微生物-化学联合工艺脱除沼渣中重金属的研究

李晓晖1,艾仙斌2,黄凯3,孙小艳1,吴永明1

(1. 江西省科学院 江西省微生物研究所,江西省重金属污染生态修复工程技术研究中心,江西 南昌,330096;

2. 江西省科学院 能源研究所,江西 南昌,330096;

3. 北京科技大学 冶金与生态工程学院,北京,100083)

摘要:我国畜禽养殖粪污产生量大,多将其制沼气,但粪污中含有大量重金属,严重制约沼液和沼渣的资源化利用,为此提出采用微生物-化学联合工艺脱除沼渣中重金属。首先,采用以嗜酸氧化亚铁硫杆菌为优势菌种的菌液进行沼渣中重金属的微生物浸出,接种菌液的体积分数为10%,并向沼液沼渣混合体系中添加质量浓度为2 g/L的S和3 g/L的Fe2+,浸出时间为48 h;其次,采用化学浸出法进一步脱除沼渣中重金属,浸出剂选用总浓度为0.1 mol/L的混合溶液(柠檬酸和乙酸的浓度比为1:1),浸出时间为24 h;最后,浸出结束后添加质量分数为5%的膨润土作为聚沉剂。研究结果表明:经联合工艺浸出后,沼渣中铜和锌浸出率分别为89.7%和91.9%,此时沼渣中铜和锌质量分数分别为0.155 mg/g和0.248 mg/g,酸度为4.13,达到农用污泥中污染物控制标准。微生物浸出可缩短沼液沼渣分相时间,在最佳浸出条件下,沼液沼渣分相时间仅需20 min,化学浸出后固液分相时间仅约7 min。处理后沼渣中有机质、总氮(TN)和总磷(TP)的质量分数分别为2.74%,4.31%和49.35%,符合有机肥应用要求。微生物-化学联合工艺大幅降低了沼渣中重金属质量分数,并实现畜禽粪便的资源化利用。

关键词:沼渣;重金属;微生物浸出;化学浸出;固液分相

中图分类号:X53 文献标志码:A

文章编号:1672-7207(2021)06-2071-09

Removal of heavy metals from biogas residue by combined bioleaching and chemical leaching process

LI Xiaohui1, AI Xianbin2, HUANG Kai3, SUN Xiaoyan1, WU Yongming1

(1. Jiangxi Engineering and Technology Research Center for Ecological Remediation of Heavy Metal Pollution, Institute of Microbiology, Jiangxi Academy of Sciences, Nanchang 330096, China;

2. Institute of Energy, Jiangxi Academy of Sciences, Nanchang 330096, China;

3. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: There is a large amount of livestock manure in China, which is often used to produce biogas. However, there are a lot of heavy metals in the manure, which seriously restricts the utilization of biogas slurry and biogas residue. A combined process of bioleaching and chemical leaching was proposed to remove heavy metals from biogas residue. Firstly, the bioleaching of heavy metals from biogas residue was carried out by bacteria with thiobacillus acidophilus oxide as the dominant strain. The volume fraction of inoculated bacteria solution was 10%, the mass concentration of 2 g/L S and 3 g/L Fe2+ were added to the mixture system of biogas residue, and the leaching time was 48 h. Secondly, the heavy metals in the residue were further removed by chemical leaching. The mixture of citric acid and acetic acid with a total concentration of 0.1 mol/L was selected as the leaching agent. The concentration ratio of citric acid and acetic acid was 1:1, and the leaching time was 24 h. Thirdly, bentonite with mass fraction of 5% was added as the precipitator after the chemical leaching. The results show that the leaching rates of copper and zinc in biogas residue are 89.7% and 91.9%, respectively. At this time, the mass fraction of copper and zinc in biogas residue is 0.155 mg/g and 0.248 mg/g, respectively, and the acidity is 4.13 which reaches the control standard of pollution in agricultural sluge. Bioleaching can shorten the phase separation time of biogas slurry and biogas residue, the separation time of biogas slurry and biogas residue is only 20 min under the optimum leaching conditions, and the solid-liquid phase separation time after chemical leaching is only about 7 min. The mass fraction of organic matter, total nitrogen(TN) and total phosphorus(TP) in the treated biogas residue are 2.74%, 4.31% and 49.35%, respectively, which meets the application requirements of organic fertilizer. In conclusion, the combined bioleaching and chemical leaching treatment method can significantly reduce the mass fraction of heavy metals in biogas residue and realize the resources utilization of livestock manure.

Key words: biogas residue; heavy metal; bioleaching; chemical leaching; solid-liquid separation

随着我国农业现代化进程加快,畜禽养殖业规模不断扩大,环境问题日益凸显。据2017年农业部数据,我国畜禽粪污产生量约38亿t,但综合利用率不足60%。目前畜禽粪便的主要利用方式包括作饲料、制肥料和制沼气[1]。此外,研究最多的是畜禽粪便发酵制沼气,沼液和沼渣分别用于肥田和制作有机肥,但畜禽养殖过程中,在饲料中添加重金属以抗病、促生长,其中约95%以上的重金属直接排泄,进入粪便池,严重制约沼液和沼渣的应用[2-3]。为实现畜禽粪便沼气发酵技术的广泛应用,亟需解决畜禽粪便中重金属污染问题。

目前,国内外主要通过钝化稳定化和分离去除2种方式解决畜禽粪便的重金属污染问题。堆肥是实现畜禽粪便重金属稳定化的有效途径,但长期施用会增加土壤重金属存量,随着外界条件变化,稳定态重金属可能转变为生物有效态[4-10]。淋洗法可有效脱除畜禽粪便中的重金属,该技术的关键是寻找一种既能提取目标重金属又对废弃物基质破坏小的淋洗剂。研究较多的淋洗剂包括化学淋洗剂和生物淋洗剂[11-13]。最常用的化学淋洗剂有盐酸、硫酸、硝酸和一些有机络合剂,如EDTA和柠檬酸等[14-18]。化学淋洗法对有机肥中重金属的去除率高,但淋洗过程和中和过程消耗大量的化学试剂,成本较高[19]。

生物淋洗法通过微生物的新陈代谢溶解重金属,该方法借鉴矿物中用于有价金属分离提取的微生物冶金技术[20-22]。微生物冶金技术中多采用以氧化亚铁硫杆菌和氧化硫硫杆菌为优势菌种的菌群浸出矿物中的铜和金等金属,借助菌种对Fe2+或硫化物的氧化作用,直接或间接浸出矿物中有价金属。周俊等[20]研究采用以嗜酸性硫杆菌为优势菌种的微生物菌剂脱除猪粪中的铜和锌,铜和锌的脱除率分别达到87.3%和91.9%。生物淋洗法作为一种经济有效并具有发展潜力的重金属处理方法,仍存在淋洗后沼液沼渣酸度低和淋洗时间长等问题。另外,畜禽粪便发酵后沼液沼渣分相困难,采用物理技术进行固液分离时,购置设备成本高、且耗能,大部分环保企业采取修筑储液槽静置分相的办法,但固液分相效果差。何足道等[23]发现采用生物沥浸技术能大幅提高城市污泥的脱水性能,可使污泥的含水率降低到60%以下。目前沼液沼渣固液分相的相关研究较少。

对于畜禽粪便中重金属最安全、无公害的办法是分离脱除,本研究针对淋洗技术在研究和应用存在的问题,结合高效有机肥研制要求,改变淋洗剂配方,控制淋洗后沼渣pH,高效去除沼渣中重金属,并解决沼液和沼渣分相难度大,固液分离不彻底的问题。

1 实验材料

实验中采用菌种分离自江西省某铜矿酸性矿坑水。沼液沼渣混合体取自江西省某环保公司,固体质量分数为30%,初始pH为7.97。微生物浸出实验中,稀释至固体质量分数为5%。实验中使用的柠檬酸、硫酸、硝酸、乙酸和甲酸等购自国药集团化学试剂有限公司,均为分析纯。

2 实验方法

2.1 接种物制备

取铜矿酸性矿坑水高速离心分离出菌种,接种至9K培养基中,调节菌液初始pH为1.80~2.00,细菌接种体积分数为5%,在33 ℃,150 r/min恒温摇床中培养菌种,多次转接,接种70 h后进入对数生长期,细菌浓度约为1×108 个/mL,用相差显微镜观察细菌的生长状况。菌种是以嗜酸氧化亚铁硫杆菌(A.ferrooxidans或A.f )为优势菌种的菌群,取菌液20 mL接种到150 mL的沼液沼渣混合溶液,多次反复接种直至细菌数量达到108 个/mL,将其作为接种物用于微生物浸出。

9K培养基成分及质量浓度如下:(NH4)2SO4为3.0 g/L,KCl为0.1 g/L,K2HPO4为0.5 g/L,MgSO4·7H2O为0.5 g/L,Ca(NO3)2为0.01 g/L,FeSO4·7H2O为44.6 g/L。

2.2 沼渣中重金属的微生物浸出

取一定体积的沼液沼渣稀释液于250 mL锥形瓶中,加入菌种接种物,接种物添加的体积分数为10%,并在溶液中添加硫和硫酸亚铁,硫加入的质量浓度为2 g/L,设定不同的Fe2+质量浓度。每个条件设置3个平行实验。在恒温摇床中进行微生物浸出实验,温度为33 ℃,每间隔一定时间取样监测混合体系的pH和氧化还原电位(ORP),并测试沼液中Fe2+,Fe3+,Cu2+和Zn2+质量浓度,计算沼渣中铜和锌浸出率,实验结束后记录沼液沼渣分相时间,并测试微生物浸出前后沼渣中有机质、总氮(TN)和总磷(TP)的质量分数,分析微生物浸出对沼渣营养成分流失的影响,评价其肥力。

2.3 沼渣中重金属的化学浸出

取一定量沼渣或微生物浸出后沼渣进行化学浸出,以柠檬酸溶液、柠檬酸-硝酸混合溶液、柠檬酸-乙酸混合溶液和柠檬酸-甲酸混合溶液为浸出剂,设置固液比为1:20,若以柠檬酸溶液为浸出剂,设置的柠檬酸浓度分别为0.01,0.03,0.05,0.10和0.20 mol/L;若以混合酸为浸出剂,混合酸浓度为0.10 mol/L,柠檬酸和其他酸的浓度比分别为1:0,2:1,1:1,1:2和0:1,每个条件设置3个平行实验,进行摇瓶实验,每间隔一定时间取样测试浸出液pH,ORP,Cu2+和Zn2+质量浓度,评价沼渣中重金属浸出效果,并测试化学浸出前后沼渣中有机质、TN和TP的质量分数,分析化学浸出对沼渣营养成分流失的影响。

2.4 沼渣化学浸出体系固液分离研究

研究聚沉剂膨润土、壳聚糖和海藻酸钠对化学浸出体系固液分相的影响。每种聚沉剂添加量分别为沼渣干质量的2.5%,5.0%,7.5%和10.0%。将聚沉剂添加到沼渣化学浸出后固液混合体中,电动搅拌30 min,搅拌桨转速为200 r/min,反应结束后测试固液分相性能,并取溶液测试Cu2+和Zn2+质量浓度,分析聚沉剂添加对浸出液中Cu2+和Zn2+质量浓度的影响。采用BCR法测试浸出渣中铜和锌的存在形态,分析聚沉剂添加对沼渣中残余重金属形态的影响。依据实验数据选择最适合沼渣化学浸出体系固液分离的聚沉剂 。

2.5 测试方法

采用上海雷磁pHS-3C pH计测试沼渣浸出体系pH和ORP;沼液沼渣分离性能采用布氏滤斗真空抽滤法测定;沼渣用HNO3-HClO3消解,消解后采用原子吸收分光光度计(日本岛津AA-6880型)和ICP-OES电感耦合等离子体原子发射光谱仪(Perkin Elmer Optima 8000)测定,沼渣中重金属元素分析结果如表1所示,沼渣中Zn质量分数为3.056 mg/g,Cu质量分数为1.502 mg/g,Hg,As,Pb和Cr等重金属质量分数低于检测线。沼渣中有机质,TN和TP质量分数分别采用文献[24]和[25]测定。

表1 沼渣中重金属成分及质量分数

Table 1 Composition and mass fraction of heavy metals in biogas residue mg/g

3 实验结果

3.1 微生物浸出法脱除沼渣中重金属

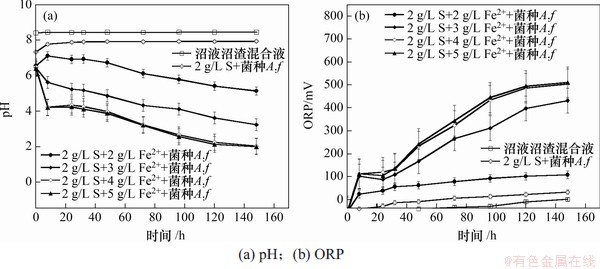

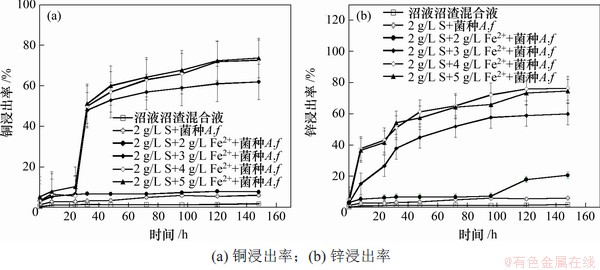

实验采用菌种以Fe2+和S为营养源,通过改变体系中Fe2+质量浓度研究微生物浸出过程中溶液pH,ORP及沼渣中铜和锌的浸出情况,实验结果如图1和2所示。从图1和2可见:Fe2+质量浓度在沼渣中铜和锌浸出中起到关键作用,空白对照和沼液沼渣混合液中仅添加S和菌种A.f时,混合体系pH和ORP变化不明显,随着Fe2+质量浓度升高,pH,ORP,Cu2+和Zn2+浸出率开始出现明显变化,当Fe2+质量浓度为4 g/L时,浸出144 h后,pH降低到2.01,ORP达到505 mV,铜和锌浸出率分别为72.7%±2.0%和76.5%±2.0%,继续提高Fe2+质量浓度,pH,ORP,Cu2+浸出率和Zn2+浸出率变化较小。

图1 Fe2+质量浓度对微生物浸出溶液体系pH和ORP影响

Fig. 1 Effect of Fe2+ mass concentration on pH and ORP of bioleaching solution system

图2 Fe2+质量浓度对微生物浸出沼渣中重金属浸出率影响

Fig. 2 Effect of Fe2+ mass concentration on leaching rate of heavy metals from biogas residue by bioleaching

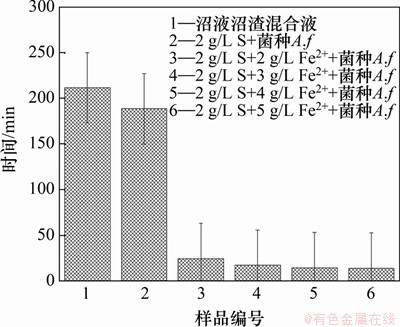

图3所示为不同Fe2+质量浓度下微生物浸出沼液沼渣分相时间,从图3可见:随着Fe2+质量浓度升高,沼液沼渣固液分相时间明显缩短,当沼液沼渣混合液中S和Fe2+的质量浓度分别为2 g/L和4 g/L时,沼液沼渣的分相时间约为15 min。分相时间缩短主要与细菌表面具有疏水和带负电荷等性质有关。A.f易吸附在疏水颗粒表面,改变固体颗粒表面电荷,减弱固体颗粒间排斥作用能,使悬浮颗粒聚沉[26]。

图3 不同Fe2+质量浓度下微生物浸出沼液沼渣分相时间

Fig. 3 Separation time of biogas residue and biogas slurry after bioleaching at different Fe2+ mass concentration

微生物浸出可脱除沼渣中重金属,加速固液分离,但高重金属浸出率伴随着低浸出pH,如:Fe2+质量浓度为4 g/L时,浸出144 h后,铜和锌浸出质量分数分别为72.7%±2.0%和76.5%±2.0%,pH降低到2.01,此时,沼液和沼渣pH低,无法将其直接还田使用,需加碱调酸度,成本大幅提高。因此,仅通过微生物浸出无法在适宜沼渣资源化利用的条件下深度脱除重金属,需要通过与化学浸出法联合达到沼渣安全利用的目的。

依据沼液沼渣资源化利用目标,选择微生物浸出条件如下:在沼液沼渣混合液中S和Fe2+的质量浓度分别为2 g/L和3 g/L,菌种接种体积分数为10%,预处理时间为48 h,此时,微生物浸出后pH为4.87,ORP为167 mV,铜和锌浸出率分别为53.0%±2.0%和45.0%±2.0%,沼渣中残余铜和锌质量分数分别为0.706 mg/g和1.681 mg/g,沼液沼渣分相时间为20 min。

3.2 化学浸出法脱除沼渣中重金属

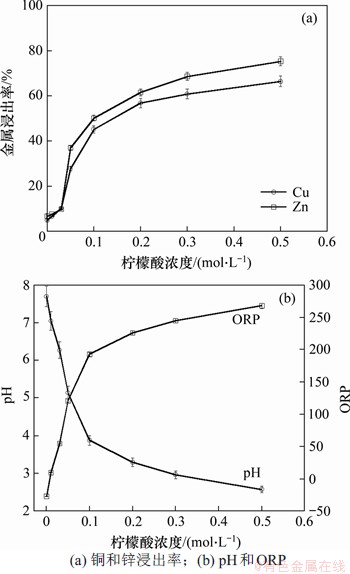

3.2.1 柠檬酸对沼渣中重金属脱除

以柠檬酸为浸出剂研究沼渣中重金属的脱除情况,分别配制浓度为0.01,0.03,0.05,0.10,0.20,0.30和0.50 mol/L的柠檬酸溶液,固液比为1:20,置于恒温振荡器,室温下浸出24 h,振荡速度为150 r/min,实验结果如图4所示。从图4可见:随着柠檬酸浓度增加,浸出后溶液pH逐渐降低,ORP升高,铜和锌浸出率逐渐增大,当柠檬酸浓度为0.5 mol/L时,浸出24 h后,溶液pH降低为2.58,ORP升高到260 mV,沼渣中铜和锌浸出率分别为66.5%±2.0%和75.4%±3.0%。

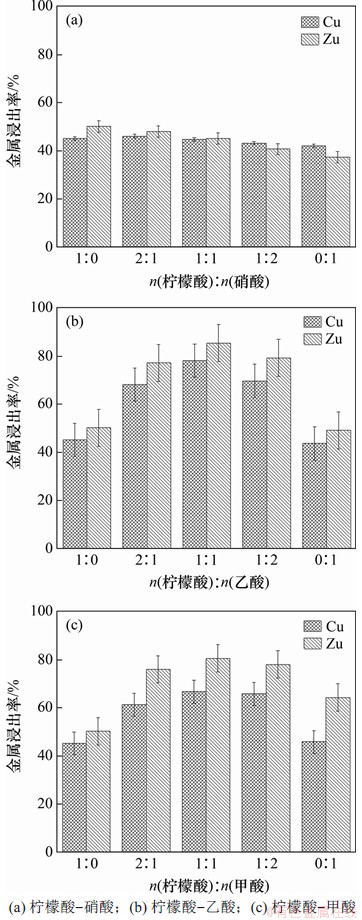

3.2.2 混合酸对沼渣中重金属浸出影响

图4 柠檬酸浓度对沼渣浸出体系铜和锌浸出率、pH和ORP影响

Fig. 4 Effect of citric acid concentration on leaching rate of Cu and Zn, pH and ORP in biogas residue

图5所示为柠檬酸-硝酸、柠檬酸-乙酸和柠檬酸-甲酸3种混合酸溶液对沼渣中铜和锌浸出影响。从图5可见:柠檬酸-乙酸和柠檬酸-甲酸呈现出协同增强沼渣中重金属浸出的变化趋势,而柠檬酸-硝酸混合酸浸出体系随着混合酸中硝酸比例增大,铜和锌浸出率呈逐渐降低变化趋势,柠檬酸和硝酸混合未起到增强沼渣中重金属浸出率的作用。柠檬酸与甲酸最佳浓度比为1:1,此时铜和锌的浸出率分别为66.7%±2.0%和80.5%±3.0%,浸出后溶液pH为5.07。柠檬酸与乙酸的最佳浓度比也为1:1,此时铜和锌的浸出率分别为78.0%±2.0%和85.3%±3.0%,浸出后溶液pH为5.19,因此,选择柠檬酸-乙酸混合酸溶液作为沼渣化学浸出的浸出剂。

图5 柠檬酸与其他酸浓度比对沼渣中重金属浸出率的影响

Fig. 5 Effect of concentration ratio of citric acid to other acid on leaching rate of heavy metals in biogas residue

柠檬酸酸性比较强,具有三元酸性质,柠檬酸电离常数分别为pK1=3.13、pK2=4.76和pK3=6.40。保持浸出后沼渣pH在5.0以上,大多数柠檬酸电离成二价或三价的柠檬酸根离子。乙酸和甲酸均为一元弱酸,电离常数分别为4.76和3.75。柠檬酸-乙酸和柠檬酸-甲酸混合酸均呈现出协同增强沼渣中重金属浸出的作用,主要和羧基、羟基与金属离子形成络合物或螯合物有关,而柠檬酸-硝酸混合液中硝酸为无机酸,仅通过提高溶液酸度溶出沼渣中的铜和锌,提高酸度易于溶出沼液中可溶态的重金属,对次稳定态的重金属溶出效果较差。

3.2.3 化学浸出固液分离研究

沼渣化学浸出后固液分离难度仍较大,需要通过添加聚沉剂加速固液分离,选择的聚沉剂有膨润土、壳聚糖和海藻酸钠。未添加聚沉剂时,沼液沼渣的固液分离时间为212 min,添加膨润土和壳聚糖化学浸出后固液分离时间明显缩短,分离时间分别为3.5 min和7.0 min,添加海藻酸钠反而加剧固液分离难度,分离时间为320 min,由于海藻酸钠与膨润土、壳聚糖表面带相反电荷,海藻酸钠被认为是阴离子聚合物[27],沼渣与海藻酸钠表面带相同电荷,两者之间形成强烈的静电斥力,使沼渣颗粒和海藻酸钠悬浮于浸出液中,加大了固液分离难度,沼渣聚沉速率与其自身和添加聚沉剂的表面电荷密切相关,阳离子聚合物-膨润土和壳聚糖与沼渣表面电荷相反,二者间呈静电引力,加速了沼渣聚集沉降。

膨润土质量分数对酸浸后沼渣中铜和锌存在形态影响如图6所示。从图6可见:随着膨润土质量分数增大,酸溶态铜质量分数明显降低,可还原态铜质量分数也呈下降趋势,可氧化态铜和残渣态铜质量分数逐渐增加;随着聚沉剂质量分数增加,沼渣中残余氧化态锌和残渣态锌质量分数呈上升趋势,酸溶态锌质量分数略降低,相比较而言,膨润土对沼渣中铜存在形态影响更显著,酸溶态和可还原态铜质量分数降低,转变为可氧化态铜,沼渣中铜存在稳定性增强,这与原文丽等[28]的研究结果一致。添加膨润土提高了沼渣中铜和锌存在稳定性,使得以微生物-化学浸出后沼渣为基体制备的有机肥更加安全、环境友好。

图6 膨润土质量分数对酸浸后沼渣中铜和锌存在形态影响

Fig. 6 Effect of bentonite dosage on forms of Cu and Zn in residue after acid leaching

4 讨论

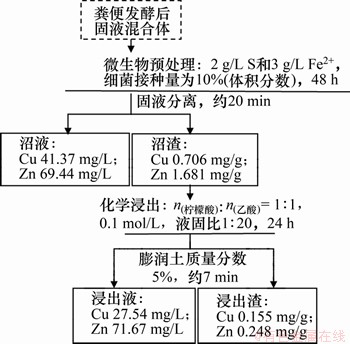

4.1 沼渣中重金属污染物处理评价

通过实验室模拟微生物-化学联合浸出工艺评价沼渣中重金属的脱除效果,结果如图7所示。沼液沼渣混合物经微生物浸出后体系pH为4.87,铜浸出率为53%,锌浸出率为45%,此时沼渣中残余铜和锌质量分数分别为0.706 mg/g和1.681 mg/g,沼液沼渣的分相时间约为20 min。

以微生物浸出后沼渣为原料进行化学浸出,浸出后沼渣中铜和锌质量分数分别为0.155 mg/g和0.248 mg/g,浸出后溶液pH为4.13,分相时间为7 min,经微生物-化学浸出联合聚沉剂添加工艺处理后,沼渣中铜和锌质量分数均降低到安全使用标准范围内,沼渣以铜和锌的污染问题最突出,汞、铅和铬等其金属污染物未被检出或在安全使用范围内(如表1所示),可知处理后的沼渣可被安全使用。

图7 沼渣中重金属脱除工艺流程

Fig. 7 Process flow of heavy metal removal from biogas residue

4.2 沼渣营养成分评价

对沼渣的有机质、TN和TP质量分数进行测试,结果如表2所示,由表2可见:沼渣经微生物-化学联合处理后有机质、TN和TP质量分数分别为2.74%,4.31%和49.35%,虽然有机质、TN和TP质量分数在浸出过程中降低,但仍符合城镇垃圾农用的有机质、总氮和总磷控制标准(有机质质量分数≥10%,总氮质量分数≥0.5%和总磷质量分数≥0.3%)。

表2 沼渣中营养成分(质量分数)

Table 2 Nutrient mass fraction of biogas residue %

5 结论

1) 以A.ferrooxidans为优势菌种的菌液进行沼渣的微生物浸出,随着Fe2+质量浓度增加,沼液沼渣混合体系pH降低、ORP升高,铜和锌浸出率逐渐提高,沼液沼渣固液分相时间明显缩短;当S和Fe2+的质量浓度分别为2 g/L和3 g/L时,菌种接种体积分数为10%,浸出48 h后,pH为4.87,ORP为167 mV,铜和锌的浸出率分别为53.0%±2.0%和45.0%±2.0%,沼液沼渣固液分离耗时20 min。

2) 化学浸出以柠檬酸-乙酸混合酸为浸出剂,柠檬酸-乙酸的最佳浓度比为1:1,此时铜和锌的浸出率分别为78.0%±2.0%和85.0%±3.0%,浸出后溶液pH为5.19。

3) 膨润土聚沉剂不仅加快了沼渣化学浸出固液分相速率,而且增强了沼渣中残余重金属的稳定性。

4) 微生物-化学联合浸出后沼渣中铜和锌质量分数分别为0.155 mg/g和0.248 mg/g,达到农用污泥中污染物控制标准,且处理后沼渣中有机质、TN和TP质量分数符合城镇垃圾农用控制标准,处理后沼渣可被安全应用于制备有机肥。

参考文献:

[1] 徐启明. 畜禽粪便的饲料化利用概述[J]. 安徽农学通报, 2014, 20(15): 136.

XU Qiming. Feed utilization of animal manure[J]. Anhui Agricultural Science Bulletin, 2014, 20(15): 136.

[2] WANG Xiankai, ZHENG Guodi, CHEN Tongbin, et al. Effect of phosphate amendments on improving the fertilizer efficiency and reducing the mobility of heavy metals during sewage sludge composting[J]. Journal of Environmental Management, 2019, 235: 124-132.

[3] RAMIREZ W A, DOMENE X, ORTIZ O, et al. Toxic effects of digested, composted and thermally-dried sewage sludge on three plants[J]. Bioresource Technology, 2008, 99(15): 7168-7175.

[4] LIU Hongtao,GUO Xiaoxia. Hydroxyapatite reduces potential Cadmium risk by amendment of sludge compost to turf-grass grown soil in a consecutive two-year study[J]. Science of the Total Environment, 2019, 661: 48-54.

[5] 王瑞, 魏源送. 畜禽粪便中残留四环素类抗生素和重金属的污染特征及其控制[J]. 农业环境科学学报, 2013, 32(9): 1705-1719.

WANG Rui, WEI Yuansong. Pollution and control of tetracyclines and heavy metals residues in animal manure[J]. Journal of Agro-Environment Science, 2013, 32(9): 1705-1719.

[6] YANG Xinping, LI Qian, TANG Zhu, et al. Heavy metal concentrations and arsenic speciation in animal manure composts in China[J]. Waste Management, 2017, 64: 333-339.

[7] HAO Jingkun, WEI Zimin, WEI Dan, et al. Roles of adding biochar and montmorillonite alone on reducing the bioavailability of heavy metals during chicken manure composting[J]. Bioresource Technology, 2019, 294: 122199.

[8] YE Shujing, ZENG Guangming, WU Haipeng, et al. Co-occurrence and interactions of pollutants, and their impacts on soil remediation—A review[J]. Critical Reviews in Environmental Science and Technology, 2017, 47(16): 1528-1553.

[9] YANG Kangjie, ZHU Longji, ZHAO Yue, et al. A novel method for removing heavy metals from composting system: The combination of functional bacteria and adsorbent materials[J]. Bioresource Technology, 2019, 293: 122095.

[10] 鲁洪娟, 马友华, 樊霆, 等. 有机肥中重金属特征及其控制技术研究进展[J]. 生态环境学报, 2014, 23(12): 2022-2030.

LU Hongjuan, MA Youhua, FAN Ting, et al. Research progress on characteristics of heavy metals in organic manure and control technology[J]. Ecology and Environmental Sciences, 2014, 23(12): 2022-2030.

[11] AKINCI G, GUVEN D E. Bioleaching of heavy metals contaminated sediment by pure and mixed cultures of Acidithiobacillus spp[J]. Desalination, 2011, 268(1/2/3): 221-226.

[12] NGUYEN V K, LEE M H, PARK H J, et al. Bioleaching of arsenic and heavy metals from mine tailings by pure and mixed cultures of Acidithiobacillus spp[J]. Journal of Industrial and Engineering Chemistry, 2015, 21: 451-458.

[13] 周俊, 王电站, 刘奋武, 等. 生物沥浸法去除猪粪中重金属和提高其脱水性能研究[J]. 环境科学学报, 2011, 31(2): 388-394.

ZHOU Jun, WANG Dianzhan, LIU Fenwu, et al. Removal of heavy metals and dewaterability of pig slurry facilitated by bioleaching[J]. Acta Scientiae Circumstantiae, 2011, 31(2): 388-394.

[14] 李振东, 刘东方, 黄文力, 等. EDTA、皂素及其混剂淋洗去除猪粪中Cu、Zn的研究[J]. 农业环境科学学报, 2019, 38(1): 220-228.

LI Zhendong, LIU Dongfang, HUANG Wenli, et al. Removing Cu and Zn from pig manure via the leaching method with EDTA, saponin, and their mixture[J]. Journal of Agro-Environment Science, 2019, 38(1): 220-228.

[15] 杨宁, 杨洋, 彭亮, 等. 超声和酸化对猪粪中Cu、Zn去除的影响[J]. 农业环境科学学报, 2014, 33(7): 1429-1435.

YANG Ning, YANG Yang, PENG Liang, et al. Removal of Cu and Zn from pig manure by acids and ultrasound[J]. Journal of Agro-Environment Science, 2014, 33(7): 1429-1435.

[16] 杜丽琼, 刘东方, 黄文力, 等. 有机酸对猪粪中重金属的浸提[J]. 农业环境科学学报, 2017, 36(10): 2121-2128.

DU Liqiong, LIU Dongfang, HUANG Wenli, et al. Removal of heavy metals from pig manure by organic acids[J]. Journal of Agro-Environment Science, 2017, 36(10): 2121-2128.

[17] ZHANG Weihua, HUANG Hao, TAN Fenfang, et al. Influence of EDTA washing on the species and mobility of heavy metals residual in soils[J]. Journal of Hazardous Materials, 2010, 173(1/2/3): 369-376.

[18] FENG Weijin, ZHANG Shirong, ZHONG Qinmei, et al. Soil washing remediation of heavy metal from contaminated soil with EDTMP and PAA: properties, optimization, and risk assessment[J]. Journal of Hazardous Materials, 2020, 381:120997.

[19] 李春凤, 廉新慧, 王静, 等. 畜禽粪便中重金属去除技术研究进展[J]. 中国饲料, 2012, (24): 15-17.

LI Chunfeng, LIAN Xinhui, WANG Jing, et al. Research progress of heavy metal removal in livestock and poultry manure[J]. Chinese Feed, 2012, (24): 15-17.

[20] 周俊, 刘奋武, 崔春红, 等. 生物沥浸对城市污泥脱水及其重金属去除的影响[J]. 中国给水排水, 2014, 30(1): 86-89.

ZHOU Jun, LIU Fengwu, CUI Chunhong, et al. Effect of bioleaching on dewaterability of sewage sludge and removal of heavy metals[J]. China Water & Watewater, 2014, 30(1): 86-89.

[21] MARCHENKO O, DEMCHENKO V, PSHINKO G. Bioleaching of heavy metals from sewage sludge with recirculation of the liquid phase: A mass balance model[J]. Chemical Engineering Journal, 2018, 350: 429-435.

[22] WANG Shimei, ZHENG Guanyu, ZHOU Lixiang. Heterotrophic microorganism Rhodotorula mucilaginosa R30 improves tannery sludge bioleaching through elevating dissolved CO2 and extracellular polymeric substances levels in bioleach solution as well as scavenging toxic DOM to Acidithiobacillus species[J]. Water Research, 2010, 44(18): 5423-5431.

[23] 何足道, 王电站, 颜成, 等. 城市污泥生物沥浸法和化学法调理的效果比较: 对污泥理化性质及其深度脱水性能的影响研究[J]. 中国环境科学, 2019, 39(3): 1019-1025.

HE Zudao, WANG Dianzhan, YAN Cheng, et al. Effects of bioleaching and chemical conditioning on sludge dewaterability and physicochemical properties[J]. China Environmental Science, 2019, 39(3): 1019-1025.

[24] NY/T 53—1987. 土壤全氮测定法(半微量开氏法)[S].

NY/T 53—1987. Method for the determination of soil total nitrogen (Semi-micro Kjedahl method)[S].

[25] GB/T 6437—2002. 饲料中总磷的测定—分光光度法[S].

GB/T 6437—2002. Determination of phosphorus in feed—Sepctphotometry[S].

[26] 李晓晖. 钴镍矿微生物浸出液萃取除杂过程乳化物形成机制研究[D]. 北京: 北京有色金属研究总院, 2014: 38-53.

LI Xiaohui. Study on the formation mechanism of emulsion in impurity extraction process of cobalt and nickel sulfide ore bioleaching[D]. Beijing: General Research Institute for Nonferrous Metals, 2014: 38-53.

[27] 袁毅桦. 基于壳聚糖与海藻酸钠的改性聚合物的制备结构与性能研究[D]. 广州: 华南理工大学, 2012: 20-26.

YUAN Yihua. Preparation, structure and properties of modified polymers based on chitosan and sodium alginate[D]. Guangzhou: South China University of Technology, 2012: 20-26.

[28] 原文丽, 冯磊, 刘永红, 等. 改性膨润土修复铜污染的土壤[J]. 湖南师范大学自然科学学报, 2016, 39(2): 43-47.

YUAN Wenli, FENG Lei, LIU Yonghong, et al. Remediation of soils contaminated with Cu using modified bentonite[J]. Journal of Natural Science of Hunan Normal University, 2016, 39(2): 43-47.

(编辑 秦明阳)

收稿日期: 2020 -10 -29; 修回日期: 2021 -01 -10

基金项目(Foundation item):江西省重点研发计划项目(20192BBF60054);国家自然科学基金资助项目(51764019,31860154) (Project(20192BBF60054) supported by the Key Research and Development Program of Jiangxi Province; Projects(51764019, 31860154) supported by the National Natural Science Foundation of China)

通信作者:艾仙斌,博士,副研究员,从事固废资源化利用研究;E-mail: axbjxas@163.com

DOI: 10.11817/j.issn.1672-7207.2021.06.037

引用格式:李晓晖, 艾仙斌, 黄凯, 等. 微生物-化学联合工艺脱除沼渣中重金属的研究[J]. 中南大学学报(自然科学版), 2021, 52(6): 2071-2079.

Citation:LI Xiaohui, AI Xianbin, HUANG Kai, et al. Removal of heavy metals from biogas residue by combined bioleaching and chemical leaching process[J]. Journal of Central South University(Science and Technology), 2021, 52(6): 2071-2079.