J. Cent. South Univ. Technol. (2011) 18: 1487-1492

DOI: 10.1007/s11771-011-0864-6

Preset model of bending force for 6-high reversing cold rolling mill based on genetic algorithm

CAO Jian-guo(曹建国)1, XU Xiao-zhao(徐小照)1, ZHANG Jie(张杰)1,

SONG Mu-qing(宋木清)2, GONG Gui-liang(宫贵良)2, ZENG Wei(曾伟) 2

1. National Engineering Research Center of Flat Rolling Equipment,

School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Wuhan Iron & Steel (Group) Corp., Wuhan 430083, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2011

Abstract: The hydraulic roll-bending device was studied, which was widely used in modern cold rolling mills to regulate the strip flatness. The loaded roll gap crown mathematic model and the strip crown mathematic model of the reversing cold rolling process were established, and the deformation model of roll stack system of the 6-high 1 250 mm high crown (HC) reversing cold rolling mill was built by slit beam method. The simulation results show that, the quadratic component of strip crown decreases nearly linearly with the increase of the work roll bending force, when the shifting value of intermediate roll is determined by the rolling process. From the first pass to the fifth pass of reversing rolling process, the crown controllability of bending force is gradually weakened. Base on analyzing the relationship among the main factors associated with roll-bending force in reversing multi-pass rolling, such as strip width and rolling force, a preset mathematic model of bending force is developed by genetic algorithm. The simulation data demonstrate that the relative deviation of flatness criterions in each rolling pass is improved significantly and the mean relative deviation of all five passes is decreased from 25.1% to 1.7%. The model can keep good shape in multi-pass reversing cold rolling process with the high prediction accuracy and can be used to guide the production process.

Key words: cold rolling mill; strip; bending force; mathematic model; genetic algorithm

1 Introduction

The control of the strip profile and flatness still remains unsatisfactory in cold rolling mills with more stringent demand on the quality of cold-rolled strip. New generation high-tech mills for profile and flatness control in wide strip rolling, such as 4-high or 6-high continuously variable crown (CVC) mill, 4-high SmartCrown mill, 4-high edge drop and crown compact (ECC) mill, 6-high HC mill, have been developed and applied to the production of cold-rolled strip. Currently, the 6-high reversing cold rolling mill is widely used because of its less investment but effective and powerful ability to control shape. The important control technology of the 6-high HC reversing cold rolling mill is work roll bending, which is widely used in the online control of strip profile and flatness [1-2]. For the cold rolling, a complete shape control system is built up by the preset control module and the feedback control module [3-4], and both of them need the model of bending force, so the preset model of bending force directly affects the shape quality.

Many studies are focused on the preset model of bending force for rolling mill, but there are few studies on the model of bending force for the 6-high reversing cold rolling mill. Most current models are based on industrial data, or use some intelligent methods such as the neural network [5]. In Ref.[6], the theoretical model and on-line model are developed by the roll deformation calculation model and control strategy, and the model has theoretical basis and prediction accuracy, but the relationship of unit crown in multi-pass reversing cold rolling process is ignored. In this work, the reversing cold rolling mill was taken as the researching object, the deformation model of roll system was built up, the crown and flatness coordinations were taken as the main goal, and the genetic algorithm [7-8] was used to optimize the preset model, which could guarantee the accuracy and the relationship of unit crown in multi-pass rolling, and can be applied to the practical production.

2 Mathematical model of bending force in 6-high mills

Bending force is associated with a variable number of factors [9]. The main factors influencing the bending force in production process are: rolling specifications (in particular, the width), crown, rolling force (containing the material properties, thickness, reduction rate and other factors of the rolling), roll type, roll shifting position and others. In this work, the main consideration is the quadratic component of strip flatness, as shown in Eq.(1):

(1)

(1)

where B is the strip width, P is the rolling force, Cw is the crown of work roll, Ci is the crown of intermediate roll, Cb is the crown of back-up roll, ΔDw is the difference between the using roll diameter and baseline roll diameter of work roll, Hc is the crown of the strip before rolling, W2 is the parallel wear of work roll, W3 is the intermediate wear of work roll, W4 is the edge wear of work roll, H is the thickness of the strip before rolling, and a1-a16 are the coefficients.

There are so many factors, and it is difficult to optimize Eq.(1). Therefore, the equation needs to be simplified. Some factors that contribute to slow change such as thermal crown and roll wear will not be considered, and these factors will be modified artificially in the rolling process. The simplified bending force model is shown in Eq.(2):

(2)

(2)

3 Objective function and models

3.1 Objective function

The principle of the similar unit crown is a good way to judge if the strip can meet the demand of flatness. Usually, the geometric similarity of the entry and exit section can be used as the flatness criterion, which keeps the unit crown as a constant. Without considering the lateral flow of metal strip, the principle should be satisfied to get a good strip flatness [10-11]:

(3)

(3)

where CH is the entry crown of strip, H is the entry thickness of strip, Ch is the exit crown of strip, h is the exit thickness of strip, and Const is the standard flatness criterion.

According to this principle, the objective function is to make the deviation of unit crown the smallest in each pass. In addition to meeting the flatness of the exit strip, the final crown is also on the same claim strictly in the actual production process. The general requirement for the exit crown of strip is less than 10 μm. Furthermore, a lot of industrial rolling data show that when the first pass has a certain deviation, which actually does not cause buckling because of the largest thickness and the conditions of lateral flow of metal of unit crown, the deviation of unit crown in the first and the second passes can be relaxed, and the ratio of these two passes can be reduced to achieve the demand in the actual optimization process [12]. The objective function is obtained as

(4)

(4)

where the exit crown of strip is less than 10 μm. In the actual calculations, both k(1) and k(2) are 0.1, and the remaining coefficients are 0.2.

3.2 Strip crown model

There are many mathematical models about the strip crown control. The model must be simple, have clear physical meaning and ensure the accuracy in order to meet the needs of the online control. In the reversing cold rolling mill, the mathematical model Eq.(5) [13-15] is commonly used, in order to consider the genetic effect of the entry strip crown at the exit crown in the rolling process, and the influence of the roll deformation and lateral flow of metal, reasonably, can response to the real size of the crown of exit strip rolling steel:

(5)

(5)

where η is the genetic coefficient of crown, and C is the crown of loaded gap.

The crown of loaded gap can be simplified as

(6)

(6)

where P is the rolling force, which comes from a modified Bland-Ford-Hill explicit model [16]. KG is the gap transversal stiffness; FW is the bending force of work roll; δ is the shifting value of intermediate roll; KBW is the control effect of work roll bending; Kδ is the control effect of intermediate roll shifting; KW, KI and KB are the coefficients, which could be taken by the deformation model of roll system. The impacts of width, thickness and other factors on the shape are reflected in Eq.(5).

3.3 Deformation model of roll system

In order to analyze the parameters in the model of the crown of loaded gap, and research the control performance of the shape adjustment means [17-19] from reversing cold rolling mill, the deformation model of roll system is built by the influence function method [20-21], which is used to analyze the relevant parameters in each pass. The calculation process is shown in Fig.1. Specific model parameters are as follows. Dimensions of work roll barrel are 420 mm × 1 250 mm, dimensions of intermediate roll barrel are 470 mm × 1 250 mm, dimensions of back-up roll barrel are 1 260 mm × 1 250 mm, load center distance of bending force is 2 230 mm, and restrict center distance of back-up roll is 2 410 mm.

Fig.1 Roll system model diagram based on influence function method

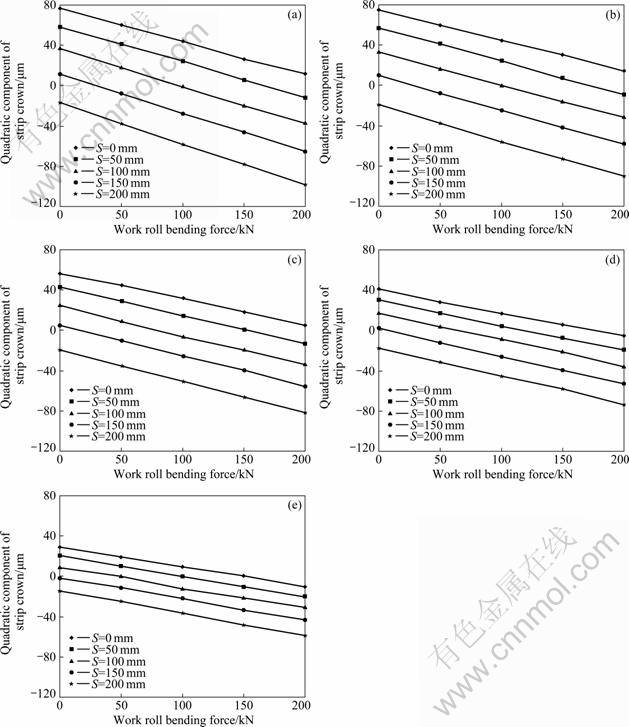

When the strip width is 950 mm, the change disciplines of quadratic component of strip crown at different work roll bending forces and intermediate roll shifting positions in each pass can be obtained by the model simulation. The results are shown in Fig.2.

The simulation results show that the quadratic component of strip crown decreases with the increase of the work roll bending force or the intermediate roll shifting value gradually, and there is nearly linear relationship between these two factors. From the first pass to the fifth pass, the slope gradually decreases on the whole, which means that the ability to control the crown is gradually weakened. So, the crown is changed more easily in the beginning pass than the ending pass when using these two controls.

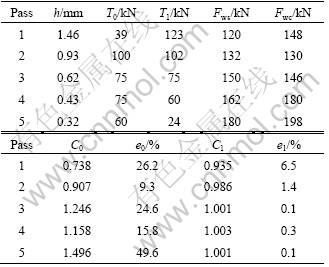

Also, some correlation coefficients have been calculated under the current specifications, such as KG, KBW, Kδ and P. As shown in Table 1, in this calculation, KW, KI and KB are not considered because of the flat roll. In addition, the gap transversal stiffness is calculated as 67.3 kN/μm.

4 Optimization of preset model parameters by genetic algorithm

The preset model of bending force is mainly based on the strip initial data, including steel grade, width, entry thickness and thickness of end product. Then, by calculating the crown of loaded gap, and using the genetic algorithm, the bending force model is found, which can minimum the objective function in each pass. The calculation process is shown in Fig.3.

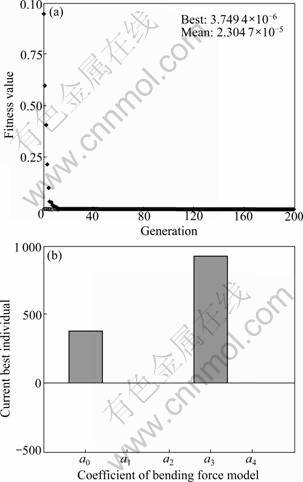

In this work, genetic algebra was taken as 200, the value of crossover probability was taken as 0.8, and the mutation probability was taken as 0.01. According to the relevant experience in the industrial practice, for the speed and accuracy of algorithm optimization, the range of initial value was selected as [100 -0.1 0 0 0; 500 0 100 20 000 2].

5 Simulation results and analysis

According to the on-site intermediate roll shift model, the shifting value of intermediate roll was 100 mm in each pass under this specification ((2.2- 0.32 mm) × 950 mm), and then the optimal solution of the various parameters were received in the preset model of bending force as Eq.(7). The change of the average value in population objective function and the best individual variables after 200 genetic iterations are shown in Fig.4.

(7)

(7)

The results are compared before and after optimization using the calculated model, as listed in Table 2.

Fig.2 Quadratic components of strip crown at different work roll bending forces and intermediate roll shifting positions of 6-high rolling mill: (a) First pass; (b) Second pass; (c) Third pass; (d) Fourth pass; (e) Fifth pass

Table 1 Correlation coefficient in each pass

In Table 2, T0 is the entry tension, T1 is the exit tension, Fws is the setting value of bending force, Fwc is the calculated value of bending force, C0 is the flatness criterion before optimization, C1 is the flatness criterion after optimization, e0 is defined as the relative deviation of flatness criterion before optimization, and e1 is defined as the relative deviation of flatness criterion after optimization. The relative deviation of flatness criterion is defined as Eq.(8):

, n=0, 1 (8)

, n=0, 1 (8)

Fig.3 Calculation diagram of bending force

As can be seen from Table 2, the mean relative deviation of five passes drops from 25.1% to 1.7%, the relative deviation of flatness criterion reduces significantly in each pass, and the new bending force model can maintain the proportion of the unit crown. The relative deviation of flatness criterion in the last pass is only 0.1% after optimization, and the good shape is ensured. The relative deviation of flatness criterion drops from 26.2% to 6.5% in the first pass, which has the maximum rolling thickness. Not only the shape quality is guaranteed, but also the control of the strip cross-section crown is achieved when the thickness is large. The digestion ability to incoming the shape changes is kept, the adaptability to rolling specification changes is maintained, and the condition for getting a good shape in later passes is created [22-23]. These situations are consistent with the setting of objective function which relaxes the deviation of unit crown in the first and second pass. By the above analysis, the model could keep the good shape in multi-pass reversing cold rolling process and the high prediction accuracy.

Fig.4 Results of genetic algorithm optimization: (a) Fitness value; (b) Current best individual

Table 2 Results of bending force model

6 Conclusions

1) The deformation model of roll system for 6-high reversing cold rolling mill is built up by the influence function method. According to the simulation results, the quadratic component of strip crown decreases with the increase of the work roll bending force and it is shown nearly linear relationship between these two factors, when the shifting value of intermediate roll is determined by the rolling process. From the first pass to the fifth pass, the ability to control the crown is gradually weakened.

2) The 1250 HCM 6-high reversing cold rolling mill is taken as the researching object, the loaded gap crown model and the strip crown model are established, and then the relationship of some factors associated with roll-bending force such as strip width and rolling force is analyzed. Base on these, a preset model of bending force is developed based on the genetic algorithm. The simulation results demonstrate that, the error between the flatness criterion and the standard is improved in each pass, and the good shape in multi-pass reversing cold rolling and the precision can be kept by the model. Besides, the model can be used to guide the production process.

References

[1] ARIF A F M, KHAN O, SHEIKH A K. Roll deformation and stress distribution under thermo-mechanical loading in cold rolling [J]. Journal of Materials Processing Technology, 2004, 147: 255-267.

[2] KADOYA Y, OOI T, WASHIKITA Y, SEKI Y. Strip gage and tension control at cold tandem mill based on I.L.Q. design theory [C]// Proceedings of the 1999 IEEE International Conference on Control Applications. Kohala Coast-Island of Hawaii, 1999: 22-27.

[3] ALBERTO B, DANIELE B, FRANCESCO A C, ANDREA S. Optimization-based automatic flatness control in cold tandem rolling [J]. Journal of Process Control, 2010, 20(4): 396-407.

[4] PENG Yan, LIU Hong-min, DU R. A neural network-based shape control system for cold rolling operations [J]. Journal of Materials Processing Technology, 2008, 202: 54-60.

[5] CHANG An, DI Hong-shuang, TONG Qiang, BAI Jin-lan, YANG Dai-jun. Optimizing of bending force preset based on BP neural network [J]. Steel Rolling, 2006, 23(5): 55-57. (in Chinese)

[6] BAI Jin-lan. Research on shape preset theory of single-stand reversing cold rolling mill [D]. Qinhuangdao: Yanshan University, 2006. (in Chinese)

[7] LIANG Xi-ming, ZHU Can, YAN Dong-huang. Novel genetic algorithm based on species selection for solving constrained non- linear programming problems [J]. Journal of Central South University: Science and Technology, 2009, 40(1): 185-189. (in Chinese)

[8] YANG Jing-ming, CHE Hai-jun, DOU Fu-ping, ZHOU Tao. Genetic algorithm-based optimization used in rolling schedule [J]. Journal of Iron and Steel Research International, 2008, 15(2): 18-22.

[9] WANG D D, TIEU A K, LU C, D’ALESSIO G, YUEN W Y D. Modeling and optimization of threading process for shape control in tandem cold rolling [J]. Journal of Materials Processing Technology, 2003, 140: 562-568.

[10] MA Hui-wen. Calculation of unit crown distribution of hot rolled strip considering transverse flow coefficient [J]. Steel Rolling, 2009, 26(3): 11-17. (in Chinese)

[11] GU Yun-zhou, ZHANG Jie, ZHANG Qing-dong, YANG Quan. Automatic setting of roll-bending force in cold tandem mill [J]. Journal of University of Science and Technology Beijing, 2000, 22(2): 174-176. (in Chinese)

[12] KIM T H, LEE W H, HANG S M. An integrated FE process model for the prediction of strip profile in flat rolling [J]. ISIJ International, 2003, 43(12): 1947-1956.

[13] LUO Yong-jun, CAO Jian-guo, WANG Chang-song, ZHANG Jie, LI Jiang-jie. Preset control of bending force for hot strip mill based on GA [J]. Research on Iron and Steel, 2004(3): 42-45. (in Chinese)

[14] HU Xian-lei, ZHAO Zhong, QIU Hong-lei, LIU Xiang-hua. High precision plate crown model for on-line application [J]. Journal of Northeastern University, 2004, 25(10): 965-968. (in Chinese)

[15] WANG Xiao-dong, HE An-rui, YANG Quan, XIE Zhi, YANG Hong-tao. Study and application of crown feedback control in hot strip rolling [J]. Journal of University of Science and Technology Beijing, 2007, 14(2): 190-194.

[16] WANG J S, JIANG Z Y, TIEU A K, LIU X H, WANG G D. Adaptive calculation of deformation resistance model of online process control in tandem cold mill [J]. Journal of Materials Processing Technology, 2005, 162/163: 585-590.

[17] CAO Jian-guo, DAI Bao-quan, ZHANG Jie, YANG Guang-hui, SONG Ping, SU Yi, YAN Tan-li. Profile and flatness control technology of wide non-oriented electrical steel in hot strip mills [J]. Journal of Central South University: Science and Technology, 2008, 39(4): 771-775. (in Chinese)

[18] LI Hong-bo, ZHANG Jie, CAO Jian-guo, SI Xiao-ming, ZHANG Shu-shan, LI Yao-hui. Characteristics of profile control on CSP hot strip mill [J]. Journal of Central South University: Science and Technology, 2008, 40(2): 422-428. (in Chinese)

[19] CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, Wei Gang-cheng. Control of roll contour for strip profile and flatness in hot rolling [C]// The 44th Mechanical Working and Steel Processing Conference & 8th Steel Rolling International Conference Proceedings. Florida, 2002: 1001-1010.

[20] JIANG Z Y, ZHU H T, TIEU A K. Study of work roll edge contact in asymmetrical rolling by modified influence function method [J]. Journal of Materials Processing Technology, 2005, 162/163: 512- 518.

[21] JIANG Z Y, WEI D, TIEU A K. Analysis of cold rolling of ultra thin strip [J]. Journal of Materials Processing Technology, 2009, 209: 4584-4589.

[22] CAO Jian-guo, WEI Gang-cheng, ZHANG Jie, CHEN Xian-lin, ZHOU Yi-zhong. VCR and ASR technology for profile and flatness control in hot strip mills [J]. Journal of Central South University: Science and Technology, 2008, 15(2): 264-270.

[23] CHEN Xian-lin. Flatness control in New Generation High-tech Mills for Wide Strip Rolling [J]. Journal of University of Science and Technology Beijing, 1997, 19(S1): 1-5. (in Chinese)

(Edited by YANG Bing)

Foundation item: Project(20050311890) supported by the Science and Technology Development Foundation of University of Science and Technology Beijing, China

Received date: 2010-07-29; Accepted date: 2011-01-24

Corresponding author: CAO Jian-guo, Professor, PhD; Tel: +86-10-62332835; E-mail: geocao@ustb.edu.cn