文章编号:1004-0609(2007)03-0378-06

电沉积条件对Pd-Co合金微观相结构和耐蚀性的影响

关晓洁1,钟美娥2,肖耀坤3,陈宗璋4

(1. 广东省城市建设技工学校 工业分析与质量检验专业, 广州 510650;

2. 华南理工大学 材料科学与工程学院,广州 510641;

3. 湖南大学 材料学院,长沙 410082;4. 湖南大学 化学化工学院,长沙 410082)

摘 要:利用X射线衍射分析和动电位扫描技术等测试手段,考察电沉积工艺条件对Pd-Co合金镀层微观相结构和耐蚀性的影响。结果表明:钯钴合金沉积层的晶粒尺寸D(111)随电流密度、pH值和沉积时间的增加呈先减小后增大的变化趋势,随着镀液温度的升高而不断增大;当电流密度为1.0 A/dm2,pH值为8.3,沉积时间为30 min时,其晶粒尺寸最小,为8.239 6 nm;当电流密度为1.0 A/dm2,镀液温度为35 ℃,pH值为8.3时,钯钴合金沉积层的耐蚀性最强;而沉积时间对合金耐蚀性的影响不大。

关键词:Pd-Co合金;电沉积;微观结构;耐蚀性

中图分类号:TQ 153.2 文献标识码:A

Effects of process conditions on microstructure and corrosion-resistance of electrodepositing Pd-Co alloy

GUAN Xiao-jie1, ZHONG Mei-e2, XIAO Yao-kun3,CHEN Zong-zhang4

(1. Industry Analysis and Quality Check, Guangdong Province Urban Construction Technical School, Guangzhou 510650, China;

2. School of Materials Science and Engineering, South China University of Technology, Guangzhou 510641, China;

3. School of Material, Hunan University, Changsha 410082, China;

4. School of Chemistry and Chemical Engineering, Hunan University, Changsha 410082, China)

Abstract:The influence of process parameters on the microstructure and corrosion-resistance of Pd-Co alloy was studied by X-ray diffractometry and potentiodynamic polarization techniques. The results show that with the increase of current density, pH value and electrodeposited time, the crystallite size of Pd-Co alloy decreases firstly whereas increases subsequently. With the increase of bath temperature, the crystallite size increases. When the current density is 1.0 A/cm2, pH is 8.3, and deposited time is 30 min, the crystallite size of Pd-Co alloy reaches the minimum value, which is 8.239 6 nm. When the current density is 1.0 A/cm2, temperature is 35 ℃, pH is 8.3, Pd-Co alloy exhibits the maximum corrosion-resistance, but the electrodeposited time has little influence on it.

Key words:Pd-Co alloy; electrodepositing; microstructure; corrosion-resistance

钯及其合金外观优美,具有较高的硬度、较低的孔隙率、较强的耐蚀性、较低的接触电阻及可靠的焊接性能,已被广泛地应用于装饰行业和电子工业等领 域[1-8]。目前,人们研究较多的钯合金镀层为Pd-Ni合金。但是,当沉积层以镍为底层时,Pd-Ni合金无法以X射线荧光法准确测定其组成和镀层厚度,该合金镀层在温度高于125 ℃时不稳定,且人体对镍过敏,产生危害[9]。而Pd-Co合金沉积层能克服Pd-Ni合金的缺点且具有许多优越性能,如较高的硬度、较强的抗磨损性、较长的使用寿命等,该合金还具有较低的孔隙率和极强的抗腐蚀性,因此,研究Pd-Co合金具有重要意义[10-12]。目前,人们对钯钴合金的研究报道较少,且电沉积条件对钯钴合金的结构和性能有极其重要的影响,在此,本文作者采用X射线衍射分析(XRD)和动电位扫描技术考察电流密度、pH值、镀液温度和沉积时间等对钯钴合金的微观结构和耐蚀性能的影响。

1 实验

1.1 镀液组成及工艺条件

纯钯质量浓度为4.5 g/L;钴质量浓度为2.4 g/L;pH值(用氨水调节)为7.8~8.7;温度为35~60 ℃;电流密度Dc为0.5~2.0 A/dm2;镀液质量浓度(用氯化铵调)为1.067 g/L;阳极为Pt电极;阳极与阴极面积比为4?1。

实验中所用药品均为分析纯,溶液采用去离子水配制。

1.2 试样制备及镀层微观结构和耐蚀性的测定

基底材料为0.5 cm2紫铜片,其非工作面用环氧树脂绝缘。沉积之前将工作面依次经过4#~6#金相砂纸打磨抛光、除油、酸洗,在以上工艺条件下直流电沉积30 min(除制备不同沉积时间的样品外)。

利用德国Siemens-D5000型X射线衍射仪,采用CuKα靶(电压为35 kV,电流为30 mA),波长λ =0.154 06 nm,扫描速度为2 (°)/min,扫描范围为10°~110°,对镀层进行微观结构分析。实验结果中晶粒尺寸采用Sherrer公式进行计算:

电化学实验在上海辰华CHI660B电化学工作站上进行。采用Tafel技术测定钯钴合金镀层在3.5% NaCl溶液中的腐蚀曲线,电位扫描在开路电位±250 mV范围内进行。测试时,系统温度为室温,扫描速度为0.5 mV/s,研究电极面积为0.5 cm2,参比电极为饱和甘汞电极,辅助电极为大面积铂片。

2 结果与讨论

2.1 电流密度对Pd-Co合金镀层微观结构的影响

图1所示为不同电流密度下Pd-Co合金镀层的XRD结果。将其与标准XRD图谱对照可知,这些峰是PdCo2和基体铜的不同晶面衍射峰。另外,衍射图上还出现1个无定形物质的衍射峰。将封胶基体与不封胶基体对比并进行XRD测试,结果表明该衍射峰是绝缘材料环氧树脂的衍射峰。另外,由图1中 Pd-Co合金的衍射峰的峰位,可求出各衍射线的sin2θ之比,即sin2θ1?sin2θ2?sin2θ3?sin2θ4=3?4?8?11,与该4个角(θ1, θ2, θ3和θ4)相对应的晶面为(111),(200),(220)和(311),表明钯钴合金沉积层在电流密度为0.5,1.0和2.0 A/dm2时均为面心立方晶格(FCC),电流密度对镀层的相结构没有影响,镀层的晶粒尺寸D(111)分别为14.457 1,8.239 6和9.545 1 nm。

图1 不同电流密度下制备的Pd-Co合金镀层XRD结果

Fig.1 XRD patterns of Pd-Co alloy prepared with different current densities

根据电结晶理论,电沉积层的晶粒大小取决于两个因素:一是新晶核的生成速度;二是已有晶核的生长速度。钯钴共沉积过程受阴极极化和浓差极化的影响,当阴极极化起控制作用时,随着电流密度的增加,新晶核的生成速度增大,沉积层的晶粒尺寸随电流密度的增加而减小;当浓差极化起控制作用时,随着电流密度的增加,阴极-溶液界面上Pd2+和Co2+ 的损耗变大,在直流电沉积时,这种损耗得不到及时补充,出现浓差极化,从而导致成核率降低,晶粒增大。由此可见,钯钴共沉积过程在电流密度小于1.0 A/dm2时主要受阴极极化的影响;当电流密度大于1.0 A/dm2时,其沉积过程则受扩散控制。

图2和图3所示分别为钯钴合金沉积层在电流密度为0.5和1.0 A/dm2的SEM图片。由图2和图3可知,当电流密度小于1.0 A/dm2时,随着电流密度的增大,晶粒尺寸减小,但是两者尺寸变化并不大。这与XRD分析结果一致。

图2 Dc=0.5 A/dm2时Pd-Co合金的SEM图

Fig.2 SEM image of Pd-Co alloy when current density is 0.5 A/dm2

图3 Dc=1.0 A/dm2时Pd-Co合金的SEM图

Fig.3 SEM image of Pd-Co alloy when current density is 1.0 A/dm2

图4和表1示出了上述相应电流密度下制备的钯钴合金镀层在3.5% NaCl溶液中的耐蚀性。由图4和表1可知,随着沉积电流密度的增大,腐蚀电流不断增大,当沉积电流密度大于1.0 A/dm2时,腐蚀电流增加幅度较小,而腐蚀电位在沉积电流密度为1.0 A/dm2时最小。由文献[13-14]可知,沉积电流密度增大,合金镀层的钴含量迅速增加,当沉积电流密度大于1.0 A/dm2时,合金中的钴含量随电流密度的变化趋于缓慢。而合金沉积层的耐蚀性与镀层中的钴含量有关,当沉积电流密度为1.0 A/dm2时,获得钴含量为26.7%的Pd-Co合金镀层,此时镀层的耐蚀性最强。该结果与本文的研究结果一致,即当沉积电流密度为1.0 A/dm2时,镀层的耐蚀性最强。

图4 沉积电流密度对钯钴合金镀层在3.5% NaCl溶液中耐蚀性的影响

Fig.4 Tafel curves of Pd-Co alloy prepared with different current densities in 3.5% NaCl solution

表1 沉积电流密度对Pd-Co合金镀层腐蚀电流密度和腐蚀电位的影响

Table 1 φcorr and Jcorr of Pd-Co deposits prepared with different current densities

2.2 温度对Pd-Co镀层微观结构的影响

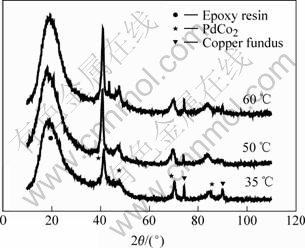

温度是影响镀层的结构和性能的重要因素之一。图5所示为不同温度下制得的Pd-Co合金镀层的XRD结果。可见,温度对钯钴合金镀层的相结构没有影响,在镀液温度为35,50和60 ℃时,钯钴合金镀层仍为面心立方晶格(FCC)。此外,计算各温度下所得镀层的晶粒尺寸D(111)分别为8.239 6,9.115 8和11.990 5 nm,即镀层的晶粒尺寸随温度的升高而不断增大。这可能是由于提高温度能够降低结晶过电位,从而晶核的数目减少,晶粒的尺寸增大;同时,温度提高将使晶核的生长速度增大,从而使晶核长大。

图5 不同温度下制备的钯钴合金镀层的XRD结果

Fig.5 XRD patterns of Pd-Co alloy at different temperatures

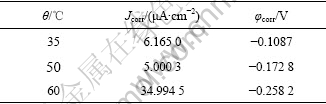

图6和表2示出了上述相应镀液温度下制备的钯钴合金镀层在3.5% NaCl溶液中的腐蚀行为。可见,随着镀液温度的升高,腐蚀电位逐步负移,腐蚀电流在镀液温度为60 ℃时最大。由文献[13-14]可知:镀层中的钴含量随镀液温度的升高而略有升高,但当温度大于50 ℃时,镀层中的钴含量随温度的升高反而迅速下降;此外,镀层的耐蚀性与镀层中钴的含量有关,当镀液温度为35 ℃时,获得钴含量为26.7%的最佳耐蚀镀层。这与本文的研究结果一致。

表2 镀液温度对Pd-Co合金镀层腐蚀电流密度和腐蚀电位的影响

Table 2 φcorr and Jcorr of Pd-Co at different temperatures

图6 镀液温度对Pd-Co合金镀层在3.5% NaCl溶液中耐蚀性的影响

Fig.6 Tafel curves of Pd-Co alloy at different temperatures in 3.5% NaCl solution

2.3 pH值对Pd-Co镀层微观结构的影响

pH值对钯钴合金镀层微观结构的影响如图7所示。可见,当镀液pH值为7.8,8.3和8.7时,pH值对合金镀层的相结构没有影响,均为面心立方晶体(FCC),且随着镀液pH值的升高,镀层的特征峰逐渐变弱,在高角度处呈现铜基体的择优取向峰。此外,计算相应条件下镀层的晶粒尺寸分别为9.322 6, 8.239 6和9.764 9 nm,即随着镀液pH值的增大,晶粒尺寸呈先减小后增大的趋势。

图7 不同pH时制备的Pd-Co合金镀层的XRD结果

Fig.7 XRD patterns of Pd-Co alloy at different pH values

pH值对金属共沉积的影响主要是它改变了金属离子的化学结合状态,并有许多络合离子的组成是pH值的函数[15]。当镀液pH值较低时,溶液中的金属离子尚未络合完全,随着镀液pH值的升高,金属离子的络合度逐渐增大,金属的沉积电位逐步负移,阴极极化增大,晶核数目增加,镀层的晶粒细化。但是,当pH值升高到一定程度时,金属离子达到络合平衡,此时,继续升高镀液pH值对沉积过电位的影响不大;又由于过电位较大时,容易在电极表面引起浓差极化,当浓差极化对成核率的影响大于过电位的增加对成核率的影响时,成核数目减少,晶粒尺寸增大。所以,钯钴合金镀层的晶粒尺寸随镀液pH值的升高呈现先减小后增大的趋势。pH值对钯钴合金镀层在3.5% NaCl溶液中耐蚀性的影响如图8和表3所示。

由图8和表3可知:pH值对合金镀层耐蚀性的影响没有一定的规律,当镀液pH值为8.3时,其腐蚀电位最小。由文献[13-14]可知:镀液pH值对合金中钴含量的影响有一最佳范围,当镀液pH值为8.0~8.5时,合金中钴含量达最大,且随镀液pH值的变化基本不变;当pH值大于8.5时,镀层中钴含量随pH值的升高反而降低。又因为钯钴镀层的耐蚀性与镀层中的钴含量有关,当镀液pH值为8.3时获得的镀层耐蚀性最强。这与本文的研究结果一致,即当镀液pH值为8.3时,合金镀层的耐蚀性最强。

表3 镀液pH值对钯钴合金镀层腐蚀电流密度和腐蚀电位的影响

Table 3 φcorr and Jcorr of Pd-Co at different pH values

图8 镀液pH值对Pd-Co合金镀层在3.5% NaCl溶液中耐蚀性的影响

Fig.8 Tafel curves of Pd-Co alloy at different pH values in 3.5% NaCl solution

2.4 沉积时间对Pd-Co合金微观结构的影响

沉积时间对Pd-Co合金微观结构的影响如图9所示。由图9可知,沉积时间对Pd-Co合金的微观结构没有影响,均为面心立方晶体(FCC),且当沉积时间为15 min和45 min时,合金沉积层在高角度处出现铜基体的择优取向峰。镀层的晶粒尺寸在沉积时间为15,30和45 min时分别为10.778 7,8.239 6和 10.492 8 nm,即随着沉积时间的增大呈先减小后增大的变化趋势。这表明镀层的晶粒尺寸并不随着沉积时间的延长而增大,而是与镀层的择优取向程度有关。这可能是随着时间的变化,Pd-Co合金在某个晶面上的生长速度发生变化,而使得其晶粒尺寸发生相应改变。

图9 不同沉积时间制备的钯钴合金镀层的XRD结果

Fig.9 XRD patterns of Pd-Co alloy deposits in different depositing time

沉积时间对Pd-Co合金镀层在3.5% NaCl溶液中的耐蚀性的影响如图10和表4所示。可见,沉积时间对合金镀层腐蚀电位的影响并不大,在沉积时间为45 min时,腐蚀电位略小。

图10 沉积时间对Pd-Co合金镀层在3.5% NaCl溶液中耐蚀性的影响

Fig.10 Tafel curves of Pd-Co alloy deposits in different depositing time in 3.5% NaCl solution

表4 电沉积时间对钯钴合金镀层腐蚀电流密度和腐蚀电位的影响

Table 4 φcorr and Jcorr of Pd-Co at different depositing time

这是因为,简单地延长沉积时间并不能改变镀层的成分,而钯钴合金镀层的耐蚀性与镀层的成分有关,故沉积时间对合金镀层耐蚀性的影响不大。

2.5 腐蚀介质对Pd-Co合金镀层的耐蚀性的影响

通过研究Pd-Co合金镀层在1.0 mol/L HCl,3.5% NaCl和1.0 mol/L NaOH 3种不同腐蚀介质中的耐蚀性发现,钯钴合金镀层的耐蚀性按腐蚀介质为中性、酸性、碱性的顺序逐步降低,从而说明钯钴合金镀层在碱性介质中的耐蚀性最弱。

3 结论

1) Pd-Co合金镀层的晶粒尺寸D(111)随电流密度、pH值和沉积时间的增加呈先减小后增大的变化趋势,随着镀液温度的升高而增大。当电流密度为1.0 A/dm2,pH值为8.3,沉积时间为30 min时,其晶粒尺寸最小,为8.239 6 nm。

2) Pd-Co合金共沉积过程在电流密度小于1.0 A/dm2时主要受阴极极化的影响;当电流密度大于1.0 A/dm2时则受浓差极化的控制。

3) 当电流密度为1.0 A/dm2,温度为35 ℃,pH值为8.3时,Pd-Co合金沉积层的耐蚀性最强,而沉积时间对合金的耐蚀性影响不大。

4) 通过比较工艺条件对镀层微观结构的影响还发现,当钯钴合金镀层的晶粒尺寸较小时,合金镀层的耐蚀性最强,其原因还有待进一步研究。

REFERENCES

[1] 杨防祖,黄 令,姚士冰, 等. 钯及其合金的电沉积[J]. 电镀与涂饰, 2002, 24(2): 20-27.

YANG Fang-zu, HUANG Ling, YAO Shi-bing, et al. Electrodeposition of palladium and its alloys[J]. Plating & Finishing, 2002, 24(2): 20-27.

[2] 王丽丽. 电镀钯[J]. 半导体技术, 1996(6): 42-43.

WANG Li-li. Palladium plating [J]. Semiconductor Technology, 1996(6): 42-43.

[3] 徐明丽,张正富,杨显万, 等. 钯及其合金电镀的研究现状[J]. 材料保护, 2003, 36(10): 4-8.

XU Ming-li, ZHANG Zheng-fu, YANG Xian-wan, et al. Present study of palladium and its alloy electroplating[J]. Materials Protection, 2003, 36(10): 4-8.

[4] 李宏弟. 电镀金-钯-铜三元合金[J]. 电镀与环保, 1996, 16(1): 28-29.

LI Hong-di. Au-Pd-Cu tri-alloys plating [J]. Electroplating & Pollution Control, 1996, 16(1): 28-29.

[5] 文明芬,郭忠诚. 钯及钯合金镀层的应用[J]. 云南冶金, 1998, 27(4): 48-54.

WEN Ming-fen, GUO Zhong-cheng. Applications of palladium and its alloys [J]. Yunnan Metallurgy, 1998, 27(4): 48-54.

[6] Moretti G, Guidi F, Tonini R. Alloys at low nickel-release: Pd-Ni coatings on copper[J]. Plating and Surface Finishing, 2001, 88(4): 70-73.

[7] Pap A E, Kordas K, Peura R, et al. Simultaneous chemical silver and palladium deposition on porous silicon; FESEM, TEM, EDX and XRD investigation[J]. Applied Surface Science, 2002, 201(1-4): 56-60.

[8] Quayum M E, SHEN Ye, Uosaki K. Mechanism for nucleation and growth of electrochemical palladium deposition on an Au(111) electrode[J]. Journal of Electroanalytical Chemistry, 2002, 520(1-2): 126-132.

[9] Abys J A, Breck G F, Straschil H K, et al. The eletrodeposition & material properties of palladium-cobalt [J]. Plating and Surface Finishing, 1999, 86(1): 108-115.

[10] 杨瑞鹏,蔡 旬,陈秋龙. 钯和钯合金及其在电子元器件方面的应用[J]. 电子元件和材料, 2000, 19(2): 30-31.

YANG Rui-peng, CAI Xun, CHEN Qiu-long. Palladium and its alloys: properties and application on electronic components[J]. Electronic Components & Materials, 2000, 19(2): 30-31.

[11] 杨富国,朱琼霞. Pd-Co合金电镀工艺及其维护[J]. 材料保护, 2000, 33(8): 21.

YANG Fu-guo, ZHU Qiong-xia. Process and maintenance of Pd-Co alloy [J]. Materials & Protection, 2000, 33(8): 21.

[12] Fan C, Xu C, Kudrak E J, et al. Ultra-thin Pd/Co Au surface finishes for electronic packaging[J]. Plating and Surface Finish- ing, 2004, 91(4): 44-47.

[13] XIAO Yao-kun, ZHONG Mei-e, CHEN Zong-zhang. Studies of microstructure and properties on electrodeposited Pd-Co alloy[J]. Journal of Applied Surface Finishing, 2006, 1(4): 25-30.

[14] 钟美娥,何莉萍,肖耀坤, 等. 电沉积钯钴合金的工艺研究[J]. 材料保护,2006, 39(6): 26-29.

ZHONG Mei-e, HE Li-ping, XIAO Yao-kun, et al. Electrodepositing technology of Pd-Co alloy[J]. Material Protection, 2006, 39(6): 26-29.

[15] 屠振密. 电镀合金的原理与工艺[M]. 北京:国防工业出版社,1993:117.

TU Zhen-mi. Principle and Technology of Electrodepositing Alloy[M]. Beijing: National Defence Industry Press, 1993: 117.

收稿日期:2006-07-25;修订日期:2006-12-13

通讯作者:陈宗璋,教授;电话:0731-8822276;E-mail: xiaomei9902@126.com

(编辑 陈灿华)