文章编号:1004-0609(2012)07-1897-07

调节片熔模铸造过程的应力数值模拟

洪耀武1, 2,王铁军3,韩大平3,许庆彦1, 2,柳百成1, 2

(1. 清华大学 机械工程系,北京 100084;2. 清华大学 先进成形制造教育部重点实验室,北京 100084;

3. 沈阳黎明航空发动机(集团)有限责任公司,沈阳 110043)

摘 要:采用商用软件ProCAST对调节片熔模铸造过程的应力进行数值模拟,分析调节片凝固过程中的应力变化情况,结果表明:裂纹缺陷处应力较大,凝固较慢。针对调节片裂纹的成因,提出在裂纹处增加内浇道的改进工艺方案,并对其在改进工艺下的铸造应力进行数值模拟。模拟结果表明:改进方案可明显减小原方案裂纹处的应力,消除该处裂纹缺陷,提高产品合格率。实际生产表明:改进方案明显消除了原方案的裂纹缺陷,合格率提高了30%。

关键词:铸造应力;数值模拟;调节片;熔模铸造

中图分类号:TG21+3 文献标志码:A

Numerical simulation of stress of adjustment sheet during investment casting process

HONG Yao-wu1, 2, WANG Tie-jun3, HAN Da-ping3, XU Qing-yan1, 2, LIU Bai-cheng1, 2

(1. Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China;

2. Key Laboratory for Advanced Materials Processing Technology, Ministry of Education, Tsinghua University, Beijing 100084, China;

3. Shenyang Liming Aero-Engine (Group) Corporation, Shenyang 110043, China)

Abstract: The commercial software ProCAST was used to simulate the stress of adjustment sheets during the solidification, and then the stress change tendency of the adjustment sheets during the solidification was analyzed. The results indicate that the stress is bigger and the solidification is slower in the places where the crack defects may easily happen. The casting stress of an improved scheme for adjustment sheets was also simulated. The simulated results show that the improved scheme can reduce the casting stress and get higher yield. The real production indicates that the improved scheme can eliminate defect and increase the yield by 30%.

Key words: casting stress; numerical simulation; adjustment sheet; investment casting

调节片作为航空发动机矢量喷口的重要部件,其在熔模铸造过程中容易产生裂纹缺陷,本文作者利用ProCAST软件对铸造过程产生的应力进行了数值模拟和分析,其研究对解决实际问题具有指导意义。计算机的发展,为铸造过程的模拟计算提供了硬件基础。通过数值模拟技术人们不仅可以“看到”铸件的充型及凝固过程,还能通过各种判据如Niyama判据来进行铸件的缩孔、缩松缺陷预测,从而使改进工艺所需的试验次数大大减少,缩短试制周期,降低生产成 本[1]。目前,铸造凝固过程应力场的模拟技术发展迅速,并逐渐应用于生产实践。李辉等[2]采用商用软件ProCAST对HT250应力框试件的热应力进行了数值模拟研究。朱慧等[3]对HT200发动机刚体在两种不同约束条件下的应力进行了模拟研究。康进武等[4]等基于FDM/FEM集成铸件热应力分析系统对HT200应力框试件的热应力进行了数值模拟研究。SABAU等[5-7]对A365铝合金阶梯试块熔模铸件最终尺寸进行了模拟预测。在铸造应力模拟中,铸件与铸型间的相互作用具有重要影响,基于Ansys接触单元法,刘小刚 等[8-9]等将面面接触单元法用于处理铸件与铸型间界面的相互作用。针对熔模铸造过程模拟人们也进行了相应的研究,如SCHEPPE和SAHM[10]利用MAGMASOFT计算分析了不同工艺条件下NiAl基金属间化合物熔模铸件的温度场,STEMMLER等[11]在熔模铸件和型腔之间耦合了接触模型和传热计算,考虑了间隙的形成对传热过程的影响,利用CASTS对型壳的预热和铸件的凝固进行了计算。此外,GRIFFITHS[12]、HALLAM[13]、SCHENEFELT[14]和WOODBURRY等[15]对界面传热的计算方法和界面换热系数的确定方法进行了研究。由于高温合金的高温力学性能尤其是糊状区的力学性能很难得到,目前对于高温合金铸件的铸造应力模拟还较少,故对调节片熔模铸造过程中应力进行数值模拟研究具有重要 意义。

本文作者采用商业软件ProCAST对调节片进行熔模铸造应力数值模拟,分析调节片在凝固过程中的温度场及应力场变化,从而得到其产生裂纹缺陷的原因;同时对调节片工艺改进方案进行铸造过程数值 模拟。

1 力学模型与热学边界条件

1.1 力学模型

目前热应力数值模拟主要采用热弹塑性模型,该模型不直接计入黏性效应,它认为材料屈服前为弹性,屈服后为塑性,弹性模量与屈服应力是温度的函数,且当材料接近熔点时,弹性模量与屈服应力均变为 零。本研究采用ProCAST软件中提供的热弹塑性 模型。

对于弹性模型,应力和应变符合如下关系:

{dσe}=[De]{dεe} (1)

式中:{dσe}、[De]和{dεe}分别为弹性应力增量、弹性模量矩阵、弹性应变增量,下标e以及后面的p和t分别表示弹性、塑性及传热。

在热弹塑性模型中,应变增量可表示为

dε=dεe+dεp+dεt (2)

且应力与总应变符合如下关系:

{dσ}=[D]ep({dεe}+{dεp})=[D]ep({dε}-{dεt}) (3)

式中:[D]ep为弹塑性模量矩阵。

热应变增量包括温度变化产生的收缩以及弹性 模量和线膨胀系数随温度变化而引起的增量,可以表示为

(4)

(4)

式中:T0是初始温度;T是瞬时温度;α是线膨胀 系数。

塑性应变增量的大小和方向由流动准则确定:

(5)

(5)

式中:H′为材料的塑性硬化模量,可由简单的拉伸曲线得到。由以上各式可得出热弹塑性模型的本构 方程:

(6)

(6)

1.2 热学边界条件

熔模型壳的存在对铸件的散热和凝固过程具有重要影响,建立铸件、型壳及环境相互之间的传热模型是对熔模铸件凝固过程进行数值模拟的前提。浇注 后,铸件、铸型和环境之间存在动态复杂的换热过程:在铸件、型壳及其二者之间的界面处,保温毡、砂箱及其二者之间界面处,热量(ΔQ)依靠热传导形式进行传递:

ΔQ=h(T1-T2) (7)

式中:h为界面换热系数;T1和T2分别为界面两侧的温度。

在型壳表面,保温毡表面及砂箱表面与环境之间存在辐射和对流换热,在铸件冒口与环境之间也存在辐射和对流换热过程:

ΔQ=h1(T-Ta)+σε(T4-Ta4) (8)

式中:h1表示模壳或者砂箱等表面与环境的对流换热系数;T表示模壳或者砂箱等表面的温度;Ta表示环境温度;ε表示辐射换热系数。

关于具体的热学边界赋值、铸件/铸型力学模型研究的具体内容及力学边界条件设置可见文献[16]。

2 调节片结构分析

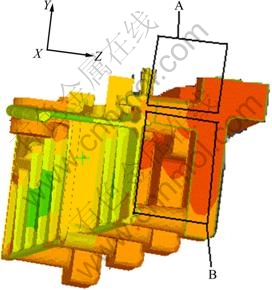

所研究的调节片铸件为薄壁结构件,采用K424合金熔模精铸而成,其铸件结构如图1所示。该铸件长约为360 mm、宽约为110 mm、最小壁厚0.9 mm,调节片生产时容易在图1(b)中所指位置出现裂纹缺陷,合格率较低,因此,有必要对调节片进行模拟研究,分析裂纹缺陷的原因,为工艺改进提供理论依据。

图1 调节片结构示意图

Fig. 1 Schematic diagram of adjustment sheet casting: (a) Side view; (b) Top view

调节片浇注时两件一组,对称排布,如图2(a)所示。生产时型壳放在置有保温毡的砂箱中。型壳、砂箱及保温毡预热温度为1 070 ℃,浇注温度为1 480 ℃。模拟时根据对称性,取整个浇注系统的1/4,如图2(b)所示。采用四面体网格,最长网格边长为1 mm,网格总体单元数量为7.8×105。模壳的力学模型采用线弹性模型,铸件的力学模型采用热弹塑性模型。

图2 调节片铸造工艺简图及有限元模型

Fig. 2 Casting process diagram of adjustment sheet (a) and FEM model (b)

调节片铸件的材质为K424,表1~6所列分别为K424的主要合金成分、K424及型壳的部分热物性参数及其高温力学性能[17]。

表1 K424合金的化学成分[17]

Table 1 Chemical composition of K424 alloy (mass fraction, %)[17]

表2 K424合金的热物性参数[17]

Table 2 Thermo-physical parameters of K424 alloy[17]

表3 型壳材料的热物性参数[17]

Table 3 Thermo-physical parameters of mold material[17]

表4 K424合金的弹性模量随温度的变化[17]

Table 4 Elastic modulus of K424 alloy at different temperatures[17]

表5 K424合金的屈服强度随温度的变化[17]

Table 5 Yield strength of K424 alloy at different temperatures[17]

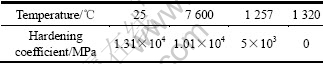

表6 K424合金的硬化系数随温度的变化[17]

Table 6 Hardening coefficient of K424 alloy at different temperatures[17]

3 模拟结果及分析

3.1 温度场模拟结果与分析

温度场的模拟是应力场模拟的基础,因此,首先分析叶片温度场分布情况。图3所示为调节片在不同温度区间的冷却速率。从图3中可以明显看出,凝固前期调节片的底板中无肋板的中心部位冷却速率较快,此时调节片从该处往外冷却,后期调节片地板边缘冷却速率较快,调节片从底板边缘向内冷却。图4所示为调节片冷却不同时刻的温度场分布。从图4(a)和(b)可以看出,冷却前期调节片由底板中心向外冷却,从图4(c)~(e)可以看出冷却后期调节片由底板边缘向内冷却。同时从图3(a)可以看出,1、2两处冷速慢于周围的,故其凝固慢于周围的的凝固。图5所示为调节片凝固不同时刻的固相分数分布。

图3 调节片不同温度区间的冷却速率

Fig. 3 Cooling rate of adjustment sheet between different temperature zones: (a) 1257-1480 ℃; (b) 800-1 000 ℃

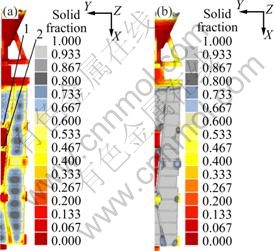

从图5(a)和(b)可以看出,1、2两处(结构上处于调节片中心两侧的悬空梁处)在周围已经凝固时还未完全凝固,尚处于糊状区,而此时受周围收缩产生的拉应力,当拉应力达到此两处在该温度下的强度极限时,就会产生微裂纹,在后续凝固中由于拉应力的进一步累积,微裂纹扩展,因而1与2两处为调节片在生产中容易产生裂纹缺陷的位置,与实际生产中的裂纹位置一致。对于调节片在图5(a)中的1处截取截面YZ,从结构上对调节片1处的应力进行分析,结果如图6所示。

图4 调节片的温度场分布

Fig. 4 Evolution of temperature field of adjustment sheet: (a) t=152 s; (b) t=182 s; (c) t=234 s; (d) t=330 s; (e) t=1 300 s

图5 不同时刻调节片固相分数分布

Fig. 5 Solid fraction of adjustment sheet at different times: (a) t=152 s; (b) t=182 s

图6 调节片的YZ截面

Fig. 6 YZ cross-section of adjustment sheet casting

图6中两个矩形框A和B,为横浇道、内浇道与调节片底板之间组成的框架结构,由框架的应力变化规律可知,横浇道(相当于框架的粗杆)的收缩会通过内浇道(相当于横梁)对调节片平板(相当于细杆)产生拉伸作用,且由于型壳的阻碍作用,调节片底板始终处于受拉状态。因此,图3(a)的1处于此框架的受拉位置,该处的应力比较大,当超过该温度下的屈服极限时就会产生裂纹。

3.2 应力场模拟结果与分析

基于上述温度场的模拟分析结果,进一步对调节片凝固过程中铸造应力开展了模拟研究。通过数值模拟得到了调节片在凝固过程中的应力场及其变化,定义Y方向正应力为σY,等效应力为σeff。

图7所示为调节片在不同时刻的σY分布云图。结合图5不同时刻调节片固相分数分布图对图7的Y方向应力σY进行分析,由于1、2两处周围金属液先凝固收缩会受到周围阻碍其收缩的拉应力,而力的作用是相互的,所以1、2两处会受到周围先凝固部位的拉应力,图7(b)显示1、2两处在Y方向上受拉应力,而此时图5(b)显示1、2两处仍处于糊状区,此时这两处受的拉应力如果超过材料的屈服极限,则这两处可能出现微裂纹。在后续的凝固过程中,调节片底板进一步冷却收缩,由于型壳的阻碍作用,1、2两处的拉应力会逐渐积累,可能使微裂纹扩展。从结构上看,1、2两处均处在调节片底板与横浇道和内浇道间组成的框架结构中,因此,此两处最终在Y方向上的应力由于框架使得其受拉而显得比较大,属于应力集中部位。

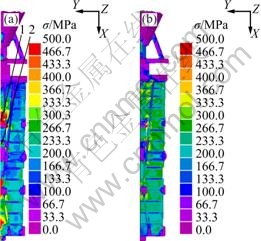

图8所示为调节片冷却末期的Y向应力与等效应力分布云图。从图8中可看出,1、2两处属于应力集中区,根据上述分析,1、2两处可能会有微裂纹存在,所以,1、2两处应力的较高水平可能使得微裂纹扩展,故此两处容易在生产中产生裂纹,与实际生产裂纹位置一致。

图7 不同凝固时刻σY分布图

Fig. 7 Evolution of σY at different solidification times: (a) t= 152 s; (b) t=182 s; (c) t=134 s

图8 调节片冷却末期应力分布

Fig. 8 Evolution of stress field for adjustment sheet casting at final solidification stage: (a) σY; (b) σeff

4 改进工艺方案及其模拟结果

在调节片的实际生产中,容易在图3(a)所示的1、2两处产生裂纹。从上述调节片凝固过程中温度场与应力场分析看,此两处产生裂纹的主要原因是这两处相对周围凝固较慢,受来自周围的拉应力,且均处于调节片底板、横浇道和内浇道组成的框架中,凝固过程中会受到较大的拉应力。因此,对调节片提出改进的工艺方案,在图9的A处增加内浇道(图9为调节片局部图),可去除1、2两处的框架结构,又可进行补缩,减小这两处微裂纹形成的可能性,从而减少这两处裂纹的产生。

图9 调节片工艺改进方案

Fig. 9 Improved scheme of adjustment sheet casting

图10所示为调节片冷却末期原方案与工艺改进方案的等效应力分布云图。从图10可以看出,由于去除了上述框架结构,1、2两处在凝固末期的等效应力明显减小,因此,这两处在实际生产中产生的裂纹基本消除。

进一步从热裂指数(具体计算方程可参考ProCAST软件介绍)对两种方案进行分析,图11所示为两种方案下调节片各处热裂指数。从图11可以看出,改进方案可明显的消除2处的热裂趋势;而1处的热裂趋势并未消除,但是由于1处加了内浇道,可对1处进行补缩,且加了内浇道之后,该处的应力明显减小,所以,实际生产中,1处产生的裂纹减少。

图10 两种方案下调节片冷却末期的应力分布

Fig. 10 Evolution of stress field for adjustment sheet casting under different schemes at final solidification stage: (a) Initial scheme; (b) Improved scheme

图11 两种方案下调节片热裂指数图

Fig. 11 Hot tearing indicator of adjustment sheet casting under different scheme: (a) Initial scheme; (b) Improved scheme

经过上述模拟分析可知,改进的工艺方案可有效减少调节片裂纹产生,提高调节片的合格率。沈阳黎明航空发动机(集团)有限责任公司的实际生产表明,改进的工艺方案可提高调节片的产品合格率30%。由此可见,铸造应力数值模拟技术可以对铸造工艺的改进提供科学依据。

5 结论

1) 对调节片凝固过程温度场进行了模拟,冷却前期调节片由底板心部向外冷却,冷却后期调节片由底板边缘向内冷却。

2) 调节片1、2两处受拉应力,且属于较晚凝固部位,冷却末期等效应力也较大,该处可能产生裂纹。

3) 改进方案可以明显较小1、2两处的应力和热裂指数,减少这两处的裂纹产生。实际生产表明,改进方案可以消除1、2两处裂纹,提高产品合格率 30%。

REFERENCES

[1] 孙长波, 唐 宁, 史凤岭, 费 晶, 许庆彦, 柳百成. 机匣件真空熔模铸造的数值模拟[J]. 铸造, 2010, 59(2): 169-173.

SUN Chang-bo, TANG Ning, SHI Feng-ling, FEI Jing, XU Qing-yan, LIU Bai-cheng. Numerical simulation of vacuum investment casting cartridge receiver [J]. Foundry, 2010, 59(2): 169-173.

[2] 李 辉, 时建松, 张爱琴. 应力框热应力数值模拟及变形分析[J]. 铸造, 2010, 59(1): 38-41.

LI Hui, SHI Jian-song, ZHANG Ai-qin. Numerical simulation and deformation analysis of thermal stresses in stress frame [J]. Foundry, 2010, 59(1): 38-41.

[3] 朱 慧, 黄天佑, 康进武. 两种不同约束条件下发动机缸体铸件热应力场的数值模拟[J]. 铸造, 2006, 55(6): 604-607.

ZHU Hui, HUANG Tian-you, KANG Jin-wu. Numerical simulation of thermal stress of diesel engine cylinder block castings under two different constraints [J]. Foundry, 2006, 55(6): 604-607.

[4] 康进武, 朱 慧, 黄天佑. 基于有限差分网格的铸件热应力分析[J]. 铸造, 2006, 55(3): 259-261.

KANG Jin-wu, ZHU Hui, HUANG Tian-you. Thermal stress analysis of castings based on finite difference meshes [J]. Foundry, 2006, 55(3): 259-261.

[5] SABAU A S. Alloy shrinkage factors for the investment casting process [M]. Metallurgical and Materials Transactions B, 2006, 37(1): 131-140.

[6] SABAU A S, VISWANATHAN S. Material properties for predicting wax pattern dimensions in investment casting [J]. Materials Science and Engineering A, 2003, 362(1): 125-134.

[7] CANNELL N, SABAU A S. Predicting pattern tooling and casting dimensions for investment casting, phase II, ORNL/TM- 2005/228 [R]. Oak Ridge, Tennessee: Oak Ridge National Laboratory, 2005.

[8] 刘小刚, 康进武, 黄天佑, 边敦亭, 张良红. 大型轧钢机机架凝固过程温度场应力场模拟分析[J]. 铸造, 2006, 55(9): 922- 926.

LIU Xiao-gang, KANG Jin-wu, HUANG Tian-you, BIAN Dun-ting, ZHANG Liang-hong. Numerical simulation of the solidification process of a heavy roll stand for temperature field and thermal stress field [J]. Foundry, 2006, 55(9): 922-926.

[9] 刘小刚, 康进武, 罗通国, 杨小兵, 王长建, 程建国, 黄天佑, 柳百成. 水轮机下环铸件凝固过程热应力模拟分析[J]. 铸造技术, 2006, 27(9): 984-987.

LIU Xiao-gang, KANG Jin-wu, LUO Tong-guo, YANG Xiao-bing, WANG Chang-jian, CHENG Jian-guo, HUANG Tian-you, LIU Bai-cheng. Thermal stress analysis of the solidification process of francis turbine band casting [J]. Foundry Technology, 2006, 27(9): 984-987.

[10] SCHEPPE F, SAHM P R. Comparison of the numerical simulation and the cast process of nickel aluminides [C]// Modeling of Casting, Welding and Advanced Solidification Process. Warrendale: TMS, 2000: 207-214.

[11] STEMMLER M, LASCHET G, HAAS L. Simulation of investment casting: Coupling of contact and heat transfer calculation between casting and mold during solidification [C]// Modeling of Casting, Welding and Advanced Solidification Process. Warrendale: TMS, 2000: 222-229.

[12] GRIFFITHS W D. The determination of the heat transfer coefficient in experiments involving unidirectional solidification [C]// Modeling of Casting, Welding and Advanced Solidification Process. Warrendale: TMS, 2000: 143- 150.

[13] HALLAM P C. Modeling of the interfacial heat transfer between an Al-Si alloy casting and a coated die steel [C]// Modeling of Casting, Welding and Advanced Solidification Process. Warrendale: TMS, 2000: 159-166.

[14] SCHENEFELT J R, LUCK R, TAYLOR R P. Reducing uncertainty in the use of the inverse method of determining heat transfer coefficient data [C]// Modeling of Casting, Welding and Advanced Solidification Process. Warrendale: TMS, 2000: 215-221.

[15] WOODBURRY K A, PIWONKA T S, KE Q. Interfacial heat transfer coefficients during solidification of aluminum in resin-bonded and green sand molds [C]// Modeling of Casting, Welding and Advanced Solidification Process. Warrendale: TMS, 2000: 270-277.

[16] 洪耀武. 镍基高温合金熔模铸件铸造应力数值模拟[D]. 北京: 清华大学, 2011: 13-22.

HONG Yao-wu. Numerical simulation of casting stress of Ni-based superalloy casting during investment casting process [D]. Beijing: Tsinghua University, 2011: 13-22.

[17] 《工程材料实用手册》编辑委员会. 工程材料实用手册[M]. 第二卷. 北京: 中国标准出版社, 2002: 645-651.

《Engineering materials practical manual》Editorial Committee. Engineering materials practical manual [M]. 2nd ed. Beijing: China Standards Press, 2002: 645-651.

(编辑 陈卫萍)

基金项目:国家高技术研究发展计划资助项目(2007AA04Z141)

收稿日期:2011-06-28;修订日期:2012-03-09

通信作者:许庆彦,教授,博士;电话:13701087143;E-mail: scjxqy@tsinghua.edu.cn