石膏基墙板热泵干燥过程中温度场的有限元仿真

朱桂华,高旭光,李抗,胡均平,何将三

(中南大学 机电工程学院,湖南 长沙,410083)

摘 要:基于石膏基墙板主要依靠自然风干或简易高能耗隧道烘干法的不足,将热泵技术应用于石膏基墙板的干燥,并选择以干燥室进气温度恒定的热泵干燥装置,分析其工作过程。在此基础上,运用ANSYS热分析模块模拟干燥室进气温度为70 ℃时干燥过程墙板内部瞬态温度场分布。研究结果表明:加热干燥前期石膏基墙板升温快,高温区主要集中在外表面的边角区域;在加热干燥中期,墙板内部温度上升速度变慢;加热6 h后墙板温度与载荷温度趋于一致;在石膏基墙板榫头底部即空心墙板的实体最厚部位,墙板温度最后达到与载荷温度一致;在墙板长度方向上石膏基墙板中间段温度梯度基本上为0 ℃/m;对墙板的温度场进行仿真得到温度场变化规律,可为墙板的干燥装置设计和干燥工艺流程设计提供参考。

关键词:石膏基墙板;热泵;干燥;温度场;有限元

中图分类号:TK173; TK124 文献标志码:A 文章编号:1672-7207(2010)05-1828-06

Finite element simulation of temperature fields of gypsum wallboard in heat pump drying process

ZHU Gui-hua, GAO Xu-guang, LI Kang, HU Jun-ping, HE Jiang-san

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Based on the fact that gypsum wallboard mainly relies on natural air-drying or simple tunnel drying with high energy consumption method, heat pump technology was applied to dry gypsum wallboard and a heat pump drying device was designed to control the drying chamber inlet temperature constant, and the procedure was analyzed. ANSYS thermal analysis module was used to simulate the distribution of transient temperature field of the internal gypsum wallboard in the drying process when the drying chamber for the intake air temperature was 70 ℃. The results show that the temperature of gypsum wallboard goes up fast at the pre-heating stage, the high temperature zone is mainly the outside surface’s corner region; at medium-term heating stage, the internal temperature of gypsum wallboard rises slowly. After 6 h, the temperature of gypsum wallboard is the same as the loading temperature; the bottom of rabbet of wallboard that is the thickest part of gypsum wallboard reaches the final steady-state temperature; in the direction of the length of gypsum wallboard middle temperature gradient is 0 basically. Changes of temperature field from simulation of temperature field offer references for improving the drying device and the drying process.

Key words: gypsum wallboard; heat pump; drying; temperature fields; finite element

石膏基墙板具有密度低、速成、保温、隔音、耐火等特点,而且对环境无污染,节约能源,是一种典型的绿色建材产品和理想的新型墙体材料。据了 解,发达国家中石膏墙体在整个建筑墙体中占40%~50%(美国高达70%),而我国不到5%。目前,我国石膏墙板渐渐得到应用[1-2]。现在我国工业生产中墙板生产成型及后期养护干燥等工艺设备比较落后,石膏墙板质量难以得到保证,大力开发石膏基墙板生产工艺设备具有十分重要的意义。干燥是石膏墙板生产中的重要工艺过程。合理的干燥装置设计能提高墙板的生产率,保证石膏墙板的质量。Schuette等[3]开发了快速干燥石膏板系统,该系统有独立的干燥房,具有多层、紧密、连续等特点,热空气在干燥房中作为干燥介质从高速、交错的喷嘴中射出,掠过移动的石膏板;该系统具有空气再循环的功能,并有防止墙板边缘过渡加热措施。Nowick等[4]设计了一种石膏墙板干燥方法和设备,这种设备将空气通过风扇加速、经过高温火焰加热进而对石膏墙板烘干除水。长沙归一建材科技有限公司开发了一套简易的石膏墙板养护干燥房,使石膏墙板得到高效、高质干燥。韩玮[5]以此干燥房为原型,通过实验测定数据,得到了石膏墙板干燥速率曲线,总结了石膏墙板的失水率与干燥温度的关系。目前,国内外对于石膏墙板干燥的热源及新型设备和干燥过程的研究很少。石膏基墙板的特点是导热系数小,干燥温度低,干燥时间长,质量保护要求高。热泵干燥装置是一种新型高效节能装置,将高效制冷制热的热泵技术与干燥技术有机集成[6-7],应用于石膏基墙板干燥具有独特的优势。在此,本文作者对石膏基墙板热泵干燥装置的工作过程及优点、墙板干燥过程温度场模拟等进行研究。

1 石膏基墙板的干燥工艺

1.1 墙板干燥的目的

石膏基墙板生产过程主要发生的化学反应为[8]:

Ca2SO4·1/2H2O+3/2H2O= Ca2SO4·2H2O (1)

在石膏基墙板的生产配方中,加入的水分只有一部分参加了如式(1)的水化反应,变成了结晶水,而更多的为剩余游离状态的水留在石膏墙板中。石膏基墙板干燥主要是通过干燥介质与墙板的热湿交换将墙板中游离状态的水排出去。

1.2 墙板干燥常规方法

石膏基墙板干燥常采用自然晾干或把墙板置于专门的干燥室内加热烘干。自然风干干燥法干燥周期长,占地面积大,受气候影响较大,特别是南方地区雨水多,湿度大,难以保证干燥质量。采用室内隧道烘干干燥法生产效率较高,在没有余热利用的地方能源消耗大,干燥成本高。虽然可以采用窑炉余热、烟道废气、暖风机交换的热空气为热源,但采用这些热源的来源和稳定性会受配套设备较大影响,热源温度及湿度的变化极易使墙板变形、炸裂、粉化等,这就要求制定合理的干燥制度,严格执行工艺规定。与常规干燥相比,热泵干燥具有以下优点:节约能耗;提高产品质量;干燥条件可调节范围宽;节约干燥时间;环境友好。

1.3 墙板干燥工艺

根据湖南大学复合材料研究所提供的数据,综合考虑经济性和干燥效果,采用如下干燥工艺:干燥介质为热空气,通过热泵加热环境空气至70 ℃,热风流向与墙板内部孔道方向保持平行,有利于提高其对流换热效果,提高干燥效率,减少干燥时间。此干燥条件不会对石膏的化学性质产生影响。热空气通过风机通入干燥室与墙板形成强迫对流换热,干燥室通风良好,因干燥室空间较小,可在较短时间达到70 ℃,然后,保持干燥房温度恒温(70 ℃)。

石膏基墙板干燥采取热泵干燥装置,保证墙板可以在较短时间内尽快排除多余游离状态的水,提高石膏基墙板的强度,避免石膏墙板开裂,快速达到出厂要求,达到提质创效的效果。

2 石膏基墙板热泵装置的确定

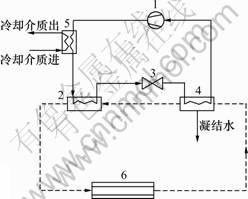

热泵是一种高效制热装置(产出的热能/消耗的能量>100%)[9],带辅助冷凝器热泵干燥装置能够满足墙板干燥的工艺要求,空气呈闭式循环[10-15]。系统由热泵和干燥室2个单元组成,系统流程如图1所示。

1—压缩机;2—冷凝器;3—节流阀;4—蒸发器;

5—辅助冷凝器;6—干燥室

图1 石膏基墙板热泵干燥装置流程图

Fig.1 Flow of heat pump device of plaster

2.1 干燥装置的工作过程

图1所示热泵干燥装置由2个子系统组成:热泵工质循环子系统1—2—3—4—1和空气循环子系统6—4—2—6。热泵子系统是由压缩机1、冷凝器2、节流阀3、蒸发器4、辅助冷凝器5等组成的封闭回路,热泵工质在其中循环流动,其功能是在蒸发器中将循环空气(湿空气)中的水分除去,之后又在冷凝器中将干燥空气加热到合适的温度进入干燥室吸收物料水分;空气循环子系统由干燥室6、蒸发器4(空气侧)、冷凝器2(空气侧)等组成,空气在其中循环流动,其功能是通过循环将干燥室中湿物料的水分带走,经蒸发器时将水分凝结排出。

在墙板热泵干燥过程中,蒸发器的2个主要作用是:一方面吸收来自干燥房空气中的显热和潜热使制冷剂能在蒸发器内充分蒸发汽化,另一方面是对空气进行降温除湿以提高空气的吸湿能力。因此,蒸发器在制冷循环中的主要作用是去湿冷却即减焓去湿。

2.2 热泵干燥装置的优点

该装置以控制干燥室进气温度恒为70 ℃为目标设计的。由于在墙板干燥前期和中期,除湿主要是除去墙板的多余的游离态水分,此时,外界空气参数对系统除湿速度影响大,空气的除湿能力取决于干燥室进出口空气含湿量差值,因此, 本系统采用带辅助冷凝器的闭式热泵干燥装置,将热泵循环系统的冷凝器分成2部分,其中一个作为辅助冷凝器将热泵干燥装置达到设定工作温度后的多余热量传送给环境。此结构的优势在于控制干燥温度灵活方便,能保持干燥箱在恒定的温度下运行,而且辅助冷凝器的换热系数较高,不需要特殊技术的换热器。另外,还可利用辅助冷凝器加热外界空气对物料进行预干,回收这部分温度较高的冷凝热,既节约了能源,又提高了系统的 效率。

3 墙板内部温度场ANSYS仿真

加热干燥过程对于石膏基墙板的后期性能有重要的影响:温度过高会破坏墙板的内部结构,而温度过低则降低墙板的生产效率。在实际生产中,墙板温度尤其是内部温度难以通过正常的方法测量得到。通过有限元仿真,不但能得到石膏基墙板内部任意点的温度变化情况,而且还能判断石膏墙板内外温度何时能够达到基本一致,从而为热泵干燥装置的设计提供参考。石膏基墙板温度场在加热干燥过程中随时间发生变化,属于瞬态热分析,ANSYS软件的热分析模块可以支持瞬态热分析。

根据能量守恒原理,瞬态传热可以用公式表达 为[14]:

(2)

(2)

式中:K为传导矩阵,包含导热系数、对流系数、辐射率和形状系数;C为比热容矩阵;T为节点温度向量; 为温度对时间的导数;Q为节点热流率向量,包含热生成。

为温度对时间的导数;Q为节点热流率向量,包含热生成。

3.1 参数的确定

3.1.1 墙板尺寸参数

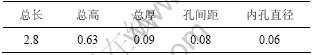

墙板的尺寸参数如表1所示。由表1可知:墙板长度为2.80 m。而过长的石膏墙板模型大大增加了单元数量,减慢了运行速度,所以,在建模中进行了一定简化,将总长缩短到1.00 m。根据实际仿真的结果,长度方向上石膏墙板中间段温度梯度基本上为0 ℃/m,这样,不仅对仿真结果没有影响,而且可以适当增加载荷步的数量和单位长度上单元的数量,提高仿真结果的精度。

表1 石膏基墙板的尺寸参数

Table 1 Size parameters of gypsum wallboard m

3.1.2 仿真参数及边界条件

石膏建材的导热系数为0.20~0.28 W/(m2?℃)。在石膏基墙板上施加的边界条件属于第一类边界条件即环境温度条件,是一种面载荷,载荷温度条件需施加到石膏墙板的外表面。

初始条件是石膏墙板的初始温度和对流传热边界条件。石膏浆料浇注、凝固后,化学反应放出的热量可以使石膏基墙板温度达30 ℃左右,此即为初始温度。在墙板加热干燥过程中,空气介质温度为70 ℃ 左右。

环境中的热量将通过干燥介质与墙板的接触界面向墙板传递,表征这种对流换热过程强烈程度的是对流传热系数。

对流传热系数主要由如下因素决定:流体流动的起因、流体有无相变、流体的流动状态、换热表面的几何因素、流体的物理性质等,因此,墙板的外表面与内空面的对流换热系数是不相同的。墙板内孔面的强制对流换热系数 的计算公式为:

的计算公式为:

,

,

当Re≥104,0.6<Pr<160时 (3)

墙板外表面的强制对流换热系数 为[15]:

为[15]:

,Re≤2×105 (4)

,Re≤2×105 (4)

式中:Re为干燥介质的雷诺数;Pr为干燥介质普朗特数;e为修正系数,针对短管l/d=30~40时(l为墙板长度,d为内孔直径),e取值范围为1.02~1.07; 为干燥介质的热导率,W/(m2?℃);u为干燥介质流速,m/s;

为干燥介质的热导率,W/(m2?℃);u为干燥介质流速,m/s; 为状态下的介质密度,kg/m?;

为状态下的介质密度,kg/m?; 为干燥介质动力黏度,Pa?s;cp为干燥介质的比定压热容,kJ/(kg?℃);n为经验指数,当干燥介质被冷却时,n取0.3。

为干燥介质动力黏度,Pa?s;cp为干燥介质的比定压热容,kJ/(kg?℃);n为经验指数,当干燥介质被冷却时,n取0.3。

3.2 不同时刻的温度分布云图

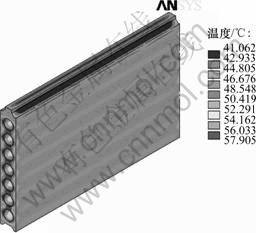

利用ANSYS内的post1处理器可得到任意时刻墙板的温度场分布图,分别取0.5,2和5 h的温度场分布云图。

图2所示为墙板加热0.5 h的温度场分布图(注:图右边每个色块对应其上、下2种温度范围,下同)。从图2可以看到:墙板内部存在非常明显的温度梯度分布,从41.062~57.905 ℃不等,石膏基墙板内部的温度较初始温度时明显升高。

图2 空气温度为70 ℃时,墙板加热干燥0.5 h的温度场分布

Fig.2 Distribution of temperature field after drying at air temperature 70 ℃ for 0.5 h

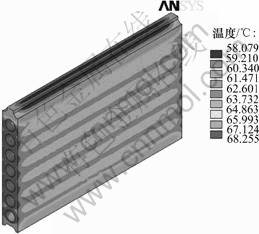

图3所示为墙板加热2 h的温度场分布图。可见:石膏基墙板温度区间为58.079~68.255 ℃,墙板温度升高速度较加热前1 h变慢。

图3 空气温度为70 ℃时,墙板加热干燥2 h的温度场分布

Fig.3 Distribution of temperature field after drying at air temperature 70 ℃ for 2 h

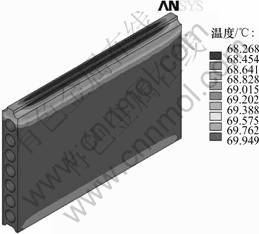

图4所示为墙板加热5 h的温度场分布图。可见:墙板温度范围为68.268~69.949 ℃,整个温度场已趋于稳态,接近70 ℃。

图4 空气温度为70 ℃时,墙板加热干燥5 h的温度场分布

Fig.4 Distribution of temperature field after drying at air temperature 70 ℃ for 5 h

3.3 结果分析

从图2~4可看到墙板温度升高的过程。在干燥前期,石膏基墙板升温较快,在表面有棱的区域,产生了类似于应力集中的高温集中。这是因为相对其他区域,有棱的区域接触热空气的表面积比较大,热交换进行得较充分。前1.5 h可以认为是干燥预热期。到了加热干燥中期,约2 h后,墙板内部温度场整体上升变慢。因为温度场与热空气的温度越来越接近,外部对流换热效率降低,而石膏墙板的导热系数又很 小,故内部传热也较慢。当加热时间为5 h时,石膏墙板内部温度达到68 ℃以上,干燥的加热阶段趋于结束。随着时间的增加,温度场趋于与载荷温度场一致。在考虑节能的情况下加热6 h后,可以将热风速度降至2 m/s,但在加热过程中会伴随着水分蒸发现象,水分蒸发会消耗部分热能,因此,可以预见实际墙板温度比仿真温度偏低。另外,因石膏基墙板的结构特 殊,上部有较厚的榫头,该部位温度最低,是最后到达稳态温度的部位,即图6中2602号节点所在部位。而在长度方向上,石膏基墙板中间段温度梯度基本上为0 ℃/m。

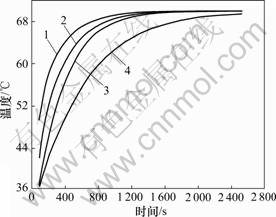

3.4 不同部位温度随时间的变化

某横截面上几个不同节点位置如图5所示。利用ANSYS内的post26时间历程后处理器,可以得出石膏墙板在载荷温度为70 ℃时,内部节点随温度变化的情况,如图6所示。

从图6可以看出:不同的节点对载荷温度的响应不尽相同,总体来说,外部节点比内部节点温度升高较 快,石膏基墙板有内孔表面比侧面的节点温度升高快。在加热6 h左右时,石膏墙板内、外温度基本上一致。

干燥房内要将石膏墙板放整齐,确保四角落地平稳,应用卡具将石膏墙板定位,墙板与墙板之间要有适当均匀的间距。墙板干燥处要保持洁净,避免粉尘多堵塞墙板毛细孔,影响墙板的干燥效果。

图5 不同位置节点位置图

Fig.5 Location of different node

1—19322号节点,为墙板内孔棱边上的点(代表最高温处节点);2—26408号节点,为外侧面表面取的点;3—39317号节点,为墙板内部的节点;4—2602号节点,为榫头底部的点

图6 石膏基墙板上不同位置节点温度变化图

Fig.6 Variation of node temperature at different positions

4 结论

(1) 将热泵技术应用到石膏基墙板的干燥研究,其研究结果为石膏基墙板的干燥提供了一种既节能又高效的方法。

(2) 建立了石膏基墙板加热干燥温度场有限元热分析仿真模型并确定了热力边界条件。此仿真方法对其他多孔介质类建筑材料的干燥过程温度场模拟有参考意义。

(3) 在加热空气加热墙板过程中(空气温度为70 ℃),随着加热时间增加,墙板温度升高速率降低。外部节点比内部节点温度上升快。在长度方向上墙板中间段温度梯度基本为0 ℃/m。加热干燥到5 h,石膏墙板内部温度达到68 ℃以上,干燥的加热阶段趋于结束,在石膏基墙板榫头底部即墙板最厚部位,最后与载荷温度趋于一致,这与实际情况相符。仿真结果可用于指导石膏基墙板干燥系统的设计。

参考文献:

[1] 李志鹏. 石膏基墙板螺旋挤压机成型机理研究[D]. 长沙: 中南大学机电工程学院, 2009: 2-3.

LI Zhi-peng. Molding mechanism research of screw extruder mechanism of plaster[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2009: 2-3.

[2] 向才旺. 建筑石膏及其制品[M]. 北京: 中国建材工业出版社, 1998: 91-102.

XIANG Cai-wang. Building gypsum and products[M]. Beijing: China Building Material Industry Press, 1998: 91-102.

[3] Schuette H W, Hune R N, Portland. Method and apparatus for high-speed drying of gypsum board: United States, 3529357[P]. 1970-09-22.

[4] Nowick C R, Williamsville, Alfred DeFranza, et al. Method of drying gypsum wallboard and apparatus therefore: United States, 4050885[P]. 1977-09-27.

[5] 韩玮. 基于ANSYS的石膏养护烘干过程仿真及理论研究[D]. 长沙: 中南大学机电工程学院, 2007: 9-10.

HAN Wei. Simulation of the process of maintaining gypsum wallboard damp-warm circumstances based on ANSYS and theoretical study[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2007: 9-10.

[6] 李满峰, 陈东, 谢继红, 等. 热泵干燥装置在生物物料干燥中的应用分析[J]. 化工装备技术, 2004, 25(6): 1-4.

LI Man-feng, CHEN Dong, XIE Ji-hong, et al. The application analysis of heat pump drying device in drying biological materials[J]. Chemical Equipment Technology, 2004, 25(6): 1-4.

[7] Chua K J, Chou S K, Ho J C, Hawlader M N A. Heat pump drying: Recent developments and future trends[J]. Drying Technology, 2002, 20(8): 1579-1610.

[8] 李天富. 石膏墙板成型设备自动开模控制系统研究[D]. 长沙: 中南大学机电工程学院, 2007: 11-19.

LI Tian-fu. The automatic open model system research of shaping devices of plasterboard[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2007: 11-19.

[9] 许树学, 陈东, 乔木. 热泵干燥装置的结构及应用特性分析[J]. 化工装备与技术, 2005, 26(5): 1-5.

XU Shu-xue, CHEN Dong, QIAO Mu. The application characteristics and structure of analysis of heat pump drying device[J]. Chemical Equipment Technology, 2005, 26(5): 1-5.

[10] Mujumdar A S. Handbook of industrial drying. Revised and expanded[M]. 2nd ed. Basel: Marcel Dekker Inc, 1995: 1100-1106, 1241-1275.

[11] 马一太, 张嘉辉, 马远. 热泵干燥系统优化的理论分析[J]. 太阳能学报, 2000, 21(2): 208-213.

MA Yi-tai, ZHANG Jia-hui, MA Yuan. The optimal analysis of the drying heat pump system[J]. Acta Energiae Solaris Sinica, 2000, 21(2): 208-213.

[12] Oktay Z, Hepbasli A. Performance evaluation of a heat pump assisted mechanical opener dryer[J]. Energy Conversion and Management, 2003(44): 1193-1207.

[13] 谢继红, 陈东. 热泵干燥装置的结构分析[J]. 轻工机械, 2006, 24(3): 49-52.

XIE Ji-hong, CHEN Dong. Analysis of heat pump dryer structures[J]. Light Industry Machinery, 2006, 24(3): 49-52.

[14] Teeboonma U, Tiansuwan J, Soponronnarit S. Optimization of heat pump fruit dryers[J]. Journal of Food Engineering, 2003, 59: 369-377.

[15] Babas’Haq R F. Forced convection heat transfer from a pipe to air flowing turbulently inside it[J]. Experimental Heat Transfer, 1992, 5(2): 161-173.

(编辑 陈灿华)

收稿日期:2009-11-03;修回日期:2010-02-01

基金项目:湖南省科技重大专项计划项目(2009FJ10080-4);国家重点新产品计划项目(2007GRD20023);湖南省科技攻关项目(2008JT1014)

通信作者:朱桂华(1962-),男,湖南双峰人,博士研究生,副教授,从事机电液一体化技术和建材装备研究;电话:0731-88837095;E-mail: zhuguihuaok@163.com