DOI:10.19476/j.ysxb.1004.0609.2019.03.16

微观尺度下晶粒尺寸和冷却速率对多晶NiTi合金相变温度的影响

丁 军1,赵昊男1,黄 霞1,曾祥国2,王路生1,宋 鹍1

(1. 重庆理工大学 机械工程学院,重庆 400054;

2. 四川大学 建筑与环境学院,成都 610065)

摘 要:采用分子动力学方法研究了微观尺度下晶粒尺寸和冷却速率对NiTi合金相变温度的影响和相变微观机理。结果表明:当冷却速率为-5 K/ps,晶粒尺寸从17.5 nm减小到8.1 nm时,马氏体相变起始温度从230 K下降到80 K,马氏体相变形核点的数目逐渐减少且主要出现在晶粒内部,降温过程中马氏体相成核后向晶界处扩散生长,当晶粒尺寸减小至4.1 nm时,马氏体相变效应则受到抑制;而升温过程中,奥氏体相变形核点主要出现在晶界处,且随着温度的升高,形核点主要向晶粒内部聚集生长。当冷却速率从-5 K/ps增加到-15 K/ps,晶粒尺寸为17.5 nm的模型中马氏体相变结束温度从190 K减小到20 K。随着冷却速率的增加,马氏体晶粒细化程度相应增加,相变滞后宽度(Mf-Af)随着冷却速率的增加相应增大,但是冷却速率对马氏体相变生长机制影响相对较小。

关键词:形状记忆合金;相变温度;冷却速率;分子动力学

文章编号:1004-0609(2019)-03-0569-10 中图分类号:TG111.5 文献标志码:A

近年来,NiTi合金由于其优异的形状记忆效应、高强度和良好的热循环稳定性被广泛地应用在航空航天和机械装备等领域[1-3]。形状记忆效应是温度或应力诱发引起合金材料中热弹性马氏体形成、变化和消失的相变过程,在微机电领域,NiTi合金更是凭其变形温度响应速度快和优异的形状记忆效应被广泛地应用在高效热敏传感器元件当中[4]。已有研究表明,晶粒尺寸和冷却速率是影响NiTi合金相变温度的两个重要因素[5-6],因此开展NiTi合金马氏体相变温度影响因素及其相变微观机理研究尤为重要。

由于热处理方法不同,在材料加工过程中将不可避免地在合金材料内部产生晶界等微观缺陷,晶粒尺寸对NiTi合金的相变行为将产生较大影响。目前研究人员已经开展了晶粒尺寸对NiTi合金力学性能影响的系列研究工作,这些工作主要集中在实验观察方面。如SHI等[6-7] 通过结合使用差示扫描量热法和透射电子显微镜(TEM)观察发现,对于温度诱发马氏体相变,在晶粒尺寸为50~150 nm的Ni50.2-Ti材料中,随着晶粒尺寸逐渐减小,R→B19′相的相变温度逐渐降低,并指出晶粒尺寸小于50 nm的Ni50.2-Ti样本的退火过程中较难观察到马氏体相的出现。而对于应力诱发马氏体相变,AHADI等[8-9]通过TEM以及选区电子衍射方法观察到,晶粒尺寸为10~90 nm的Ni-Ti49.1合金在循环应变加卸载条件下的相变过程,并且发现随着晶粒尺寸减小,加载过程中的马氏体相变现象逐渐减弱。通过观察应力-应变曲线发现晶粒尺寸为10 nm的NiTi合金试件表现出较高的屈服强度,且应力迟滞现象较弱。通过X射线衍射发现,当晶粒尺寸为10 nm时,拉伸过程中试样内部会有少量B19′马氏体相产生,因此,可以预测晶粒尺寸为10~50 nm的NiTi合金可能发生温度诱发相变,而在该尺寸范围内,现有的实验分析手段较难观测到马氏体相变产生。同时,对于NiTi合金相变行为随着晶粒尺寸减小而逐渐较弱这一现象,其成因也不明确,因此,温度诱发NiTi合金相变行为的机理仍需更进一步深入探讨。

另一方面,冷却速率也是影响NiTi合金相变温度的重要因素。MOTEMANI等[10]、FANG等[11]和NERVEREN等[12]通过将三种Ni含量较高的NiTi合金 实验试件加热到1000 ℃后在不同的条件下冷却(炉冷、水冷、干冰浴),并使用差示扫描量热法和X射线衍射法来分析在不同冷却条件下NiTi合金的相变行为,实验结果表明随着冷却速率的增加马氏体相变结束温度逐渐降低。ZHANG等[13]使用同样的方法也观察到马氏体相变结束温度随着冷却速率的增加而下降,并且降低冷却速度有利于提高奥氏体相变温度,且相变滞后宽度(Af-Mf)随着冷却速率的增加而增大。RAGHAVENDRA等[14]将冷却前材料所处的环境温度(300~700 ℃)和恒温时间也作为影响因素考虑到其对Ni50.8-Ti合金材料的相变温度影响当中,发现冷却速率不仅能够影响马氏体相变的温度,而且还能影响在马氏体相变过程中不同相的生成顺序,因此NiTi合金中马氏体相变温度与冷却速率有极大关系。由于NiTi合金温度响应速度快,实验观察往往只能捕捉到相变前后的始末状态,而对合金材料的相变过程及其相变微观机理的探索和解析,则需要借助于以LAMMPS软件为主的微观分子动力学模拟分析,以对冷却速率改变NiTi合金相变温度的机理做更进一步探索。

文献综述发现,虽然从实验角度已经针对晶粒尺寸和冷却速率对多晶NiTi合金相变温度的影响开展了较丰富的工作,但由于实验观察条件的限制,使得NiTi合金相变温度影响因素及机理更深层次的研究受到阻碍。而文献[15-16]表明,温度降至0 K左右时仍可能是NiTi合金马氏体相变的起始点,而且还会有爆发性马氏体相变现象发生,但在绝对0 K左右开展实验观察极其困难。另一方面,对于非等原子比例的NiTi合金材料,在产生温度诱发马氏体相变时,冷却过程中产生的亚稳态结构的中间R相NiTi2、Ni3Ti、Ni4Ti3会干扰马氏体相变的观察[10, 11, 17],但是分子动力学方法可以为研究温度诱发相变过程及其微观机理提供一种很好的解决方案[18-19]。综上所述,本文拟采用分子动力学方法,研究温度诱发NiTi合金相变行为的微观机理,模拟晶粒尺寸和冷却速率对NiTi相变温度的影响,并讨论以上因素对NiTi合金相变过程中马氏体相和奥氏体相微观生长机制的影响。

1 模拟方法

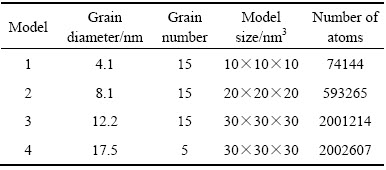

采用泰森多边形方法[20]构建多晶NiTi合金模型,该方法通过随机选择模型中晶粒的晶体学取向和位置分布来模拟材料中的晶粒分布,并将模型尺寸和晶粒个数作为评价晶粒尺寸大小的两个因素[21]。建立晶粒尺寸分别为4.1、8.1、12.2和17.5 nm的4个多晶NiTi合金模型,各模型参数如表1所列。

表1 不同模型的平均晶粒尺寸、晶粒个数、模型尺寸、原子数目

Table 1 Average grain diameter, number of grains, cell dimensions and number of atoms in different models

通过LAMMPS代码[22]编程来实现NiTi合金相变行为的分子动力学模拟[23],在NPT系综下对模型进行弛豫,将周期性边界条件分别施加在X、Y、Z三个方向上消除表面效应。将时间步长设定为2 fs,采用Nosé-Hoover[24]和Parrinello-Rahman[25]方法分别对温度和压力进行控制,在400 K温度下弛豫600 ps以达到稳定结构。弛豫结束后,为了研究NiTi合金的形状记忆效应,将温度从最初的400 K下降到10 K,然后再从10 K升温到400 K,以此完成一次温度循环加载[26]。通过输出不同温度下的平均原子体积来判别多晶NiTi合金的相变情况[27-28]。

分子动力学模拟中采用由KO等开发的改进的嵌入原子法(MEAM)来描述原子之间的相互作用力,该势函数能够准确描述由温度和应力诱发的等原子比例NiTi形状记忆合金的相变过程[27]。MEAM是在EAM的基础上,把原子i的势能分为嵌入能和对势两部分,其计算公式为

(1)

(1)

式中:下标i、j分别代表第i、j个原子;F为嵌入能是电子云密度函数; 为对势相互作用。对于体心立方(BCC)结构而言,嵌入能F为

为对势相互作用。对于体心立方(BCC)结构而言,嵌入能F为

(2)

(2)

式中:参数N表示面心立方(FCC)结构和体心立方(BCC)结构的能量差异;Ec为黏性能; 为平衡时的电子密度;

为平衡时的电子密度; 为电子云密度,其计算公式为

为电子云密度,其计算公式为

(3)

(3)

(4)

(4)

式中: 为原子密度指数衰减因子;ti为原子密度权值;re为原子平衡时的位置,对于体心立方结构,其对势计算公式为:

为原子密度指数衰减因子;ti为原子密度权值;re为原子平衡时的位置,对于体心立方结构,其对势计算公式为:

(5)

(5)

(6)

(6)

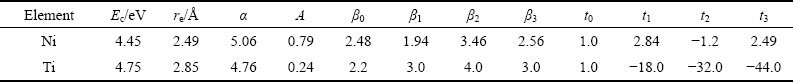

MEAM势涉及到的主要参数有:黏性能Ec (eV),原子平衡位置re ( ),能量函数中指数衰减因子

),能量函数中指数衰减因子 ,嵌入能函数的缩放因子A,原子密度的指数衰减因子

,嵌入能函数的缩放因子A,原子密度的指数衰减因子 ,原子密度的权值ti,其具体参数[26]列于表2。

,原子密度的权值ti,其具体参数[26]列于表2。

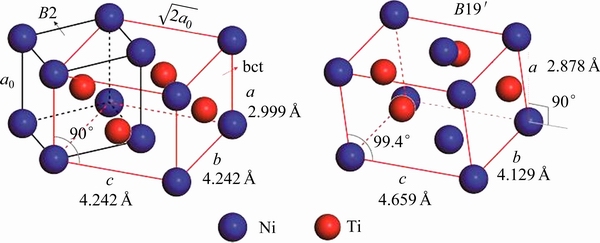

图1所示为不同晶粒尺寸下的多晶NiTi模型,采用OVITO[29]中的公共近邻分析技术(CNA)[30]技术观察多晶NiTi合金在相变过程中奥氏体相与马氏体相的演化过程,并使用Atomeye[31]软件观察模型加载过程中的局部切应变[30]。在CNA表征方法中,蓝色原子代表多晶NiTi合金中的B2奥氏体相,红色原子代表的B19′马氏体相,灰色原子代表晶界或其他不可识别原子。对于本文中涉及到的奥氏体相和马氏体相原子结构,如图2所示。

2 结果与讨论

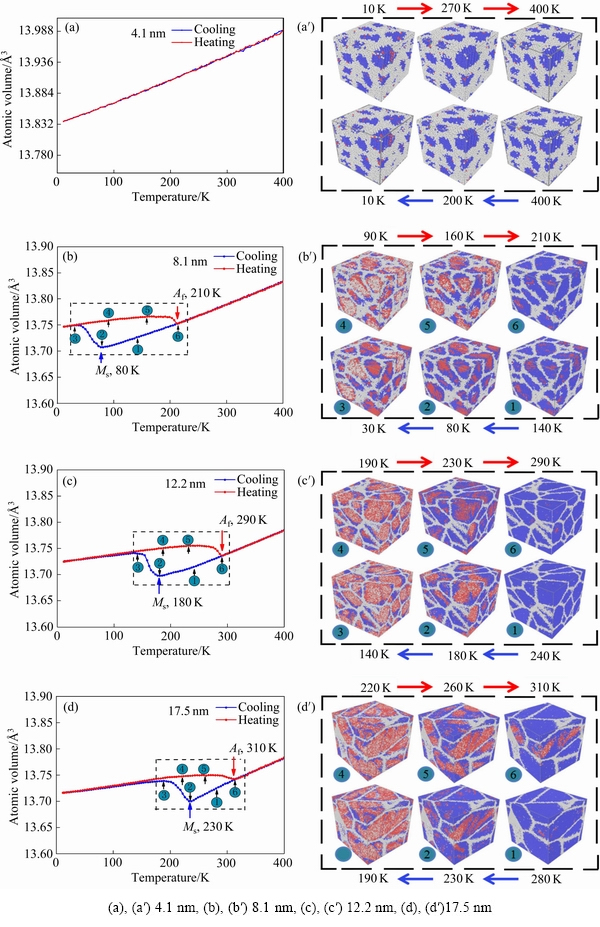

2.1 晶粒尺寸对NiTi合金相变温度的影响

为了研究晶粒尺寸对NiTi合金相变温度的影响以及相变过程中马氏体相和奥氏体相的生长机制,本文对不同晶粒尺寸(4.1~17.5 nm)的NiTi合金模型进行升、降温速率均为±5 K/ps条件下温度循环加载,温度循环加载过程中的原子体积随温度变化曲线及相变区域内原子排列结构如图2所示。

表2 Ni、Ti原子的MEAM势参数[26]

Table 2 Parameters of MEAM potential for Ni and Ti systems[26]

图1 不同晶粒尺寸下多晶NiTi合金模型

Fig. 1 Models of polycrystal NiTi alloys with grain size from 4.1 nm to 17.5 nm

图2 B2奥氏体相和B19′马氏体相原子结构图

Fig. 2 Atom structures of B2 austenite(a) and B19′martensite(b)

图3 温度循环加载条件下,不同晶粒尺寸的原子体积随温度变化曲线以及相变区域内原子排列构型

Fig. 3 Plots of atomic volume of nanocrystalline NiTi against variation in temperature during one cycle of cooling and heating process for grain size from 4.1nm to 17.5 nm, and its corresponding atomic configuration (In each snapshot, blue atoms correspond to B2 austenite structure, red atoms to B19′ martensite structure and gray atoms to grain and boundary)

对图3(a)~(d)中的原子体积随温度变化曲线的观察中发现,当晶粒尺寸为4.1 nm时,原子体积与温度的改变呈线性关系。当晶粒尺寸从8.1 nm增大到17.5 nm,蓝色曲线代表的降温过程中的原子体积曲线均在不同温度下发生突变,此时原子体积的突变代表模型发生由奥氏体相向马氏体相的转变,且Ms(马氏体相变起始温度)随着晶粒尺寸的增加从80 K上升到230 K;红色曲线代表的升温过程中的原子体积曲线同样也在不同温度下发生突变,此时原子体积的突变代表模型中马氏体相已完全转化成奥氏体相,且Af(奥氏体相变结束温度)随着晶粒尺寸的增大从210 K上升310 K;同时(Ms-Af)代表的相变区域随着晶粒尺寸的增加逐渐减小,该模拟结果与文献[6, 33-34]中的结果保持一致。对图3(a′)~(d′)中相变区域内的原子排列图可以发现,当晶粒尺寸为4.1 nm时,整个温度循环过程中模型内主要以蓝色原子代表的奥氏体相存在,并未发生明显的相变现象;而随着晶粒尺寸从8.1 nm增加到17.5 nm,NiTi合金模型中发生了由奥氏体相转化成马氏体相,再由马氏体相转化成奥氏体相的过程,同时随着晶粒尺寸的增大,马氏体相变结束时模型中残留的奥氏体相逐渐减少。

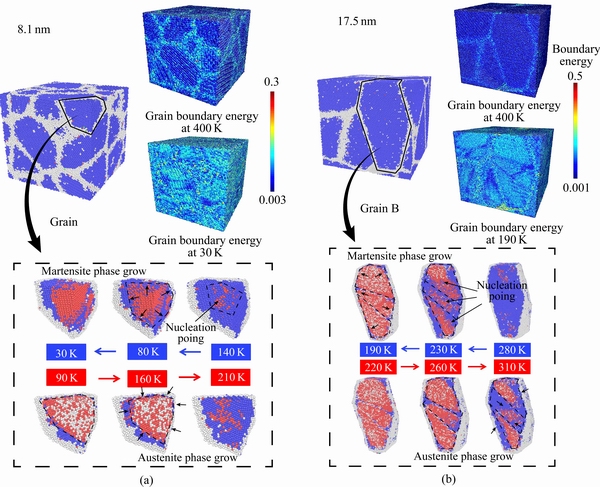

图4 晶粒尺寸为8.1 nm模型的晶界能(400 K和30 K)及晶粒A的相变过程以及晶粒尺寸为17.5nm模型的晶界能(400 K和190 K)及晶粒B的相变过程(其中蓝色原子代表B2奥氏体结构,红色原子代表B19′马氏体结构,灰色原子代表晶界与其他不可识别原子)

Fig. 4 Grain boundary energy at 400 K and 30 K(a) for model of 8.1 nm and phase transformation of grain A and grain boundary energy at 400 K and 190 K(b) for model of 17.5 nm and phase transformation of grain B (In each snapshot, blue atoms correspond to B2 austenite structure, red atoms to B19′ martensite structure and gray atoms to grain and boundary)

通过观选取不同模型的晶粒进行观察,如图4(a)和(b)所示可以发现晶粒尺寸越小,降温时晶粒中形核点生存的几率和数目均逐渐减小,并且在晶粒尺寸从17.5 nm减小到8.1 nm的过程中,马氏体相变起始温度逐渐下降。按照经典的形核理论,形核能垒越大,形核阻力越大,形核温度越低,形核几率越小,形核所需要的时间则越长。合金材料中的马氏体相变阻力可以用切变强度来表示[35],按照Hall-Petch公式,晶体的切变强度 与晶体材料的晶粒大小(晶粒直径d)有关:

与晶体材料的晶粒大小(晶粒直径d)有关:

(7)

(7)

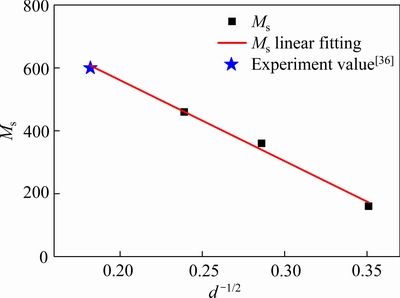

式中: 与K均为常数。随晶粒尺寸的减小,材料的切变强度逐渐增加,由此可以证明:随着NiTi合金晶粒尺寸的减小,马氏体相变温度会逐渐降低。本文模拟得到马氏体相变温度与晶粒尺寸的关系如图5所示。由图5可见,随着晶粒尺寸由17.5 nm减小到4.1 nm,马氏体相变温度逐渐下降直至相变发生被抑制。通过拟合马氏体相变起始温度与晶粒直径曲线,与文献[36]中实验测得的晶粒尺寸30 nm试件中马氏体相变起始温度相比,两者有较好的吻合性,且该拟合结果与文献[37]结果一致。文献[37]对Cu-Zn-Al合金中马氏体相变起始温度与晶粒直径的线性关系进行拟合,并以相变过程中自由能的变化导出Ms和d-1/2的关系,通过实验表明该关系式能适用于无异相约束条件下马氏体相变的晶粒尺寸效应。

与K均为常数。随晶粒尺寸的减小,材料的切变强度逐渐增加,由此可以证明:随着NiTi合金晶粒尺寸的减小,马氏体相变温度会逐渐降低。本文模拟得到马氏体相变温度与晶粒尺寸的关系如图5所示。由图5可见,随着晶粒尺寸由17.5 nm减小到4.1 nm,马氏体相变温度逐渐下降直至相变发生被抑制。通过拟合马氏体相变起始温度与晶粒直径曲线,与文献[36]中实验测得的晶粒尺寸30 nm试件中马氏体相变起始温度相比,两者有较好的吻合性,且该拟合结果与文献[37]结果一致。文献[37]对Cu-Zn-Al合金中马氏体相变起始温度与晶粒直径的线性关系进行拟合,并以相变过程中自由能的变化导出Ms和d-1/2的关系,通过实验表明该关系式能适用于无异相约束条件下马氏体相变的晶粒尺寸效应。

图5 马氏体相变温度与晶粒直径的关系

Fig. 5 Relationship between Ms and diameter of grain

以上结果证明:随着晶粒尺寸的增大,马氏体相变起始温度会逐渐增大。但是在本文的模拟过程中观察到,马氏体相变的形核过程最初均在形成晶粒内部形成,且随着加载温度的降低成核的马氏体相逐渐并向晶界处蔓延生长。如图4(a)所示,直至马氏体相变结束晶粒尺寸为8.1 nm模型的晶界处仍有明显的奥氏体残留相存在,但该现象在图4(b)中却并不明显。文献[38]指出温度和应力诱导的NiTi相变成因相同,通过建立Ginzbury-Landua模型对NiTi合金中马氏体相变在晶界处是连续展开讨论,研究结果指出马氏体晶界能高于奥氏体晶界能(与图4中模拟结果一致),晶粒尺寸小于12.8 nm的模型需在晶界处损失更多的应变能才能使得相变过程在晶界处连续发生,为了避免在晶界处造成应力集中进而导致材料失效,因此马氏体相变在晶界处不连续,晶界附近会残留有少许奥氏体相,与文中晶粒尺寸为8.1 nm的模拟结果相同,同样该理论也可以解释随着晶粒尺寸的进一步减小,马氏体相变将被抑制这一现象,文献结果与本文模拟结果一致。在升温过程中,由图4(b)可知,马氏体相变结束时,晶界处应变能小于晶粒内马氏体相储存的应变能;随着温度上升,原子扩散速度逐渐增加,因此奥氏体相由晶界处成核逐渐向晶粒内部聚集生长;随着晶粒尺寸的增大,相变阻力逐渐减小,奥氏体相变温度升高。

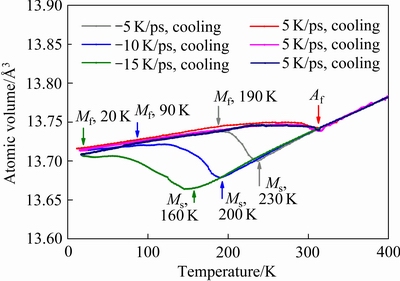

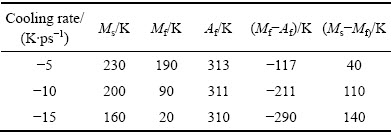

2.2 冷却速率对马氏体相变温度的影响

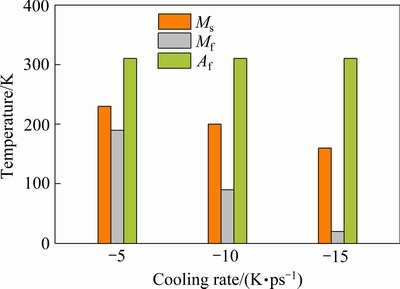

为了研究冷却速率对马氏体相变温度的影响,本文对晶粒尺寸为17.5 nm的模型分别进行冷却速率为-5 K/ps、-10 K/ps、-15 K/ps条件下的温度循环加载。从图6中可以观察到,尽管模型尺寸相同,但不同冷却速率会改变相变驱动力的大小,使得模型中原子体积在不同的温度下发生突变,这意味着马氏体相变温度会因冷却速率的改变而发生改变,随着冷却速率由-5 K/ps增加到-15 K/ps,NiTi合金中马氏体相变结束温度呈减小趋势,由190 K减小到20 K,详细信息见表3。通过观察柱状图7发现相变带滞后宽度(Mf-Af)随着冷却速率的增加而增大,文献[10-13]中通过在实验中设置不同冷却条件,将相同高温下的相同NiTi合金试件分别置于炉冷、水冷、干冰浴(冷却速率依次增加)的条件下进行冷却,本文中所得到的模拟结果与文献中已有的实验结果具有相同趋势,因此可以判定该情况下模拟结果的正确性。

图6 在不同冷却条件下纳米晶NiTi的原子体积-温度曲线

Fig. 6 Atomic volume-temperature curves of nanocrystalline NiTi under different cooling conditions

表3 相同晶粒尺寸模型在不同冷却速率下相变温度

Table 3 Value of phase transformation temperature in same model with same grain size under different cooling rates

图7 不同冷却速率下马氏体相变开始温度和结束温度以及奥氏体相变结束温度比较

Fig. 7 Comparison among temperatures of Ms, Mf and Af under different cooling rates

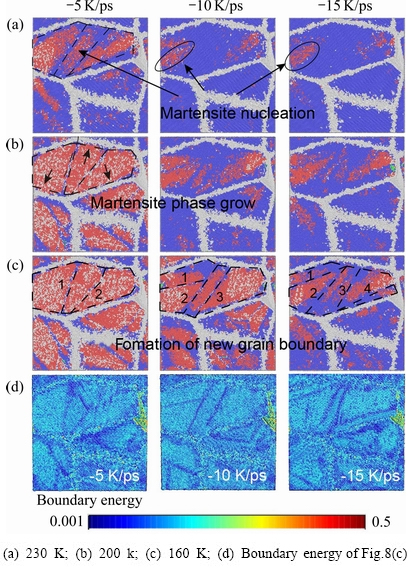

在对晶粒尺寸为17.5 nm的NiTi合金进行不同冷却速率条件下的降温加载时,降温过程中230、200和160 K下各模型原子排列图如图8所示,其中蓝色原子代表B2奥氏体结构,红色原子代表B19′马氏体结构,灰色原子代表晶界与其他不可识别原子。由图8可见,在相同温度下冷却速率为-5 K/ps时,模型中马氏体相所占有的体积分数要多于其他两模型中马氏体相所占有的体积分数;并且直至马氏体相变结束前,在相同温度下各模型马氏体相的体积分数随冷却速率的增加依次减小。该现象的成因是:在较慢冷却速率条件下,原子与原子之间的热传递时间更长,温度下降梯度更小,相同温度下感应到温度传递的原子数量更多,导致模型发生原子体积突变时的温度在不同冷却速率条件下有所差异。另外,通过对比表3中不同冷却速率对应的(Ms-Mf)值可以发现,随着冷却速率从-5 K/ps增加到-15 K/ps,该值从40 K增大到140 K,(Ms-Mf)的增大代表完成马氏体相变所需要的时间增加。在图8中对于不同冷却速率而言,马氏体相形核点同样主要集中出现在晶粒区域内部,随着冷却速率的增加,晶粒中的马氏体相变形核点数目逐渐增加。当温度持续降低,一方面,马氏体相形核点逐渐形成小片区域的贯通;另一方面,当两组或更多形核区域相遇时,因马氏体相内储存的应变能较高,晶粒内部为了避免应力集中而形成新的晶界。由图8(d)可知,新晶界形成处的应变能明显低于马氏体相变区域的应变能,因此,新晶界的形成阻止了应力集中所造成的材料失效。随着冷却速率的增加,晶粒中的马氏体形核点数目得到增加,导致晶粒细化程度也相应地增加,该现象与文献[39]结果一致。在冷却过程中模型晶粒内成核的马氏体相逐渐向晶界处扩散生长直至相变结束,冷却速率对马氏体相变温度影响较大,而升温过程中保持升温速率一定,因此加载过程中的相变驱动力不变。由于冷却过程中,冷却速率未发生较大改变,且仅在少数尺寸较大晶粒中造成不同程度的晶粒细化现象,从而改变奥氏体相形核能垒的大小[40],因此升温过程中Af 会出现小幅度波动,与文献[10]的实验结果一致。

图8 不同冷却速率条件下模型在不同温度时的原子排列图及其晶界能大小

Fig. 8 Atomic configuration for model of 17.5 nm at different temperatures under different cooling rates (In each snapshot, blue atoms correspond to B2 austenite structure, red atoms to B19′ martensite structure and gray atoms to grain and boundary)

3 结论

1) 晶粒尺寸因素是影响多晶NiTi合金相变温度的重要因素。当晶粒尺寸小于4.1 nm时,温度循环过程中NiTi合金未发生明显相变现象;当晶粒尺寸大于4.1 nm时,温度循环过程中原子体积均发生明显突变,且降温时马氏体相变起始温度随着晶粒尺寸的增大逐渐上升,升温时奥氏体相变完成温度也随着晶粒尺寸的增大而上升。

2) 冷却速率是影响多晶NiTi合金相变温度的重要因素。当模型中晶粒尺寸大小相同时,随着冷却速率的逐渐增加,马氏体相变完成温度逐渐减小,且相变滞后宽度(Mf-Af)随着冷却速率的增加也呈增大趋势。

3) 升、降温过程中奥氏体相与马氏体相的生长机制呈相反趋势。冷却过程中的马氏体相形核点主要出现在晶粒内部,并且在晶粒区域内伴有形成新晶界分割原始晶粒的现象,且冷却速率越大,马氏体晶粒细化程度增加。随着温度继续下降晶粒内部成核的马氏体相会逐渐向晶界处扩散生长直至马氏体相变结束。而升温过程中奥氏体相生长机制与之相反,奥氏体相形核点最初较多会出现在晶界处,并且随着温度的升高逐渐向晶粒内部聚集生长直至奥氏体相变结束。

REFERENCES

[1] MAY H, ZHANG Q C, ZHANG D Y, SCARPA F, LIU B. The mechanics of shape memory alloy metal rubber[J]. Acta Mater, 2015, 96: 89-100.

[2] ZOTOV N, PFUND M, POLATIDISA E, MARK A F, MITTEMEIJER E J. Change of transformation mechanism during pseudoelastic cycling of NiTi shape memory alloys[J]. Materials Science & Engineering A, 2017, 682: 178-191.

[3] PAN G J, CRISTINA B, LUCA M, SPRIANO S. Microstructure and transformation temperatures in rapid solidified Ni-Ti alloys. Part I: The effect of cooling rate[J]. Journal of Alloys and Compounds, 2014, 589: 628-632.

[4] 鲁 军, 李 侠, 王重马, 于庆洋, 高 琳, 吴立天. 基于小波分析的MSMA振动传感器信号处理与故障检测[J]. 电工技术学报, 2015, 30(10): 354-360.

LU Jun, LI Xia, WANG Chong-ma, YU Qing-yang, GAO Lin, WU Li-tian. Signal process and fault detection of MSMA vibration sensor based on wavelet analysis[J]. Transactions of China Electrotechnical Society, 2015, 30(10): 354-360.

[5] WANG X, KUSTOV S, LI K, SCHRYVERS D, VERLINDEN B, HUMBEECK J V. Effect of nanoprecipitates on the transformation behavior and functional properties of a Ti–50.8at.% Ni alloy with micron-sized grains[J]. Acta Materialia, 2015, 82: 224-233.

[6] SHI X B, MA Z Y, ZHANG J S, DING H L, GUO F M. Grain size effect on the martensitic transformation temperatures of nanocrystalline NiTi alloy[J]. Smart Materials and Structures, 2015, 24(7): 1-5.

[7] SHI X B, CUI L S, JIANG D Q, YU C, GUO F M, YU M Y, REN Y, LIU Y N. Grain size effect on the R-phase transformation of nanocrystalline NiTi shape memory alloys[J]. J Mater Sci, 2014, 49: 4643-4647.

[8] AHADI A, SUN Q P. Effects of grain size on the rate-dependent thermomechanical responses of nanostructured superelastic NiTi[J]. Acta Materialia, 2014, 76: 186-197.

[9] AHADI A, SUN Q P. Stress-induced nanoscale phase transition in superelastic NiTi by in situ X-ray diffraction[J]. Acta Materialia, 2015, 90: 272-281.

[10] MOTEMANI Y, NILI-AHMADABAD M, TAN M J, BORNAPOUR M, RAYAGAN S. Effect of cooling rate on the phase transformation behavior and mechanical properties of Ni-rich NiTi shape memory alloy[J]. Journal of Alloys and Compounds, 2009, 469(1/2): 164-168.

[11] FANG H, WONG M B, BAI Y, LUO R. Effect of heating/cooling rates on the material properties of NiTi wires for civil structural applications[J]. Construction and Building Materials, 2015, 101(1): 447-455.

[12] NURVEREN K, AKDOAN A, HUANG W M. Evolution of transformation characteristic with Heating/cooling rate in NiTi shape memory alloys[J]. Journal of Materials Processing Technology, 2008, 196(1/3): 129-134.

[13] ZHANG Y Q, JIANG S Y, ZHAO Y N, TANG M. Influence of cooling rate on phase transformation and microstructure of Ti-50.9%Ni shape memory alloy[J]. Trans Nonferrous Met Soc China, 2012, 22(11): 2685-2690.

[14] ADHARAPURAPUA R R, VECCHIO K S. Effects of aging and cooling rate on the transformation of nanostructured Ti-50.8Ni[J]. Journal of Alloys and Compounds, 2017, 693: 150-163.

[15] KULIN S A, COHEN M. On the martensitic transformation at temperature approaching absolute zero[J]. Trans AIME, 1950, 188(9): 1139-1143.

[16] MACHLIN E S,COHEN M. Burst phenomenon in the martensitic transformation[J]. Trans AIME, 1951, 191(9): 746-754.

[17] 石 俊. Ni-Ti基合金薄膜相变行为及其力学特性研究[D]. 南京: 南京大学, 2014.

SHI Jun. Study on the phase transformation behavior and mechanical properties of Ni-Ti based alloy films[D]. Nanjing: Nanjing University, 2014.

[18] REN J Q, SUN Q Y, XIAO L, SUN J. Temperature and strain rate effect of the deformation-induced phase transformation in pure titanium nanopillars oriented along [0001][J]. Computational Materials Science, 2017, 126: 66-73.

[19] MA G F, QIN S J, SHANG J X, WANG F H, CHEN Y. Atomistic study on the phase transformation in NiTi under thermal cycling[J]. Journal of Alloys and Compounds, 2017, 705: 218-225.

[20] FROSETH A G, VAN S H, DERLET P M. Developing realistic grain boundary networks for use in molecular dynamics simulations[J]. Acta Materialia, 2005, 53(18): 4847-4856.

[21] 李小凡, 胡望宇, 肖时芳, 邓辉球. 单晶和多晶钼纳米丝轴向拉伸的模拟对比[J].中国有色金属学报, 2009, 19(11): 1982-1986.

LI Xiao-fan, HU Wang-yu, XIAO Shi-fang, DENG Hui-qiu. Comparison of simulation of single-crystalline and polycrystalline Mo nanowires under uniaxial tensile strain[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1982-1986.

[22] STEVE P. Fast parallel algorithms for short-range molecular dynamics[J]. Computational Materials Science, 1995, 117(1): 1-19.

[23] MORRISON K R, CHERUKARA M J, KIM H, STRACHAN A. Role of grain size on the martensitic transformation and ultra-fast superelasticity in shape memory alloys[J]. Acta Materialia, 2015, 95: 37-43.

[24] NOSE S C. A unified formulation of the constant temperature molecular dynamics methods[J]. Chem. Phys, 1984, 81(1): 511-519.

[25] PARRINELLO M, RAHMA A. Polymorphic transitions in single crystals: A new molecular dynamics method[J]. Appl Phys, 1981, 52(12): 7182-7190.

[26] 齐卫红, 汪明朴. 铅纳米薄膜熔化温度尺寸效应的分子动力学研究[J]. 中国有色金属学报, 2006, 16(7): 1161-1165.

QI Wei-hong, WANG Ming-pu. Molecular dynamic study on size dependent melting temperature of Pb nanofilms[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(7): 1161-1165.

[27] KO W S, GRABOWSKI B, NEUGEBAUER J. Development and application of a Ni-Ti interatomic potential with high predictive accuracy of the martensitic phase transition[J]. Physical Review B, 2015, 92(13): 134107.

[28] PROKOSHKIN S D, KOROTISKIY A V, BRAILOVSKI V, TURENNE S, KHMELEVSKAYA I Y, TRUBITSYNA I B. On the lattice parameters of phases in binary Ti-Ni shape memory alloys[J]. Acta Materialia, 2004, 52(15): 4479-4492.

[29] STUKOWSKI A. Visualization and analysis of atomistic simulation data with OVITO—The open visualization tool[J]. Modelling Simul Mater Sci Eng, 2010, 18(1): 1-7.

[30] STUKOWSKI A. Structure identification methods for atomistic simulations of crystalline materials[J]. Modelling Simul Mater Sci Eng, 2012, 20(4): 1-15.

[31] LI J. AtomEye: An efficient atomistic configuration viewer[J]. Modelling and Simulation in Materials Science and Engineering, 2003,11(2): 173-177.

[32] FUTOSHI S, SHIGENOBU O, LI J. Theory of shear banding in metallic glasses and molecular dynamics calculations[J]. Materials Transactions, 2007, 48(11): 2923-2927.

[33] WAITZ T, ANTRETTER T, FISCHER F D, SIMHA N K, KARNTHALER H P. Size effects on the martensitic phase transformation of NiTi nanograins[J]. Journal of the Mechanics and Physics of Solids, 2007, 55(2): 419-444.

[34] SHI X B, CUI L S, JIANG D Q, YU C, GUO F. Grain size effect on the R-phase transformation of nanocrystalline NiTi shape memory alloys[J]. J Mater Sci, 2014, 49(13): 4643-4647.

[35] 徐祖耀. 相变导论[M]. 上海: 上海交通大学出版社, 2014.

XU Zu-yao. Introduction to phase transformation[M]. Shanghai: ShanghaiJiao TongUniversity Press, 2014.

[36] KO W S, MAISEL S B, GRABOWSKI B, JEON J B, NEUGEBAUER J. Atomic scale processes of phase transformations in nanocrystalline NiTi shape-memory alloys[J]. Acta Materialia, 2017,123: 90-101.

[37] TU J B, JIANG B H, HSU T Y. The size effect of the martensitic transformation in ZrO2-containing ceramics[J]. J Mater Sci, 1994, 29(6): 1662-1665.

[38] AHLUWALIA R, QUEK S S, WU D T. Simulation of grain size effects in nanocrystalline shape memory alloys[J]. J Applied Phys, 2015, 117(24): 244305.

[39] HOU Z, TIAN Z, LIU R, DONG K, YU A. Formation mechanism of bulk nanocrystalline aluminium with multiply twinned grains by liquid quenching: A molecular dynamics simulation study[J]. Computational Materials Science, 2015, 99: 256-261.

[40] 梁高飞, 王成全, 方 园. AISI304不磁钢加热过程中高温δ相形核与生长的原位观察[J]. 金属学报, 2006, 42(8): 805-809.

LIANG Gao-fei, WANG Cheng-quan, FANG Yuan. In situ observation of nucleation and growth of high-temperature δ phase in steel AISI 304 during heating[J]. Acta Metallurgica Sinica, 2006, 42(8): 805-809.

Microscopic investigation to influence of grain size and cooling rate on phase transformation temperature for polycrystalline NiTi alloy

DING Jun1, ZHAO Hao-nan1, HUANG Xia1, ZENG Xiang-guo2, WANG Lu-sheng1, SONG Kun1

(1. College of Mechanical Engineering, Chongqing University of Technology, Chongqing, 400054, China;

2. School of Architecture and Environment, Sichuan University, Sichuan, 610065, China)

Abstract: The molecular dynamic simulation was conducted to analyze the influence of grain size and cooling rate to the phase transformation temperature, and the phase transformation mechanism for the alloy was also studied. The result shows that when the cooling rate is -5 K/ps, as the grain size decreases from 17.5 nm to 8.5 nm, the martensite formation temperature decrease from 230 K to 80 K, the number of nucleation point also decreases gradually and only nucleate inside the grain, the martensite grows towards the grain boundary in the process of cooling. When the grain size decreases to 4.1 nm, the transformation is suppressed. In the process of heating, the nucleation point of austenits nucleates near the grain boundary and grows towards inside of the grain. When the cooling rate increases from -5 K/ps to -15 K/ps, the finish transformation temperature of martensite decreases from 190 K to 20 K, the grain refinement increases and the transformation hysteresis width (Af-Mf) decreases with the increase in cooling rate in the model of 17.5 nm. While the effect of cooling rate on martensitic phase growth mechanism is relatively small.

Key words: shape memory alloy; phase transformation temperature; cooling rate; molecular dynamics

Foundation item: Project(U1530140) supported by the National Natural Science Fund Committee of China and China Academy of Engineering Physics Mutual Funds; Projects(CSTC2016JCYJA0517, CSTC2017JCYJAX0357) supported by the Foundation and Frontier Research of Chongqing, China; Project (KJ1709224) supported by the Education Committee Science and Technology of Chongqing, China

Received date: 2018-01-02; Accepted date: 2018-04-25

Corresponding author: DING Jun; Tel: +86-23-62563039; E-mail: dingjunawen@126.com

(编辑 何学锋)

基金项目:国家自然科学基金委员会与中国工程物理研究院联合基金资助项目(U1530140);重庆市基础与前沿研究计划资助项目(CSTC2016JCYJA0517,CSTC2017JCYJAX0357);重庆市教育委员会科学技术研究资助项目(KJ1709224)

收稿日期:2018-01-02;修订日期:2018-04-25

通信作者:丁 军,教授,博士;电话:023-62563039;E-mail:dingjunawen@126.com