基于磁化水的含硫高黏性全尾砂充填新技术

王新民,李帅,张钦礼,贺严,康虔

(中南大学 资源与安全工程学院,湖南 长沙,410083)

摘要:为解决某硫铁矿含硫全尾砂浆体黏度大、易结块和管道输送性能差的问题,将磁化水引入全尾砂胶结充填的配浆试验中,研究不同磁化条件下,磁化水-全尾砂浆体的主要流变参数的变化规律;基于Fluent 软件的充填管道输送流速和压力变化模拟,对磁化水-全尾砂浆体的输送性能进行分析。研究结果表明:在磁感应强度为0.1~0.2 T,磁化时间为20~30 min,水循环流速为2 m/s左右时,磁化水全尾砂浆体的表观黏度下降25%~30%,屈服剪切应力下降15%~20%,管道沿程阻力损失减少40%。磁化水在降低含硫高黏性全尾砂的屈服剪切应力和表观黏度、改善其管道输送性能、提高管道输送效率方面具有显著的优越性。

关键词:磁化水;含硫高黏性全尾砂;流变性能;磁化机理;Fluent数值模拟

中图分类号:TD8 文献标志码:A 文章编号:1672-7207(2014)12-4245-06

New technique of high viscosity sulfur-content total tailings backfilling based on magnetized water

WANG Xinmin, LI Shuai, ZHANG Qinli, HE Yan, KANG Qian

(School of Resources and Safety Engineering, Central South University, Changsha 410083, China)

Abstract: To solve the problem of high viscosity, easy caking and poor transportability produced by the sulfur-content total tailings slurry in a pyrite mine, magnetized water was introduced to the proportion test of total tailings. Furthermore, the change laws of rheological properties about the total tailings slurry were explored under different magnetization conditions. Afterwards, the evaluation was performed through the numerical simulation of flow velocity change and pressure variation with the software of Fluent. The results show that the decrease of apparent viscosity, shear stresses and friction loss of pipes are 25%-30%, 15%-20% and about 40% respectively with the magnetic induction being 0.1-0.2 T, magnetized time being 20-30 min and cycling rate being 2 m/s. Therefore, the new backfilling technique based on magnetized water is capable of reducing the viscosity and shear stresses of the sulfur-content total tailings slurry, and improving its transportability and transport efficiency.

Key words: magnetized water; sulfur-content total tailings slurry; rheological properties; magnetization mechanism; Fluent numerical simulation

全尾砂胶结充填具有工艺简单、生产能力大、安全环保等优点,在有色金属矿山应用越来越广泛[1]。但是国内部分矿山如新桥硫铁矿、和睦山铁矿、罗河铁矿等在进行全尾砂胶结充填的现场工业试验中发现,由于尾矿中杂质成分复杂,残留硫含量较大,导致全尾砂黏度增大,新鲜尾砂极易黏结成团,堆放时间过长易结块,繁琐的搅拌破碎工艺严重影响了全尾砂胶结充填管道输送效率,制约了全尾砂胶结充填技术在含硫矿山的推广应用。针对这些问题,国内外的主要研究方向集中在尾砂脱硫和破碎工艺上。Hulshof等[2]利用有机覆盖法,发现黏浆状有机废物覆盖可以使硫的最高还原速度达到5 g/(L·a)。万淑娟等[3]通过改变菌种培养试验条件研究了氧化亚铁硫杆菌在尾矿脱硫中的作用。张钦礼等[4]通过调整全尾砂储存方式,增加了打散、破碎装置,采用尾矿活化运输来保证下料顺利和生产的正常运行。但是尾矿脱硫技术成本高、工艺复杂,尾砂破碎活化系统费时费力,易堵管溢流,充填效率难以保证,全尾砂胶结充填技术在含硫高黏性矿山的应用仍然举步维艰。磁化水是近些年迅速发展起来的在工业锅炉除垢防垢、油田的防蜡降黏、农业磁化育苗、医学磁化杀菌、城市污水处理等诸多领域得到广泛应用的一门新技术[5-6]。霍广新等[7]研究了磁处理在提高高水充填材料胶凝体抗压强度方面的作用,王贵和等[8]通过将磁化水与膨润土进行配浆,研究磁化水在改变膨润土浆液流变特性的变化规律,这些研究为磁化水在矿山生产实践应用提供了参考。在此,本文作者把磁化水引入全尾砂胶结充填配浆试验中,结合某硫铁矿含硫全尾砂的实际情况,探究不同磁化条件下,磁化水-全尾砂浆体的主要流变参数屈服剪切应力、表观黏度以及管道输送性能的变化规律。

1 磁化水系统

1.1 磁化水机理

磁化水是一种被磁场磁化了的水。由法拉第的电磁理论,有一定导电性的水流在外力作用下通过磁场,做切割磁感线运动时,会产生电动势,水即被磁化。磁场给水分子热运动提供了能量,由于氢键的相互吸引而聚集缔合起来的大的水分子集团不断被破坏,由原来的13~18个大分子团变成5~6个小分子团,使水的黏度和表面张力减小。磁化后水的氢键角由104.5°变成103°左右,水中的水合离子受到磁场的影响作螺旋式的圆周运动,由于正负离子旋转方向相反,它们之间的氢键被扭断。磁化后水的结构和物化性质发生了一系列的变化,主要体现在以下方面:黏度与表面张力下降,pH、电导率、盐类溶解度提升,活性增强等[9-11]。

1.2 磁化水制备

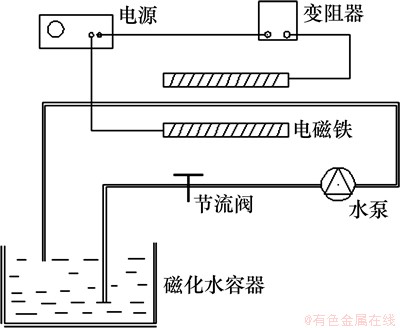

图1所示为磁化水制备系统示意图。电磁铁接入专门的磁化水电源,通过滑线变阻器调节产生不同强度的磁场,循环管路由非磁性材料有机玻璃管组成。启动水泵,在节流阀的控制下,水流可以以不同的流速通过电磁场,从而获得磁化程度各异的磁化水[12]。

图1 磁化水制备系统示意图

Fig. 1 Sketch map of magnetized water system

2 磁化水全尾砂配浆试验

2.1 全尾砂物化性能

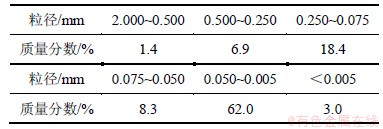

表1所示为某硫铁矿全尾砂粒径组成,表2所示为新桥矿全尾砂化学成分。新桥矿含硫全尾砂粒级较细(见表1),0.05 mm以下颗粒占68%(质量分数)以上,中值粒径仅为0.038 mm,渗透系数小(1.62×10-4~4.41×10-4 cm/s);尾砂中含有较多的杂质成分(见表2),其中残留硫含量较大,新鲜全尾砂容易黏结成团,如图2所示,堆放时间过长易结块,不利于储存和输送。

表1 某硫铁矿全尾砂粒径组成

Table 1 Composition of total tailings’ grain diameter in a pyrite mine

表2 某硫铁矿全尾砂化学成分(质量分数)

Table 2 Chemical composition of a pyritic mine’s total tailing %

2.2 浆体流变参数测定

矿山充填料浆是典型的固液两相流体,充填料浆的表观黏度、屈服剪切应力等指标在管道输送压力损失计算、流速分布规律研究、管道磨损性能评价等方面都有很重要的作用[13]。旋转黏度计是适用简便且准确的新型黏度测量仪器,黏度测量步骤如下:将被测浆体置于直径为100 mm、高度150 mm的烧杯中,准确地控制被测浆体的温度,调整仪器使得水准器气泡居中。采用不同的转子类型,更换不同的转速对某硫铁矿含硫全尾砂浆体(质量分数为70%)的表观黏度和屈服剪切应力进行测定,并多次测量平均值。

图2 某硫铁矿含硫全尾砂黏结成团照片

Fig. 2 Photo of caking sulfur-content total tailings of a pyrite mine

2.3 试验步骤

潍坊博思特公司生产的磁水器磁化面积大,磁场均匀性好,磁感应强度精确可调,可满足室内磁化水制备实验的各项要求。磁场强度过高,磁化耗能负担大,不符合现场生产节能减排的要求;水流速度过快,磁化时间过短,水得不到充分有效地磁化。借鉴前人关于磁化水处理的成果,确定试验初选的磁化条件为:磁场强度B控制在0.1~0.4 T,水流在管径中循环流速v控制在1~4 m/s,磁化时间t控制在10~40 min。

1) 室内磁化水制备:磁化水制备系统安放要求稳定可靠,避免外界磁干扰。按照初选的磁化条件调节磁化电源、管路节流阀、控制磁化时间,制备磁化条件不同、磁化效果各异的磁化水。

2) 磁化水-全尾砂配浆:将磁化程度各异的磁化水和新桥全尾砂相混合,配制成质量分数为70%的全尾砂浆体,高速搅拌10 min。

3) 磁化条件初选:利用漏斗法测试等量磁化水-全尾砂浆体通过相同漏斗的时间,时间越短,黏度越小。初选出适宜的磁感应强度、磁化时间、循环流速。

4) 控制磁感应强度、水流循环速度为初选的适宜值,利用旋转黏度计测定不同磁化时间下的磁化水-全尾砂浆体流变参数的变化规律。

5) 控制水流循环速度、磁化时间为初选的适宜值,利用旋转黏度计测定不同磁场强度下的磁化水-全尾砂浆体流变参数的变化规律。

6) 控制磁感应强度、磁化时间为初选的适宜值,利用旋转黏度计测定不同循环流速下的磁化水-全尾砂浆体流变参数的变化规律。

7) 磁化条件优选:根据影响磁化水-全尾砂浆体流变参数的变化规律,优选适合某硫铁矿全尾砂的磁化条件。

3 结果与分析

3.1 磁化条件初选

将100 mL磁化程度各异的磁化水-全尾砂浆体依次通过直径为10 cm的漏斗,记录浆体滴落过程所需时间(至最后一滴滴落的时间为准),并与自来水全尾砂浆体的滴落时间做对比,部分适宜磁化条件下的滴落时间见表3。经初选出适宜的磁化条件如下:磁感应强度为0.1~0.2 T,磁化时间为10~20 min,水流循环速度为1~2 m/s。

表3 不同磁化条件的全尾砂浆体滴落实验结果

Table 3 Dripping test results of different magnetized total tailings slurry

3.2 磁化时间对浆体流变参数的影响

在磁感应强度B=0.2 T,循环速度v=2 m/s时,磁化水-全尾砂浆体的流变参数随磁化时间变化的曲线如图3所示。t=0时,即是没有经过磁化的普通自来水全尾砂浆体,此时其表观黏度为和屈服剪切应力均为最大值。随着磁化时间的增加,磁化水-全尾砂浆体的表观黏度和屈服剪切应力逐渐降低。当循环磁化的时间达到20 min时,表观黏度和屈服剪切应力降至最低值,分别下降31%和16%左右;随着磁化时间的继续增加,表观黏度和屈服剪切应力趋于稳定。

图3 磁化时间对流变参数的影响

Fig. 3 Influence of magnetizing time on rheological parameter

3.3 磁感应强度对浆体流变参数的影响

在循环速度v=2 m/s,磁化时间为20 min时,不同磁感应强度下产生的磁化水-全尾砂浆体的流变特性如图4所示。从图4可见:当B=0 T时,为未经磁化的普通自来水全尾砂浆体;随着磁感应强度的增大,磁化水全尾砂浆体的表观黏度和屈服剪切应力下降明显;在0.1~0.2 T时降低的幅度最大,在0.2 T时降到最低,屈服剪切应力下降19%,表观黏度下降26%;当磁感应强度大于0.2 T后,表观黏度和屈服剪切应力有增大的趋势,但仍低于普通自来水配置的全尾砂浆体。

3.4 循环速度对浆体流变参数的影响

水以不同的流速通过磁场切割磁感线时,水的磁化效果亦不相同。图5所示为在磁感应强度B=0.2 T,磁化时间为20 min时由循环速度各异的磁化水配置的全尾砂浆体的流变参数变化曲线。由图5可知:循环速度对磁化水-全尾砂浆体的流变性有很大的影响。对比水流循环速度为0 m/s时未经磁化的普通自来水全尾砂浆体,随着水流循环速度的增大,浆体的流变参数不断降低,在2 m/s时降至最低值,此时屈服剪切应力降低约16%,表观黏度降低23%;当循环速度大于2 m/s时,表观黏度和屈服剪切应力持平。

图4 磁感应强度对流变参数的影响

Fig. 4 Influence of magnetic induction intensity on rheological parameter

图5 循环速度对流变参数的影响

Fig. 5 Influence of cycling rate on rheological parameter

3.5 磁化水配浆降黏减切机理分析

随着现代科学技术的不断进步,更高精准度的表面张力仪、电子显微镜等设备,X线衍射和红外光谱等技术被应用到磁化水机理分析中。一般地,全尾砂浆体的表观黏度和屈服剪切应力受到全尾砂的固相含量、颗粒组成、粒径分布表面特性(ζ电位)和水化程度等多方面因素的影响[14-15]。硫铁矿全尾砂含有较多的杂质硫(8.5%),固相含量高;粒级较细,分散度高;ζ电位小,水化膜较薄,这些因素都使浆体极易形成网状结构,导致黏度和切力增大。

水经磁化以后,水分子极性增大,在全尾砂颗粒表面的吸附力增大,同时受磁激化后的水分子趋于定向排列,水化膜的强度和厚度增大。磁化水中存在大量长的缔合分子链和阳离子缔合物,使得水中游离的阳离子数目相对减小,提高了全尾砂颗粒表面的ζ电位。因此,磁化水-全尾砂配制的浆体不易形成网状结构,比一般普通水配置的全尾砂浆体有更低的黏度和切力。

在一定范围的磁化条件作用下,磁化水-全尾砂浆体的黏度和切力下降明显;随着磁化条件的增强,黏度和切力保持不变甚至还会升高,原因在于:在较弱的磁化条件下,磁场能量不足以使水分子中的氢键发生松弛并断裂;磁场强度增大,磁化时间变长,易使被拉断的氢键与其他氢键相互靠近并重新组合,导致水的活性降低,磁化效果下降。

4 磁化水-全尾砂浆体输送性能评价

由上述试验结果可知:在磁感应强度B=0.1~0.2 T,磁化时间t=20~30 min,水流循环速度v=1~2 m/s的条件下,某硫铁矿全尾砂经磁化水配浆后流变性能得到了极大的改善,其主要的流变参数与普通自来水全尾砂浆体对比见表4。

为了验证磁化水在降低含硫全尾砂浆体的黏度和切力,改善其流变性能,提高浆体管道输送效率的优越性,结合某硫铁矿充填现场工业试验实际情况,进行磁化水-全尾砂浆体和普通自来水全尾砂浆体充填管道输送的Fluent模拟[16]。磁化条件为B=0.2 T,t=20 min,v=2 m/s的磁化水-全尾砂浆体和普通自来水全尾砂浆体,在组成配比、质量分数(均为65%)、管道流量(90 m3/h)、入口流速(1.7 m/s)等都相同的情况下,通过同一个内径为98 mm、管道粗糙度为0.12 mm、充填倍线为3.0的充填管路,其流速变化、压力损失、阻力计算对比如下。

表4 普通水与磁化水-全尾砂浆体流变指标对比

Table 4 Comparison of rheological parameter about magnetized water and tap water tailing slurry

设水平钻孔弯管处压力为0 MPa,在其他条件相同的情况下,磁化水和普通自来水全尾砂浆体经由相同的充填管道,磁化水-全尾砂浆体的出口压力为-1.08 MPa,普通自来水全尾砂浆体的出口压力为-3.07 MPa。在水平充填钻孔管道输送过程中,磁化水-全尾砂浆体出口压力损失更小,输送性能更佳。

由图6和图7可知:在相同管道的同样部位,磁化水-全尾砂浆体的最大管径流速可达到2.98 m/s,而普通自来水全尾砂浆体的最大管径流速为2.49 m/s。磁化水-全尾砂浆体在水平钻孔弯管处的主要流速区间是1.94~2.98 m/s,远高于普通自来水全尾砂浆体的1.49~2.24 m/s。

图6 普通自来水全尾砂浆体水平钻孔底端弯管处流速分布

Fig. 6 Duct velocity distribution of tap water tailing slurry

图7 磁化水-全尾砂浆体水平钻孔底端弯管处流速分布

Fig. 7 Duct velocity distribution of magnetized water-tailings slurry

运用Fluent软件模拟计算出在整个管道输送过程中,磁化水-全尾砂浆体的管道沿程阻力损失为2.4 MPa,较之普通自来水全尾砂浆体的4.0 MPa,降低约40%。

5 结论

1) 通过漏斗滴落实验初选和磁化水-全尾砂配浆实验优选出适合某硫铁矿的磁化条件为:磁感应强度B=0.1~0.2 T,磁化时间t=10~20 min,水循环流速V=2 m/s左右。此时,磁化水-全尾砂浆体对比普通自来水全尾砂浆体,其表观黏度下降25%~30%,屈服剪切应力下降15%~20%。

2) 基于Fluent软件的充填管道输送过程模拟,磁化水-全尾砂浆体的出口压力损失为-1.08 MPa,小于普通自来水全尾砂浆体的-3.07 MPa;磁化水-全尾砂浆体在水平钻孔弯管处的主要流速区间是1.94~2.98 m/s,高于普通自来水全尾砂浆体的1.49~2.24 m/s;磁化水-全尾砂浆体的管道沿程阻力损失为2.4 MPa,比普通自来水全尾砂浆体降低约40%。

3) 基于磁化水的含硫高黏全尾砂充填新技术具有工艺简单、降黏剪切效果明显、便于在矿山实际开展等优点,可以为国内其他含硫高黏性矿山充填生产提供参考。

参考文献:

[1] 王新民, 古德生, 张钦礼. 深井矿山充填理论与管道输送技术[M]. 长沙: 中南大学出版社, 2010: 9-10.

WANG Xinmin, GU Desheng, ZHANG Qinli. Theory and technology of deep mine backfilling[M]. Changsha: Central South University Press, 2010: 9-10.

[2] Hulshof A H M, David W B, Gouldb W D. Evaluation of in situ layers for treatment of acid mine drainage: A field comparison[J]. Water Research, 2006, 40(9): 1816-1826.

[3] 万淑娟, 党志. 氧化亚铁硫杆菌在尾矿脱硫过程中的作用研究[J]. 矿物岩石地球化学通报, 2009, 28(1): 438-440.

WAN Shujuan, DANG Zhi. The function of thiobacillus ferrooxidans on tailings desulfurization[J]. Journal of Mineral Geochemistry of the Rock, 2009, 28(1): 438-440.

[4] 张钦礼, 康虔, 肖富国, 等. 含硫高黏性尾砂胶结充填关键技术[J]. 金属矿山, 2010, 413(11): 39-41.

ZHANG Qinli, KANG Qian, XIAO Fuguo, et al. Key technology of cemented backfilling with high viscosity sulfur-content tailings[J]. Mental Mine, 2010, 413(11): 39-41.

[5] Fathia A, Mohameda T, Claudeb G, et al. Effect of a magnetic water treatment on homogeneous and heterogeneous precipitation of calcium carbonate[J]. Water Res, 2006, 40(10): 1941-1950.

[6] Maheswari B L, Harsham Singh Grewal. Magnetic treatment of irrigation water: Its effects on vegetable crop yield and water productivity[J]. Agricultural Water Management, 2009, 96(8): 1229-1236.

[7] 霍广新, 张洪涛, 胡全利, 等. 磁处理提高高水充填材料凝胶体的抗压强度[J]. 东北大学学报, 1996, 17(2): 163-166.

HUO Guangxin, ZHANG Hongtao, HU Quanli, et al. Magnetic treatment for improving the strength of pack material with high water content[J]. Journal of Northeastern University, 1996, 17(2): 163-166.

[8] 王贵和, 李洵. 磁化水-膨润土浆液流变特性的实验研究[J]. 现代地质, 1996, 10(4): 562-565.

WANG Guihe, LI Xun. Study on rheology property of magnetized water-bentonite mud[J]. Geoscience, 1996, 10(4): 562-565.

[9] Goncharuk V V, Bagrii V A. Crystallization of calcium carbonate in magnetized water in the presence of paramagnetic substances[J]. Journal of Water Chemistry and Technology, 2009, 31(3): 172-176.

[10] Pang X F. The conductivity properties of protons in ice and mechanism of magnetization of liquid water[J]. The European Physical Journal B, 2006, 49(1): 5-23.

[11] WANG Xingguo, LI Li, ZHENG Yuzhou, et al. Experimental study on sprayed concrete mixed with magnetized water[J]. Applied Mechanics and Materials, 2011, 1366(71): 3524-3528.

[12] 余太泉. 可控电磁磁化器的开发与试验研究[D]. 广州: 华南理工大学机械与汽车工程学院, 2012: 17-30.

YU Taiquan. Controllable electromagnetic magnetizer development and experimental research[D]. Guangzhou: South China University of Technology. School of Mechanical and Automotive Engineering, 2012: 17-30.

[13] 王新民, 张德明, 张钦礼, 等. 基于FLOW-3D软件的深井膏体管道自流输送性能[J]. 中南大学学报(自然科学版), 2011, 42(7): 2101-2107.

WANG Xinmin, ZHANG Deming, ZHANG Qinli, et al. Pipeline self-flowing transportation property of paste based on FLOW-3D software in deep mine[J]. Journal of Central South University (Science and Technology), 2011, 42(7): 2101-2107.

[14] Coey J M D. Magnetic water treatment-how might it work?[J]. Philosophical Magazine, 2012, 92(31): 3857-3865.

[15] Kozicc V, Hamler A, Ban I. Magnetic water treatment for scale control in heating and alkaline conditions[J]. Desalination and Water Treatment, 2010, 22(1): 65-71.

[16] 耿俊俊. 龙首矿深部充填系统可靠性及扩能技术方案研究[D]. 长沙: 中南大学资源与安全工程学院, 2009: 79-90.

GENG Junjun. Study of Longshou mine deep piping reliability and expansion technique project[D]. Changsha: Central South University. School of Resources and Safety Engineering, 2009: 79-90.

(编辑 陈爱华)

收稿日期:2014-03-22;修回日期:2014-05-10

基金项目(Foundation item):“十一五”国家科技支撑计划项目(2008BAB32B03)(Project (2008BAB32B03) supported by the National Science & Technology Pillar Program during the Eleventh Five-year Plan Period)

通信作者:王新民(1957-),男,安徽安庆人,教授,博士生导师,从事采矿与充填技术研究;电话:13187011058;E-mail:wxm1958@126.com