Microstructure and mechanical properties of dissimilarresistance spot welded DP1000–QP1180 steel sheets

来源期刊:中南大学学报(英文版)2019年第1期

论文作者:Imren OZTURK YILMAZ Abdullah Yasin BILICI Hakan AYDIN

文章页码:25 - 42

Key words:DP1000 steel; QP1180 steel; electrical resistance spot welding; microstructure; mechanical properties

Abstract: In this study, the effect of welding parameters on the microstructure and mechanical properties of the dissimilar resistance spot welded DP1000–QP1180 joints was investigated. Heat affected zone (HAZ) width of QP1180 side was smaller than that of DP1000 side. HAZ width and indentation depth increased with increasing welding current and welding time. The nugget size increased with increasing welding current whereas it increased at lower currents and decreased at higher currents with increasing welding time. The lowest hardness was on the DP1000 side. On the QP1180 side, the center of HAZ had the peak hardness. With increasing welding current, hardness values throughout the weld zone decreased and the tensile shear load increased. At lower welding currents, the welding time did not affect the tensile shear load. Tensile elongation decreased with the increase of welding time, whereas there is no relationship between the welding current and elongation. The spot-welded joints having higher strength exhibited a more ductile fracture characteristic.

Cite this article as: Imren OZTURK YILMAZ, Abdullah Yasin BILICI, Hakan AYDIN. Microstructure and mechanical properties of dissimilar resistance spot welded DP1000–QP1180 steel sheets [J]. Journal of Central South University, 2019, 26(1): 25–42. DOI: https://doi.org/10.1007/s11771-019-3980-3.

J. Cent. South Univ. (2019) 26: 25-42

DOI: https://doi.org/10.1007/s11771-019-3980-3

Imren OZTURK YILMAZ1, Abdullah Yasin BILICI1, Hakan AYDIN2

1. Beycelik Gestamp Inc., BTSO Organized Industrial Zone, Bursa 16215, Turkey;

2. Department of Mechanical Engineering, Uludag University, Bursa 16059, Turkey

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract: In this study, the effect of welding parameters on the microstructure and mechanical properties of the dissimilar resistance spot welded DP1000–QP1180 joints was investigated. Heat affected zone (HAZ) width of QP1180 side was smaller than that of DP1000 side. HAZ width and indentation depth increased with increasing welding current and welding time. The nugget size increased with increasing welding current whereas it increased at lower currents and decreased at higher currents with increasing welding time. The lowest hardness was on the DP1000 side. On the QP1180 side, the center of HAZ had the peak hardness. With increasing welding current, hardness values throughout the weld zone decreased and the tensile shear load increased. At lower welding currents, the welding time did not affect the tensile shear load. Tensile elongation decreased with the increase of welding time, whereas there is no relationship between the welding current and elongation. The spot-welded joints having higher strength exhibited a more ductile fracture characteristic.

Key words: DP1000 steel; QP1180 steel; electrical resistance spot welding; microstructure; mechanical properties

Cite this article as: Imren OZTURK YILMAZ, Abdullah Yasin BILICI, Hakan AYDIN. Microstructure and mechanical properties of dissimilar resistance spot welded DP1000–QP1180 steel sheets [J]. Journal of Central South University, 2019, 26(1): 25–42. DOI: https://doi.org/10.1007/s11771-019-3980-3.

1 Introduction

The car body design with light weight and enhanced safety is a key issue in the modern automotive industry [1].The response of steel industry both to reduce the vehicles weight and to improve passenger safety is a rapid development of higher strength steels, named advanced high strength steels (AHSS)[2]. Dual phase (DP) steels are the common used AHSS grades for fabrication of lightweight automobile parts, which can meet the demands of weight, ductility and strength [3]. DP steels are mainly composed of dispersed islands of martensite in a ferritic matrix [4–9]. The ductility is controlled by the ferrite, while the strength is controlled by the martensite [4, 8, 9]. DP steels having a much higher ultimate tensile strength (TS), a higher initial work hardening rate, and a lower yielding-to-tensile strength ratio (YS/TS) are obtained by the work-hardening rate and the excellent elongation [10, 11]. In recent years, DP1000 sheet steels are gaining popularity in manufacturing automotive body components where a higher strength is necessary, e.g., A and B pillars and bumpers [4, 12, 13]. When DP1000 steel sheet deformation occurs, it produces a unique high work-hardening ratio. On the other hand, nowadays, global steel manufacturers have been focused to develop the 3rd generation AHSS in order to produce light-weight body in white (BIW) structures for automotive industry due to strict regulations of fuel efficiency for lower CO2 emission and improve passenger safety standards. Quenching & partitioning (Q&P) steel is one of the leading examples of this new generation AHSS. This steel exhibiting an excellent combination of strength and ductility consists of ferrite (in the case of partial austenitization), martensite, and retained austenite [14–17]. So, QP1180 steel sheets are expected to be popular in automotive body structure applications in the very near future.

The use of steel sheets for car body manufacturing in the automotive applications inevitably involves welding [4, 18]. Resistance spot welding (RSW) is one of the main joining methods used in the automotive industry, and there are several thousand resistance spot welds on each vehicle. Investments in automotive companies also show that RSW is the dominant combination of automotive subsidiary industry in the coming years. However, the designed microstructure of AHSS steel sheets is destroyed during the RSW process due to the welding thermal cycle. The microstructural evolution during RSW is highly dependent on the welding parameters, such as welding current and welding time. Weld thermal cycle during RSW process causes the heat affected zone (HAZ) to soften in AHSS sheets, which in turn affects the mechanical properties. Depending on the increase in weld heat input, the degree of softening in the HAZ also increases [6, 10, 11, 16, 17, 19–23].

Car bodies are built by assembling several sheet steel parts by RSW. So, dissimilar welding of AHSSs used in automotive industry is frequently encountered in assembly processes. Dissimilar welding processes may need more attention than similar welding process because of the properties such as their different melting temperatures and thicknesses. Performing dissimilar RSW of DP1000 and QP1180 sheet steels is an inevitable demand within a few years in the modern automotive industry because of their superior functional capabilities. Several studies have been conducted to investigate the weld properties of similar and dissimilar RS welded AHSS [4, 24–40], but there is not available work on dissimilar RS welded DP1000-QP1180 sheet steels. The application of these steel sheets in the automotive industry requires a more complete understanding of the issues associated with the RSW of these steel sheets. It is thus important to study the welding behavior of the RS-welded dissimilar DP1000–QP1180 joints. Therefore, in this experimental study, the microstructural changes, microhardness, tensile shear properties and fracture morphologies of dissimilar DP1000–QP1180 steel sheets welded at different welding current and welding time were investigated in detail.

2 Experimental procedure

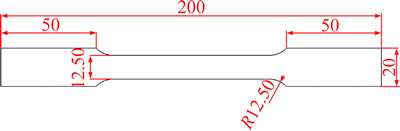

Sheets of DP1000 steel and QP1180 steel were used as the workpiece materials. The nominal sheet thicknesses of DP1000 and QP1180 commercial automotive steels are 1.0 mm and 1.2 mm, respectively. The chemical compositions of these sheets are listed in Table 1. For the mechanical properties of the base sheets, the tensile test specimens were cut along the rolling direction of the sheets and ASTM E8/E8M sheet type specimen was taken into consideration as shown in Figure 1 [41]. The obtained mechanical properties of the base metals used in this study are shown in Table 2.

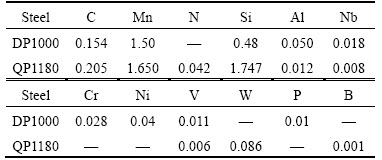

Table 1 Chemical compositions of DP 1000 and QP1180 steels used in present study (mass fraction, %)

Figure 1 Dimensions of tensile test specimen of base metals (ASTM E8/E8M sheet type specimen) [41] (Unit: mm)

Table 2 Mechanical properties of DP 1000 and QP1180 steels used in this investigation

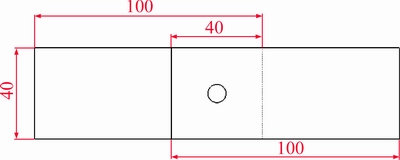

The steel sheets were cut into pieces for welding process using laser cutting machine with the dimensions of 100 mm×40 mm, as shown in Figure 2. These cut sheets were cleaned properly with ethanol to remove dirt, oil, oxide and surface scale before welding. Welding was performed by overlapping the sheets with a width of 40 mm using a digitally controlled medium frequency RSW machine having 240 kV·A capacity. A specific designed weld fixture for the work pieces was used to provide the same position of all weld samples during RSW process. Cu alloy electrodes with tip diameter of 6 mm were used in the RSW processes. Welding studies were carried out by the process window method with different welding current and welding time while keeping other parameters constant. The welding current was increased from 7 to 11 kA by 1.0 kA increments, with welding times of 12 cycle, 20 cycle and 28 cycle, and with the electrode force of 2.5 kN. The electrode force was continuously controlled during the experiments. Also, in order to avoid the effect of the electrode tip diameter, the electrode tip was changed after each 25 welding period. After welding process, the spot welded joints were left in open air to cool.

Figure 2 Spot welded tensile shear test sample (Unit: mm)

For microstructural examinations, the welded samples were cut along the center of the spot welding steel in the direction of the width of specimens, polished with conventional metallographic methods, and then etched by 4% nital reagent (4 mL HNO3 and 96 mL alcohol) for 20 s. After the etching, these metallographic samples were studied via a Nikon DIC optical microscope (OM) with a Clemex image analysis system. The nugget size (NS) of the spot welds was measured through the fractured specimens in all welding conditions using a digital caliper. Also, the electrode indentation depth value of the joints was measured using an ultrasonic resistance spot weld analyzer. In order to determine the mechanical properties of the spot welded joints, microhardness

measurements and tensile shear tests were conducted. Vickers microhardness measurements across the fusion zone (FZ), the HAZ and the base metal (BM) were carried out at 100 g load for holding 15 s using DUROLINE-M microhardness tester. Five microhardness measurements were taken within each zone in order to obtain the average hardness of each zone. The tensile tests of spot weld were carried out according to the American Welding Society standard AWS D8.9M [42], and tensile experiments of spot weld were performed on a fully computerized Zwick tensile testing machine, at room temperature and with a crosshead displacement speed of 5 mm/min. The tensile properties were evaluated through averaging the value of five specimens under the same welding condition. Finally, a Zeiss EVO 40 XVP type SEM operated at 20 kV was used to characterize the fracture surfaces of the tensile shear test samples.

3 Results and discussion

3.1 Microstructure

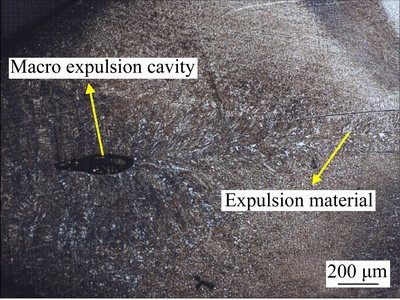

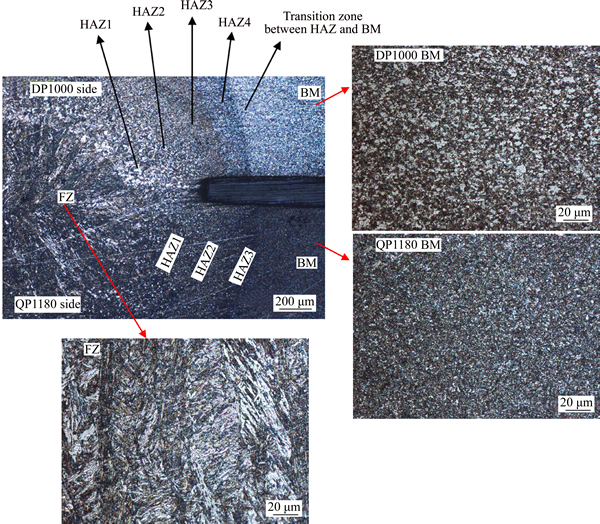

Except for the spot welded joint with the weld current of 11 kA and welding time of 28 cycle, all other dissimilar combinations of DP1000 and QP1180 sheet steels were successfully welded with the RSW technique under the investigated welding parameters without obvious weld defects. The joint (11 kA, 28 cycle) had a macro expulsion cavity in the FZ resulting from the molten material loss in the FZ during RSW process due to the higher heat input (Figure 3). However, the presence of this macro defect could not profoundly affect the shear–tension strength of the joint since the load component on this defect is almost zero in the tensile shear loading condition. Typical microstructures of dissimilar resistance spot-welded DP1000-QP1180 steel sheet joint (7 kA-12 cycle) can be seen in Figure 4. It can be seen that the joint consists mainly of FZ, HAZs encircling the nugget and BMs of both steels. Considering the distinct HAZ microstructures in the welded zone, HAZs of DP1000 and QP1180 sides of the joints were divided into four and three regions, respectively. The DP1000 side of the joint also had a transition zone between HAZ and BM. By contrast, this zone on the QP1180 side of the joints was not observed. Figure 4 also shows optical micrographs of FZ and BMs of these sheet steels. The FZ shown in Figure 4 is characterized by the coarse columnar dendritic nature of rapid solidification mainly consisting of a full martensitic structure owing to the presence of water-cooled copper electrodes and their quenching effect as well as the short welding cycle. In the DP1000 BM microstructure, the hard martensite islands (black color) are dispersed in the soft ferrite matrix (light color) (Figure 4). The microstructure of QP1180 steel is composed of predominantly martensitic matrix with retained austenite and a little ferrite islands (Figure 4). KU EROV

EROV et al [43] stated that the retained austenite forms mainly thin films whose size is below resolution limit of optical microscopy and only small white ferrite islands can be seen in the optical micrographs.

et al [43] stated that the retained austenite forms mainly thin films whose size is below resolution limit of optical microscopy and only small white ferrite islands can be seen in the optical micrographs.

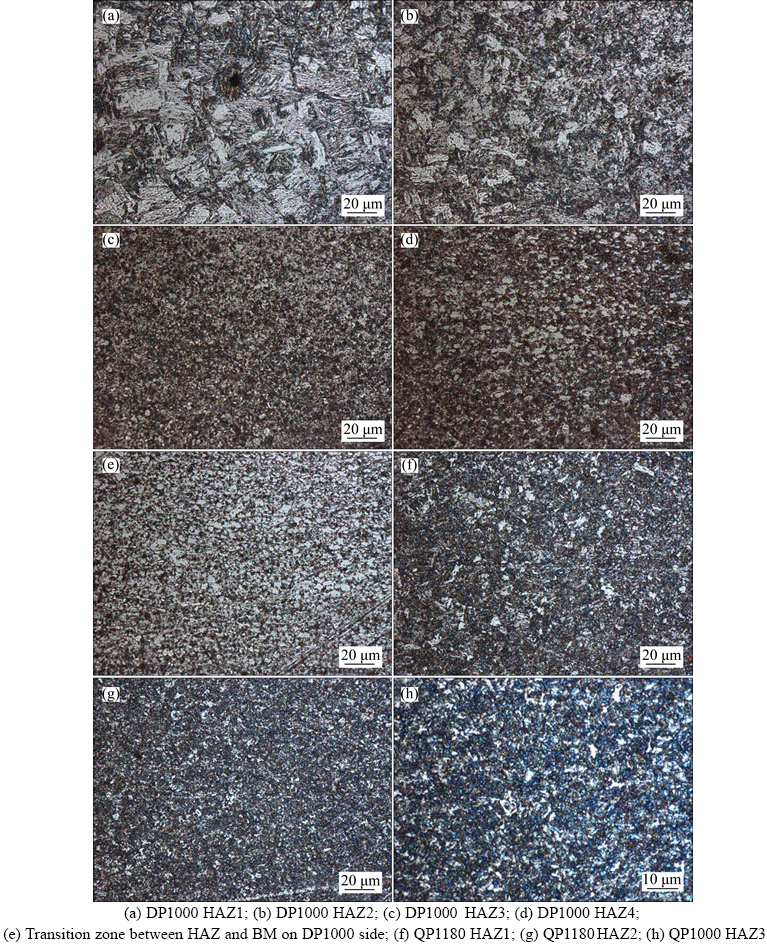

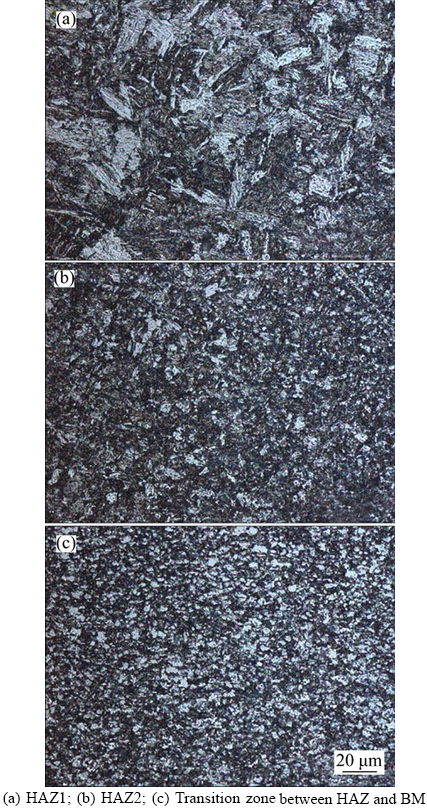

Figure 5 shows the HAZ microstructures on both sides of the joints indicated in Figure 4. Prior austenite grains (PAGs) in the HAZ1 and HAZ2 are much coarser on the DP1000 side than the QP1180 side. This may be attributed to substantially pinning effect of probable fine carbide particle on the austenitic grain growth (inhibiting the grain growth) during re-austenitization in the thermal cycle of RSW process at the QP1180 side of the joints and lower thermal coefficient of QP1180 steel. HAZ1-3 microstructures on the DP1000 side of the joints are composed of martensitic and bainitic structures (Figures 5(a)–(c)). This indicates that the peak temperature in these zones during welding process exceeded Ac3, which is the temperature at which transformation of ferrite to austenite is completed during heating [24, 44–46]. The grain structure becomes finer from HAZ1 to HAZ3 due to relatively less heat exposure. HAZ4 on DP1000 side, in which the peak temperature exceeded Ac1, which is the temperature at which austenite begins to form during heating, but below Ac3, consists of martensite and polygonal ferrite (PF) [24, 44–46]. The transition zone between HAZ and BM in which the peak temperature was below Ac1 in the thermal cycle of the resistance spot welding is composed of tempered martensite and coarse PF [4]. On the other hand, the HAZ1 and HAZ2 on the QP1180 side consist of predominantly martensite and some bainite formed by cooling from Ac3. The retained austenite and little ferrite islands in the QP1180 BM microstructure transformed into bainite in these zones. Far away from FZ, HAZ3 microstructure on the QP1180 side has martensite, bainite and PF formed by cooling from a temperature between the Ac1 and Ac3. With increasing welding current, on the DP1000 side of the joints, the fraction of bainite in HAZ1-4 relatively increased (the fraction of martensite decreased), and tempered martensite in transition zone was more tempered since the cooling rate is slower with the higher heat input (Figure 6).Similarly, on the QP1180 side of the joints, the fraction of bainite in HAZs should be expected to be relatively increased with increasing welding current owing to the slower cooling rate due to the higher heat input during RSW process.

Figure 3 Formation of macro expulsion cavity (joint with 11 kA-28 cycle)

Figure 4 Typical microstructures of RSWed dissimilar DP1000-QP1180 steel sheet (7 kA-12 cycle), and BMs of these sheet steels (FZ: Fusion zone; HAZ: Heat affected zone; BM: Base metal)

Figure 5 HAZ microstructures on both sides indicated in Figure 4:

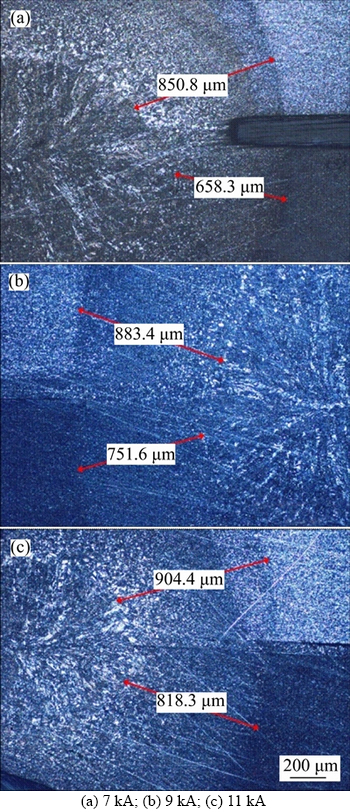

HAZ width measurements on both sides of the joints can be seen in Figure 7. HAZ widths on QP1180 side are smaller than those on DP1000 side. As mentioned above, this may be associated with lower thermal coefficient of QP1180 steel and pinning effect of probable fine carbide and nitride particles on grain growth during re-austenitization. The thermal conductivity of steels varies widely with alloy type and content and can be greatly decreased by alloying. More carbon and alloying elements result in lower thermal conductivity [47, 48]. Also, thermal conductivity of steels depends on the arrangement of crystalline structure. Every phase in a steel has a different thermal conductivity due to the specific crystal structure: Thermal conductivity differs for the austenite, ferrite, martensite and pearlite microstructures. For example, more martensite leads to lower thermal conductivity [49, 50]. On the other hand, steels often have extremely fine particles of carbide and nitride due to the presence of strong carbide or nitride forming alloy elements [51]. The austenite grain boundaries are pinned by the finely dispersed carbide, nitride, carbonitride particles, inhibiting their movement during the thermal cycle [52–55]. This phenomenon is known as the Zener pinning effect [56–58]. The strongest grain growth retardants are Nb, V, Ti, Al, Zr, W, Mo, and Cr, Ni and Si produce a weaker retarding effect. OIKAWA et al [59] stated that this phenomenon has a well- established industrial application such as suppression of grain coarsening in HAZ of weld. A high number of small secondary phase particles have a larger pinning effect than a small number of large particles [60]. Also, the pinning force is governed by the thermodynamic stability of these secondary phase particles in austenite [52, 61]. However, the dissolution of these particles leads to a decrease in pinning effect [60]. The austenite grain boundary pinning can be controlled by especially AlN at temperatures below 1125°C, but by Nb(C,N) at higher temperatures [57, 60, 62]. Thus, more carbon and the presence of nitrogen in QP1180 steel lead to higher number density of pinning particles during weld thermal cycle.

Figure 6 HAZ microstructures on DP1000 side of RSWed dissimilar DP1000-QP1180 steel sheet (11 kA-12 cycle):

Figures 8 and 9 show the effect of welding current and welding time on the HAZ width. On DP1000 side, with increasing welding current, a significant increase in HAZ width was observed at 28 cycle, whereas the increase in HAZ width at 12 and 20 cycle is negligible. On QP1180 side, with increasing welding current, there was a considerable increase in HAZ width at 12 and 20 cycle, whereas a negligible decrease in HAZ width was observed at 28 cycle. On the other hand, on both sides, the HAZ widths increased linearly with increasing welding time (Figures 9(a) and (b)): The coefficients of determination (R2) for the linear correlation between the HAZ width and welding time are 0.95–1.00 on DP1000 side and 0.98–1.00 on QP1180 side by fitting a linear model using regression analysis to the obtained results, as shown in Figure 9. So, as the results indicated in Figures 8 and 9, the main factor influencing the HAZ width on both sides of the spot welded joints is the welding time. The heat input during RSW process is higher at higher welding time. So, the higher heat input makes the HAZ wider and coarser.

Figure 7 HAZ width measurements on resistance spot-welded dissimilar DP1000-QP1180 steel sheets:(Welding cycle: 12 cycles)

Figure 8 HAZ width of resistance spot-welded dissimilar DP1000-QP1180 steel joints versus welding current:

Figure 9 HAZ width of resistance spot-welded dissimilar DP1000-QP1180 steel joints versus welding time:

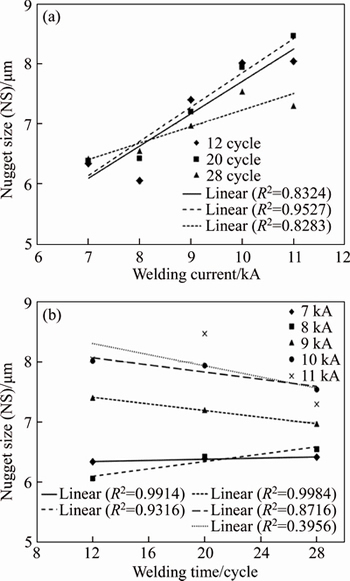

NS is the most important parameter for the mechanical performance of the spot welds. GOODARZ et al [63] stated that for small NSs, shear stress reaches its critical value before tensile stress causes necking; so the failure tends to occur under interfacial failure mode referring to lower deformation energy. The experimental results indicated that the NS was related to the welding current and welding time (Figure 10). A higher welding current produced a larger NS, since the supply of heat is larger. The NS increased almost linearly with an increasing of the welding current [64]: The coefficient of determination (R2) for the linear correlation between the NS and the welding current varies between 0.83 and 0.95, as shown in Figure 10(a). The increase in NS with increasing welding current from 7 kA to 11 kA at relatively lower welding times (12–20 cycle) is around 30%, whereas this increase with increasing welding current from 7 kA to 10 kA at highest welding time (28 cycle) is relatively limited, roughly 18%. It should be noted that the NS decreases at 11 kA of welding current and 28 cycle of welding time through expulsion owing to the excessive heat input. Similarly, at lower welding currents (7 and 8 kA), the NS increased almost linearly with the increasing of the welding time: The coefficient of determination (R2) for the linear correlation between the NS and the welding time is 0.99 and 0.93, respectively in Figure 10(b). With the increasing of welding time from 12 cycle to 28 cycle, the increase in NS at 8 kA is 8.1%, whereas the increase in NS at 7 kA is fairly low, 1.2%. At higher welding currents (9 and 10 kA), the NS decreases almost linearly with the increasing of the welding time: The coefficient of determination (R2) for the correlation between the NS and the welding time is 1.0 and 0.87, respectively in Figure 10(b). With the increasing of welding time from 12 cycle to 28 cycle, the decrease in NS at 9–10 kA is around 6%. However, at 11 kA, a linear relationship between the NS and the welding time is weak (R2=0.40). With the increasing of welding time from 12 cycle to 28 cycle, the decrease in NS at 11 kA is roughly 9%. Finally, it is possible to say that the effect of welding current on the NS of the resistance spot-welded DP1000-QP1180 joints is greater than that of welding time. Indentation depth may also affect the mechanical performance of the spot welds. Figure 11 illustrates the variance in the indentation depth with the increase in the welding current and welding time. According to Figure 11, the indentation depth increased relatively slow with the increasing of the welding time, while it exhibited a relatively rapid increase with the increase in the welding current. This increase was attributed to the increase in the heat (energy) input observed in increasing welding currents. The increase in the indentation depth with the increase of welding current and welding time is almost linear (Figure 11): The coefficient of determination (R2) for the linear correlation varies between 0.98–1.00 for welding current and between 0.78–1.00 for welding time. Also, the enhanced expulsion phenomenon in the joint with 11 kA and 28 cycle may also have contributed to the highest indentation depth value owing to the highest heat input during RSW process.

et al [63] stated that for small NSs, shear stress reaches its critical value before tensile stress causes necking; so the failure tends to occur under interfacial failure mode referring to lower deformation energy. The experimental results indicated that the NS was related to the welding current and welding time (Figure 10). A higher welding current produced a larger NS, since the supply of heat is larger. The NS increased almost linearly with an increasing of the welding current [64]: The coefficient of determination (R2) for the linear correlation between the NS and the welding current varies between 0.83 and 0.95, as shown in Figure 10(a). The increase in NS with increasing welding current from 7 kA to 11 kA at relatively lower welding times (12–20 cycle) is around 30%, whereas this increase with increasing welding current from 7 kA to 10 kA at highest welding time (28 cycle) is relatively limited, roughly 18%. It should be noted that the NS decreases at 11 kA of welding current and 28 cycle of welding time through expulsion owing to the excessive heat input. Similarly, at lower welding currents (7 and 8 kA), the NS increased almost linearly with the increasing of the welding time: The coefficient of determination (R2) for the linear correlation between the NS and the welding time is 0.99 and 0.93, respectively in Figure 10(b). With the increasing of welding time from 12 cycle to 28 cycle, the increase in NS at 8 kA is 8.1%, whereas the increase in NS at 7 kA is fairly low, 1.2%. At higher welding currents (9 and 10 kA), the NS decreases almost linearly with the increasing of the welding time: The coefficient of determination (R2) for the correlation between the NS and the welding time is 1.0 and 0.87, respectively in Figure 10(b). With the increasing of welding time from 12 cycle to 28 cycle, the decrease in NS at 9–10 kA is around 6%. However, at 11 kA, a linear relationship between the NS and the welding time is weak (R2=0.40). With the increasing of welding time from 12 cycle to 28 cycle, the decrease in NS at 11 kA is roughly 9%. Finally, it is possible to say that the effect of welding current on the NS of the resistance spot-welded DP1000-QP1180 joints is greater than that of welding time. Indentation depth may also affect the mechanical performance of the spot welds. Figure 11 illustrates the variance in the indentation depth with the increase in the welding current and welding time. According to Figure 11, the indentation depth increased relatively slow with the increasing of the welding time, while it exhibited a relatively rapid increase with the increase in the welding current. This increase was attributed to the increase in the heat (energy) input observed in increasing welding currents. The increase in the indentation depth with the increase of welding current and welding time is almost linear (Figure 11): The coefficient of determination (R2) for the linear correlation varies between 0.98–1.00 for welding current and between 0.78–1.00 for welding time. Also, the enhanced expulsion phenomenon in the joint with 11 kA and 28 cycle may also have contributed to the highest indentation depth value owing to the highest heat input during RSW process.

Figure 10 Effect of welding current (a) and welding time (b) on NS of RSWed dissimilar DP1000-QP1180 steel joints [64]

Figure 11 Effect of welding current (a) and welding time (b) on indentation depth of RSWed dissimilar DP1000- QP1180 steel joints

3.2 Microhardness

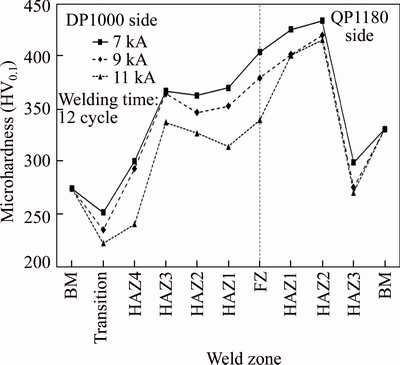

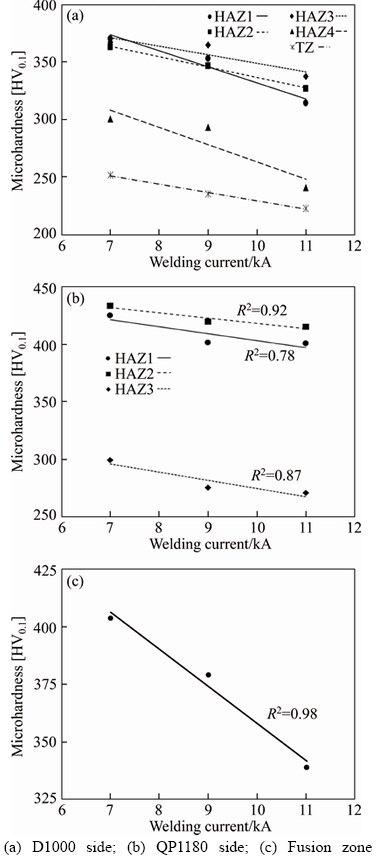

Microhardness measurements were carried out on the spot-welded joints with different welding current in order to determine the hardness variation in the welding zone and observe the effect of heat input during RSW process on microhardness. Figure 12 shows the typical spot weld microhardness profiles with different welding currents consisting of three main zones on both sides of the joints: FZ, HAZs and BMs. The FZ hardness in the spot welded joint at 7 kA and 12 cycle is about 1.5 times the value for DP1000 BM and about 1.25 times the value for QP1180 BM, due to a full martensitic structure in this zone. The weld zone hardness of the RSWed dissimilar DP1000-QP1180 steel joints is mainly influenced by phase transformation, rather than grain size. As a general, the hardness values on the DP1000 side increased from BM to the FZ and the highest hardness was observed in the FZ. On the QP1180 side, the highest hardness was observed in the HAZ2 (where the region near the center of the HAZ) due to a full martensitic and bainitic structure. High change in hardness values in HAZs on both sides of the spot welded joints is due to the severe microstructure gradient in HAZs owing to the weld cycle thermal gradient during RSW process. The hardness values in HAZ1–3 on DP1000 side (especially the regions near the FZ) were fairly higher than that of the BM due to the formation of martensitic and bainitic structures. HAZ4 (the region near the BM) was observed to have lower hardness values owing to the formation of PF beside martensite, but still relatively higher hardness values than the BM. Also, a significant softening due to PF coarsening and tempered martensite was observed in the transition zone between HAZ and BM of the DP1000 side. This zone had the lowest hardness throughout the weld zone. On the other hand, the hardness values in HAZ1 and HAZ2 on QP1180 side were significantly higher than that of the BM of QP1180 steel. However, HAZ3 (the region near the BM) on QP1180 side had the lowest hardness values owing to the formation of PF beside martensite and bainite. The change in welding current had a significant influence on the hardness of the weld zone: Increasing the welding current resulted in decreased the hardness values throughout weld zone (Figure 13). This may attributed to the changes in the microstructure through relatively slower cooling rate due to the higher heat input during RSW process. In addition, this decrease in hardness with increasing welding current is almost linear.

Figure 12 Microhardness values in distinct microstructural zones of RSWed dissimilar DP1000- QP1180 steel joints at various welding currents (see Figure 4 for the zones)

Figure 13 Effect of welding current on microhardness of distinct microstructural zones of spot welded joints:(Welding time: 12 cycles; TZ: Transition zone)

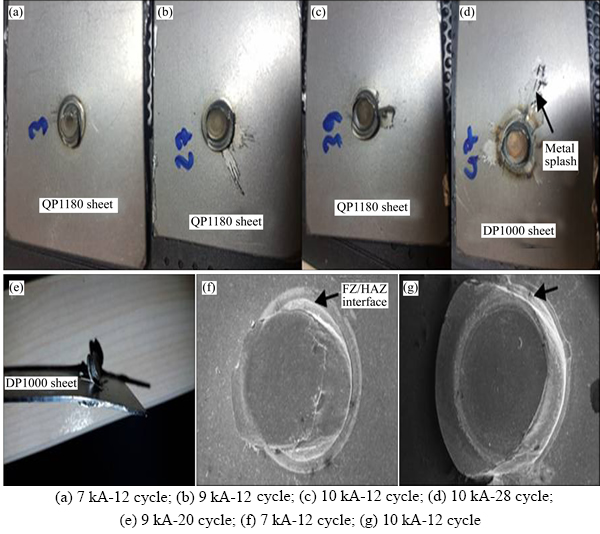

3.3 Tensile properties and fractography

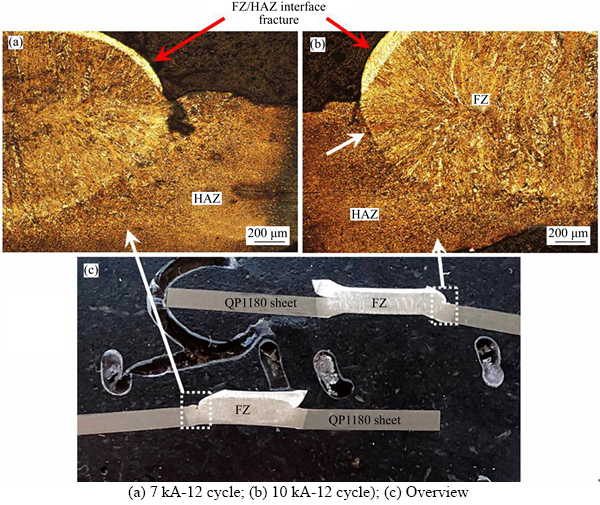

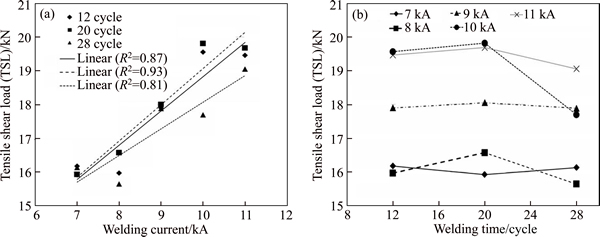

The peak tensile shear load (TSL) obtained from the tensile shear test was used to quantify the static load-carrying capabilities of spot welds [63, 65]. The fracture type affects the load-carrying capacity of spot welds. Interfacial fracture mode has a reducing effect on the vehicle crashworthiness. So, the welding parameters in this study was adjusted so that the button pullout failure mode is guaranteed ensuring reliability of spot welds during vehicle lifetime. As shown in Figures 14 and 15, all resistance spot-welded QP1180/DP1000 joints after the shear tension tests exhibited a button pull-out failure mode referring to higher deformation energy, in which fracture occurs at the FZ/HAZ interface during tensile shear testing. The reason for the fracture at the FZ/HAZ interface is the remarkable difference in the internal structure between the FZ and the HAZ (Figures 4–6, 15). The FZ is composed of a full martensitic structure in a coarse columnar dendritic nature, while the HAZ consists of granular martensitic and bainitic structures. Therefore, the interface between the FZ and the HAZ is clearly visible and relatively brittle (Figure 15). This becomes a weak region in the joints, resulting in the concentration of strain within this interface during tensile shear testing, and so primary failure occurs in this interface. The button pulls after tensile shear test were observed both in the QP1180 side and in the DP1000 side regardless of the welding parameters. Some of them experienced sheet tearing after button withdrawing from DP1000 sheet (Figure 14(e)). Moreover, metal expulsions originating metal splashes close to the border of the button pulls occurs with the increase of welding current and welding time, as shown in Figures 14(a)–(d). The effect of welding current and welding time on the TSL value of the spot welded joints representing an average of five samples is shown in Figure 16. The TSL values obtained with the welding parameters used in this study vary roughly between 16 kN and 20 kN and the highest TSL value with 19.81 kN was obtained with the parameter combination of 10 kA and 20 cycle. The TSL of the spot welded joints increased almost linearly with an increasing of the welding current while other parameters are kept constant [64]: The coefficient of determination (R2) for the linear correlation between the welding current and TSL varies between 0.81 and 0.93, as shown in Figure 16(a). This increase could be attributed to the increase of the NS owing to the higher heat input with increasing of welding current. At 12 and 20 cycle, the TSL reached the maximum value at 10 kA of welding current: With an increasing of welding current from 7 kA to 10 kA, the increase in TSL at 12 and 20 cycle of welding time is 21% and 24%, respectively. The decrease in TSL at 11 kA may be attributed to the increased indentation. At 28 cycle, with the increasing of welding current from 7 kA to 11 kA, the increase in TSL is 18%. On the other hand, in general, at lower welding currents (7–9 kA), the welding time did not significantly affect the TSL of the joints: TSL values in different welding times are too close to each other. At higher welding currents (10 kA and 11 kA), it can be said that TSL of the joints decreased at the highest welding time (28 cycle). This decrease could be associated with the decrease of NS and increase of the indentation depth with excessive expulsion due to the overheating of welding zone. It should also be noted that TSL values were relatively higher at 20 cycle of welding time.

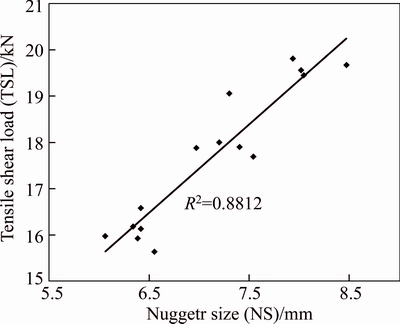

A remarkable relationship was observed between the NS and the TSL of the spot welded joints [64]: As shown in Figure 17, the coefficient of determination (R2) for the linear correlation between the NS and the TSL is 0.88. So, it can be said that TSL of the joints increased almost linearly with an increasing of NS. The maximum TSL value was obtained with 8 mm of NS.

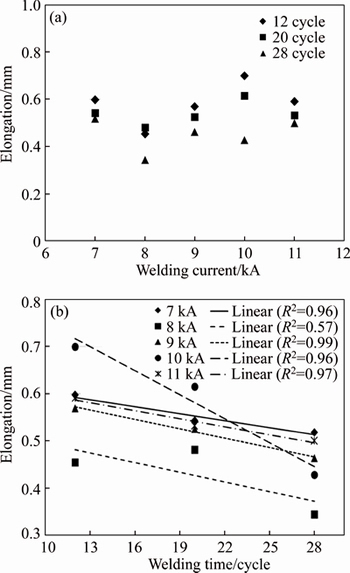

The effect of the welding parameters on the tensile shear deformation of the RSWed dissimilar DP1000-QP1180 steel joints is shown in Figure 18. There is no relationship between the welding current and elongation of the joints. Despite the increased welding current, elongation values mostly vary between 0.4 mm and 0.6 mm. On contrary to welding current, a remarkable relationship was found between the welding time and elongation: Elongation values of the joints decrease almost linearly with the increase of welding time.

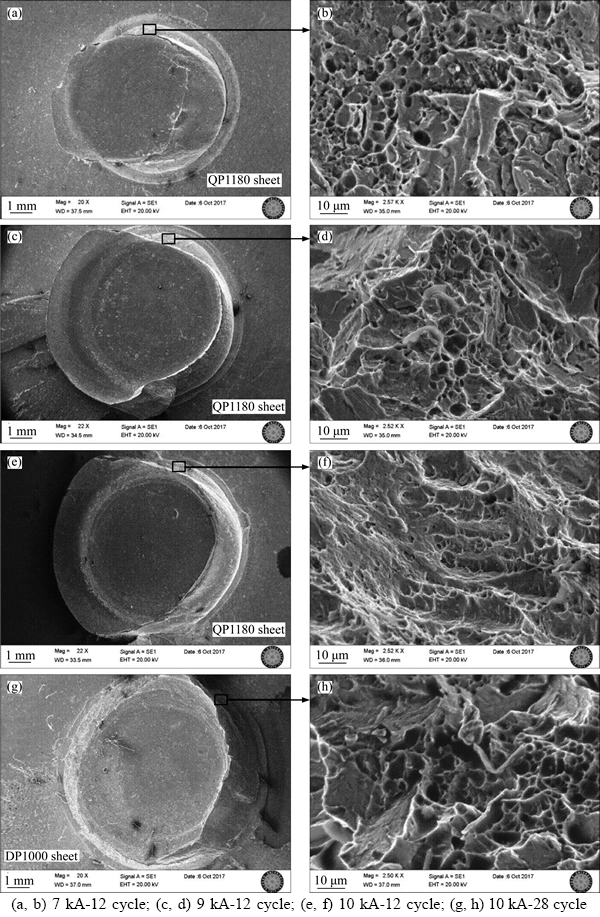

Figure 19 display the fracture surfaces of the joints after shear tension tests as obtained by SEM. The very fine voids and dimples observed in all fracture surfaces of the joints could be related to the presence of impurities formed in the FZ/HAZ interface at high temperatures as commonly encountered in bare sheets RSWs, suggesting that microcracks and micro-void nucleation during tensile testing mostly initiates at these impurities [66]. Figures 19(a) and (b) show that the fracture of the joint having low weld strength with the lowest welding current and shortest welding time occurs in a predominantly brittle manner exhibiting facets among voids and some intra layered fractures with some characteristics of a ductile failure indicating the formation of relatively deeper voids and limited dimples. The fracture surfaces of the joints having moderate weld strength exhibit a predominantly brittle manner, indicating some cleavage fracture areas with some shallow fine voids and dimples (Figures 19(c), (d), (g), (h)). A mixed ductile/brittle mode fracture surface with the formation of small round elongated dimples along the direction of shear stress exhibiting some characteristics of a ductile failure, and with quasi-cleavage areas among the dimples indicating a brittle fracture was observed in the joint having high weld strength with the higher welding current and shortest welding time (Figures 19(e),(f)).

Figure 14 Button pull-out failure modes and DP1000 sheet tearing of spot welded joints:

Figure 15 Fracture locations of spot welded joints:

Figure 16 Effect of welding current (a) and welding time (b) on tensile shear load of RSWed dissimilar DP1000-QP1180 steel joints [64]

Figure 17 Effect of nugget size on tensile shear load of RSWed dissimilar DP1000-QP1180 steel joints [64]

Figure 18 Effect of welding current (a) and welding time (b) on elongation of the RSWed dissimilar DP1000-QP1180 steel joints.

4 Conclusions

The present study was focused on the microstructure and the mechanical properties of resistance spot welded DP1000–QP1180 steel joints fabricated at different welding current and welding time. From this investigation, the following conclusions can be derived:

1) HAZ width of QP1180 side is smaller than that of DP1000 side. HAZ of DP1000 side has five distinct regions while HAZ of QP1180 side consists of three characteristic regions. In general, HAZ width on both sides increases with increasing welding current and welding time. Especially, this increase is more effective and almost linear with the welding time.

2) The nugget size increases almost linearly with increasing welding current. With increasing welding time, the nugget size increases at lower welding currents and decreases at higher welding currents.

3) The increase in the indentation depth is almost linear with the increase of welding current and welding time. This increase is more effective with the welding current.

4) On both steel sides, there is a distinctive softening zone. The maximum hardness is in the center of HAZ on the QP1180 side while the lowest hardness is in the softening zone on the DP1000 side. Hardness values throughout the weld zone decrease almost linearly with increasing the welding current.

5) Weld strength increases almost linearly with increasing welding current. The welding time does not significantly affect the weld strength at lower welding currents. At higher welding currents, weld strength decreases especially at 28 cycle. The parameter combination of 10 kA and 20 cycle leads to the highest weld strength for the spot-welded QP1180/DP1000 joints.

6) Elongation values of the joints decreases almost linearly with the increase of welding time. On the other hand, there is no relationship between the welding current and elongation.

7) The spot welded joints are fractured at FZ/HAZ interface. So, weld strength increases almost linearly with increasing nugget size.

8) The spot-welded QP1180/DP1000 joints having higher strength show more ductile fracture characteristic.

Figure 19 Fracture surfaces of spot welded joints:

References

[1] KWON O, LEE K Y, KIM G S, CHIN K G. New trends in advanced high strength steel developments for automotive application [J]. Material Science Forum, 2010, 638–642: 136–141. DOI: 10.4028/www.scientific.net/MSF.638-642. 136.

[2] KUZIAK R, KAWALLA R, WAENGLER S. Advanced high strength steels for automotive industry [J]. Archives of Civil and Mechanical Engineering, 2008, 8(2): 103–117. DOI: 10.1016/S1644-9665(12)60197-6.

[3] ROCHA I, MACHADO I, MAZZAFERRO C. Mechanical and metallurgical properties of DP 1000 steel square butt welded joints with GMAW [J]. International Journal of Engineering & Technology, 2015, 4(1): 26–34. DOI: 10. 14419/ijet.v4i1.3928.

[4] AYDIN H. The mechanical properties of dissimilar resistance spot-welded DP600-DP1000 steel joints for automotive applications [J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 2015, 229(5): 599–610. DOI: 10.1177/ 0954407014547749.

[5] KO Y G, LEE C W, NAMGUNG S, SHIN D H. Strain hardening behavior of nanostructured dual-phase steel processed by severe plastic deformation [J]. Journal of Alloys and Compounds, 2010, 504(1): 452–455. DOI: 10. 1016/j.jallcom.2010.02.109.

[6] XIA M, BIRO E, TIAN Z, NORMAN ZHOU Y. Effects of heat input and martensite on HAZ softening in laser welding of dual phase steels [J]. ISIJ International, 2008, 48(6): 809–814. DOI: 10.2355/isijinternational.48.809.

[7] POURANVARI M, MARASHI S P H. Key factors influencing mechanical performance of dual phase steel resistance spot welds [J]. Science and Technology of Welding and Joining, 2010, 15(2): 149–155. DOI: 10.1179/ 136217109X12590746472535.

[8] MOLAEI M J, EKRAMI A. The effect of dynamic strain aging on fatigue properties of dual phase steels with different martensite morphology [J]. Materials Science and Engineering A, 2009, 527(1, 2): 235–238. DOI: 10.1016/ j.msea.2009.08.005.

[9] CHEN D L, WANG Z G, JIANG X X, AI S H, SHIH C H. The dependence of near-threshold fatigue crack growth on microstructure and environment in dual-phase steels [J]. Materials Science and Engineering A, 1989, 108: 141–151. DOI: 10.1016/0921-5093(89)90415-2.

[10] WANG J, YANG L, SUN M, LIU T, LI H. A study of the softening mechanisms of laser-welded DP1000 steel butt joints [J]. Materials and Design, 2016, 97: 118–125. DOI: 10.1016/j.matdes.2016.02.071.

[11] KEELER S, KIMCHI M. Advanced high-strength steels application guidelines version 5.0(R), 2014. [EB/OL] [2017-10-16].http://309fbf2c62e8221fbaf0-b80c17cbaf20104b072d586b316c6210.r88.cf1.rackcdn.com/AHSS_Guidelines_V5.0_20140514.pdf

[12] ANAND D, CHEN D L, BHOLE S D, ANDREYCHUK P, BOUDREAU G. Fatigue behavior of tailor (laser)-welded blanks for automotive applications [J]. Materials Science and Engineering A, 2006, 420(1, 2): 199–207. DOI: 10.1016/ j.msea.2006.01.075.

[13] PARKES D, XU W, WESTERBAAN D, NAYAK S S, ZHOU Y, GOODWIN F, BHOLE S, CHEN D L. Microstructure and fatigue properties of fiber laser welded dissimilar joints between high strength low alloy and dual-phase steels [J]. Materials and Design, 2013, 51: 665–675. DOI: 10.1016/j.matdes.2013.04.076.

[14] WANG L, SPEER J G. Quenching and partitioning steel heat treatment [J]. Metallography, Microstructure, and Analysis, 2013, 2: 268–281. DOI: 10.1007/s13632-013-0082-8.

[15] SPENA P R, DE MADDIS M, D'ANTONIO G, LOMBARDI F. Weldability and monitoring of resistance spot welding of Q&P and TRIP steels [J]. Metals, 2016, 6(11): 270. DOI: 10.3390/met6110270.

[16] SPEER J, MATLOCK D K, DE COOMAN B C, SCHROTH J G. Carbon partitioning into austenite after martensite transformation [J]. Acta Materialia, 2003, 51(9): 2611–2622. DOI: 10.1016/S1359-6454(03)00059-4.

[17] SPEER J G, DE MOOR E, FINDLEY K O, MATLOCK D K, DE COOMAN B C, EDMONDS D V. Analysis of microstructure evolution in quenching and partitioning automotive sheet steel [J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2011, 42: 3591–3601. DOI: 10.1007/s11661-011-0869-7.

[18] AYDIN H, TUTAR M, BAYRAM A. The influence of welding time on mechanical properties of resistance spot welded TWIP steel sheets [C]// XIII International Scientific Congress Machines, Technolоgies, Materials. Varna: Summer Session, 2016: 16–19. http:// mtmcongress. com/proceedngs/2016/Summer/2/04.THE%20INFLUENCE%20OF%20WELDING%20TIME%20ON%20MECHANICAL%20PROPERTIES%20OF%20RESISTANCE%20SPOT%20WELDED%20TWIP%20STEEL%20SHEETS.pdf.

[19] TUMULURU M. Resistance spot welding techniques for advanced high-strength steels (AHSS) [M]// Welding and Joining of Advanced High Strength Steels (AHSS). Amsterdam: Elsevier Ltd, 2015.

[20] CHABOK A, VAN DER A A E, DE HOSSON J T M, PEI Y T. Mechanical behavior and failure mechanism of resistance spot welded DP1000 dual phase steel [J]. Materials and Design, 2017, 124: 171–182. DOI: 10.1016/j.matdes. 2017.03.070.

[21] NOH W R, KIM W J, YANG X, KANG M J, LEE M G, CHUNG K S. Simple and effective failure analysis of dissimilar resistance spot welded advanced high strength steel sheets [J]. International Journal of Mechanical Sciences, 2017, 121: 76–89. DOI: 10.1016/j.ijmecsci.2016.12.006.

[22] PAKKANEN J, VALLANT R, KICIN M. Experimental investigation and numerical simulation of resistance spot welding for residual stress evaluation of DP1000 steel [J]. Weld World, 2016, 60(3): 393–402. DOI: 10.1007/s40194- 016-0301-4.

[23] WANG B, DUAN Q Q, YAO G, PANG J C, LI X W, WANG L, ZHANG Z F. Investigation on fatigue fracture behaviors of spot welded Q&P980 steel [J]. International Journal of Fatigue, 2014, 66: 20–28. DOI: 10.1016/j.ijfatigue.2014. 03.004.

[24] TAMIZI M, POURANVARI M, MOVAHEDI M. Welding metallurgy of martensitic advanced high strength steels during resistance spot welding [J]. Science and Technology of Welding and Joining, 2017, 22(4): 327–335. DOI: 10.1080/13621718.2016.1240979.

[25] POURANVARI M. Understanding the factors controlling the interfacial failure strength of advanced high-strength steel resistance spot welds: Hardness vs fracture toughness [J]. Science and Technology of Welding and Joining, 2018, DOI: 10.1080/13621718.2017.1421303.

[26] KONG J P, KANG C Y. Effect of alloying elements on expulsion in electric resistance spot welding of advanced high strength steels [J]. Science and Technology of Welding and Joining, 2016, 21(1): 32–42. DOI: 10.1179/ 1362171815Y.0000000057.

[27] KHAN M I, KUNTZ M L, ZHOU Y. Effects of weld microstructure on static and impact performance of resistance spot welded joints in advanced high strength steels [J]. Science and Technology of Welding and Joining, 2008, 13(3): 294–304. DOI: 10.1179/174329308X271733.

[28] WEI S T, LIU R D, LV D, LIN L, XU R J, GUO J Y, WANG K Q, LU X F. Weldability and mechanical properties of similar and dissimilar resistance spot welds of three-layer advanced high strength steels [J]. Science and Technology of Welding and Joining, 2015, 20(1): 20–26. DOI: 10.1179/ 1362171814Y.0000000250.

[29] LOPEZ-CORTEZ V H, REYES-VALDES F A. Understanding resistance spot welding of advanced high-strength steels [J]. Welding Journal, 2008, 87(12): 36–40. http://citeseerx.ist.psu.edu/viewdoc/download?doi= 10.1.1.453.1689&rep=rep1&type=pdf.

[30] HAN Z, INDACOCHEA J E, CHEN C H, BHAT S. Weld nugget development and integrity in resistance spot welding of high-strength cold-rolled sheet steels [J]. Welding Journal, 1993, 72: 209–216. https://app.aws.org/wj/supplement/WJ_ 1993_05_s209.pdf.

[31] TUMULURU M. Resistance spot welding of coated high- strength dual-phase steels[J]. Welding Journal, 2006, 85(8): 31–37. https://www.a-sp.org/~/media/Files/Autosteel/Great% 20Designs%20in%20Steel/GDIS%202006/35%20-%20Resistance%20Spot%20Welding%20of%20Coated%20High%20Strength%20Dual%20Phase%20Steels.pdf.

[32] VANIMISETTI S K, SIGLER D R. Improving fatigue performance of spot welds in advanced high-strength steels [J]. Welding Journal, 2014, 93(5): 153–161. https://www. researchgate.net/publication/279036854_Improving_Fatigue_Performance_of_Spot_Welds_in_Advanced_High-Strength_Steels.

[33] RADAKOVIC D J, TUMULURU M. An evaluation of the cross-tension test of resistance spot welds in high-strength dual-phase steels [J]. Welding Journal, 2012, 91(1): 8–15. http://files.aws.org/wj/supplement/WJ_2012_ 01_s8.pdf.

[34] HERNANDEZ B V H, KUNTZ M L, KHAN M I, ZHOU Y. Influence of microstructure and weld size on mechanical behaviour of dissimilar ahss resistance spot welds [J]. Science and Technology of Welding and Joining, 2008, 13(8): 769–776. DOI: 10.1179/136217108X325470.

[35] POURANVARI M, MOUSAVIZADEH S M, MARASHI S P H, GOODARZI M, GHORBANI M. Influence of fusion zone size and failure mode on mechanical performance of dissimilar resistance spot welds of AISI 1008 low carbon steel and DP600 advanced high strength steel [J]. Materials and Design, 2011, 32(3): 1390–1398. DOI: 10.1016/j.matdes. 2010.09.010.

[36] SAFANAMA D S, MARASHI S P H, POURANVARI M. Similar and dissimilar resistance spot welding of martensitic advanced high strength steel and low carbon steel: metallurgical characteristics and failure mode transition [J]. Science and Technology of Welding and Joining, 2012, 17(4): 288–294. DOI: 10.1179/1362171812Y.0000000006.

[37] POURANVARI M. Susceptibility to interfacial failure mode in similar and dissimilar resistance spot welds of DP600 dual phase steel and low carbon steel during cross-tension and tensile-shear loading conditions [J]. Materials Science and Engineering A, 2012, 546: 129–138. DOI: 10.1016/ j.msea.2012.03.040.

[38] KHAN M S, BHOLE S D, CHEN D L, BIRO E, BOUDREAU G, DEVENTER J V. Welding behaviour, microstructure and mechanical properties of dissimilar resistance spot welds between galvannealed HSLA350 and DP600 steels [J]. Science and Technology of Welding and Joining, 2009, 14(7): 616–625. DOI: 10.1179/ 136217109X12464549883295.

[39] WEI S T, LV D, LIU R D, LIN L, XU R J, GUO J Y, WANG K Q. Similar and dissimilar resistance spot welding of advanced high strength steels: Welding and heat treatment procedures, structure and mechanical properties [J]. Science and Technology of Welding and Joining, 2014, 19(5): 427–435. DOI: 10.1179/1362171814Y.0000000211.

[40] NOH W, KIM W, YANG X, KANG M, LEE M G, CHUNG K. Simple and effective failure analysis of dissimilar resistance spot welded advanced high strength steel sheets [J]. International Journal of Mechanical Sciences, 2017, 121: 76–89. DOI: 10.1016/j.ijmecsci.2016.12.006.

[41] ASTM E8/E8M-16a. Standard Test Methods for Tension Testing of Metallic Materials [S]. ASTM International, West Conshohocken, PA, 2016, www.astm.org. DOI: 10.1520/ E0008_E0008M-16A.

[42] AWS D8.9M:2012. An American National Standard. Test Methods for Evaluating the Resistance Spot Welding Behavior of Automotive Sheet Steel Materials [S]. https://pubs.aws.org/p/1067/d89m2012-test-methods-for-evaluating-the-resistance-spot-welding-behavior-of-automotive-sheet-steel-materials.

[43] KUCEROVA L, OPATOV K, JANDOV

K, JANDOV A. Metallography of AHSS steels with retained austenite [EB/OL]. [2017-06-28]. http//www.microscopy7.org/book/ 455-463.pdf.

A. Metallography of AHSS steels with retained austenite [EB/OL]. [2017-06-28]. http//www.microscopy7.org/book/ 455-463.pdf.

[44] DANCETTE S, FABR GUE D, MASSARDIER V, MERLIN J, DUPUY T, BOUZEKRI M. Experimental and modeling investigation of the failure resistance of Advanced High Strength Steels spot welds [J]. Engineering Fracture Mechanics, 2011, 78(10): 2259–2272. DOI: 10.1016/ j.engfracmech.2011.04.013.

GUE D, MASSARDIER V, MERLIN J, DUPUY T, BOUZEKRI M. Experimental and modeling investigation of the failure resistance of Advanced High Strength Steels spot welds [J]. Engineering Fracture Mechanics, 2011, 78(10): 2259–2272. DOI: 10.1016/ j.engfracmech.2011.04.013.

[45] ZHANG W. Design and implementation of software for resistance welding process simulations [J]. SAE Technical Papers, 2003, 112: 105–113. DOI: 10.4271/2003-01-0978.

[46] SAHA D C, CHANG I, PARK Y-D. Heat-affected zone liquation crack on resistance spot welded TWIP steels [J]. Materials Characterization, 2014, 93: 40–51. DOI: 10.1016/ j.matchar.2014.03.016.

[47] British Iron and Steel Research Association, Metallurgy (General) Division, Thermal Treatment Sub-Committee. Physical constants of some commercial steels at elevated temperatures: Based on measurements made at the National Physical Laboratory [M]. London: Teddington. Butterworth, 1953.https://trove.nla.gov.au/work/19508921?selectedversion=NBD4026909.

[48] SMITHELLS C J, BRANDES E A, BROOK G B. Smithells Metals Reference Book [M]. 7th Ed. Oxford: Butterworth- Heinemann, 1992. http://pmt.usp.br/academic/martoran/notas solidificacao/Smithells%20Metals%20Reference%20Book%207e.pdf.

[49] PEET M J, HASAN H S, BHADESHIA H K D H. Prediction of thermal conductivity of steel [J]. International Journal of Heat and Mass Transfer, 2011, 54(11, 12): 2602–2608. DOI: 10.1016/j.ijheatmasstransfer.2011.01.025.

[50] WILZER J, LUDTKE F, WEBER S, THEISEN W. The influence of heat treatment and resulting microstructures on the thermophysical properties of martensitic steels [J]. Journal of Materials Science, 2013, 48(24): 8483–8492. DOI: 10.1007/s10853-013-7665-2.

[51] GHOSH R N. Structural steel II [L]. Lecture 39, Indian Institute of Technology Kharagpur. [2017-08-11]. http:// nptel.ac.in/courses/113105023/Lecture39.pdf.

[52] GIBSON J L, JIM NEZ C, GARC

NEZ C, GARC A DE ANDR

A DE ANDR S C, DAN

S C, DAN N C A, LUPPO M I. Evaluation of the Abnormal Grain Growth in an ASTM 213 Grade T91 Steel [J]. Procedia Materials Science, 2015, 8: 1118–1126. DOI: 10.1016/ j.mspro.2015.04.175.

N C A, LUPPO M I. Evaluation of the Abnormal Grain Growth in an ASTM 213 Grade T91 Steel [J]. Procedia Materials Science, 2015, 8: 1118–1126. DOI: 10.1016/ j.mspro.2015.04.175.

[53] KLUEH R L. Elevated-temperature ferritic and martensitic steels and their application to future nuclear reactors [J]. International Materials Review, 2005, 50(5): 287–310. DOI: 10.1179/174328005X41140.

[54] MAROPOULOS S, KARAGIANNIS S, RIDLEY N. Factors affecting prior austenite grain size in low alloy steel [J]. Journal of Materials Science, 2007, 42(4): 1309–1320. DOI: doi.org/10.1007/s10853-006-1191-4.

[55] YAN P, BHADESHIA H K D H. The austenite–ferrite transformation in enhanced-niobium, low-carbon steel [J]. Materials Science and Technology, 2015, 31(9): 1066–1076. DOI: 10.1179/1743284714Y.0000000673.

[56] ZENER C. Grains, phases, and interfaces: An interpretation of microstructure [J]. Transactions of the AIME, 1949, 175: 15–51.

[57] LECHUCK S J. A study of austenite grain growth in a Ti-Nb HSLA steel [D]. The University of British Columbia, 2000. https://open.library.ubc.ca/media/download/pdf/831/1.0078671/2.

[58] OIKAWA T, ENOMOTO M. Distribution of carbide particles and its influence on grain growth of ferrite in Fe-C alloys containing B and V [C]// 1st International Conference on 3D Materials Science. Seven Springs, Pennsylvania, USA. 2012: 107–112. DOI: 10.1007/978-3-319-48762-5_16.

[59] OIKAWA T, ZHANG J J, ENOMOTO M, ADACHI Y. Influence of carbide particles on the grain growth of ferrite in an Fe–0.1C–0.09V alloy [J]. ISIJ International, 2013, 53(7): 1245–1252. DOI: 10.2355/isijinternational.53.1245.

[60] PERSSON E. An investigation on steel grades 100Cr6 and 100CrMnMoSi8-4-6 [R]. Degree project in Materials design and engineering Second cycle Stockholm, Sweden, 2014.

[61] GLADMAN T, PICKERING F B. Grain coarsening of austenite [J]. Journal of the Iron and Steel Institute, 1967, 205: 653–664.

[62] KUNDU A. Austenite grain boundary pinning during reheating by mixed AlN and Nb(C,N) particles [J]. ISIJ International, 2014, 54(3): 677–684. DOI: 10.2355/ isijinternational.54.677.

[63] GOODARZI M, MARASHI S P H, POURANVARI M. Dependence of overload performance on weld attributes for resistance spot welded galvanized low carbon steel [J]. Journal of Materials Processing Technology, 2009, 209(9): 4379–4384. DOI: 10.1016/j.jmatprotec.2008.11.017.

[64] OZTURK YILMAZ I, BILICI A Y, AYDIN H. An investigation into the effect of welding parameters on mechanical properties of dissimilar resistance spot welded DP1000–QP1180 steel joints [C]// The Proceedings of Third International Iron and Steel Symposium. Karabuk: UDCS’17, 2017: 391–395.

[65] ZHOU M, ZHANG H, HU S J. Relationships between quality and attributes of spot welds [J]. Welding Journal, 2003, 82: 72–77. http://ca.brainboxusa.info/downloads/ reference/Relationships_Between_Quality_and_Attributes_ of _Spot_Welds.pdf.

[66] KRAJCARZ F, GOURGUES-LORENZON A F, LUCAS E, PINEAU A. Fracture toughness of the molten zone of resistance spot welds [J]. International Journal of Fracture, 2013, 181(2): 209–226. DOI: 10.1007/s10704-013-9836-1.

(Edited by HE Yun-bin)

中文导读

电阻点焊异质DP1000–QP1180钢板的组织和力学性能

摘要:研究了焊接参数对电阻点焊DP1000–QP1180异质接头组织和力学性能的影响。QP1180侧的热影响区宽度比DP1000侧的小。热影响区的宽度和压痕深度随着焊接电流增大和焊接时间的延长而增大。熔核尺寸随着焊接电流的增大而增大,但在低电流条件下,熔核尺寸随着焊接时间的延长而增大,在高电流条件下,熔核尺寸随着焊接时间的延长而减小。DP1000侧的硬度最低。在QP1180侧,热影响区中心硬度最高。随着焊接电流的增大,焊缝区硬度降低,拉伸剪切载荷增大。在较低的焊接电流下,焊接时间对拉伸剪切载荷没有影响。伸长率随焊接时间的延长而减小,而焊接电流与伸长率之间没有关系。强度较高的点焊接头具有较强的韧性断裂特性。

关键词:DP1000钢;QP1180钢;电阻点焊;微观结构;力学性能

Foundation item: Project supported by Beycelik Gestamp Inc., Turkey

Received date: 2017-12-21; Accepted date: 2018-06-06

Corresponding author: Hakan AYDIN, PhD, Associate Professor; Tel: +90-224-2940652; E-mail: hakanay@uludag.edu.tr; ORCID: 0000-0001-7364-6281