文章编号:1004-0609(2009)09-1548-07

Mg对原位合成TiB2/Al-7Si复合材料的

微观组织及力学性能的影响

赵瑞锋1,刘忠侠1,杨明生2,张天清2,余焕伟1,任 波1,刘栓江1

(1. 郑州大学 物理工程学院,郑州 450052;

2. 登封电厂集团铝合金有限公司,登封 452477)

摘 要:采用K2TiF6和KBF4混合盐原位反应法制备TiB2/Al-7Si复合材料,利用XRD、SEM、金相显微镜、HV硬度测试和磨损实验等方法研究了Mg对复合材料的微观组织和力学性能的影响。结果表明:反应生成的TiB2颗粒平均尺寸约为0.5 μm,材料的硬度和耐磨性随着TiB2含量的增加而提高;添加1.5%Mg(质量分数)元素可明显细化TiB2颗粒,且使其分布更加均匀,增强TiB2颗粒的弥散强化和细晶强化效果,复合材料的硬度和耐磨性显著改善;过量的Mg元素(3%)会造成TiB2颗粒细化效果的下降,但其硬度和耐磨性能继续得到改善。

关键词:TiB2/Al-7Si复合材料;Mg;微观组织;硬度;力学性能

中图分类号:TB 333; TG 290.2 文献标识码:A

Effect of Mg on microstructures and mechanical properties of in-situ TiB2/Al-7Si composite

ZHAO Rui-feng1, LIU Zhong-xia1, YANG Ming-sheng2, ZHANG Tian-qing2,

YU Huan-wei1, REN Bo1, LIU Shuan-jiang1

(1. College of Physics Engineering, Zhengzhou University, Zhengzhou 450052, China;

2. Deng Dian Ji Tuan Aluminum alloys Co. Ltd., Dengfeng 452477, China)

Abstract:In-situ TiB2/Al-7Si composites were fabricated by K2TiF6 and KBF4 compounds reaction in Al-7Si melt. The effect of Mg on the microstructures and mechanical properties of TiB2/Al-7Si were investigated by using XRD, SEM, optical microscopy, hardness and wear testing techniques. The results show that TiB2 particles with average size of about 0.5 μm are produced. The hardness and wear resistance increase with increasing TiB2 content. Adding about 1.5%Mg in melt restrains the conglobation of the TiB2 particles, which makes the size of TiB2 particle decrease and the distribution of TiB2 particle is more homogeneous. The strengthening effect of TiB2 particles is enhanced and the hardness and wear resistance of composites are obviously improved. The excess Mg decreases the refinement effect of TiB2 particles, but the hardness and wear resistance are improved continuously.

Key words:TiB2/Al-7Si composites; Mg; microstructure; hardness; mechanical properties

2原位合成的TiB2以其低密度、高熔点、高硬度 、高弹性模量、优异的化学稳定性和抗腐蚀性、良好的高温导电性及界面润湿性等优点[1-7],成为铝基复合材料理想的强化相。但TiB2颗粒的表面能较大,易于团聚,严重影响了TiB2/Al复合材料力学性能的提高。因此,如何有效阻止TiB2颗粒团聚是TiB2/Al复合材料的制备关键技术之一。提高熔体温度[8]、采用快速冷却[9],气体搅拌和电磁搅拌[6-9]等工艺可以有效抑制TiB2颗粒的团聚,改善TiB2颗粒的分布状态,提高复合材料的力学性能,但这些方法工艺复杂、成本高、工艺可控性较差。近年的研究发现[9-13],通过向合金熔体中加入适量的微量元素如Mg、Li、Zr、RE、Te和Ti等是一种简单、有效的缓解TiB2颗粒的偏聚与沉降的工艺方法,特别是Mg的加入使得TiB2颗粒的细化效果更加明显,这是目前的研究热点之一。王鹏等[11]发现,Mg可以改善TiB2颗粒与铝液界面的润湿情况,有效地抑制颗粒的团聚,获得在基体内均匀分布的TiB2颗粒。张树瑜等[14]认为Mg易于在铝液中生成MgA12O4相,形成TiB2/MgAl2O/A1界面,新界面的生成促进了TiB2与A1液的结合,有利于TiB2的分散。ZHANG等[12-13]认为Ti和Mg的加入有助于TiB2颗粒的细化和均匀化分布。铝硅合金铸造性能优良,是工程中使用最多的铸造铝合金之一。然而,有关原位合成TiB2增强铝硅合金的文献报道较少。本文作者以TiB2/Al-7Si复合材料为研究对象,原位制备了不同TiB2含量的TiB2/Al-7Si复合材料,在优化工艺条件下,研究了Mg元素对TiB2/Al-7Si复合材料显微组织、硬度和耐磨性能的影响。

1 实验

实验材料为电解低钛铝合金(Ti含量为0.5%)、结晶硅、工业纯Mg和K2TiF6、KBF4混合盐,并添加适量的反应助剂Na3AlF6。所有复合材料样品的制备均在7.5 kW高温电阻炉中进行。首先根据Ti和B的化学计量比混合K2TiF6、KBF4与Na3AlF6,在875 ℃时加入到Al-7Si熔体中并用石墨棒搅拌均匀;在750 ℃时加入纯Mg,并进行氩气精炼、除渣、静置;在 730 ℃时浇入预热后的金属模具中。部分试样进行T6热处理,合金的名义化学成分如表1所列。

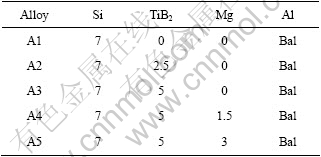

表1 基体和复合材料的化学成分

Table 1 Chemical composition of alloy and composites (mass fraction, %)

微观组织采用X’Pert PROX射线衍射仪、JSM6700F场发射扫描电子显微镜和带有图像采集和分析系统的OLYMPUS BX51金相显微镜分析。干磨试验在MRH-3高速环块磨损试验机上进行,采用环块对磨方法,试验载荷分别为15、30和45 N,磨损时间为10 min,磨环转速为400 r/min。每种试样取4个样品进行试验,然后取其平均值。

2 结果与分析

2.1 微观组织

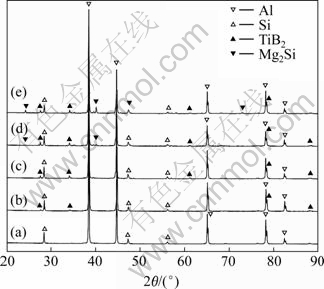

图1所示为实验材料的XRD谱。由图1可看出,没有加入Mg的样品中主要包括α(Al)、Si和TiB2相。加入Mg元素后,有少量的Mg2Si相存在。图2所示为合金A1-A5的铸态金相组织。由图2可看出,基体中的初生α(Al)相呈发达的树枝状,粗大的针状共晶Si分布于共晶区(见图2(a));含有2.5%TiB2时,α(Al)相和共晶Si得到细化(见图2(b));含有5%TiB2时,α(Al)相转变为球状或等轴状,共晶Si也转变为粒状(见图2(c))。表明TiB2颗粒具有细化α(Al)晶粒和改变α(Al)结晶形态的作用。其原因是TiB2 与α(Al)存在局部共格关系, ∥

∥ ,(200)Al与

,(200)Al与 共格,部分TiB2颗粒成为α(Al)的非均质形核核心,而多余的TiB2颗粒则阻碍α(Al)晶粒的生长[15]。Mg元素的加入使α(Al)和共晶Si相更加细小,当Mg元素含量为3%时,金相组织中出现少量黑色Mg2Si颗粒(见图2(d)~(e))。

共格,部分TiB2颗粒成为α(Al)的非均质形核核心,而多余的TiB2颗粒则阻碍α(Al)晶粒的生长[15]。Mg元素的加入使α(Al)和共晶Si相更加细小,当Mg元素含量为3%时,金相组织中出现少量黑色Mg2Si颗粒(见图2(d)~(e))。

图1 基体和复合材料的XRD谱

Fig.1 XRD patterns of Al-7Si alloy and composites: (a) Alloy A1; (b) Alloy A2; (c) Alloy A3; (d) Alloy A4; (e) Alloy A5

图2 基体和复合材料的铸态金相 组织

Fig.2 Metallographic microstructure of as-cast alloys and composites: (a) Al- 7Si; (b) 2.5%TiB2/Al-7Si; (c) 5%TiB2/ Al-7Si; (d) 5%TiB2/Al-7Si+1.5%Mg; (e) 5%TiB2/Al-7Si+3%Mg

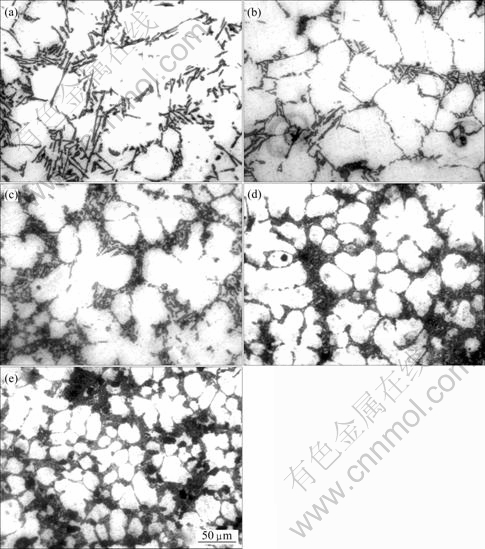

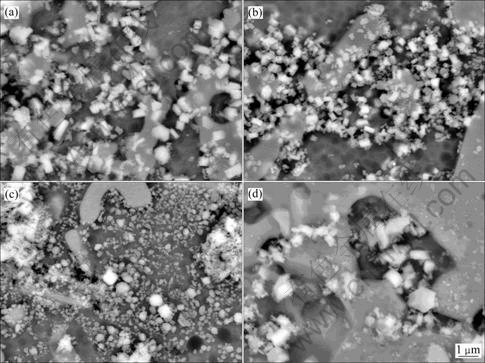

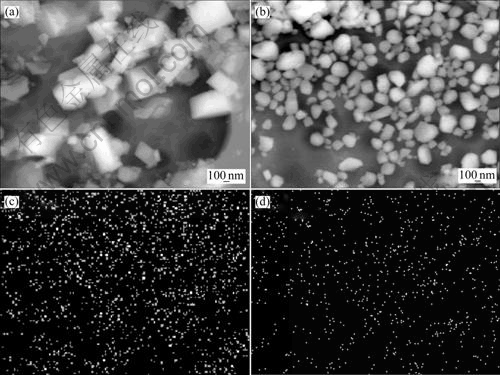

图3所示为TiB2/Al-7Si复合材料中TiB2颗粒的形貌。由图3可看出,基体中均匀分布的白色颗粒为TiB2,形状呈规则的多边形或卵圆形。当TiB2含量2.5%时,TiB2颗粒尺寸较大,平均尺寸为0.5 μm左右(见图3(a));当TiB2含量为5%时,TiB2颗粒尺寸较2.5%时细小,平均尺寸为0.4 μm左右(见图3(b));当加入1.5%Mg后,TiB2颗粒分布更加均匀,平均尺寸也减小到20~200 nm(见图3(c));当Mg含量为3%时对TiB2颗粒的细化效果反而变弱(见图3(d))。图4所示为图3(b)和(c)的放大形貌。由图4可看出,没有加Mg时,TiB2颗粒呈多面体状团聚于α(Al)和共晶Si附近区域;加入1.5%Mg后,TiB2颗粒呈卵圆形分布于基体中。图4(c)和(d)所示为图4(b)中Ti和B元素的面扫描结果。Ti元素与B元素分布均匀,表明适量Mg元素的加入,促进了TiB2颗粒分布的均匀化。

图3 复合材料中TiB2颗粒的形貌

Fig.3 Morphologies of TiB2 particles in composites: (a) 2.5%TiB2/Al-7Si; (b) 5%TiB2/Al-7Si; (c) 5%TiB2/Al-7Si+1.5%Mg; (d) 5%TiB2/Al-7Si+3%Mg

图4 复合材料中TiB2颗粒的SEM像及图4(b)中元素的面扫描分布

Fig.4 SEM images of TiB2 particles in composites and area scanning distribution of elements in Fig.4(b): (a) 5%TiB2/Al-7Si; (b) 5%TiB2/Al-7Si+1.5%Mg; (c) Ti; (d) B

高温熔体中生成的细小TiB2颗粒具有很大的表面能,易于相互吸引长大降低表面能[7]。Mg元素的加入一方面可能有以下反应生成MgAl2O4[14]:

Mg+2Al+4O=MgAl2O4 (1)

这样界面变成了TiB2增强相/MgAl2O4/Al界面,这不但可以改善TiB2颗粒与铝液界面的润湿性[13],而且能使TiB2颗粒生成后,首先吸附Al液中的Mg元素,然后再与Al形成较好的结合,从而降低TiB2颗粒的表面能,阻止TiB2颗粒的团聚和沉降[11]。另一方面,Mg元素的加入使Al液的粘度增加,由Stocks 公式

式中:v为粒子沉降速率; 为运动粘度;

为运动粘度; 和

和 分别为球形粒子与介质的密度;r为粒子半径;g为重力加速度。可知,增加复合材料的粘度可以减低颗粒的移动速度,不但减小了颗粒相互接触而团聚团聚的几率,且在凝固过程中也容易被α(Al)晶粒所捕获,增加颗粒的均匀性。但Mg元素与Si元素间相互作用强,Mg2Si的形核机率增大[16],当Mg元素的含量达到3%时,部分的Mg与Si反应生成了Mg2Si,降低Mg对TiB2颗粒的细化效果。

分别为球形粒子与介质的密度;r为粒子半径;g为重力加速度。可知,增加复合材料的粘度可以减低颗粒的移动速度,不但减小了颗粒相互接触而团聚团聚的几率,且在凝固过程中也容易被α(Al)晶粒所捕获,增加颗粒的均匀性。但Mg元素与Si元素间相互作用强,Mg2Si的形核机率增大[16],当Mg元素的含量达到3%时,部分的Mg与Si反应生成了Mg2Si,降低Mg对TiB2颗粒的细化效果。

2.2 力学性能

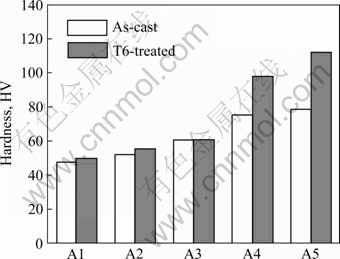

图5所示为热处理前后基体及复合材料的硬度变化情况。由图5可看出,热处理前,5%TiB2/Al-7Si复合材料的硬度比基体合金提高了27%;加入1.5%Mg和3%Mg后,其硬度与基体合金相比分别提高了58%和65%;热处理没有改善未加Mg的A1-A3合金的硬度,但使添加镁合金的硬度明显提高,加入1.5%Mg和3%Mg后,与热处理前相比分别提高了29%和42%。

图5 基体及复合材料的硬度

Fig.5 Hardness of alloys and composites

TiB2颗粒对复合材料的强化作用缘于TiB2颗粒的弥散强化和细晶强化。原位内生TiB2颗粒尺寸小,分布弥散,可以有效地阻碍位错运动起到强化作用,不但具有良好的弥散强化效果[7],而且由于其可以作为α(Al)的异质形核核心,细化α(Al),产生良好的细晶强化效果[7]。Mg的加入不但进一步细化TiB2颗粒,且在铸造组织中存在少量的高强度的初晶Mg2Si相。经T6热处理时,组织中析出大量与基体存在良好的共格和半共格关系的Mg2Si过渡组织β″或β′析出相,使复合材料的强度和硬度明显提高。

2.3 耐磨性能

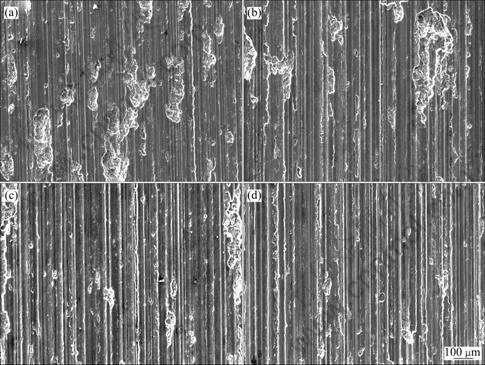

图6所示为热处理后不同复合材料在干磨条件下的磨损量和摩擦因数。由图6可看出,5%TiB2/Al-7Si复合材料的耐磨性能优于Al-7Si基体材料的,Mg使复合材料的耐磨性能进一步提高,磨损量和摩擦因数分别降低5%~10%。图7所示为复合材料在干磨条件下的磨损表面形貌。由图7可看出,由于基体材料较软,硅颗粒粗大,产生严重的粘着磨损和磨粒磨损(见图7(b));磨损表面剥落坑减少,犁沟细小而较浅,其磨损机理兼有粘着磨损和磨粒磨损,很明显这与复合材料中细小、分布均匀的TiB2颗粒与基体的良好结合和及其对基体的弥散强化和细晶强化有关(见图7(b))[17]。一方面,细小的TiB2颗粒与基体的良好结合及其对共晶硅颗粒的细化作用,减少了在赫兹应力作用下二者与基体分离和自身开裂从而脱落的几率;另一方面,基体强度较高,增强了基体的抗裂能力,即使细小的TiB2和共晶硅颗粒从基体脱落,其切入α相的深度也较浅。但由于复合材料中TiB2含量较低,其抗粘着能力不高,仍然存在粘着磨损。Mg的加入强化了基体,增加了颗粒与基体的结合强度和基体的抗粘着能力,使复合材料的耐磨性能进一步改善。从图7(c)和(d)可以看出,其磨损表面没有出现明显的剥落坑,犁沟也较浅,材料磨损机制明显为磨粒磨损机制。虽然过量的Mg降低了TiB2的细化效果,但由于组织中出现初晶Mg2Si颗粒和时效析出的β″或β′相,使复合材料的强度和硬度进一步提高,材料的耐磨性能进一步改善。

图6 载荷对基体与复合材料的磨损量及摩擦因数的影响

Fig.6 Effect of loads on mass loss(a) and friction coefficient(b) of Al-7Si alloy and composites

图7 基体及复合材料的磨损表面形貌

Fig.7 Morphologies of wear surface of Al-7Si alloy and composites: (a) Al-7Si; (b) 5%TiB2/Al-7Si; (c) 5%TiB2/ Al-7Si+1.5%Mg; (d) 5%TiB2/Al-7Si +3%Mg

3 结论

1) 采用混合盐反应工艺制备的TiB2/Al-7Si复合材料中,TiB2颗粒呈多边形或卵圆形,易于在α(Al)相与共晶Si附近发生团聚;加入1.5%Mg后能有效抑制TiB2的聚集状态,减小TiB2颗粒的尺寸;当Mg含量达到3%时,对TiB2细化作用减弱。

2) Mg元素的加入明显提高了复合材料的硬度。加入1.5%Mg和3%Mg后,其硬度与基体合金相比分别提高了58%和65%;热处理后,加入1.5%Mg和3%Mg复合材料的硬度与热处理前相比分别提高了29%和42%。

3) TiB2/Al-7Si复合材料的耐磨性能明显高于基体材料Al-7Si合金的,加入Mg后,复合材料的耐磨性能得到进一步改善,其磨损量和摩擦因数分别降低5%~10%。

REFERENCES

[1] ZHANG Yi-jie, MA Nai-heng, WANG Hao-wei, LE Yong-kang, LI Xian-feng. Damping capacity of in situ TiB2 particulates reinforced aluminium composites with Ti addition[J]. Materials and Design, 2007, 28(2): 628-632.

[2] HUANG Min-hwa, LI Xian-feng, YI Hong-zhan, MA Nai-heng, WANG Hao-wei. Effect of in situ TiB2 particle reinforcement on the creep resistance of hypoeutectic Al-12Si alloy[J]. Journal of Alloys and Compounds, 2005, 389(1/2): 275-280.

[3] BARTELS C, RAABE D, GOTTSTEIN G, HUBER U. Investigation of the precipitation kinetics in an A16061/TiB2 metal matrix composite[J]. Mater Sci Eng A, 1997, 237(1): 12-23.

[4] EMAMY M, MAHTA M, RASIZADEH J. Formation of TiB2 particles during dissolution of TiAl3 in Al-TiB2 metal matrix composite using an in situ technique[J]. Composites Science and Technology, 2006, 66(7/8): 1063-1066.

[5] TEE K L, LU L, LAI M O. In situ processing of Al-TiB2 composite by the stir-casting technique[J]. Journal of Materials Processing Technology, 1999, 89/90: 513-519.

[6] YI Hong-zhan, MA Nai-heng, ZHANG Yi-jie, LI Xian-feng, WANG Hao-wei. Effective elastic module of Al-Si composites reinforced in situ with TiB2 particles[J]. Scripta Materialia, 2006, 54(6): 1093-1097.

[7] 李忠华. (TiB2+TiAl3)/AlSi6Cu4复合材料的研究[J]. 铸造, 2001, 50(12): 734-736.

LI Zhong-hua. Study on the (TiB2+TiAl3)/AlSi6Cu4 composite[J]. Foundry, 2001, 50(12): 734-736.

[8] 杨 平. 原位合成铝基复合材料凝固组织中TiB2粒子的特征[J]. 中国有色金属学报, 1999, 9(4): 753-758.

YANG Ping. Characterization of TiB2 particles in solidification structures of in situ processed aluminum matrix composites[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 753-758.

[9] 闫卫平, 荣福杰, 宋国金, 翟 虎, 马志毅, 冯志军. 混合盐法制备TiB2/Al复合材料的研究现状[J]. 铸造, 2006, 55(11): 1114-1117.

YAN Wei-ping, RONG Fu-jie, SONG Guo-jin, ZHAI Hu, MA Zhi-yi, FENG Zhi-jun. Present status of studying of TiB2/Al composite fabricated by mixed salts method[J]. Foundry, 2006, 55(11): 1114-1117.

[10] 乐永康, 陈 东, 张亦杰, 等. 原位TiB2颗粒增强铝基复合材料及其力学性能[J]. 特种铸造及有色合金, 2006, 26(8): 518-520.

LE Yong-kang, CHEN Dong, ZHANG Yi-jie, et al. Mechanical properties and fracture morphology of in-situ TiB2 particle reinforced aluminum matrix composites[J]. Special Casting and Nonferrous Alloys, 2006, 26(8): 518-520.

[11] 王 鹏, 马乃恒, 李险峰, 王浩伟. 原位合成铝基复合材料中颗粒沉降的研究[J]. 特种铸造及有色合金, 2004, 24(2): 30-32.

WANG Peng, MA Nai-heng, LI Xian-feng, WANG Hao-wei. The deposition of particulate in the in situ TiB2 reinforced aluminum matrix composites[J]. Special Casting and Nonferrous Alloys, 2004, 24(2): 30-32.

[12] ZHANG Yi-jie, MA Nai-heng, WANG Hao-wei, LE Yong-kang, LI Song-chun. Effect of Ti and Mg on the damping behavior of in situ aluminum composites[J]. Materials Letters, 2005, 59(28): 3775-3778.

[13] ZHANG Yi-jie, MA Nai-heng, WANG Hao-wei, LE Yong-kang, LI Song-chun. Effect of Ti on the damping behavior of aluminum composite reinforced with in situ TiB2 particulate[J]. Scripta Materialia, 2005, 53(10): 1171-1174.

[14] 张树瑜, 柴跃生. 原位TiB2颗粒增强铝基复合材料形核机制及转变动力学[J]. 材料导报, 2002, 16(8): 68-70.

ZHANG Shu-yu, CHAI Yue-sheng. Growth mechanism and transformation kinetics of in-situ TiB2 participate reinforcement aluminium matrix composites[J]. Materials Review, 2002, 16(8): 68-70.

[15] 赵芳欣, 张瑛洁, 尹绍奎, 李德成, 李玉胜. 原位生成铸造TiB2/Al-Si复合材料的微观特征及弹性模量[J]. 铸造, 1998, 47(12): 13-16.

ZHAO Fang-xin, ZHANG Ying-jie, YIN Shao-kui, LI De-cheng, LI Yu-sheng. Micro feature and Young’s modulus of cast TiB2/Al-Si composite fabricated by in situ reaction[J]. Foundry, 1998, 47(12): 13-16.

[16] ZHANG J, FAN Z, WANG Y Q, ZHOU B L. Microstructural evolution of the in situ Al-15wt. %Mg2Si composite with extra Si contents[J]. Scripta Material, 2000, 42(11): 1101-1106.

[17] MANDAL A, CHAKRABORTY M, MURTY B S. Effect of TiB2 particles on sliding wear behaviour of Al-4Cu alloy[J]. Wear, 2007, 262(1/2): 160-166.

收稿日期:2008-04-06;修订日期:2009-06-08

通信作者:刘忠侠,教授,博士;电话:0371-67767776;E-mail: liuzhongxia@zzu.edu.cn

(编辑 李艳红)