DOI: 10.11817/j.issn.1672-7207.2016.02.011

Cr12MoV冷作模具钢渗铬层界面能谱分析

张垒,孔德军

(常州大学 机械工程学院, 江苏 常州,213164)

摘要:采用粉末法对Cr12MoV冷作模具钢进行渗铬处理,通过SEM,XRD和EDS等手段对渗铬层表面-界面形貌、物相组成和化学元素线能谱、面能谱扫描进行分析,探讨渗铬层组织结构和元素变化。研究结果表明:渗铬层由沉积层和扩散层构成,Cr和C原子在沉积层相互结合,形成铬碳化物Cr23C6相,在一定程度上抑制Cr原子的扩散和O原子的侵蚀;扩散层内Cr和Fe原子相互渗透,形成Fe-Cr固溶体相。

关键词:Cr12MoV钢;渗铬处理;线能谱;面能谱

中图分类号:TG156.8+8;O657.62 文献标志码:A 文章编号:1672-7207(2016)02-0430-06

Energy spectrum analysis of chromized coating interface for Cr12MoV cold working die steel

ZHANG Lei, KONG Dejun

(College of Mechanical Engineering, Changzhou University, Changzhou 213164, China)

Abstract: The surface of Cr12MoV cold working die steel was chromized with powder method, the surface-interface morphologies, phase components and line scan and plane scan of chromized interface were analyzed with SEM, EDS and XRD respectively, and the changes of structure and elements of chromized layer were discussed. The results show that the chromized layer is composed of sediment and diffusion layers, of which the atoms of Cr and C are combined mutually to form chromium carbide phase of Cr23C6, preventing the diffusion of Cr and the erosion of O to a certain degree. The elements of Cr and Fe are diffused into each other in the diffusion layer to form the solid solution phase of Fe-Cr.

Key words: Cr12MoV steel; chromizing treatment; line scan; plane scan

Cr12MoV钢是一种高碳高铬的冷作模具钢[1],具有较好的韧性、耐磨性及淬透性,在冷冲、冷压等形状复杂模具方面有较为广泛的应用[2]。经锻造的钢组织以铁素体和马氏体为主,弥散分布着能提高硬度和耐磨性能的Cr3C2,在最后冷凝过程中容易产生网状共熔Cr3C2和奥氏体,这些网状共熔混合物降低了Cr12MoV钢韧性、抗冲击性和弯曲强度等力学性能[3]。在模具成型、分离过程中,坯料与模具工作面之间会发生强烈的冲击与相互摩擦,致使模具发生磨损失效[4],因此,一般需要对其进行表面强化处理。常见的强化处理方法有渗碳、渗氮、渗硼及预热淬火处理等。其中渗碳与渗硼的共同缺点是渗层脆性较高,厚度不够,渗硼层在工作过程中易发生脱落[5]。为降低渗铬温度,近年来出现了一些复合渗铬工艺,采用先渗氮再渗铬的方法,提高铬的吸收效率,使得在短时间内形成致密的渗铬层,降低热处理变形[6]。目前国内外学者对Cr12MoV钢的强化研究主要集中在渗硼工艺的优化、宽带激光强化、离子注入技术、离子束热处理和涂层等方面[7-9],对于渗铬层界面能谱研究鲜见报道。本文作者对Cr12MoV模具钢渗铬层表面与界面进行了SEM分析,对渗铬层界面进行线能谱和面能谱分析,为改进渗铬工艺和Cr12MoV模具钢表面性能提供实验基础。

1 实验

实验材料为Cr12MoV模具钢,其化学成分(质量分数,%)为:C 1.45~1.70,Si 0.4,Mn 0.40,Cr 11.00~12.50,Mo 0.40~0.60,V 0.15~0.30,其余为Fe。采用粉末法对试样进行渗铬处理,渗剂由50%铬粉(含Cr量98%)+48%Al2O3(填充剂)+2%NH4Cl(催化剂)组成。将试样与渗剂装入渗铬箱后,经300 ℃烘烤40~60 min,然后用水玻璃耐火泥封住箱盖,放入保温炉中在1 100 ℃下保温12 h后,随炉冷却至600 ℃取出空冷,即得实验所需试样。用JSUPRA55型场发射扫描电子显微镜观察试样表面与界面形貌,并用其配置的能谱分析仪对渗铬层表面与界面化学元素分布进行表征,并用D/max2500PC型X线衍射分析渗铬层物相组成。

2 分析与讨论

2.1 表面与界面形貌

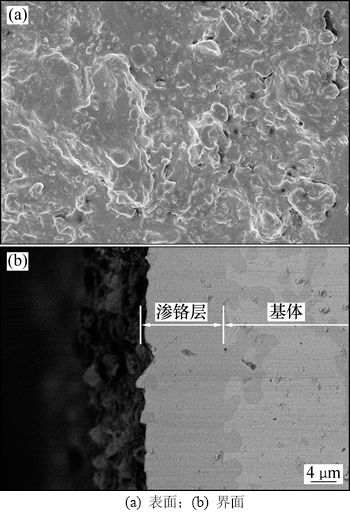

图1所示为渗铬后表面-界面形貌。由图1(a)可见:渗铬层表面呈银灰色,且比较平整,沉积的铬碳化物颗粒和粒径分布均匀。渗铬层界面形貌如图1(b)所示,存在着完整的浅灰色界面,厚度约为10 μm。渗层内部无明显的渗透缺陷和杂质颗粒,具有较好的连续性和致密性。

图1 渗铬后表面-界面形貌

Fig. 1 Surface-interface morphologies after chromizing

渗层与基体过渡段之间有明显的扩散区域,且成块状扩散,深度不一,主要与保温时间和局部C原子摩尔分数有关。其深度δ与保温时间t满足下列关系[10]:

(1)

(1)

其中:DC为扩散常数; 为基体中C原子摩尔分数;

为基体中C原子摩尔分数; 为扩散区C原子摩尔分数;

为扩散区C原子摩尔分数; 为渗铬层中C原子摩尔分数。

为渗铬层中C原子摩尔分数。

由式(1)可知:在基体与扩散区C原子摩尔分数变化不大时,渗铬层C原子摩尔分数增加比较缓慢,合理地控制保温时间t可以获到较深的Cr扩散层。

2.2 EDS与XRD分析

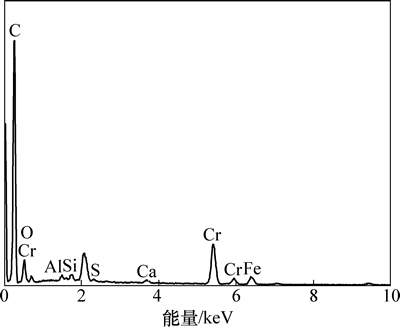

图2所示为渗铬层表面EDS谱。其质量分数为:C 68.34%,O 13.48%,Al 0.30%,Si 0.23%,S 0.16%,Ca 0.30%,Cr 12.33%,Fe 4.86%。渗铬层中C和Cr原子含量较高,说明基体中C原子在高温环境下向试样表面发生了迁移,在表面形成一层富碳层,其中部分C原子与渗入表面的Cr原子结合形成铬碳化物。在高温还原气氛下试样表层Fe原子一部分与渗剂发生置换反应而消耗,另一部分与铬碳化物结合形成Fe-Cr置换固溶体和(Cr,Fe)碳化物相,导致Fe原子间隙变大,加速Cr原子的渗入,同时,也会导致一些杂质原子的渗入。

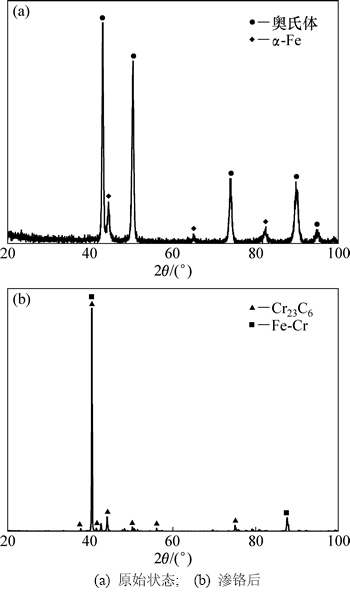

图3所示为渗铬层XRD谱。由图3(a)可见:渗铬前试样表面是由奥氏体相和马氏体等α-Fe相构成,奥氏体溶碳能力强,故试样中碳含量较高。由于奥氏体相属于亚稳定相,经过渗铬后易发生分解[11],其中C与Cr原子作用形成较为稳定的铬碳化物Cr23C6,如图3(b)所示。由于Fe与Cr原子直径数量级相同,渗入试样表面的Cr原子在高温固溶作用下,代替了原Fe相中晶格空位和质点,形成Fe-Cr置换固溶体。随着渗铬的继续进行,Cr原子不断向基体内部渗透,使得沉积层不断增厚,在该区域内由于基体内部C原子的不断迁移而形成富碳区[12],其中一部分C原子溶解入Fe-Cr固溶体,形成结构更为复杂的(Cr,Fe)碳化物相,其物相分析与图2中元素含量分析结果基本一致。

图2 渗铬层EDS谱

Fig. 2 EDS pattern of chromized layer

图3 渗铬层XRD谱

Fig. 3 XRD patterns of chromized layer

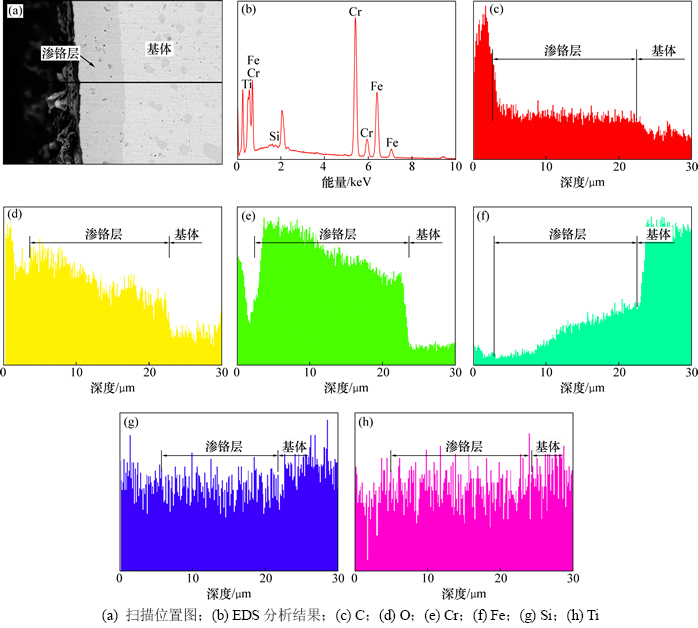

2.3 界面线能谱分析

图4(a)所示为渗铬层界面线能谱扫描位置,其扫描结果如图4(b)所示。元素质量分数为:C 41.15%, O 6.05%,Cr 21.21%,Fe 31.33%,Si 0.19%,Ti 0.07%。渗铬层主要由Cr,C和Fe元素组成,同时并含有少量的Ti和Si等元素。Si和Ti原子作为碳化物的稳定剂加入到渗剂中,有利于渗铬层厚度的增加。C和Cr原子含量的增加说明了渗层中沉积较高含量的铬碳化物。由图4(c)可见:C原子在渗铬层中含量高于基体,这表明在渗铬过程中基体内部C原子向渗铬层发生了迁移。由基体沿渗层向外方向,C与Cr原子呈逐渐上升趋势,至渗层内部趋于平衡,如图4(c)和(e)所示,这表明渗铬层内中存在着大量铬碳化物。在渗层与基体界面处2种原子扩散区含量均呈上升趋势,但C原子上升较为平缓(图4(c)),说明C原子在向渗层迁移时速率较慢,基体与渗铬层之间没有出现较大的浓度差。这是由于Cr12MoV钢属于高碳钢,含C量较高,同时基体中C原子不断向表面迁移,提供了足够的C原子与Cr原子结合。因此,渗铬层扩散区不会出现低碳钢渗铬时产生的贫碳区,而是呈现C原子的缓慢增长趋势。由图4(d)可见:渗铬层由表及里O原子含量逐渐降低,且幅度较小,至渗层界面处陡降至极低的水平,说明渗铬后能有效地提高材料高温氧化性能[13],并能有效地阻碍O原子对基体的侵蚀。Cr原子在渗铬层扩散区含量变化较大,如图4(e)所示,表明Cr原子通过铬碳化物沉积层后向内扩散能力较弱,且越往内越难扩散。Cr原子从渗层表面到内部呈现平缓下降趋势,最大含量出现在表面,这种变化趋势与活性Cr供应能力有关。在渗铬初始阶段,渗铬层较薄,有足够的活性Cr进入基体,在表面形成铬碳化物。随着渗铬层的增厚,活性Cr原子越来越少,其扩散速度和含量也相应地逐渐降低。当渗铬层达到一定厚度后,活性Cr原子几乎不存在,其扩散速率和含量出现急速下降趋势。图4(f)显示了渗铬层Fe原子含量极低,越接近渗层表面其含量越低,这是由于高碳钢渗铬初期渗入的活性Cr含量极高,发生置换反应消耗了大量Fe原子。由图4(e)和(f)可知:渗铬层内部Cr原子含量的变化趋势与Fe原子基本相反,但较为平缓,至界面处才出现陡降和陡升,表明渗铬速率适中,渗铬层组织结构也比较致密均匀,不存在原子聚集或分布不均匀等现象。由图4(g)和(h)中Si和Ti原子分布可知:渗铬层中O元素主要以SiO2和TiO2的形式存在,起到稳定铬碳化物和增加渗层厚度的作用[14],其中表面O原子含量最高,主要是由于渗剂中Cr粉和CrCl4表面氧化膜被还原而残留在渗层表面所致。Si和Ti原子在渗铬层中含量均保持在一个恒定的水平,表明这2种原子在渗铬过程中没有发生扩散现象。

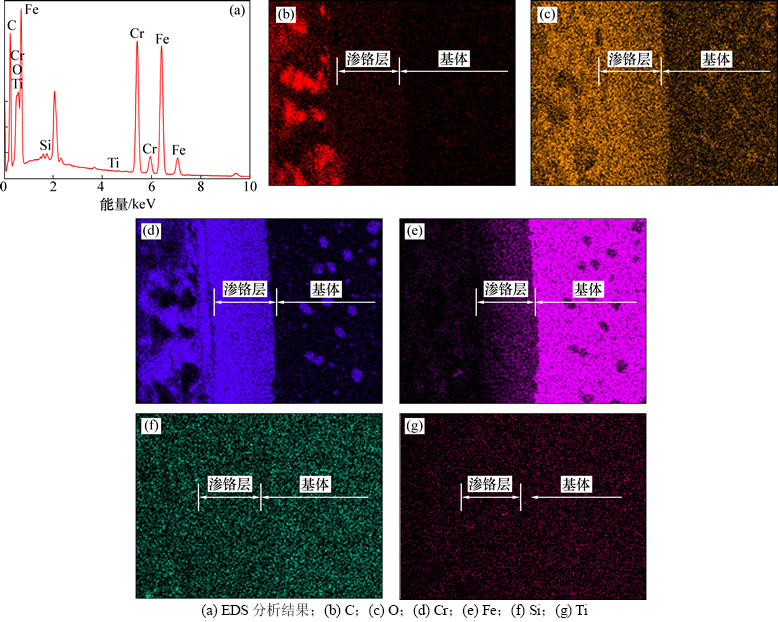

2.4 界面面能谱分析

图5(a)所示为图4(a)中扫描位置的面能谱分析结果。元素质量分数为:C 25.71%,O 3.31%,Cr 22.94%,Fe 47.72%,Si 0.22%,Ti 0.10%。渗铬层界面主要由Cr,C和Fe等元素组成,并含有少量的Ti,Si和O等元素,与界面线能谱分析结果一致。由图5(b)和(c)可见:C和O原子出现分层富集现象,其中C原子在渗铬层与基体交界处未出现含量突变现象,表明基体中C原子向渗铬层迁移率较低。两侧之间没有形成过大的浓度落差,也没有出现因迁移速率过高而出现的贫碳区,其存在形式为铬碳化物。图5(c)中O原子主要富集在渗铬层一侧,存在形式为Si和Ti的氧化物以及少量作为渗剂填充剂的Al2O3。基体与渗铬层间O原子浓度落差明显,说明渗铬层能有效地阻隔O原子对基体的侵蚀。渗铬层中Cr和Fe原子出现了非常明显的分层富集现象,在渗铬层中观察到Cr原子含量在靠近表面一侧高于靠近基体一侧,如图5(d)所示,这表明渗铬层中铬碳化物对Cr原子扩散起到抑制作用。由图5(e)可见:Fe原子在基体一侧出现富集区,越靠近渗铬层表面Fe原子含量越低,至渗铬层表面几乎不存在Fe原子,其原子分布规律与Cr原子分布规律相反,说明表层渗铬质量较好,未出现其他原子干扰渗铬反应。在渗铬层深处由于Cr23C6等铬碳化物的抑制和阻隔作用,加之缺少还原气氛且Cr原子活性大大降低,导致置换和还原反应难以发生,Fe原子含量有所提高。图5(f)和图5(g)分别考察了Si和Ti原子在界面处分布情况,2种原子在渗铬层界面都表现为弥散分布,未出现富集现象。

图4 渗铬后界面线扫描分析结果

Fig. 4 Line scan analysis results of chromized layer interface

3 结论

1) Cr12MoV钢表面渗铬处理后渗铬层组织主要为铬碳化物Cr23C6和Fe-Cr固溶体,其界面分为沉积层和扩散层。

图5 渗铬后界面面扫描分析结果

Fig. 5 Plane scan analysis results of chromized layer interface

2) Cr12MoV钢表面渗铬层中产生的Cr23C6对Cr的持续渗透有一定抑制作用,能有效地阻隔O原子进入基体内部,基体中C原子向渗铬层发生缓慢迁移现象,其他原子的面分布均匀。

参考文献:

[1] KHEIRANDISH S, SAGHAFIAN H, HEDJAZI J, et al. Effect of heat treatment on microstructure of modified cast AISI D3 cold work tool steel [J]. Journal of Iron and Steel Research, International, 2010, 17(9): 40-45, 52.

[2] LIN Naiming, XIE Faqin, ZOU Jiaojuan, et al. Application of artificial neural network in predicting the thickness of chromizing coatings on P110 steel[J]. Journal of Wuhan University of Technology (Materials Science Edition), 2013, 28(1): 196-201.

[3] MOMENI M, KHEIRANDISH S, SAGHAFIAN H, et al. Effects of heat treatment on mechanical properties of modified cast AISI D3 tool steel[J]. Materials and Design, 2014, 54: 742-747.

[4] 陶立民, 孙文娟, 陈继超, 等. Cr12MoV钢等离子体氮碳共渗工艺及稀土催渗[J]. 材料热处理学报, 2013, 34(5): 158-163.

TAO Limin, SUN Wenjuan, CHEN Jichao, et al. Process parameters and effect of rare earth element on plasma nitrocarburzing of Cr12MoV steel[J]. Transactions of Materials and Heat Treatment, 2013, 34(5): 158-163.

[5] 赵彦辉, 巴宏波, 郎文昌. 电弧等离子体辅助渗氮处理Cr12MoV钢的组织结构及硬度[J]. 材料热处理学报, 2012, 33(S2): 151-154.

ZHAO Yanhui, BA Hongbo, LANG Wenchang, et al. Microstructure and hardness of Cr12MoV steel treated by arc plasma-assisted nitriding process[J]. Transactions of Materials and Heat Treatment, 2012, 33(S2): 151-154.

[6] 曹辉亮, 罗承萍, 刘江文, 等. 20钢复合渗铬生长纳米结构Cr2N/CrN层[J]. 材料热处理学报, 2008, 29(4): 135-139.

CAO Huiliang, LUO Chengping, LIU Jiangwen, et al. Formation of nanostructured Cr2N/CrN layer on plain 20 carbon steel by duplex chromizing process[J]. Transactions of Materials and Heat Treatment, 2008, 29(4): 135-139.

[7] SAKLAKOGLU N, SAKLAKOGLU I E, CEYHUN V, et al. Sliding wear behaviour of Zr-ion-implanted D3 tool steel[J]. Tribology International, 2007, 40(5): 794-799.

[8] SONG R G, ZHANG K, CHEN G N. Electron beam surface treatment. Part I: surface hardening of AISI D3 tool steel[J]. Vacuum, 2003, 69: 513-516.

[9] CAICEDO J C, YATE L, MONTES J. Improving the physicochemical surface properties on AISI D3 steel coated with Ti-W-N[J]. Surface & Coatings Technology, 2011, 205(8): 2947-2953.

[10] 孔德军, 周朝政, 吴永忠. TD处理制备VC涂层-基体元素扩散与界面特征[J]. 材料热处理学报, 2012, 33(8): 140-146.

KONG Dejun, ZHOU Chaozheng, WU Yongzhong. Element diffusion and interface characteristics of VC coating on die steel prepared by TD process[J]. Transactions of Materials and Heat Treatment, 2012, 33(8): 140-146.

[11] 伍翠兰, 元敏, 陈汪林, 等. 20钢渗氮表面500 ℃盐浴渗铬层微观组织结构研究[J]. 湖南大学学报(自然科学版), 2010, 37(9): 60-64.

WU Cuilan, YUAN Min, CHEN Wanglin. Microstructure of the composite chromized layer on 0.2 wt % steel after 500 ℃ salt-bath chromizing[J]. Journal of Hunan University (Natural Sciences), 2010, 37(9): 60-64.

[12] L Shoudan, WANG Zhenbo, LU Ke. Chromizing treatment of the surface-nanocrystallized AISI H13 steel and the improved wear resistance[J]. Baosteel Technical Research, 2010, 4(4): 22-27.

Shoudan, WANG Zhenbo, LU Ke. Chromizing treatment of the surface-nanocrystallized AISI H13 steel and the improved wear resistance[J]. Baosteel Technical Research, 2010, 4(4): 22-27.

[13] SUN Jianfeng, ZHOU Yuebo, ZHANG Haijun. Preparation and oxidation behavior of a novel CeO2-modified chromizing coating[J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 1375-1381.

[14] LIN Naiming, XIE Faqin, ZHONG Tao, et al. Influence of adding various rare earths on microstructures and corrosion resistance of chromizing coatings prepared via pack cementation on P110 steel[J]. Journal of Rare Earths, 2010, 28(2): 301-304.

[15] LEE SY, KIM GS, KIM B S. Mechanical properties of duplex layer formed on AISI 403 stainless steel by chromizing and boronizing treatment[J]. Surface and Coatings Technology, 2004, 177/178: 178-184.

(编辑 陈爱华)

收稿日期:2015-03-28;修回日期:2015-06-07

基金项目(Foundation item):江苏省科技支撑计划项目(BE2014818)(Project (BE2014818) supported by the Jiangsu Province Science and Technology Program)

通信作者:孔德军,博士,教授,从事材料改性处理与摩擦磨损研究;E-mail:kong-dejun@163.com