双膜三室电解槽中电沉积金属钴

来源期刊:中国有色金属学报(英文版)2016年第6期

论文作者:周键 王三反 宋小三

文章页码:1706 - 1713

关键词:钴;电沉积;阴离子交换膜;阳离子交换膜;膜电解槽

Key words:cobalt; electrodeposition; anion exchange membrane; cation exchange membrane; membrane electrolytic reactor

摘 要:对离子交换膜电解槽中电沉积钴的参数进行了优化研究,并探讨了阴极液成分、电流密度、温度等因素对电沉积钴的电流效率、单位能耗、质量的影响规律。阴极液为含氯化钴混合溶液,初始中间液为稀盐酸溶液,阳极液为硫酸溶液。采用阴离子交换膜将阴极液与中间液隔开,阳离子交换膜将阳极液与中间液隔开。结果表明:最佳实验条件为80 g/L钴、20 g/L硼酸、3 g/L氟化钠、pH 4、电流密度250 A/m2、温度50 °C,在该条件下电流效率为97.5%。中隔室可得到电化学再生的盐酸,酸浓度达到0.45 mol/L,实现了产酸抑氯同步化。

Abstract: The process parameters were optimized for the electrodeposition of cobalt from cobalt chloride solution in the membrane electrolytic reactor. Effects of parameters such as catholyte composition, current density and temperature on the current efficiency, specific power consumption and quality of deposition were studied. The catholyte was a mixed solution of cobalt chloride, the initial middle electrolyte consisted of diluted hydrochloric acid, and the anolyte was sulfuric acid. An anion exchange membrane separated the catholyte from the middle electrolyte, and a cation exchange membrane separated the anolyte from the middle electrolyte. The results showed that a maximum current efficiency of 97.5% was attained under the optimum experimental condition of an catholyte composition of 80 g/L Co2+, 20 g/L H3BO3, 3 g/L NaF and pH of 4, at a cathode current density of 250 A/m2 and a temperature of 50 °C. HCl could be produced in the middle compartment electrochemically up to 0.45 mol/L.

Trans. Nonferrous Met. Soc. China 26(2016) 1706-1713

Jian ZHOU1,2, San-fan WANG1,2, Xiao-san SONG1,2

1. School of Environmental and Municipal Engineering, Lanzhou Jiaotong University, Lanzhou 730070, China;

2. Engineering Research Center for Cold and Arid Regions Water Resource Comprehensive Utilization, Ministry of Education, Lanzhou Jiaotong University, Lanzhou 730070, China

Received 16 September 2015; accepted 3 March 2016

Abstract: The process parameters were optimized for the electrodeposition of cobalt from cobalt chloride solution in the membrane electrolytic reactor. Effects of parameters such as catholyte composition, current density and temperature on the current efficiency, specific power consumption and quality of deposition were studied. The catholyte was a mixed solution of cobalt chloride, the initial middle electrolyte consisted of diluted hydrochloric acid, and the anolyte was sulfuric acid. An anion exchange membrane separated the catholyte from the middle electrolyte, and a cation exchange membrane separated the anolyte from the middle electrolyte. The results showed that a maximum current efficiency of 97.5% was attained under the optimum experimental condition of an catholyte composition of 80 g/L Co2+, 20 g/L H3BO3, 3 g/L NaF and pH of 4, at a cathode current density of 250 A/m2 and a temperature of 50 °C. HCl could be produced in the middle compartment electrochemically up to 0.45 mol/L.

Key words: cobalt; electrodeposition; anion exchange membrane; cation exchange membrane; membrane electrolytic reactor

1 Introduction

Cobalt metal is an essential component of magnetic alloy [1,2], heat-resisting alloy [3], cemented carbide [4] and anti-corrosion alloy [5]. All of these alloys are used in various industries such as chemical, machine manufacturing, aviation and aerospace, so, cobalt is a strategic metal resource.

Generally speaking, cobalt occurs in nature in a widespread but dispersed form, almost in admixtures with ores of other metals. Most of the worldwide cobalt production is derived from sulfide ores while the balance of that is derived from lateritic sources [6]. Electrowinning of cobalt can be carried out in sulphate electrolyte [7-9], chloride electrolyte [10,11] and a mixture of both [12,13]. The several advantages of using chloride electrolyte compared with sulphate electrolyte are as follows: higher electrical conductivity and lower viscosity of solution, higher solubility, higher current efficiency and lower power consumption, lower cobalt deposition and anodic chloride overpotential, easier and more specific nickel-cobalt separation by solvent extraction [10,14]. There are some enterprises using chloride electrolyte including Falconbridge Ltd in Canada, Jinchuan cobalt smelting plant in China, Sumitomo metal company in Japan. The disadvantage of using chloride electrolytes is the evolution of chlorine gas at the anode.

The gas must be treated to harmlessness because of its toxicity and corrosivity. The common way is either alkali absorption [15] or burning the chlorine with hydrogen. The above methods require a complex, secure and reliable collection system of chlorine gas. It complicates the design of electrolytic cell and operation, and increases the cost of cobalt electrowinning. In addition, the anode bag made of chemical fiber fabric, was used for collecting chlorine gas, which is easily broken after using for a period of time. Consequently, the leakage of chlorine gas is unavoidable.

To solve these problems thoroughly, the process of direct electrolytic regeneration of chloride in the form of HCl and simultaneous electrodeposition of cobalt in the ion exchange membrane electrolytic reactor from chloride electrolyte was proposed [16]. The flow diagram of the novel approach to recover cobalt in double ion exchange membranes electrolytic reactor is shown in Fig. 1.

Fig. 1 Flow chart of membrane electrolysis system

In this work, the optimization of parameters for cobalt electrodeposition was studied. The effects of the following parameters on the current efficiency, energy consumption and quality of cobalt deposited was explored, including concentration of Co2+, cathode current density, temperature of electrolyte, bath pH, NaF and H3BO3. Finally, the possibility of regenerating chloride in the form of HCl was discussed.

2 Experimental

2.1 Chemical regents and materials

The synthetic catholyte was prepared by dissolving analytical grade cobalt chloride (CoCl2·6H2O), boric acid (H3BO3) and sodium fluoride (NaF) in pure water. Sodium hydroxide (NaOH) and hydrochloric acid (HCl) were used to adjust the pH of catholyte.

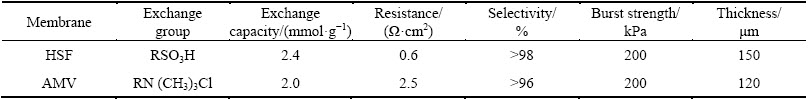

The anolyte was sulfuric acid (H2SO4) solution. Diluted hydrochloric acid solution was selected as the initial middle electrolyte. The HSF and AMV were employed as a cation exchange membrane and an anion exchange membrane, respectively, and made in Asahi Glass Co., Ltd., as listed in Table 1.

Before use, HSF and AMV were dipped in sulfuric acid and hydrochloric acid respectively for 24 h, and then washed with pure water.

2.2 Membrane electrolytic reactor

All the electrowinning experiments were carried out in an acrylic glass cell [17], which was composed of three compartments with same dimensions and separated by a piece of anion exchange membrane (AEM) and a piece of cation exchange membrane (CEM). These compartments, namely anode compartment, middle compartment and cathode compartment, were clamped together firmly with external tie rods. The solution in the middle compartment is named as middle electrolyte. Each compartment, having a volume of 500 mL, consisted of an inlet for desired electrolyte and an outlet from where the spent electrolyte overflowed into the buffer tank.

The temperature was maintained by operating the cell in a thermostatic water bath with a variation of ±1 °C. The cathode was rectangular stainless steel plate. A layer of insulating varnish was applied on one side of cathode, and the other side of cathode was polished with metallographic abrasive paper. The dimensionally stable electrode (DSA) was used as the anode, made of titanium sheet coated with IrO2-Ta2O5 (Baoji Junhang Metal Material Co., Ltd., China). The effective surface areas of the anode and the cathode were both 80 cm2. DC power supply was used for obtaining a constant current. For measuring cell voltage and current at regular intervals, precision voltmeter and ammeter were connected into the circuit. The pH of electrolyte was measured by the PHS-3G pH meter.

2.3 Principle

Under the action of electric field and concentration gradient, the possible ion transport in the membrane electrolytic reactor is shown in Fig. 2. In the cathode compartment, Co2+ and H+ ions migrate in the direction of cathode. There is electrodeposition of cobalt followed by evolution of hydrogen on the cathode:

Co2++2e→Co↓, φΘ=-0.28 V (1)

2H++2e→H2↑, φΘ=0 V (2)

In the anode compartment, there is oxidation reaction of water:

H2O-2e→2H++1/2O2↑, φΘ=1.23 V (3)

The H+ ions produced in the anode compartment migrate towards cathode, passing through the cation exchange membrane, but being retained in the middle compartment since they cannot pass through the anion exchange membrane. Similarly, the Cl- ions in the cathode compartment migrate in the direction of anode, passing through the anion exchange membrane into the middle compartment; however, they are retained because they cannot pass through the cation exchange membrane. As a result, the Cl- and H+ ions originating respectively from the cathode and anode compartments meet to form HCl in the middle compartment.

Table 1 Property of membranes used in experiments

Fig. 2 Schematic diagram of principle

2.4 Date processing

Current efficiency is the ratio of the current effectively used for the electrodeposition of cobalt to the total current, also yields the ratio of actual mass of deposited cobalt to theoretical mass of cobalt calculated by the Faraday’s law of electrolysis. Current efficiency was calculated by Eq. (4):

(4)

(4)

where η is the cathode current efficiency, %; m is the mass of cobalt obtained on the cathode over the time interval t, g; n is the valence of cobalt ion (2+); F is the Faraday constant (96485.33), C/mol; M is the molar mass of cobalt (58.93), mol/g; I is the apparent current density, A/m2; S is the effective surface of cathode, m2; t is the electrolysis time, s.

The specific power consumption for the electrodeposition of cobalt was calculated by Eq. (5):

(5)

(5)

where E is the specific power consumption, (kW·h/kg); U is the cell voltage, V.

2.5 Procedure

A mixed solution of cobalt chloride with desired pH was filled in both cathode compartment and catholyte tank. The anode compartment and anolyte tank were filled with 1% sulfuric acid solution. The middle compartment and middle-electrolyte tank contained 0.5% hydrochloric acid solution. Three types of electrolytes were circulated respectively by using metered peristaltic pumps. The anode and the cathode were placed in the anode compartment and cathode compartment respectively with a distance of 60 mm. The experiments were carried out under the constant current and desired temperature. After electrolysis, the cathode was removed, rinsed thoroughly with deionized water, dried in an oven, and then weighed on a precision electronic balance. The mass gain was used for the calculation of current efficiency. All the electrodeposition tests were conducted for at least 3 h in the cobalt chloride solution.

3 Results and discussion

3.1 Effect of Co2+ concentration

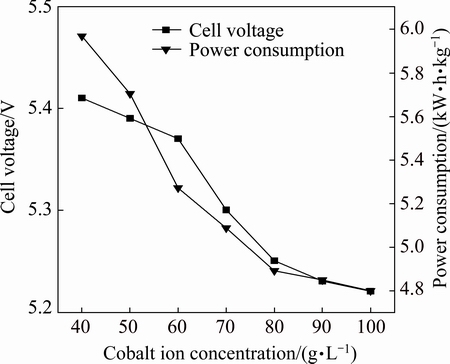

Electrolysis was performed by varying the Co2+ concentration of catholyte from 40 g/L to 100 g/L in the presence of 20 g/L boric acid and 4 g/L sodium fluoride, at a temperature of 50 °C, pH 4 and a current density of 250 A/m2. The experimental results are plotted in Fig. 3 and Fig. 4. As can be seen from Fig. 3, the current efficiency increases steadily with the increase of Co2+ concentration from 40 to 80 g/L, and it almost keeps constant with the increase of Co2+ concentration from 80 to 100 g/L.

Fig. 3 Effect of cobalt concentration on current efficiency

During electrolysis at a low concentration of cobalt ions, it was also observed that there were stressed and brittle electrodeposits which were flaked away easily from stainless steel plate. This is explained by the greater availability of cobalt ions vis-a-vis hydrogen ions, at higher Co2+ concentrations, while at lower Co2+ concentration, the higher hydrogen evolution which leads to lower cathode current efficiency and stressed deposits.

Fig. 4 Effect of cobalt concentration on cell voltage and power consumption

Figure 4 depicts that the cell voltage also reduces as the cobalt concentration increases. It is obvious due to the increase of conductivity of electrolyte with the increase of Co2+ concentration. The energy required to deposit cobalt decreases gradually with cobalt concentration. This is a result of the increased current efficiency and the decreased cell voltage. Since there is no benefit for current efficiency beyond 80 g/L, this value was taken as optimal cobalt concentration.

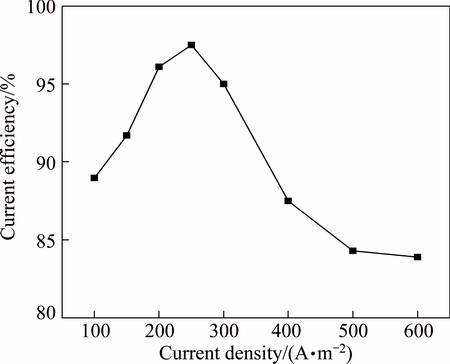

3.2 Effect of cathode current efficiency

Figure 5 presents the effect of cathode current density on the current efficiency at a electrolyte composition of 80 g/L cobalt and 4 g/L sodium fluoride and 20 g/L boric acid, pH of 4 and a temperature of 50 °C. The current efficiency increases from 88.6% to 97.5% as cathode current density increases from 100 to 250 A/m2, and then drops rapidly to 82.3% with the increase of cathode current density from 250 to 600 A/m2. It is observed that the current efficiency goes through a maximum at 250 A/m2. Beyond this value, the current efficiency decreases because the effective Co2+ ions in the electric double layer of cathode reduce sharply, which results in the acceleration of hydrogen evolution and suppression of cobalt electrodeposition.

Fig. 5 Effect of current efficiency on current efficiency

The cell voltage increases almost linearly as shown in Fig. 6. The total voltage across membrane electrolytic cell is composed of decomposition potential of electrolyte, polarization potential and potential drop of resistance of conductors including solutions, electrodes and electrical connections, all of which are affected strongly by current density. One reason is the increase in cathodic polarization potential and anodic polarization potential besides membrane potential. Another possible reason is that the insoluble cobalt hydroxide forms in the vicinity of cathode due to the marked increase in the surface pH at higher current density.

Fig. 6 Effect of current density on cell voltage and power consumption

At lower current density (<200 A/m2), there was dull grey and non-uniform deposit in addition to detaching from the cathode easily. This may be due to a small part of hydrogen incorporating into cobalt electro-crystallization which gives rise to cobaltic lattice distortion and excessive internal stress so that the deposit started to dehisce and layer. As the cathode current density increased, the deposit became brighter, smoother and more adherent. When the cathode current density was more than 600 A/m2, the surface of deposited cobalt sheet was coarse, and the edge of that was very thick growth and in extreme case powdery, dendritic growth. This is ascribed to the higher current concentration at the edges and the more abundant availability of cobalt ions at the edges. Based on the consideration of quality of cobalt deposits and current characteristic of ion exchange membrane, a proper cathode current density was 250 A/m2.

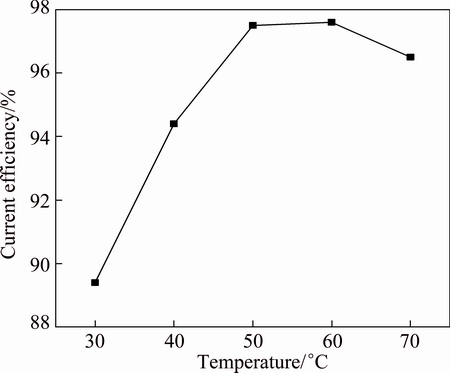

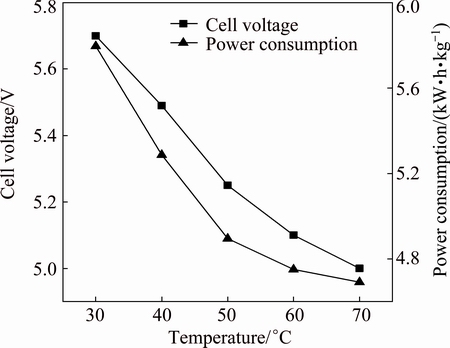

3.3 Effect of temperature

Temperature has a great influence on the electrochemical process and physical properties of deposits. The experiments were conducted by varying the temperature of electrolyte from 30 to 70 °C in the presence of 80 g/L Co2+, 20 g/L boric acid and 4 g/L sodium fluoride, at a current density of 250 A/m2, a temperature of 50 °C and pH of 4.

From Fig. 7, it can be seen that the current efficiency increases dramatically as the temperature raises from 30 to 50 °C, beyond 50 °C there is no benefit for current efficiency. The higher current efficiency is obviously attributed to the increased ionic migration rate of electrolytes and decreased overpotential for cobalt deposition at higher temperature. Because of the decrease in resistance of electrolytes and ion exchange membranes,the cell voltage decreases linearly with the increase of temperature, as shown in Fig. 8. The drop of cell voltage mainly results in the decrease in power consumption.

Fig. 7 Effect of temperature on current efficiency

Fig. 8 Effect of temperature on cell voltage and power consumption

During the electrodeposition of cobalt, it was also found that the deposits were dull grey, rough and non-adherent at temperature below 40 °C, and then they became bright, smooth and adherent at higher temperature. This phenomenon is probably explained by a mixture of close-packed hexagonal (α-Co) and face-centred (β-Co) [18] formed at lower temperature, which leads to stressed deposition and cracked cobalt sheet.

In view of thermal stability of ion exchange membranes and physical morphology of the cobalt deposits, a proper temperature range of 50-60 °C was chosen.

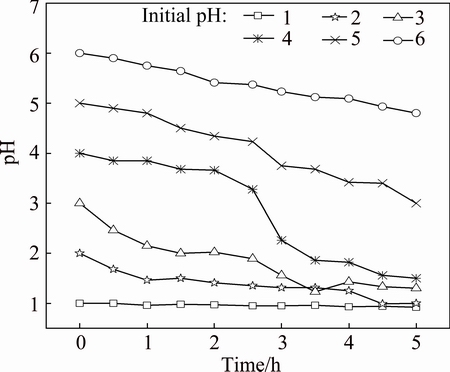

3.4 Effect of pH

As the equilibrium electrode potential for cobalt deposition is more negative, hydrogen evolution reaction occurs always as a parallel process that consumes a part of current supplied and reduces the efficiency of main reaction [19]. The experiments were carried out with varying pH in the range of 1-6 with an electrolyte composition of 80 g/L Co2+, 3 g/L NaF and 20 g/L H3BO3, at a temperature of 50 °C and a current density of 250 A/m2. The results, plotted in Fig. 9, show that the current efficiency increases sharply as the pH of catholyte rises to 4, beyond that it stabilizes. The current efficiency of cobalt electrodeposition cannot reach 100% in the whole range of pH, because a portion of current is consumed by hydrogen evolution. At lower pH, the higher hydrogen ion concentration can increase diffusion gradient of H+ in the vicinity of cathode and reduce the overpotential for hydrogen evolution, therefore, it results in substantial hydrogen gas evolution and decreases the current efficiency. It was also found that a large number of tiny circular pits formed on the surface of deposits due to the incorporation of microbubbles in the nucleation of cobalt.

Fig. 9 Effect of initial catholyte pH on current efficiency and power consumption

At pH higher than 5, a small amount of H+ discharges at the cathode, which increases the interfacial pH and initiates Co(OH)2/CoOOH precipitation [20]. The inclusion of such hydroxides in the deposits results in very poor quality cobalt plates. Hence, a pH range of 4-5 seems satisfactory.

The anion exchange membrane set between catholyte and middle electrolyte is characteristic of selective permeability for anion. In the electric field, chloride ions migrate from catholyte to middle electrolyte through the anion exchange membrane. Hydrogen ions also may migrate from middle electrolyte to catholyte forced by electric field and Donnan dialysis. The diffusion of hydrogen ions from middle electrolyte to catholyte is accelerated by the higher concentration gradient of H+. Figure 10 depicts that the pH of catholyte decreases with the electrolysis time. It also can be seen that the pH of catholyte remains steady with the electrolysis time at initial pH 1, decreasing rapidly at initial pH 2-5, and dropping steadily at initial pH 6. This result suggests that the catholyte pH must be adjusted to desired level continuously.

Fig. 10 pH variation of catholyte with electrolysis time at different initial catholyte pH

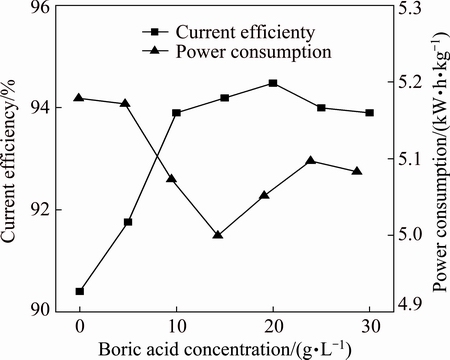

3.5 Effect of boric acid

Boric acid is commonly added to the electrolyte during the metal electrodeposition. It is widely assumed that boric acid acts as a buffer to stabilize the surface pH and prevent the formation of hydroxides [21,22]. However, some researchers observed that boric acid plays a more important role than simply as a buffer, and it also interferes with metal nucleation process [23].

In order to verify the effect of H3BO3 on the current efficiency in the electrodeposition of cobalt, experiments were operated at the variation of boric acid from 0 to 30 g/L with a current density of 250 A/m2, 80 g/L Co2+, 3 g/L NaF, pH of 3 at a temperature of 50 °C. The results, plotted in Fig. 11, indicate that the current efficiency increases steadily with increase in boric acid concentration.

The increase of current efficiency is caused by the formation of Co2+-boric acid complexes which increase the overpotential of hydrogen and decrease the evolution of hydrogen gas. The Co2+-boric acid complexes also act as a homogenous catalyst adsorbed on the cathode surface, which reduce the overpotential for cobalt deposition and move the reduction potential of cobalt to more positive direction [24].

Due to the increase of cathode current efficiency, the power consumption has a decreasing tendency as shown in Fig. 11. The lowest point of power consumption curve is a result of the minimum cell voltage and higher current efficiency. It was observed that the cell voltage stayed at about 4.8 V, so the addition of boric acid has little effect on the cell voltage.

Fig. 11 Effect of boric acid concentration on current efficiency and power consumption

The cobalt deposits became brighter and smoother, adhered to the cathode tightly in the presence of boric acid as reported by TRIPATHY et al [22]. So, the addition of H3BO3 is good for improving the quality of deposits.

3.6 Effect of sodium fluoride

Literature on the addition of NaF in combination with H3BO3 to cobalt chloride electrolyte is rather scanty. HORKANS [25] observed that the addition of NaF resulted in a small increase in current efficiency and improvement in the appearance of deposits. To verify the effect of sodium fluoride, experiments were performed by varying NaF concentration from 0 to 5 g/L in the presence of 80 g/L Co2+ and 10 g/L H3BO3, at a current density of 250 A/m2, a temperature of 50 °C and pH of 4. The results are depicted in Fig. 12. The current efficiency increases rapidly as the sodium fluoride concentration increases to 3 g/L, beyond this value, it remains steady. It was also observed that the use of NaF in the catholyte leads to a better appearance of cobalt deposits.

The reason for the increase in the current efficiency is summarized as follows: F- is probably adsorbed on the surface of cathode, which causes the inactivation of site for hydrogen evolution reaction. Moreover, Co(OH)2 film may form at the catholyte-cathode interface during evolution of H2, which affects greatly the current efficiency. The OH- group of Co(OH)2 may be replaced by F- with a substitution reaction [26], which may prevent the formation of Co(OH)2 and depress hydrogen evolution reaction.

Fig. 12 Effect of sodium fluoride concentration on current efficiency and power consumption

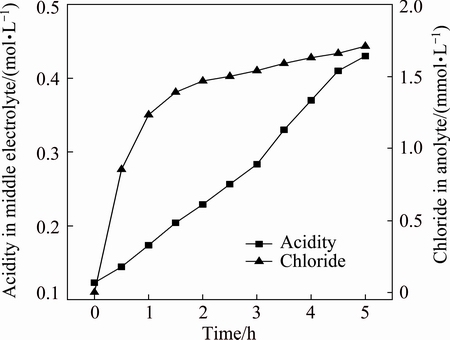

3.7 Acidity in middle electrolyte and chloride in anolyte

During electrowinning, chloride can be regenerated in the form of hydrochloric acid. This is confirmed by the acidity change in the middle electrolyte as shown in Fig. 13. From Fig. 13, it can be seen that the acidity increases linearly from 0.12 to 0.45 mol/L with the electrolysis time. This is due to migration of protons from the anolyte to the middle electrolyte by electric field and concentration gradient. Hence, protons are the important current carrier through the cation exchange membrane. It also can be seen that the chloride concentration in the anolyte increases steadily with the electrolysis time. The leakage of chloride ions into the anolyte is caused by electric field and concentration gradient, both of which are in the same direction. A low concentration of chloride ions in the anolyte is crucial for obtaining oxygen evolution reaction instead of chlorine evolution reaction at the anode. Thus, it is necessary to maintain a low chloride concentration in the anolyte for either mode of operation. The amount of chloride at the time of 5 h is acceptable for this experiment.

Fig. 13 Acidity in middle electrolyte and chloride concentration in anolyte as function of time

4 Conclusions

1) The conditions for the electrodeposition of cobalt from cobalt chloride solution were investigated. The results indicate that Co concentration, current density, pH and temperature have great influences on the current efficiency, power consumption and appearance of deposit. The addition of boric acid and sodium fluoride may improve the quality of cobalt deposit.

2) It is entirely feasible to regenerate chloride in the form of HCl in the middle compartment. The acid is used for the acid leaching of metal bearing laterite.

3) The optimum conditions for the deposition of cobalt are as follows: cobalt concentration of 80 g/L, H3BO3 concentration of 20 g/L, NaF concentration of 3 g/L, current density of 250 A/m2, pH of 4, temperature of 50 °C.

References

[1] SURZHKO O. Electrolytic deposition of a cobalt-lead alloy with magnetic properties [J]. Russian Journal of Applied Chemistry, 2013, 86(2): 182-185.

[2] ZHANG Y, SHARMA P, MAKINO A. Effects of cobalt addition in nanocrystalline Fe83.3Si4B8P4Cu0.7 soft magnetic alloy [J]. IEEE Transactions on Magnetics, 2014, 50(4): 1-4.

[3] FILIPPO B, PAOLO L, PASQUALE G. High-temperature fatigue strength of a copper–cobalt–beryllium alloy [J]. The Journal of Strain Analysis for Engineering Design, 2014, 49(4): 244-256.

[4] KURLOV A S, REMPEL A A. Effect of cobalt powder morphology on the properties of WC-Co hard alloys [J]. Inorganic Materials, 2013, 49(9): 889-893.

[5] GUSHKOVAL М О, VED М V, SAKHNENKO М D. Corrosion properties of cobalt–silver alloy electroplates [J]. Materials Science, 2013, 49(3): 292-297.

[6] LIU Da-xing. Cobalt production, consumption and technical development at home and abroad [J]. Non-Ferrous Smelting, 2000, 29(5): 4-10.

[7] SHARMA I G, ALEX P, BIDAYE A C, SURI A K. Electrowinning of cobalt from sulphate solutions [J]. Hydrometallurgy, 2005, 80(1-2): 132-138.

[8] DAS S C, SUBBAIAH T. Electrowinning of cobalt: I. Winning from pure cobalt sulphate bath [J]. Hydrometallurgy, 1984, 12: 317-333.

[9] MISHRA K G, SINGH P, MUIR D M. Electrowinning of cobalt from sulphate solutions contaminated with organic impurities [J]. Hydrometallurgy, 2002, 65(2): 97-102.

[10] KONGSTEIN O E, HAARBERG G M, THONSTAD J. Current efficiency and kinetics of cobalt electrodeposition in acid chloride solutions. Part I: The influence of current density, pH and temperature [J]. Journal of Applied Electrochemistry, 2007, 37: 669-674.

[11] LI M, WANG Z W, REDDY R G. Cobalt electrodeposition using urea and choline chloride [J]. Electrochimica Acta, 2014, 123: 325-331.

[12] HUANG J H, KARGL-SIMARD C, ALFANTAZI A M. Electrowinning of cobalt from a sulfate-chloride solution [J]. Canadian Metallurgical Quarterly, 2004, 43(2): 163-172.

[13] PRADHAN N, SINGH P, TRIPATHY B C, DAS S C. Electrowinning of cobalt from acidic sulphate solutions-effect of chlorine ion [J]. Minerals Engineering, 2001, 14(7): 115-183.

[14] KONGSTEIN O E, HAARBERG G M, THONSTAD J. Mass transfer of protons during electrodeposition of cobalt in chloride electrolytes [J]. Journal of the Electrochemical Society, 2010, 157(6): D335-D340.

[15] WU Yan-bin, WANG San-fan, ZHOU Jian, CHEN Xia. Research progress to treat chlorine pollution in cobalt electrowinning [J]. Nonferrous Metals: Extractive Metallurgy, 2014, 9: 8-11.

[16] WANG San-fan, ZHOU Jian, WANG Ting, ZHAO Hong-jing, ZHANG Xue-min, LI Le-zuo. Electrowinning of metal chlorides by the membrane electrolysis method: China patent, 102839389 [P]. 2015-06-03. (in Chinese)

[17] WANG San-fan, ZHOU Jian, WANG Ting, ZHAO Hong-jing, ZHANG Xue-min, LI Le-zuo. Electrowinning of metal chlorides in the membrane electrolytic cell: China patent, 202925116 [P]. 2013-05-08. (in Chinese)

[18] TREVOR C. Reducing the stress in cobalt alloy plating [EB/OL]. [2003]. http://www. finishing.com/204/83.shtml.

[19] SANTOS J S, TRIVINHO-STRIXION F, PEREIRA E C. Investigation of Co(OH)2 formation during cobalt electrodeposition using a chemometric procedure [J]. Surface and Coatings Technology, 2010, 205(7): 2585-2589.

[20] CUI C Q, JIANG S P, TSEUNG A C C. Electrodeposition of cobalt from aqueous chloride solutions [J]. Journal of the Electrochemical Society, 1990, 137(11): 3418-3423.

[21] LU Jing, YANG Qi-hua, ZHANG Zhao. Effects of additives on nickel electrowinning from sulfate system [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S1): s97-s101.

[22] TRIPATHY B C, SINGH P, MUIR, D M. Effect of manganese(II) and boric acid on the electrowinning of cobalt from acidic sulphate solutions [J]. Metallurgical and Materials Transactions B, 2001, 32(3): 395-399.

[23] ZECH N, LANDOLT D. The influence of boric acid and sulfate ions on the hydrogen formation in Ni-Fe plating electrolytes [J]. Electrochim Acta, 2000, 45(21): 3461-3471.

[24] ABD El-REHIM S S, ABD El-WAHAB S M, RASHWAN S M, ANWAR Z M. Electroplating of a Co-Cu alloy from a citrate bath containing boric acid [J]. Journal of Chemical Technology and Biotechnology, 2000, 75(3): 237-244.

[25] HORKANS J. On the role of buffers and anions in NiFe electrodeposition [J]. Journal of the Electrochemical Society, 1979, 126(11): 1861-1867.

[26] DAS S C, SUBBAIAH T. Electrowinning of cobalt from a sulphate bath containing H3BO3 and NaF [J]. Journal of Applied Electrochemistry, 1987, 17(4): 675-683.

周 键1,2,王三反1,2,宋小三1,2

1. 兰州交通大学 环境与市政工程学院,兰州 730070;

2. 兰州交通大学 寒旱地区水资源综合利用教育部工程研究中心,兰州 730070

摘 要:对离子交换膜电解槽中电沉积钴的参数进行了优化研究,并探讨了阴极液成分、电流密度、温度等因素对电沉积钴的电流效率、单位能耗、质量的影响规律。阴极液为含氯化钴混合溶液,初始中间液为稀盐酸溶液,阳极液为硫酸溶液。采用阴离子交换膜将阴极液与中间液隔开,阳离子交换膜将阳极液与中间液隔开。结果表明:最佳实验条件为80 g/L钴、20 g/L硼酸、3 g/L氟化钠、pH 4、电流密度250 A/m2、温度50 °C,在该条件下电流效率为97.5%。中隔室可得到电化学再生的盐酸,酸浓度达到0.45 mol/L,实现了产酸抑氯同步化。

关键词:钴;电沉积;阴离子交换膜;阳离子交换膜;膜电解槽

(Edited by Xiang-qun LI)

Foundation item: Project (2015016) supported by the Young Scholars Science Foundation of Lanzhou Jiaotong University, China; Project (2015BAE04B01) supported by the National Science-technology Support Program of China; Project (21466019) supported by the National Natural Science Foundation of China

Corresponding author: Jian ZHOU; Tel/Fax: +86-931-4956083; E-mail:zjwater123@sina.com

DOI: 10.1016/S1003-6326(16)64279-6