DOI: 10.11817/j.ysxb.1004.0609.2020-35890

自然时效Al-Zn-Mg合金团簇长大动力学及其变形断裂特性

史坤坤1, 2,赵小龙1, 2,张 鹏1, 2,匡 杰1, 2,张金钰1, 2,刘 刚1, 2,孙 军1, 2

(1. 西安交通大学 材料科学与工程学院,西安 710049;

2. 西安交通大学 金属材料强度国家重点实验室,西安 710049)

摘 要:利用电导率、显微硬度和宏观拉伸测试,结合SEM、TEM、APT和XRD等表征手段对Al-Zn-Mg合金中的团簇长大动力学以及团簇对合金变形断裂的影响进行了研究。结果表明:Al-Zn-Mg合金经过约1000 h自然时效进入稳定状态,基体中形成了超高密度的Mg-Zn团簇,材料得到有效强化;人工时效态Al-Zn-Mg合金中析出相随高温时效时间的延长发生长大,类型以亚稳η′与稳定η相为主,部分析出相逐渐不可被位错切过。T6/T7态合金小应变下可迅速形成大量位错引起材料强化,但在大应变时会发生剧烈的动态回复,造成其较弱的加工硬化能力与较低的均匀伸长率(约13%);而在T4态Al-Zn-Mg合金中,团簇和溶质原子的存在能有效抑制动态回复,并可在变形时伴生动态应变时效效应,造成材料较强的加工硬化和更优的均匀延伸性能(约25%)。

关键词:Al-Zn-Mg系铝合金;溶质原子团簇;三维原子探针;长大动力学;加工硬化

文章编号:1004-0609(2020)-11-2513-13 中图分类号:TG146.2 文献标志码:A

Al-Zn-Mg合金因其轻质高强、良好的加工性能和可焊接性等特性被广泛应用于航空航天和轨道交通领域[1]。作为典型的可热处理强化铝合金,Al-Zn-Mg合金的力学性能依赖于时效过程中形成的析出相,其主要析出序列为[2]:S.S.S.S→Solute clusters/GP I/GP II → η′→η。传统的热处理手段通过固溶、淬火、单/双级时效在基体中形成大量弥散分布的纳米级亚稳/稳定析出相以达到强化目的,但在峰值时效条件下,合金的应力腐蚀抗力(Stress corrosion resistance)往往较差[3]。为了改善传统工艺合金的短板,追求更优的综合力学性能,一些新的热处理手段如回归再时效(Reversion and re-aging)[4]和断续时效(Interrupted aging)[5]等也被提出。但是,受限于工艺条件或可适用性,上述新型热处理方法在工业实际生产中仍存在诸多问题。

近些年来,铝合金中的团簇强韧化研究引起了学界强烈的兴趣。溶质原子团簇,即溶质原子在基体中形成的纳米/亚纳米级无序聚集区,在Al-Mg-Si、Al-Cu-Mg和Al-Zn-Mg等体系中可引起显著的强化效果,能有效抵抗疲劳裂纹扩展,展现出优异的综合性能。自然时效硬化效应最早由德国人Alfred Wilm报道,他发现杜拉铝(成分近似于AA2024)淬火后室温存放会发生缓慢硬化,最终可获得将近125HB的硬度值,远高于纯铝(15HB) [6]。这种自然时效硬化效应后来被归因于合金中出现的溶质原子团簇/GP区。但是,由于溶质原子团簇极小的尺寸及其与基体高度共格的关系,在20世纪90年代之前,团簇的表征只能通过间接的方式进行,如电阻率测试、硬度测试和差热分析等。近30年来,随着科技的不断进步,材料表征手段也得到飞速地提升,人们可以通过多种方式获得更小尺度的材料信息,由此可以观察团簇的全貌。三维原子探针术(Atom probe tomography, APT)可以揭示合金元素的三维空间分布,通过算法定义并找出团簇,进而获得其尺寸和成分信息[7];双球差矫正扫描透射电镜 (Double cs-corrected STEM)具有优于传统高分辨透射电镜(HRTEM)的空间分辨率,结合高角环形暗场(HAADF)探头,能够利用原子序数衬度(Z衬度)对材料中纳米级局部区域成分变化进行表征[8];小角同步辐射X射线/中子散射(Small-angle scattering, SAS)借助高质量光源,能够在原位或离位条件下定量给出体系中团簇或析出相的尺寸、体积分数等信息进而跟踪其析出动力学[9];正电子湮灭寿命谱(Positron annihilation lifetime spectroscopy, PALS)技术利用正电子在不同类型环境中与电子湮灭释放出的γ光子能量的不同对材料内部缺陷(空位型缺陷以及溶质原子团簇型缺陷)进行表征[10];核磁共振(Nuclear-magnetic resonance, NMR) 技术能够利用原子的核磁矩与其所处的原子环境有关的特性对元素进行区分,最终定量给出某种溶质原子在基体、团簇/GP区和析出相中的分布特征等信息[11]。

研究表明,在传统合金中引入高密度的纳米级团簇或共格析出相是一种行之有效的强韧化手段。SUN等[12]利用室温循环变形引入形变空位加速团簇的形成,在常见的2024、6061、7075三种铝合金中获得了极高密度分布的溶质原子团簇(直径约1~2 nm),使得材料在短时间内获得了可媲美峰时效合金的强度和更优的延伸性能。JIANG等[13]通过调控成分和热处理工艺在马氏体时效钢中获得高密度、与基体完全共格的纳米析出相(平均直径约2.7 nm),从而在不损失延性的情况下获得了超高强钢。此外,钱鹏伟等[14]还发现自然时效处理能一定程度上提高Al-Zn-Mg合金的应力腐蚀开裂阻力,改善其抗应力腐蚀性能。目前,关于铝合金中团簇对材料塑性变形行为的研究报道较少,因此,本文着力探究铝合金中团簇化行为及其对材料变形断裂特性的影响,旨在为未来铝合金的强韧化设计提供新的思路与借鉴。

1 实验

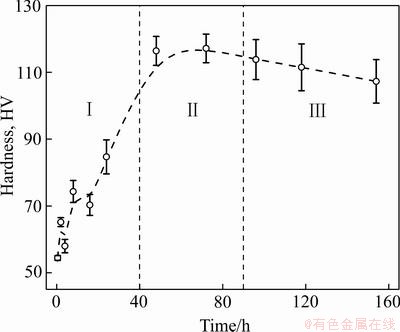

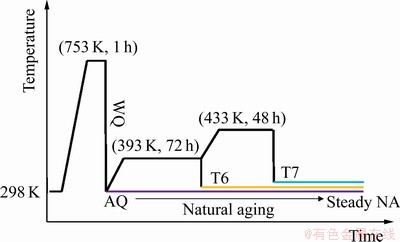

实验所用原材料为15 mm厚7B05铝合金轧制态板材,使用电火花直读光谱仪实测其化学成分为Al-4.75Zn-1.39Mg-0.35Mn-0.32Fe-(Cu, Zr, Si)(质量分数,%)。对该合金进行(480 ℃, 1 h)的固溶淬火处理后,根据120 ℃等温时效硬化曲线(见图1)确定该合金的时效工艺,并采用图2所示的热处理路径分别获得自然时效(T4)、峰时效(T6)、过时效(T7)等不同时效状态的材料。

使用D60K金属电导率测试仪对合金电导率进行测定。样品维氏硬度值使用Buehler Wilson VH3100显微硬度计测量,载荷为300 g,保载时间15 s,每种状态下测量10个位置的硬度值取其平均值。按照ASTM E8标准沿板材RD-TD面制备板状拉伸试样,其标距长度25 mm,截面积为6 mm×4 mm。使用Instron电子拉伸机进行准静态拉伸试验,引伸计标距25 mm,加载速度1.5 mm/min(应变速率为10-3 s-1)。

SEM与XRD样品均经机械打磨至2000#砂纸,然后电解抛光。抛光液为10%高氯酸+90% 乙醇(体积分数,%),抛光电压20 V,抛光温度0 ℃。使用FEI-VERIOS460扫描电镜观察其晶粒组织。TEM样品制备流程为:尺寸为8mm×8 mm×2 mm的金属薄片打磨至约200 μm厚度,然后在冲样台冲孔得到直径3 mm圆片,之后使用双喷电解减薄仪减薄至微量穿孔。双喷液采用高氯酸(体积分数,8%)的甲醇溶液,工作电压10 V,温度25 ℃。使用JEOL-2100 HRTEM观察合金中的团簇与析出相的尺寸及分布信息,工作电压200 keV。

图1 7B05铝合金120 ℃等温时效-硬化曲线

Fig. 1 Isothermal age-hardening curve of 7B05 alloy at 120 ℃(Ⅰ—Under-aged; Ⅱ—Peak-aged; Ⅲ—Over-aged)

图2 热处理工艺流程图

Fig. 2 Schematic diagram of heat-treatment protocol in this work

APT针尖状样品制备方法可参见文献[15]。APT实验在LEAP 4000HR电压脉冲模式下进行,脉冲频率200 kHz,脉冲分数20%,实验温度控制在20 K,真空度<6×10-8 Pa。APT数据重构在IVAS 3.6.8 软件上进行,使用团簇分析工具对以Zn、Mg原子为核心的团簇进行识别计数,近邻原子最大距离dmax=0.5 nm,最少核心原子数Nmin=10,除近邻原子外的其他原子与近邻原子的最大距离L=0.5 nm,剥离距离derosion= 0.1nm。

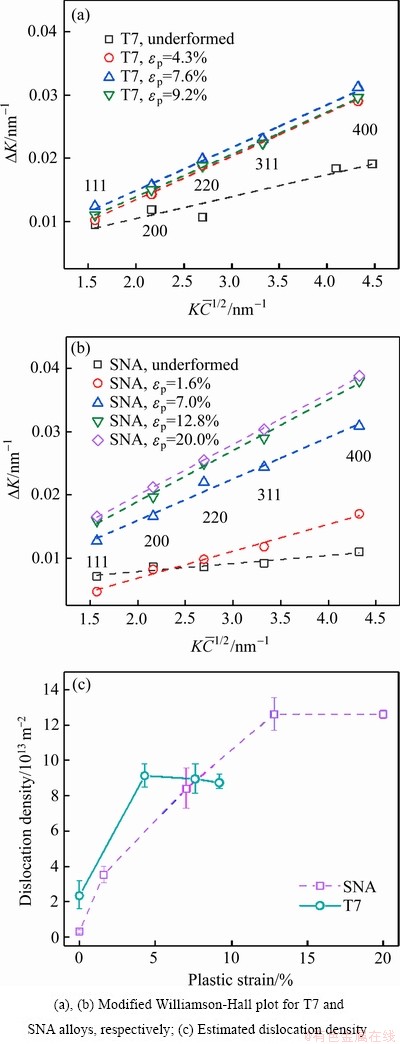

使用Bruker D8 Advance X射线衍射仪对样品进行精扫。衍射仪光源为Cu Kα射线,其中的Kα2部分在使用Jade进行峰拟合时软件去除。2θ角度范围为30°~120°,步长为0.01°,每步停留时间0.2 s。仪器半峰宽化曲线使用标准刚玉(α-Al2O3)样品的XRD曲线绘制与拟合,并在后期数据处理时进行扣除。利用XRD衍射峰宽化数据,采用修正的Williamson-Hall方法,可对合金中的位错密度进行定量表征,见式(1):

(1)

(1)

该方法中的有关参数及其他细节可参见文献[16-17]。

2 结果与分析

2.1 Al-Zn-Mg合金初始微观结构

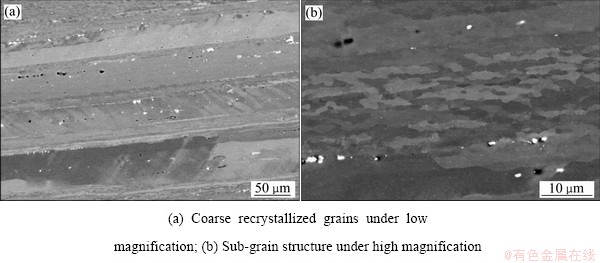

图3所示为合金热处理后的SEM像,可以看出,不同热处理工艺后,合金的晶粒组织并无明显变化,均呈现出粗大的再结晶晶粒与直径3 μm左右亚晶共存的微观组织。此外,初始材料中还含有一些Al-Fe、Al-Si等粗大共晶相颗粒沿轧向链状分布,当前热处理工艺同样不能造成它们尺寸和分布的显著变化。

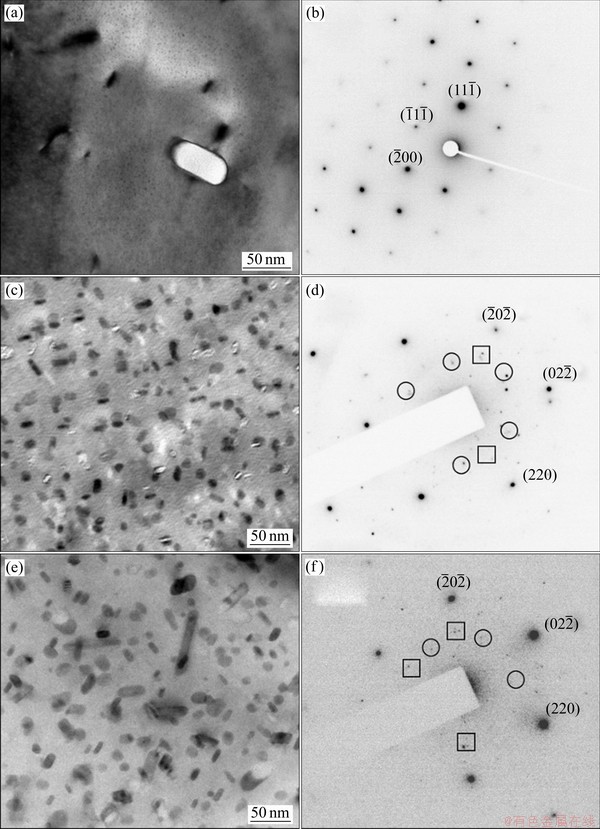

如图4所示,在T4态合金中,TEM明场像中出现了极为细密的微结构特征,其尺寸在2~3 nm左右,衬度较弱。而在T6和T7态样品中,出现了较多的析出相,选区衍射花样表明其主要为亚稳η′析出相和稳定η析出相。析出相呈球状或盘片状,径厚比较低。在峰时效态样品中,析出相的平均半径为6.6 nm,平均厚度为5.6 nm,而在过时效态样品中析出相有所长大,其平均半径和平均厚度分别为9.4 nm和7.3 nm。

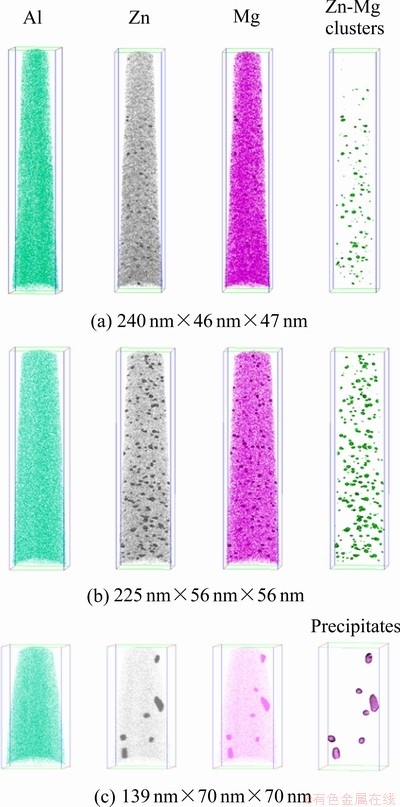

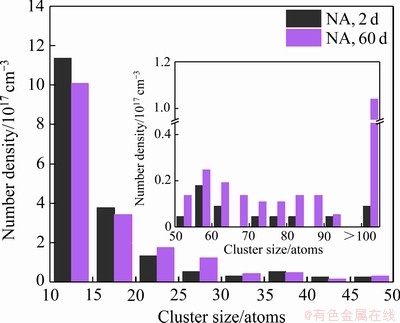

由图5可以看出,在早期自然时效(ENA,自然时效2 d)与稳定自然时效态(SNA,自然时效60 d)样品中,Zn-Mg团簇为该合金中主要的溶质原子团簇类型。如图6所示,对APT数据进行进一步统计发现,对于SNA样品,其团簇的数量密度相比于ENA样品仅略微上升,总体保持在2×1018 cm-3左右。但是,团簇所含的平均原子个数由17.6个原子增长到了25.5个原子,相应的体积分数也获得提升。值得一提的是,随着团簇的不断长大,它们的化学组分也发生了变化。在ENA样品中,团簇中的Zn/Mg比(摩尔比)约为1.05,而在SNA样品中,Zn/Mg比约为1.16。在T7态合金中,微结构以呈椭球/盘片状形貌的析出相为主(见图4(c)),它们的数量密度约为4×1016 cm-3,尺寸与TEM结果相一致,应为η′和η析出相。

2.2 自然时效Al-Zn-Mg合金电导率和硬度变化

铝合金的电导率主要受合金中的缺陷,如溶质原子、空位、团簇、位错以及晶界等的影响,这些缺陷的存在引入了晶格畸变,增加了电子在晶体内部运动时的散射效应,因此降低了合金的电导率[14]。

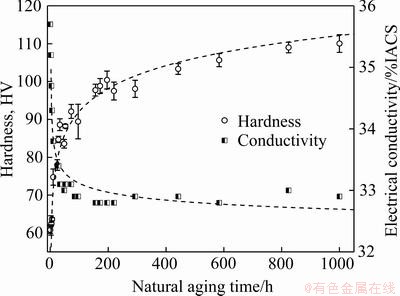

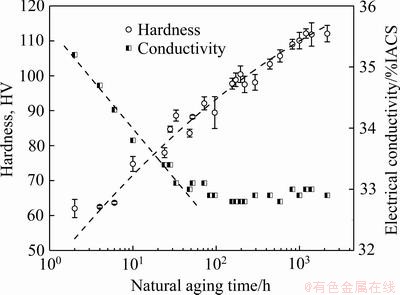

在Al-Zn-Mg合金自然时效过程中,空位浓度远小于溶质原子浓度,并且位错密度基本不变,因此溶质原子和团簇成为影响合金电导率的主要因素。如图7所示,实验发现,Al-Zn-Mg合金经过固溶与淬火处理后,其电导率不断下降,48 h后随即进入平台期,稳定在32.8% IACS左右。

自然时效早期电导率的下降是体系中团簇的形成与长大导致的。在Al-Zn-Mg合金中,由溶质原子团簇引起的电子散射效应强于组成团簇的分散的溶质原子对电子散射作用的总合。但是团簇对材料电学性能的影响方式十分复杂,合金电导率的变化并不总是与团簇的尺寸相关。随着自然时效时间的延长,电导率对于团簇行为不再敏感。前人研究指出,在Al-Zn合金中,基于均匀散射理论,团簇中原子的比电阻率(团簇总电阻率贡献/团簇中原子个数)与团簇的尺寸和成分相关,并在团簇尺寸为数十个溶质原子左右时达到最大。当团簇尺寸继续增长至约1 nm左右时,团簇的长大不会再造成电阻率的净增加[18]。因此,在自然时效48 h左右,7B05合金中的团簇应已经达到一个临界尺寸,此时电阻率的变化不能再继续反映材料内部微结构的演变。

如图7所示,自然时效Al-Zn-Mg铝合金的硬度随着时效时间的延长不断增强,在大约1000 h左右进入平台期,稳定在112HV左右,接近峰值时效硬度值(117HV)。这种强烈的自然时效硬化效应也归因于体系中的团簇强化。该合金的自然时效硬化速率随着时效时间的延长而不断下降,表明了其内部团簇生长速率的不断减缓。

图3 热处理后Al-Zn-Mg合金晶粒结构的SEM像

Fig. 3 SEM images of grain structure in Al-Zn-Mg alloy after heat treatments

图4 不同时效状态试样的TEM明场像及对应的选区电子衍射花样

Fig. 4 TEM bright-field micrographs ((a), (c), (e)) and associated  diffraction patterns ((b), (d), (f)) of T4((a), (b)), T6((c), (d)) and T7((e), (f)) materials (Diffraction spots in open circle and square are related to η′ and η phases, respectively)

diffraction patterns ((b), (d), (f)) of T4((a), (b)), T6((c), (d)) and T7((e), (f)) materials (Diffraction spots in open circle and square are related to η′ and η phases, respectively)

图5 不同时效状态7B05合金试样的三维原子重构图

Fig. 5 Atom probe reconstruction of ENA(a), SNA(b) and T7(c) samples of 7B05 alloys (Clusters are indicated by 9.0% Zn+Mg solute isosurface while precipitates by 7.0% Mg solute isosurface)

图6 ENA与SNA态试样中团簇尺寸-数量密度分布图

Fig. 6 Number densities of Zn-Mg clusters vs cluster size for early natural-aged and steady natural-aged samples

图7 7B05合金自然时效过程中电导率、显微硬度随时间的变化

Fig. 7 Evolutions of electrical conductivity and Vickers hardness of 7B05 alloy with natural aging time

2.3 不同时效态Al-Zn-Mg合金的拉伸力学行为

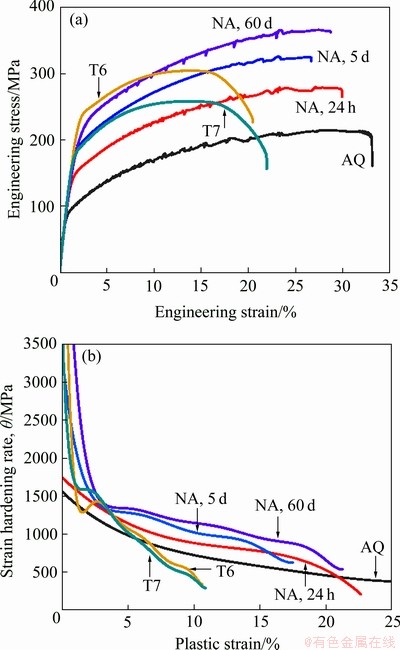

对不同时效状态下的Al-Zn-Mg合金进行了室温拉伸实验,得出的工程应力-应变曲线如图8(a)所示。可以发现,随着自然时效时间的延长,合金的屈服强度不断上升,并在60 d左右时接近峰时效强度。过时效态试样的强度相比峰时效有显著下降。

由于在不同报道中所选取的试样尺寸的不同,受颈缩后应变局部化的影响,很难通过比较断裂伸长率来对比不同工作中的合金塑性。均匀伸长率作为拉伸延性的量度,已经被广泛采用。在本实验中,可观察到团簇在有效提高合金屈服强度的同时,并没有造成其均匀伸长率的显著损失,而是始终维持在25%左右。此外,T4态试样在达到最大拉应力后立即发生断裂失效,未发生明显颈缩。峰时效态试样在近乎同等强度的情况下均匀伸长率仅13%,达到最大力点之后颈缩发生,最终断裂伸长率为20%。过时效态试样与峰时效态试样变形行为类似。由此可知含团簇的T4态铝合金展现出了较优的强塑性匹配。

使用低阶多项式对拉伸真应力-真应变曲线的塑性阶段进行拟合,并对多项式微分得到拉伸实验加工硬化曲线(见图8(b))。结果表明,在弹塑性过渡阶段之后,人工时效态试样具有较高的初始加工硬化速率,但衰减较快。而从淬火态(AQ )到稳定自然时效态,合金的初始加工硬化速率虽然均低于人工时效态试样的,但是其衰减较慢,因此总体展现出了强于人工时效试样的加工硬化能力。

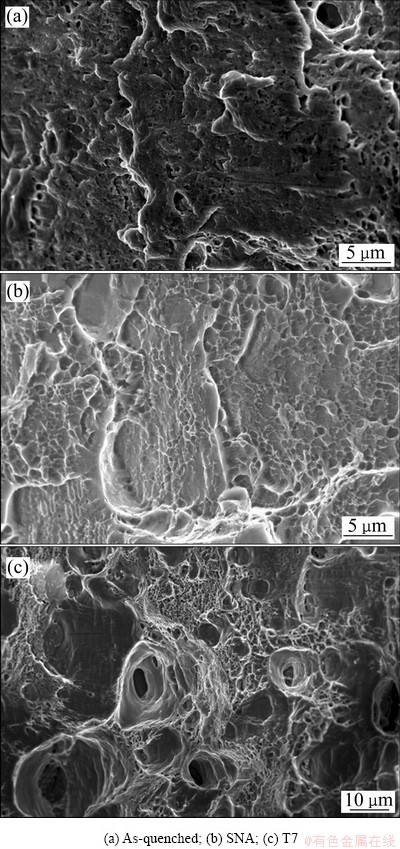

根据图9所示的断口SEM像,可对不同时效状态拉伸试样的断裂特性进行分析。可以发现,淬火态试样的断口多呈现一些较大的剪切面,无明显韧窝出现;自然时效态试样断口呈现剪切面与浅韧窝的混合形貌;而在人工时效态试样的断口中存在大量以微米级夹杂物颗粒为中心的大韧窝,且彼此之间通过较小的次级韧窝相连。尽管淬火态试样与自然时效态试样均具有较高的均匀伸长率,但其断口形貌呈现典型的剪切断裂特征,在特定的剪切面发生应变集中导致断裂。而对于人工时效态试样,它们的断口具有典型的韧窝聚合型断裂特征,在应变局部化之后,大的共晶颗粒开始脱粘或破碎,萌生微孔洞,微孔洞聚合导致最终的失效。

图8 不同时效状态7B05铝合金的拉伸力学曲线及加工硬化速率曲线

Fig. 8 Tensile mechanical curves (a) and strain hardening rate curves (b) of 7B05 alloys under different aging conditions

3 讨论

3.1 Al-Zn-Mg合金中的团簇长大动力学

图9 不同时效态7B05铝合金试样的拉伸断口形貌

Fig. 9 Morphologies of tensile fracture of 7B05 alloys under different aging conditions

在溶质原子团簇形成与长大的过程当中,空位扮演着极为重要的角色。传统观点认为,淬火产生的空位能够在极短时间内与固溶体中的溶质原子结合(当结合能为正时),形成溶质原子–空位对并参与团簇的形核及长大。但最新研究指出,在任何时刻,体系中的空位浓度均比溶质原子浓度低至少3个数量级,且铝合金中空位在基体中的扩散速率比溶质原子高5个数量级,空位与溶质原子更应该以一种动态的方式结合,即通过空位在溶质原子周围停留的时间来进行描述[9]。ZUROB等[19]基于空位可被约束在团簇周围并能以一定概率逃逸的假设,认为空位从已存在的团簇逃逸的概率是控制团簇长大速率的关键因素,并提出了如下形式的团簇长大动力学公式:

(2)

(2)

式中: 、K均为比例常数;k为玻尔兹曼常数;T为温度;Eb表示单个溶质原子与空位之间的结合能;n表示团簇中溶质原子个数;t为时效时间。由此可知,团簇所含原子个数与对数时间呈线性关系。

、K均为比例常数;k为玻尔兹曼常数;T为温度;Eb表示单个溶质原子与空位之间的结合能;n表示团簇中溶质原子个数;t为时效时间。由此可知,团簇所含原子个数与对数时间呈线性关系。

图10 7B05合金自然时效过程中电导率、硬度与自然时效时间的关系

Fig. 10 Relationships between electrical conductivity, Vickers hardness and natural aging time of 7B05 alloy

HIROSAWA等[20]提出在含团簇铝合金中,材料电阻率变化遵循:

(3)

(3)

式中: 为自然时效过程中电阻率的变化值;

为自然时效过程中电阻率的变化值; 为过饱和固溶体初始电阻率;Na为溶质原子个数;

为过饱和固溶体初始电阻率;Na为溶质原子个数; 表示单个溶质原子的电阻率贡献;N为团簇个数;g(n)表示团簇的电阻率贡献,并为其尺寸n的函数。为了简化计算分析,在上式中可假设

表示单个溶质原子的电阻率贡献;N为团簇个数;g(n)表示团簇的电阻率贡献,并为其尺寸n的函数。为了简化计算分析,在上式中可假设 ,于是得到:

,于是得到:

(4)

(4)

式中:c1与c2均为常数。由此可知,淬火后合金电阻率 应与团簇尺寸n成正比。由图10可知,在当前实验中,当自然时效时间小于48 h时,电导率随对数时间呈线性下降趋势,即

应与团簇尺寸n成正比。由图10可知,在当前实验中,当自然时效时间小于48 h时,电导率随对数时间呈线性下降趋势,即 ,于是可得

,于是可得 ,证明了式(2)所表达的动力学定律在7B05铝合金中的有效性。

,证明了式(2)所表达的动力学定律在7B05铝合金中的有效性。

合金中的团簇生长可通过硬度变化来间接地追踪。由于团簇与基体共格且尺寸极小,作为位错运动的阻碍,其与可动位错的作用形式为切过。正如前言中所提到的,已知的团簇强化方式主要有模量强化(Modulus strengthening)、有序强化(Short-range strengthening)、尺寸错配强化(Size misfit strengthening)、化学强化(Chemical strengthening)、共格强化(Coherency strengthening)等。在Al-Zn-Mg合金中,Mg的原子半径为0.1598 nm,大于Al原子半径(0.1429 nm);Zn的原子半径为0.1379 nm,小于Al原子半径[21],因此Zn-Mg团簇的弹性错配小于单个的溶质原子,尺寸错配强化不应该是Al-Zn-Mg合金中团簇强化的主导机制。化学强化来自于团簇与基体之间的界面能,但是由于团簇并不具备独立的晶体结构而是与基体高度共格,界面能极低,造成化学强化贡献有限,通常可被忽略。模量强化是由于团簇与基体的弹性模量不一致而引起的,其强化贡献可由Knowles-Kelly公式描述[22]:

(5)

(5)

有序强化的机理是溶质原子团簇作为一种短程化学有序结构,滑移面位错切过团簇时会形成反相畴界,需要额外的能量输入,其强化贡献可表示为[23]:

(6)

(6)

而传统的共格强化为:

(7)

(7)

式中:M为泰勒因子;G为铝的剪切模量;b为柏氏矢量; 为团簇与基体的剪切模量差值;

为团簇与基体的剪切模量差值; 为位错线张力;

为位错线张力; 为反相畴界能;

为反相畴界能; 为共格应变;

为共格应变; 为常数(刃位错取1,螺位错取3)。r、f分别为团簇半径(看作球形)和体积分数。在上述三种强化模型中,均可以提取出

为常数(刃位错取1,螺位错取3)。r、f分别为团簇半径(看作球形)和体积分数。在上述三种强化模型中,均可以提取出 项,即团簇强化效果与尺寸和体积分数的乘积直接相关。又因为

项,即团簇强化效果与尺寸和体积分数的乘积直接相关。又因为 ,V0为单个溶质原子体积,可得

,V0为单个溶质原子体积,可得 。当合金中团簇数量密度基本不变时,有

。当合金中团簇数量密度基本不变时,有 ,综上可知:

,综上可知:

(8)

(8)

这同样与本工作的实验数据(见图10)相吻合,表明在整个自然时效周期内,团簇尺寸均与对数时间呈线性关系:

(9)

(9)

则其生长速率与随时间变化的规律为:

(10)

(10)

此外,团簇的化学成分在自然时效期间也发生了明显变化,其Zn/Mg比由早期的1.05增长为稳定态时的1.16。这种变化可以从以下方面进行考虑:1) 尽管Mg原子与空位的结合能很小(甚至可能为负值),但是由于Mg原子半径较大,其与空位的结合从降低体系弹性能的角度来看是有利的;2) 室温(293 K)时Al-Zn-Mg合金中Mg原子的体扩散速率约为6.03×10-27 m2/s,而Zn原子的体扩散速率约为1.56×10-27 m2/s,因此Mg原子在基体中的扩散快于Zn原子[24]。据此可推测,合金淬火后,过饱和固溶体的中的空位优先与Mg原子结合,随着自然时效时间的延长,Zn原子逐渐在空位协助下迁移至团簇,导致Zn/Mg比的逐渐上升。

3.2 Al-Zn-Mg合金的加工硬化行为

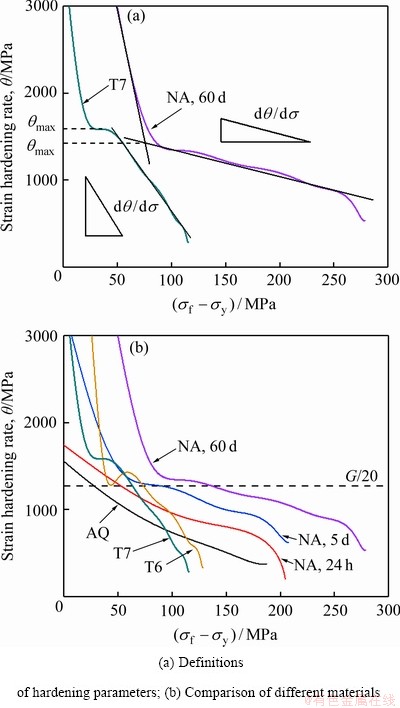

铝合金的均匀变形能力与其加工硬化性能密切相关。根据Considère颈缩判断准则,当因横截面积减小引起的应力增大超过因加工硬化引起的承载能力的增大时,颈缩开始发生。因此,较好的加工硬化能力能推迟颈缩的出现,使得材料具有更高的均匀伸长率。这里采用Kocks-Mecking图(加工硬化速率-流变应力增量曲线)对Al-Zn-Mg的加工硬化特性进行分析。在经典的Kocks-Mecking-Estrin模型框架下,对于含析出相的体系,其位错密度 随塑性应变的变化可用下式表示[25]:

随塑性应变的变化可用下式表示[25]:

(11)

(11)

式中:k1、k2、fp和kD均为常数。右侧第一项表示由长程位错相互作用引起的位错存储。第二项表示由于位错湮灭导致的动态回复,其中fp表示析出相对动态回复的影响。第三项表示由于析出相的存在引起的额外位错存储,对于可切过的析出相,kD可以去除。通常选用两个参数,即 和

和 对加工硬化行为进行定量描述,

对加工硬化行为进行定量描述, 表示塑性开始阶段材料的最大加工硬化速率,

表示塑性开始阶段材料的最大加工硬化速率, 为加工硬化第Ⅲ阶段Kocks-Mecking曲线的斜率。这两个参数的物理意义如下:

为加工硬化第Ⅲ阶段Kocks-Mecking曲线的斜率。这两个参数的物理意义如下:

在主要含可切过型析出相(如团簇)的体系中,

(12)

(12)

(13)

(13)

即 与体系的初始位错存储速率相关,而

与体系的初始位错存储速率相关,而 反映了其动态回复的速率;而在主要含不可切过析出相的体系中,

反映了其动态回复的速率;而在主要含不可切过析出相的体系中,

(14)

(14)

(15)

(15)

此时, 为kD和

为kD和 的函数,不再与初始位错存储速率直接相关,但

的函数,不再与初始位错存储速率直接相关,但 仍可用于反映位错动态回复速率。

仍可用于反映位错动态回复速率。

从图11可以发现,从淬火态到稳定自然时效态,7B05合金的 持续上升并最终稳定在G/20左右(接近多晶面心立方纯金属的理论最大位错存储速率)。由此认为,团簇的形成能够在一定程度上改变塑性变形初期位错的存储行为,使得位错存储更加有效。另外,对于不同自然时效状态的试样,

持续上升并最终稳定在G/20左右(接近多晶面心立方纯金属的理论最大位错存储速率)。由此认为,团簇的形成能够在一定程度上改变塑性变形初期位错的存储行为,使得位错存储更加有效。另外,对于不同自然时效状态的试样, 基本保持不变,表明合金中溶质原子团簇状态对于位错动态回复并无显著影响。而峰时效与过时效态合金具有更高的初始加工硬化速率,但是随着塑性变形的增大,加工硬化速率急剧下降,表明含不可切过析出相材料内部发生了强烈的位错湮灭过程。

基本保持不变,表明合金中溶质原子团簇状态对于位错动态回复并无显著影响。而峰时效与过时效态合金具有更高的初始加工硬化速率,但是随着塑性变形的增大,加工硬化速率急剧下降,表明含不可切过析出相材料内部发生了强烈的位错湮灭过程。

进一步地,选用XRD实验中5个较强的衍射峰,采用修正的Williamson-Hall方法(见图12)对不同应变下不同析出状态的合金位错密度进行测算。可以发现,在小应变下,过时效态合金中位错密度迅速增加,但是在塑性应变达到4%时,位错密度已经接近饱和,不在随应变增大而增加。而在自然时效态合金中,位错密度随塑性应变以相对较慢速度增加,并在13%左右达到饱和,其饱和位错密度高于过时效态合金。

图 11 不同时效状态7B05合金加工硬化速率与流变应力增量曲线

Fig. 11 Strain hardening rate as function of stress increment for 7B05 alloys with different aging treatments

图12 T7和SNA态7B05合金位错密度随塑性应变变化关系

Fig. 12 Dislocation density evolution during plastic deformation

位错与析出相的交互作用机制差异是不同时效状态7B05铝合金呈现不同加工硬化行为与位错变化规律的根本原因。研究表明,Al-Zn-Mg-(Cu)合金中析出相的“切过/绕过”过渡半径在3~4 nm左右[26],而在当前峰时效与过时效态样品中,析出相均已超过这一尺寸,因此发生变形时,位错主要以绕过的方式经过析出相而连续运动。尽管峰时效与过时效态合金的屈服强度存在明显差异,但由于位错与析出相交互作用方式的一致性,它们表现出了极为相似的加工硬化行为。在该种状态合金中,在塑性变形起始阶段,当可动位错遇到析出相颗粒时,为了继续向前运动,位错会绕过析出相并在析出相周围留下大量的位错环。这些位错环的累积,会在析出相周围形成较大的应力场,阻碍了后续可动位错的运动,造成背应力强化效应(Back-stress strengthening,也即随动强化,Kinematic strengthening)。但是,Orowan环一般在塑性应变3%~5%左右便已经达到饱和,不再增加[27]。因此在大应变情况下,由林位错等长程障碍引起的等向强化(Isotropic strengthening)应取代背应力强化成为主导的加工硬化机制。但是,变形前期析出相周围存储的位错环可造成额外应力场,这种应力场的存在容易引起可动位错的交滑移,使临界位错湮灭距离增大[28],有利于位错动态回复的发生。这种较强烈的动态回复软化效应会导致材料较弱的加工硬化能力,使其更早地发生颈缩。而在自然时效试样中可对位错运动进行阻碍的主要是基体中的溶质原子和团簇,由于这些障碍本身较弱,位错与障碍物的交互作用方式主要为切过,障碍物本身并不能起到有效存储位错的作用。正是由于溶质原子和团簇等不会引起位错的额外累积,因此,其初始加工硬化速率相较于峰时效和过时效试样而言较低,错位密度增长也较慢。基体中溶质原子和团簇对动态回复过程的影响可从多方面进行评估。首先,从层错能角度来看,溶质原子的添加可以有效降低合金层错能,使得交滑移的发生更加困难,变形更多以平面滑移进行,可实现位错的高密度存储,降低异号位错相互湮灭概率[29]。其次,从微观角度来看,可动位错滑移过程中,基体中的溶质原子会向位错核偏聚,进而为位错湮灭提供了额外的阻力,有效减小位错湮灭距离,抑制动态回复的发生[30]。对变形合金的流变应力进行进一步分析发现,尽管T4态合金的饱和位错密度大于T7态合金的饱和位错密度,但这仍不足以解释T4态合金远超过T7态合金的流变应力增量。稳定自然时效态试样的最大抗拉强度与屈服强度差值约为220 MPa,若全部强化增量均由新增位错贡献,那么根据泰勒强化公式:

(16)

(16)

估算出所需位错密度约为1.2×1015 m-2/s,远高于实测值。实际上,在自然时效态合金变形过程中,团簇被可动位错切过会发生重排,部分溶质原子会重新进入基体[31]。这些重溶的溶质原子,以及基体中原有的固溶原子会通过管扩散的方式迅速向可动位错核进行偏聚,发生动态应变时效(Dynamic strain aging,也称动态析出,Dynamic precipitation)效应,在位错运动前端形成溶质原子气团。这些溶质原子气团能够对位错施加额外的钉扎力,从而增加位错运动的阻力,提供可观的强化效果。自然时效态试样在拉伸试验过程中发生了明显抖动,即PLC效应,这是溶质原子与位错相互作用,钉扎与脱钉过程交替进行的结果[32-33],证明了体系中动态应变时效效应的存在。基于此,采用简单线性叠加方式,可提出自然时效态合金流变应力的表达模型:

(17)

(17)

式中: 为晶格摩擦力和Hall-Petch效应引起的强化贡献;

为晶格摩擦力和Hall-Petch效应引起的强化贡献; 、

、 、

、 、

、 分别为固溶强化、位错强化、团簇强化以及动态应变时效的强化贡献。而自然时效态合金的屈服强度为:

分别为固溶强化、位错强化、团簇强化以及动态应变时效的强化贡献。而自然时效态合金的屈服强度为:

(18)

(18)

结合式(17)与(18),有:

(19)

(19)

在变形过程中,体系中通过自然时效静态形成的团簇会被切过破坏,不能再提供原有强度,因此 为负。而由于重溶原子的增加,

为负。而由于重溶原子的增加, 为正值,但其强化贡献应小于淬火态中固溶强化效果(约40 MPa)。根据位错密度估算结果,

为正值,但其强化贡献应小于淬火态中固溶强化效果(约40 MPa)。根据位错密度估算结果, 70 MPa。因此在最大力点时,可估算动态应变时效强化贡献的最小值:

70 MPa。因此在最大力点时,可估算动态应变时效强化贡献的最小值:

≥110 MPa (20)

≥110 MPa (20)

由此可知,在自然时效态7B05铝合金中,动态应变时效效应提供了极强的强化效果,这也是拉伸变形过程中其出色的加工硬化能力的重要来源。动态应变时效强化物理解析模型的搭建仍存在很多困难,该模型应为应变速率 、温度T、溶质摩尔浓度c0和可动位错密度

、温度T、溶质摩尔浓度c0和可动位错密度 (假设正比于总位错密度

(假设正比于总位错密度 )的函数,即

)的函数,即

(21)

(21)

在恒应变速率室温拉伸实验中,动态应变时效强化效果会随塑性变形的增加,即 的增大而愈发显著。

的增大而愈发显著。

4 结论

1) Al-Zn-Mg合金经(480 ℃, 1 h)固溶和水淬处理后,室温放置(约23 ℃)会发生显著的溶质原子团簇化反应。溶质团簇的形成和长大降低了合金的电导率,提高了合金硬度。溶质团簇尺寸与对数时间呈线性关系,团簇长大速率与自然时效时间呈反比例关系,并在约1000 h后基本稳定。随着自然时效时间的延长,团簇的化学成分也发生了变化,主要体现为Zn/Mg比的逐渐增大。

2) Al-Zn-Mg合金在(120 ℃, 72 h)时效条件下可达到硬度峰值117HV,随着时效时间的继续延长,硬度会逐渐降低,进入过时效状态。T6和T7态合金中析出相均以亚稳η′和稳定η析出相为主,析出相数量密度远低于T4态合金中团簇的数量密度。

3) T4态Al-Zn-Mg合金的拉伸屈服强度为213 MPa,接近T6态合金的221 MPa,并具有优异的均匀延伸性能(约25%)。T7态合金强度低于T6态合金,但二者的塑性变形行为极为相似,它们的均匀伸长率均在13%左右。T4态拉伸试样以剪切断裂为主要断裂形式,而T6和T7态合金均为韧窝聚合型断裂。

4) 在含有不可切过型析出相的体系中,塑性变形早期位错环在析出相周围累积,引起材料快速硬化。但随着应变增大,位错动态回复过程逐渐占据主导地位,导致合金加工硬化能力快速下降从而发生软化。对于以溶质团簇为主的自然时效态合金而言,一方面,由于仍处于较高的过饱和状态,基体中的固溶原子能抑制位错回复过程,提高合金饱和位错密度;另一方面,塑性变形时伴生的动态应变时效效应能有效增加位错运动抗力,提高流变应力。二者的综合作用使材料呈现出优异的加工硬化性能。

REFERENCES

[1] 邓运来, 张新明. 铝及铝合金材料进展[J]. 中国有色金属学报, 2019, 29(9): 2115-2141.

DENG Yun-lai, ZHANG Xin-ming. Development of aluminium and aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 2115-2141.

[2] 张 勇, 李红萍, 康 唯, 张新明. 高强铝合金时效微结构演变与性能调控[J]. 中国有色金属学报, 2017, 27(7): 1323-1336.

ZHANG Yong, LI Hong-ping, KANG Wei, ZHANG Xin-ming. Aging microstructure evolution in high strength aluminum alloys and performance controlling[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(7): 1323-1336.

[3] RAO A C U, VASU V, GOVINDARAJU M, SRINADH K V S. Stress corrosion cracking behaviour of 7xxx aluminum alloys: A literature review[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1447-1471.

[4] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVRE W, BAROUX B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2010, 58(14): 4814-4826.

[5] CHEN Y, WEYLAND M, HUTCHINSON C R. The effect of interrupted aging on the yield strength and uniform elongation of precipitation-hardened Al alloys[J]. Acta Materialia, 2013, 61(15): 5877-5894.

[6] POLMEAR I J. Aluminium alloys—A century of age hardening [J]. Materials forum, 2004, 28: 1-14.

[7] MARCEAU R K W, DE VAUCORBEIL A, SHA G, RINGER S P, POOLE W J. Analysis of strengthening in AA6111 during the early stages of aging: Atom probe tomography and yield stress modelling[J]. Acta Materialia, 2013, 61(19): 7285-7303.

[8] 郑嘉玲, 秦永贵, 刘吉梓. 基于三维原子探针统计学结果的Al-Zn-Mg合金自然时效早期析出动力学研究[J]. 电子显微学报, 2018, 37(2): 128-136.

ZHENG Jia-ling, QIN Yong-gui, LIU Ji-zi. Early-stage precipitation in a naturally aged Al-Zn-Mg alloy based on atom-probe analysis[J]. Journal of Chinese Electron Microscopy Society, 2018, 37(2): 128-136.

[9] IVANOV R, DESCHAMPS A, GEUSER F D. Clustering kinetics during natural ageing of Al-Cu based alloys with (Mg, Li) additions[J]. Acta Materialia, 2018, 157: 186-195.

[10] 张天慈, 王海涛, 李正操, SCHUT H, 张征明, 贺 铭, 孙玉良. 国产RPV钢铁离子辐照脆化行为的正电子湮灭研究[J]. 金属学报, 2018, 54(4): 512-518.

ZHANG Tian-ci, WANG Hai-tao, LI Zheng-cao, SCHUT H, ZHANG Zheng-ming, HE Ming, SUN Yu-liang. Positron annihilation investigation of embrittlement behavior in Chinese RPV steels after Fe-ion irradiation[J]. Acta Metallurgica Sinica, 2018, 54(4): 512-518.

[11] DESCHAMPS A, BASTOW T J, GEUSER F D, HILL A J, HUTCHINSON C R. In situ evaluation of the microstructure evolution during rapid hardening of an Al-2.5Cu-1.5Mg (wt.%) alloy[J]. Acta Materialia, 2011, 59(8): 2918-2927.

[12] SUN W, ZHU Y, MARCEAU R, WANG L, ZHANG Q, GAO X, HUTCHINSON C. Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity[J]. Science, 2019, 363(6430): 972-975.

[13] JIANG S, WANG H, WU Y, LIU X, CHEN H, YAO M, GAULT B, PONGE D, RAABE D, HIRATA A, CHEN M, WANG Y, LU Z. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation[J]. Nature, 2017, 544(7651): 460-464.

[14] 钱鹏伟, 邓运来, 张 臻, 赵 龙, 唐鸿远, 叶凌英. 自然时效对Al-Zn-Mg合金型材抗应力腐蚀性能的影响[J]. 中国有色金属学报, 2017, 27(8): 1542-1550.

QIAN Peng-wei, DENG Yun-lai, ZHANG Zhen, ZHAO Long, TANG Hong-yuan, YE Ling-ying. Effect of natural aging time on stress corrosion cracking of aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(8): 1542-1550.

[15] SHAO D, ZHANG P, ZHANG J Y, LIU G, WANG R H, LIU W Q, SHA G, SUN J. Effect of pre-strain on the solute clustering, mechanical properties, and work-hardening of a naturally aged Al-Cu-Mg alloy[J]. Metallurgical and Materials Transactions A, 2017, 48(9): 4121-4134.

[16] UNGAR T, DRAGOMIR I, REVESZ A, BORBELY A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice[J]. Journal of Applied Crystallography, 1999, 32(5): 992-1002.

[17] ZHONG Z Y, BROKMEIER H G, GAN W M, MAAWAD E, SCHWEBKE B, SCHELL N. Dislocation density evolution of AA 7020-T6 investigated by in-situ synchrotron diffraction under tensile load[J]. Materials Characterization, 2015, 108: 124-131.

[18] LUIGGI N, SIMON J P, GUYOT P. Residual resistivity of clusters in solid solutions[J]. Journal of Physics F: Metal Physics, 1980, 10(5): 865-872.

[19] ZUROB H S, SEYEDREZAI H. A model for the growth of solute clusters based on vacancy trapping[J]. Scripta Materialia, 2009, 61(2): 141-144.

[20] HIROSAWA S, SATO T, YOKOTA J, KAMIO A. Comparison between resistivity changes and Monte Carlo simulation for GP zone formation in Al-Cu base ternary alloys[J]. Materials Transactions, JIM, 1998, 39(1): 139-146.

[21] XU X, ZHENG J, LI Z, LUO R, CHEN B. Precipitation in an Al-Zn-Mg-Cu alloy during isothermal aging: Atomic-scale HAADF-STEM investigation[J]. Materials Science and Engineering A, 2017, 691: 60-70.

[22] KELLY P M. Progress report on recent advances in physical metallurgy: (C) The quantitative relationship between microstructure and properties in two-phase alloys[J]. International Metallurgical Reviews, 1973, 18(1): 31-36.

[23] GLADMAN T. Precipitation hardening in metals[J]. Materials Science and Technology, 1999, 15(1): 30-36.

[24] DU Y, CHANG Y A, HUANG B, GONG W, JIN Z, XU H, YUAN Z, LIU Y, HE Y, XIE F Y. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation[J]. Materials Science and Engineering A, 2003, 363(1): 140-151.

[25] MECKING H, KOCKS U F. Kinetics of flow and strain-hardening[J]. Acta Metallurgica, 1981, 29(11): 1865- 1875.

[26] FRIBOURG G, BRECHET Y, DESCHAMPS A, SIMAR A. Microstructure-based modelling of isotropic and kinematic strain hardening in a precipitation-hardened aluminium alloy[J]. Acta Materialia, 2011, 59(9): 3621-3635.

[27] DA COSTA TEIXEIRA J, BOURGEOIS L, SINCLAIR C W, HUTCHINSON C R. The effect of shear-resistant, plate-shaped precipitates on the work hardening of Al alloys: Towards a prediction of the strength-elongation correlation[J]. Acta Materialia, 2009, 57(20): 6075-6089.

[28] DESCHAMPS A, BRECHET Y, NECKER C J, SAIMOTO S, EMBURY J D. Study of large strain deformation of dilute solid solutions of Al-Cu using channel-die compression[J]. Materials Science and Engineering A, 1996, 207(2): 143-152.

[29] AN X H, WU S D, WANG Z G, ZHANG Z F. Significance of stacking fault energy in bulk nanostructured materials: Insights from Cu and its binary alloys as model systems[J]. Progress in Materials Science, 2019, 101: 1-45.

[30] DESCHAMPS A, ESMAEILI S, POOLE W J, MILITZER M. Strain hardening rate in relation to microstructure in precipitation hardening materials[J]. J Phys IV France, 2000, 10: Pr6-151-Pr156-156.

[31] BAI S, LIU Z, ZHOU X, GU Y, YU D. Strain-induced dissolution of Cu-Mg co-clusters and dynamic recrystallization near a fatigue crack tip of an underaged Al-Cu-Mg alloy during cyclic loading at ambient temperature[J]. Scripta Materialia, 2011, 64(12): 1133-1136.

[32] JIANG H F, ZHANG Q C, CHEN X D, CHEN Z J, JIANG Z Y, WU X P, FAN J H. Three types of Portevin–Le Chatelier effects: Experiment and modelling[J]. Acta Materialia, 2007, 55(7): 2219-2228.

[33] GOPINATH K, GOGIA A K, KAMAT S V, RAMAMURTY U. Dynamic strain ageing in Ni-base superalloy 720Li[J]. Acta Materialia, 2009, 57(4): 1243-1253.

Cluster-growth kinetics, plastic deformation and fracture in naturally aged Al-Zn-Mg alloy

SHI Kun-kun1,2, ZHAO Xiao-long1,2, ZHANG Peng1,2, KUANG Jie1,2,ZHANG Jin-yu1,2, LIU Gang1,2, SUN Jun1,2

(1. School of Materials Science and Engineering, Xi’an Jiaotong University, Xi’an 710049, China;

2. State Key Laboratory for Mechanical Behavior of Materials, Xi’an Jiaotong University, Xi’an 710049, China)

Abstract: The clusters growth kinetics and the deformation properties in natural-aged Al-Zn-Mg alloy were investigated by electrical conductivity, microhardness and tensile tests. Multiple characterization methods including SEM, TEM, APT and XRD were applied to reveal the microstructure features. The results show that through the natural aging of about 1000 h, the high number density of solute clusters forms in 7B05 alloy and are responsible for the natural aging hardening effect. Natural-aged Al-Zn-Mg alloy exhibits better strain-hardening properties and uniform elongation than their thermally treated counterparts. The presence of shearing-resistant precipitates in thermal-treated alloys results in rapid accumulation of dislocation loops around precipitates at small strain whereas at large strain, the dislocation dynamic recovery process is dominant. In natural-aged Al-Zn-Mg alloy, the dislocation recovery is inhibited by solutes and clusters, meanwhile, the dynamic strain aging effect raises the resistance of dislocation movements, both leading to a greater strain-hardening capability.

Key words: Al-Zn-Mg alloy; solute atom clusters; atom probe tomography; growth kinetics; strain-hardening properties

Foundation item: Project(51790482, 51722104) supported by the Major Program of National Natural Science Foundation of China; Project(2019M653595) supported by the China Postdoctoral Science Foundation

Received date: 2019-12-13; Accepted date: 2020-04-07

Corresponding author: ZHANG Peng; Tel: +86-15332354731; E-mail: zhangpeng.mse@xjtu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51790482,51722104);中国博士后科学基金资助项目(2019M653595)

收稿日期:2019-12-13;修订日期:2020-04-07

通信作者:张 鹏,讲师,博士;电话:15332354731;E-mail:zhangpeng.mse@xjtu.edu.cn