.3 SEM images of oxidation layer of Ti-47Al alloy at 800 ℃ for different times

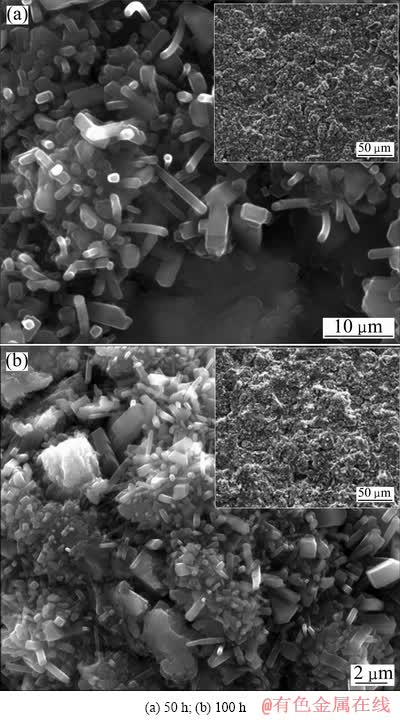

图4所示为Ti-48Al-2Cr-2Nb合金在800 ℃下氧化后氧化层的表面形貌。经过800 ℃氧化50 h后,低倍SEM下观察,Ti-48Al-2Cr-2Nb合金的表面都出现了微细颗粒,不再光滑;高倍SEM下观察,氧化后合金表面主要由细棒状的TiO2组成,其中掺杂有极少量的棱柱状TiO2。经过100 h氧化后,部分棒状TiO2长大为棱柱状,但是其表面大部分TiO2仍以棒状的形式存在,尺寸均在纳米级,少量的棱柱状TiO2其截面跨度也在1 μm以下,TiO2的尺寸相对于Ti-47Al合金要微细,氧化后合金表面氧化层的致密程度显著提高。

图4 ZrO2面层型壳浇注的Ti-48Al-2Cr-2Nb合金800 ℃氧化后氧化层的SEM像

Fig.4 SEM images of oxidation layer of Ti-48Al-2Cr-2Nb alloy at 800 ℃ for different times

图5所示为Ti-47Al合金和Ti-48Al-2Cr-2Nb合金经800 ℃氧化50 h后氧化层的SEM像及元素线扫描曲线。由图5可知,经过50 h氧化后,Ti-47Al合金出现明显的衬度发亮的氧化层,由各元素的分布分析可知,其氧化层的厚度约为6 μm。Ti-48Al-2Cr-2Nb合金在氧化50 h后,氧化层相对较不明显,其氧化层的厚度约为4 μm。

图5 ZrO2面层型壳浇注的TiAl合金800 ℃氧化50 h后氧化层的SEM像及元素线扫描曲线

Fig.5 SEM images and elemental line scanning curves of TiAl alloys after oxidation at 800 ℃ for 50 h

3 结论

1) Ti-47Al合金和Ti-48Al-2Cr-2Nb合金在浇注后都与型壳面层发生一定程度的界面反应,Ti-48Al-2Cr-2Nb合金相对于Ti-47Al合金粘砂层较薄,界面起伏程度低,显微硬度较低,总体来说其界面反应的程度要低于TI-47Al合金的。

2) 经过800 ℃的高温氧化后,Ti-47Al和Ti-48Al-2Cr-2Nb合金均发生一定程度的氧化,Ti-48Al-2Cr-2Nb合金在氧化50 h后的形貌与Ti-47Al合金的相近,但其氧化层厚度相对Ti-47Al合金的要薄;经过100 h氧化后,Ti-48Al-2Cr-2Nb合金氧化层表面为致密微细的细棒状TiO2,Ti-47Al合金氧化层表面为疏松粗大的棱柱状TiO2。总体来说,Ti-48Al-2Cr-2Nb合金的抗氧化性能优于Ti-47Al合金的。

REFERENCES

[1] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[2] IMMARIGEON J P, HOLT R T, KOUL A K, ZHAO L, WALLACE W., BEDDOES J C. Lightweight materials for aircraft applications [J]. Materials Characterization, 1995, 35(1): 41-67.

[3] LUTJERING G. Property optimization through microstructural control in titanium and aluminum alloys[J]. Materials Science and Engineering A, 1999, 263(2): 117-126.

[4] SHYHCHIN H, EMEST L. Hall plastic deformation and fracture of binary TiAl-base alloys[J]. Metallurgical and Materials Transactions A, 1991, 22(2): 427-439.

[5] 彭小敏, 夏长清, 王志辉, 黄 珍, 王金惠. TiAl合金高温氧化及防护的研究进展[J]. 中国有色金属学报, 2010, 20(6): 1116-1130.

PENG Xiao-min, XIA Chang-qing, WANG Zhi-hui, HUANG Zhen, WANG Jin-hui. Development of high temperature oxidation and protection of TiAl-based alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1116-1130.

[6] THORNE J K, BARICE W J. Advances in titanium alloy casting technology[J]. Ssmpe Quarterly, 1988, 10: 24-27.

[7] 王家芳, 王健农, 杨 杰. TiAl基合金与陶瓷界面反应的研究[J]. 特种铸造及有色合金, 2002, 5: 40-42.

WANG Jia-fang, WANG Jian-nong, YANG Jie. Study of the reaction between TiAl alloys and mould shells[J]. Special Casting & Nonferrous Alloys, 2002, 5: 40-42.

[8] LI Jun-tao, LI Shi-qiong, ZHANG Ji. Application research of centrifugal investment cast TiAl component used for advanced aircraft engine[J]. Transactions of Nonferrous Metals Society of China, 2002, 12(8): 625-628.

[9] RAHMEL A, SCHUTZE M, QUADAKKERS W J. Fundamentals of TiAl oxidation critical review[J]. Materials and Corrosion, 1995, 46(5): 271-285.

[10] 陈玉勇, 肖树龙, 徐丽娟, 韩杰才. 不同型壳材料条件下钛合金显微组织及界面反应[J]. 中国有色金属学报, 2010, 5(4): 269-273.

CHEN Yu-yong, XIAO Shu-long, XU Li-juan, HAN Jie-cai. Microstructure and interface reaction of titanium alloys casting into different mould shells[J]. The Chinese Journal of Nonferrous Metals, 2010, 19(4): 269-273.

[11] 成晓玲, 胡社军, 匡同春. 影响二氧化钛薄膜晶体结构的因素及研究进展[J]. 材料导报, 2005, 19(5): 51-54.

CHENG Xiao-ling, HU She-jun, KUANG Tong-chun. Research progress and effect factors on microstructure on nanometer TiO2 thin film[J]. Materials Review, 2005, 19(5): 51-54.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51001040; 51371064);国家重点基础研究发展计划资助项目(2011CB605502)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:徐丽娟,工程师,博士;电话:0451-86402451;E-mail:xljuan@hit.edu.cn