DOI: 10.11817/j.issn.1672-7207.2019.03.003

Al2O3对钒钛高炉渣冶金性能的影响及黏度预测模型

梁海丽1,冯聪1,储满生1,唐珏1,王挽平2

(1. 东北大学 冶金学院,辽宁 沈阳,110819;

2. 承德钢铁集团有限公司,河北 承德,067000)

摘要:为研究Al2O3对钒钛高炉渣主要冶金性能的影响,以国内某钢铁企业的钒钛磁铁矿现场高炉渣为基础,在其他组元不变的情况下采用化学试剂调控渣样成分,运用X线衍射(XRD)物相分析探索相关影响规律,从而以所得实验数据为基础,利用Weymann-Frenkel方程以及修正光学碱度Λcorr计算公式,建立相关黏度预测模型。研究结果表明,随着渣系中Al2O3质量分数的增加,炉渣高温黏度上升,熔化性温度TBr和黏流活化能Eη都呈上升趋势,渣系流动性和热稳定性均变差;所建立的黏度预测模型的平均偏差△为2.16%,模型预测值与实测值达成良好的吻合效果,可以真实有效地测量黏度,为实际生产节省成本。

关键词:钒钛磁铁矿;高炉渣;Al2O3质量分数;冶金性能;黏度预测模型

中图分类号:TF524 文献标志码:A 文章编号:1672-7207(2019)03-0514-07

Effect of Al2O3 on metallurgical properties of blast furnace slags of vanadium-titanium magnetite and viscosity prediction model

LIANG Haili1, FENG Cong1, CHU Mansheng1, TANG Jue1, WANG Wanping2

(1. School of Metallurgy,Northeastern University, Shenyang 110819, China;

2. Chengde Iron and Steel Company, Chengde 067000, China)

Abstract: In order to explore the effects of Al2O3 on the metallurgical properties of blast furnace(BF) slags about vanadium-titanium magnetite, all experiments samples were synthesized by adding the analytical reagent oxides of CaO, SiO2, MgO, Al2O3 and TiO2 into the base BF slag. Other compositions were invariable and the base BF slag was taken from Chengde Steel. The mechanism was analyzed by X-ray diffraction(XRD). The relevant viscosity prediction model was established based on experimental data using Weymann-Frenkel equation and the formula of calculating the fixed optical basicity. The results show that with the increase of Al2O3 mass fraction, the viscosity rises and the fluidity of BF slag is worse, the break-point temperature and the activation energy of viscous flow are also increased, and the thermos ability of slags is worse. The average deviation of viscosity model is 2.16%. The predicted viscosity values are in agreement with the experiment viscosity values, and the cost for the actual production is saved.

Key words: vanadium-titanium magnetite; blast furnace slag; Al2O3 mass fraction; metallurgical properties; viscosity prediction model

钒钛磁铁矿是一种多元共生铁矿,富含铁、钒、钛等重要战略资源[1]。在我国,钒钛磁铁矿储量丰富、分布集中,主要分布在攀西、承德等地,具有很高的利用价值。目前,高炉冶炼是将铁、钒、钛等金属从钒钛磁铁矿中提炼出来的主要路线。高炉渣是炼铁过程中的主要副产品,其主要组元为CaO,SiO2,MgO,Al2O3及TiO2。炉渣的冶金性能一直是制约高炉进一步提高钒钛矿使用比例的关键因素。炉渣性能差会造成渣铁分离困难、铁损高、脱硫能力低等问题,使得高炉产量、焦比和生产成本等核心经济指标未达到强化冶炼水平,严重影响企业经济效益[2-5]。炉渣成分对钒钛高炉渣的性能具有重要影响。谢洪恩等[6]分析了炉渣成分对高钛型高炉渣熔化性温度的影响规律,其中研究发现Al2O3含量升高,熔化性温度降低。黄宏虎等[7]通过黏度试验发现低钛炉渣Al2O3含量对炉渣流动性的影响较小,生产中Al2O3含量可以适当提高。穆红旺等[8]研究了高铝中钛型高炉渣黏度的试验研究,发现Al2O3的质量分数大于14.75%后对炉渣黏度的影响不明显。然而,高炉渣的成分不同,Al2O3对高炉渣冶金性能的影响也不同,人们对炉渣成分对高炉渣熔化性温度的相关研究较少,并且这些文献没有建立相关黏度预测模型。为此,本文作者以国内承钢钒钛磁铁矿现场高炉渣为基础,研究Al2O3含量对钒钛现场高炉渣冶金性能(包括黏度、熔化性温度及热稳定性)的影响规律,并依据有效的实验数据建立有关Al2O3的黏度预测模型,可有效地测量高炉渣黏度,节省工厂测量黏度的时间,提高经济效益。

1 实验原料及方法

1.1 实验方案

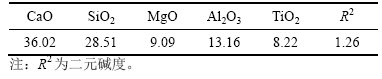

国内某钢铁企业现场钒钛高炉渣的化学成分如表1所示。本实验以此钒钛高炉渣为基础,采用分析纯化学试剂调整渣样成分,在氩气气氛下运用RTW -10熔体物性综合测定仪测定各渣系冶金性能,得到渣系黏度-温度(η-t)曲线,分析炉渣中Al2O3质量分数对渣系熔化性温度TBr、高温黏度η、黏流活化能Eη的影响规律,并依据实验数据建立相关的黏度预测模型。其中,Al2O3质量分数为10%~18%,实验方案如表2所示。

将渣系η-t曲线与横坐标成135°的斜线相切点的温度定义为熔化性温度TBr,若熔化性温度过高时,炉渣难以熔化,流动性变差;炉渣黏度过高将导致炉渣过于黏稠,流动性变差;黏流活化能Eη反映炉渣黏度对温度的敏感性,黏流活化能越高,温度对渣系黏度变化的影响越大,导致热稳定性越差,不利于高炉顺利运行。

表1 现场高炉渣化学成分(质量分数)

Table1 Chemical composition of base BF slag %

表2 实验方案

Table 2 Experiment scheme

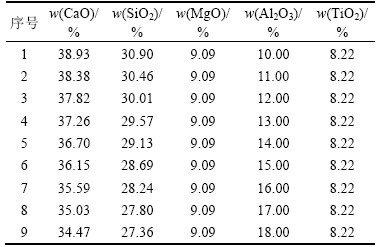

1.2 实验设备及方法

采用旋转柱体法在RTW-10型熔体物性测定仪上测定炉渣的黏度-温度曲线(η-t曲线),其原理图如图1所示。该黏度测量装置包括加热系统、旋转系统、测量系统、控制系统和气体输送系统。测定时,将准备好的140 g渣样放入钼坩埚中,一起置于高温电阻炉内,加热到1 500 ℃熔化并恒温30 min,形成均匀渣相,渣样完全融化后其在坩埚中的深度约为40 mm。随高温电阻炉炉体上升,钼测头缓慢浸入熔渣至预定深度后,进行降温测黏度,降温速度为-3 ℃/min,转速为200 r/min,得到黏度-温度曲线。当炉渣黏度达到3.5 Pa·s时,黏度测量停止。渣样重新被加热到1 500 ℃熔化,将钼测头缓慢取出。然后降温冷却,研磨成粉供实验研究使用。整个实验过程均在氩气保护气氛下进行,气体流速为1.5 L/min。

图1 RTW-10熔体物性综合测定仪原理图

Fig. 1 Schematic diagram of RTW-10 melt property tester

2 实验结果及分析

2.1 Al2O3质量分数对钒钛高炉渣熔化性温度的影响

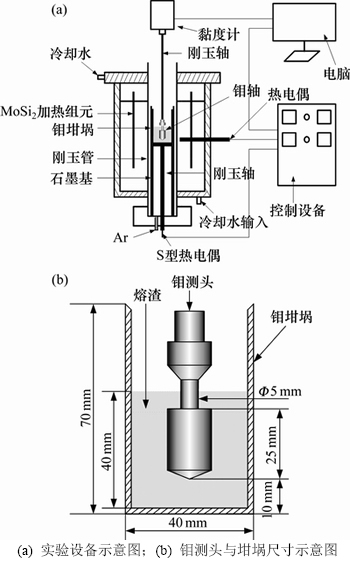

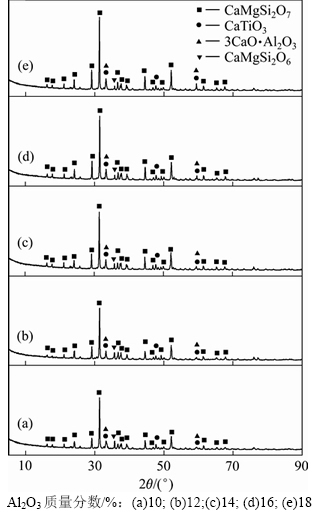

不同Al2O3质量分数下钒钛高炉渣η-t曲线如图2(a)所示,各渣系黏度温度曲线都具有明显的转折点(通过 45°切线与黏度-温度曲线相切得到),炉渣均呈“短渣”特性,熔化性温度是指渣系可以自由流动时的最低温度,同时反映渣系的熔化温度和流动性能。由图2(b)可知:随着钒钛高炉渣系Al2O3质量分数增加,渣系TBr增加;当Al2O3质量分数为10%时,TBr有最小值1 337 ℃;当MgO质量分数为18%时,TBr有最大值1 380 ℃。不同Al2O3质量分数的钒钛高炉渣物相XRD分析结果如图3所示。由图3可知:炉渣结构中主要有黄长石Ca2MgSi2O7(熔点为1 593 ℃),钙钛矿CaTiO3(熔点为1 970 ℃),铝酸三钙3CaO·Al2O3(熔点为1 600 ℃)及辉石CaMgSi2O6,黄长石是基础物相。当Al2O3质量分数由10%增至18%时,黄长石、钙钛矿及铝酸三钙的衍射峰强度逐次增强,但辉石的衍射峰强度减弱。由于黄长石、钙钛矿及铝酸三钙的熔点都比辉石的高[6],高熔点物相数量相对增加,炉渣在高温条件下的结晶析出能力变强,导致渣系液相线温度和熔化性温度TBr增加,炉渣流动性变差[8-9]。

图2 不同Al2O3质量分数下钒钛高炉渣η-t曲线和熔化性温度的变化

Fig. 2 η-t curves and variation of TBr of BF slags with different Al2O3 mass fractions

图3 不同Al2O3质量分数钒钛高炉渣物相XRD分析

Fig. 3 XRD analysis of BF slags with different Al2O3 mass fractions

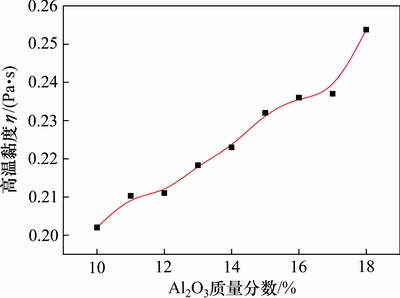

2.2 Al2O3质量分数对钒钛高炉渣黏度的影响

图4所示为不同Al2O3质量分数钒钛高炉渣的高温黏度的变化。由图4可知:随着渣中Al2O3质量分数增加,钒钛高炉渣的黏度呈现上升的趋势。Al2O3属于两性氧化物,在碱性高炉渣渣中呈弱酸性。当高炉渣系中Al2O3质量分数增加时,Al2O3吸收炉渣中自由O2-形成更多复杂复合阴离子(AlO4)5-,Al3+取代硅氧复合阴离子SixOyz-中Si4+所形成的Si—Al—O复合阴离子团数量也在增加。因此,炉渣中复杂黏流单元的聚合度增加,非均匀相数量增加,并结晶出来以固体形态存在于熔融的炉渣中,使炉渣结构中高温结晶能力较强化合物数目增多,如铝酸三钙(3CaO·Al2O3,熔点为1 600 ℃)。因此,炉渣内部结构复杂化使黏度增大,流动性变差[6,10]。

图4 不同Al2O3质量分数钒钛高炉渣的高温黏度的变化

Fig. 4 Variation of viscosity of BF slags with different Al2O3 mass fractions

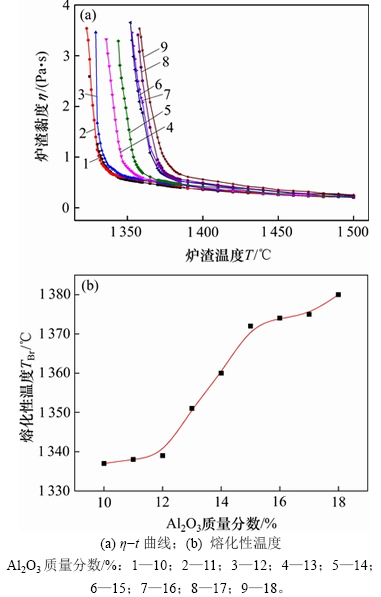

2.3 Al2O3质量分数对钒钛高炉渣稳定性的影响

渣系黏流活化能Eη可以表征炉渣流动时所受到的摩擦阻力,是影响炉渣流动性的重要因素。Eη还可以反映炉渣黏度对温度的敏感性,黏流活化能越高,温度对渣系黏度变化的影响越大,渣系热稳定性变差[3]。Eη可根据Weymann-Frenkel方程计算求得:

(1)

(1)

式中:η为黏度,Pa·s;T为热力学温度,K;A为指前因子;Eη为黏流活化能,kJ/mol;R为气体常数,8.314 J/(mol·K)。对式(1)两边取对数可得:

(2)

(2)

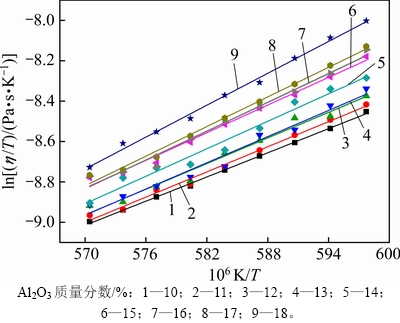

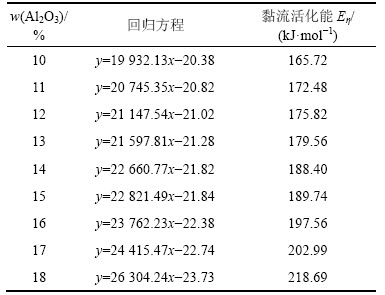

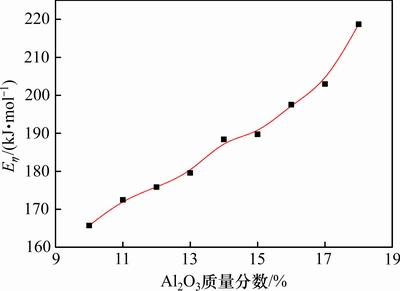

实验范围内,不同Al2O3质量分数钒钛矿高炉渣lnη与1/T拟合结果如图5所示,斜率与R的乘积即为渣系黏流活化能,黏流活化能Eη回归计算如表3所示,其Eη变化趋势如图6所示。可见,在实验范围内,随着渣中Al2O3质量分数升高,渣系黏流活化能呈升高趋势,变化范围为165.72~218.69 kJ/mol,黏度对温度波动敏感性增强,渣系热稳定性变差。

图5 不同Al2O3质量分数ln(η/T)与1/T的拟合结果

Fig. 5 Fitting results between ln(η/T) and 1/T of BF slags with different Al2O3 mass fractions

表3 不同Al2O3质量分数实验渣系Eη

Table 3 Eη of experiment slags with diffenent Al2O3 mass fractions

图6 不同Al2O3质量分数渣系Eη变化趋势

Fig. 6 Variation of Eη of experiment slags with diffenent Al2O3 mass fractions

影响黏流活化能变化的因素为炉渣结构和液相线温度。当Al2O3质量分数从10% 增加到18%,炉渣内部结构复杂化,使黏流阻力增加,炉渣黏度增加。同时,高熔点物相增多,液相线温度升高。因此,这2个因素综合导致Eη升高,渣系流动性和热稳定性变差[9-10]。

3 钒钛高炉渣黏度模型建立

3.1 模型条件

黏度是高炉渣重要的冶金性能,对高炉运行及生产效率有重要影响,但由于技术限制,在高温条件下测量黏度不仅耗时耗力,且对测量设备要求较高。因此,建立一个合理准确的黏度预测模型,对于控制和优化高炉操作具有重要意义。目前已有许多模型用于估计熔融炉渣的黏度[11-14]。这些模型的计算过程中需要太多的参数,可以方便应用于钒钛高炉渣的模型较少。本文作者利用Weymann-Frenkel方程以及修正光学碱度Λcorr计算公式,建立黏度预测模型,并利用钒钛磁铁矿高炉渣系实测黏度数据对模型进行验证,计算得出预测黏度和实验黏度之间的平均偏差,利用偏差对模型准确度进行评定。

3.2 模型描述

收集实验数据,温度和黏度之间的关系用URBAIN[15]修改的Weymann-Frenkel方程来描述。为简便计算,令Eη/R=1 000B,则式(1)可以写成

(3)

(3)

lnA与B之间存在线性关系,可用下式表示:

(4)

(4)

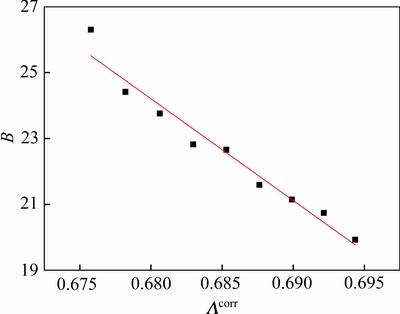

3.3 B与Λcorr之间的关系

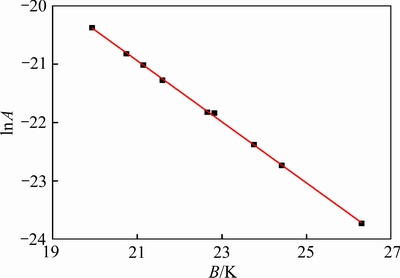

在关于黏流活化能的拟合计算中,得到了各渣系黏流活化能Eη的回归方程,方程中的常数项即lnA,将该值与B进行线性拟合分析,可得到渣系m和n的优化值。线性拟合分析如图7所示。

根据拟合结果,可得到m=-0.52,n=-9.95,即lnA与B满足如下关系:

(5)

(5)

在本模型中,用修正光学碱度Λcorr来反映炉渣的组元结构。与传统的二元碱度及三元碱度相比,光学碱度[16]能更好地反映炉渣的组元结构。光学碱度这一概念被应用到黏度预测当中,但考虑到炉渣中对Al2O3的补偿,对原概念进行了修改并将其重新定义为由Λcorr表示的修正光学碱度[11],其数值可以通过下式进行计算:

(6)

(6)

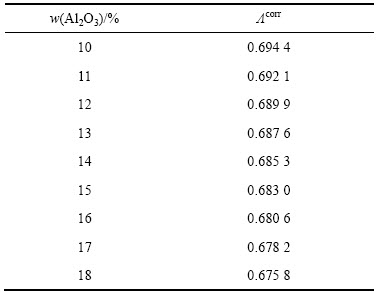

其中:xi为各组元的摩尔分数;系数1.00,0.78,0.60,0.48,0.61分别为CaO,MgO,Al2O3,SiO2和TiO2的光学碱度。将表2中的数据代入式(6),求出不同Al2O3质量分数下实验渣系的修正光学碱度,结果见表4。将修正光学碱度与B进行拟合分析,拟合结果如图8所示。

图7 lnA和B拟合结果

Fig. 7 Fitting results between lnA and B

表4 不同Al2O3渣系修正光学碱度

Table 4 Fixed optical basicity of experiment slags with different Al2O3 slags

图8 Λcorr和B拟合结果

Fig. 8 Fitting result between Λcorr and B

根据图8可得B与Λcorr之间的关系满足下式:

(7)

(7)

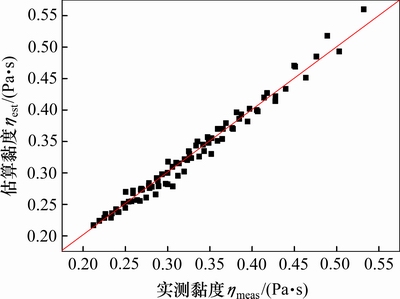

3.4 黏度预测模型验证

根据已知渣系组元成分和式(7)可求出各渣系的Λcorr,即可确定各渣系的B,将该值代入式(5)即可确定各渣系的A,最后将A,B以及相应的热力学温度T代入式(3),即可得到确定渣系组元的黏度预测值。

模型具体公式如下:

其中:T的范围为1 673~1 773 K。

针对实验钒钛高炉渣系,模型预测黏度与实测黏度的对比如图9所示。由图9可见,模型预测值与实测值取得了很好的一致性。

图9 实测黏度与预测黏度对比

Fig. 9 Comparison between measured values and predicted values

为进一步考察所建模型预测黏度的准确性,采用下式计算模型预测结果的平均偏差:

(8)

(8)

式中: 为平均偏差;

为平均偏差; 为模型预测黏度,Pa·s;

为模型预测黏度,Pa·s; 为实测黏度,Pa·s;N为黏度采集数量。

为实测黏度,Pa·s;N为黏度采集数量。

通过计算,模型平均偏差△为2.61%,模型预测值与实测值吻合度高。

4 结论

1) 随着钒钛高炉渣Al2O3质量分数的增加,黏度、熔化性温度、黏流活化能都是呈升高的趋势,渣系的热稳定性变差。

2) 结合Weymann-Frenkel方程以及修正光学碱度Λcorr概念,建立了适合该钒钛高炉渣系有关Al2O3质量分数的黏度预测模型,利用实测黏度数据对模型进行验证,模型平均偏差△=2.61%。该模型降低了工厂测量黏度的成本,提高了经济效益。

参考文献:

[1] 罗金华, 邱克辉, 张佩聪, 等. 红格钒钛磁铁矿中钛铁矿的矿物学特征[J]. 钢铁钒钛, 2013, 33(3): 1-6.

LUO Jinhua, QIUKehui, ZHANG Peicong, et al. Studies on mineralogical characteristics of ilmenite in Hongge vanadium- bearing titaniferous magnetite[J]. Iron Steel Vanadium Titanium, 2013, 33(3): 1-6.

[2] 储满生, 冯聪, 唐珏, 等. 中性气氛下钒钛磁铁矿高炉渣系研究[J]. 东北大学学报(自然科学版), 2015, 36(9): 1283-1287.

CHU Mansheng, FENG Cong, TANG Jue, et al. Study on blast furnace slag system of vanadium-titanium magnetite under neutral atmosphere[J]. Journal of Northeastern University (Natural Science), 2015, 36(9): 1283-1287.

[3] FENG Cong, CHU Mansheng, TANG Jue, et al. Effect of CaO/SiO2 and Al2O3 on viscous behaviors of the titanium- bearing blast furnace slag[J]. Steel Research International, 2016, 87: 1274-1283.

[4] SUN Yongqi, ZHENG Kai, LIAO Junlin, et al. Effect of P2O5 addition on the viscosity and structure of titanium bearing blast furnace slags[J]. ISIJ International, 2014, 54(7): 1491-1497.

[5] 冯聪, 储满生, 唐珏, 等. 不同类型含钛高炉渣主要冶金性能及物相[J]. 中南大学学报(自然科学版), 2016, 47(8): 2556-2562.

FENG Cong, CHU Mansheng, TANG Jue, et al. Main metallurgical performance and phases for different types of titanium-bearing blast furnace slags[J]. Journal of Central South University(Science and Technology), 2016, 47(8): 2556-2562.

[6] 谢洪恩, 秦兴国, 郑魁. 高钛型高炉渣熔化性温度影响因素分析[J]. 中国冶金, 2017, 27(9): 13-19.

XIE Hongen, QIN Xingguo, ZHENG Kui. Analysis of effect factors of smelting temperature of high-titanium-type blast furnace slag[J]. Chinese Metallurgy, 2017, 27(9): 13-19.

[7] 黄宏虎, 吕庆, 曹丽华, 等. 低钛高炉炉渣的流动性能研究[J]. 钢铁钒钛, 2015, 36(2): 78-83.

HUANG Honghu, LU Qing, CAO Lihua, et al. Study on flow properties of low titanium-containing blast furnace slag[J]. Iron Steel Vanadium Titanium, 2015, 36(2): 78-83.

[8] 穆红旺, 张淑会, 吕庆, 等. 中性气氛下高铝中钛型高炉渣黏度的试验研究[J]. 钢铁, 2012, 47(6): 18-21.

MU Hongwang, ZHANG Shuhui, LU Qing, et al. Experimental study on viscosity of blast furnace slag with medium titania and high alumina content under neutral atmosphere[J]. Iron and Steel, 2012, 47(6): 18-21.

[9] SOHN I, MIN D J. A review of the relationship between viscosity and the structure of calcium-silicate-based slags in iron making[J]. Steel Research International, 2012, 83(7): 611-630.

[10] FENG Cong, CHU Mansheng, TANG Jue. Effects of MgO and TiO2 on the viscous behaviors and phase compositions of titanium-bearing slag[J]. International Journal of Minerals Metals Materials, 2016, 23(8): 868-880.

[11] KIM J R, LEE Y S, MIN D J, et al. Influence of MgO and Al2O3 contents on viscosity of blast furnace type slags containing FeO[J]. ISIJ International, 2004, 44(8): 1291-1297.

[12] ZHANG Yong, TANG Jue, CHU Mansheng, et al. Optimization of BF slag for high Cr2O3 vanadium-titanium magnetite[J]. Journal of Iron Steel Research International, 2014, 21(2): 144-150.

[13] KONDRATIEV A, HAYES P C, JAK E. Development of a quasi-chemical viscosity model for fully liquid slags in the Al2O3-CaO-FeO-MgO-SiO2 system: the revised model to incorporate ferric oxide[J]. ISIJ International, 2006, 46(3): 359-384.

[14] 任允芙. 钢铁冶金岩石学[M]. 北京: 冶金工业出版社, 1982: 222-224.

REN Yunfu. Metallurgical petrology of iron and steel[M]. Beijing: Metallurgical Industry Press, 1982: 222-224.

[15] URBAIN G. Viscosity estimation of slags[J]. Steel Research International, 1987, 58(3): 111-116.

[16] GUO Hongwei, ZHU Mengyi, YAN Bingji, et al. Dynamic regional viscosity prediction model of blast furnace slag based on the partial least-squares regression[J]. JOM, 2017, 69(2): 395-401.

(编辑 赵俊)

收稿日期:2018-04-16;修回日期:2018-06-15

基金项目(Foundation item):中央高校基本科研业务专项资金资助项目(N172502005);国家自然科学基金资助项目(51574067) (Project(N172502005) supported by the Fundamental Research Funds for the Central Universities; Project(51574067) supported by the National Natural Science Foundation of China)

通信作者:储满生,教授,博士生导师,从事炼铁及冶金资源综合利用研究;E-mail:chums@smm.neu.edu.cn