文章编号:1004-0609(2013)S1-s0282-05

钛合金螺栓非正常拉伸断裂失效分析及工艺改进

姚 罡

(北京航空制造工程研究所,北京 100024)

摘 要:某型d 6 mm×1.5 mm航空用Ti6Al4V钛合金沉头螺栓在测试抗拉强度时出现了螺栓头部与光杆脱离的失效情况。通过对失效零件的宏微观断口、金相组织及化学成分分析,找出失效原因并改进工艺方案。结果表明:这种失效现象起因于螺栓头部端面的微裂纹,通过调整原材料截断装置,螺栓头部的微裂纹可以明显缩短或消除。

关键词:钛合金;螺栓;拉伸断裂;失效分析;断口分析

中图分类号:TG37 文献标志码:A

Failure analysis of non-normal stretched fracture for titanium alloy bolt and process improvement

YAO Gang

(Beijing Aeronautical Manufacturing Technology Research Institute, Beijing 100024, China)

Abstract: The failure of head and rod separation appears in a type of d 6 mm×1.5 mm aircraft Ti6Al4V titanium alloy countersunk head bolt in tensile strength test. The failed part was investigated by macro and micro fracture analysis, and the microstructure and chemical composition were analysed to find out the reason and improve the process scheme. The results show that micro cracks on the head of the bolt face are the proximate failure cause. By adjusting the raw material cutting device, micro crack on bolt head can be significantly reduced or eliminated.

Key words: titanium alloy; bolt; stretched fracture; failure analysis; fracture analysis

由于钛合金具有密度低、强度高、比强度大,及使用温度范围广、抗疲劳性能优异等特点,故非常适用在飞机等高速飞行器上[1-3]。另外,钛合金与复合材料的电极电位相近,所以钛合金紧固件也成为了复合材料的主要连接件[4-7]。特别是Ti6Al4V紧固件,目前在航空领域应用最广泛。

某型d 6 mm×1.5 mm航空用Ti6Al4V沉头螺栓设计抗拉强度为1 100 MPa,螺栓头部生产工艺为:棒材校直→截断→感应加热→镦锻。沉头面成形后经机加工、热处理、滚丝等工艺后制成成品。为提高生产效率,生产改换了1台进口连续自动镦锻机,全自动完成沉头面镦锻加工,每分钟可加工30~40件,效率提高了2倍。新设备投产一段时间后,出现了约 60%的螺栓试验件抗拉强度下降的现象,且断裂位置没有出现在头下圆角或螺纹部位的常见薄弱位置。断裂位置如图1所示,整个螺栓头部与光杆脱离,脱离的头部中间有一个不规则的穿孔。为解决此问题对零件断口及加工工艺进行了研究。

1 断口分析

1.1 宏观断口分析

如图2所示,断口基本分为4个断面,2和3区断面有明显的台阶(图2中箭头所指位置),台阶侧面花样垂直于表面且光泽较亮;2、3和4区靠外圆部位能看见不太明显的放射区;断裂试样剪切唇光亮且较短,断面收缩较小;1区断面较小,几乎垂直于轴向,无台阶。4个断面区域低倍观察未见明显的冶金缺陷,在光线下转动试样未见大量彩色反光点,初步判断螺栓属于韧性断裂[8]。

图1 螺栓断裂位置

Fig. 1 Bolt fracture position

图2 断口宏观照片

Fig. 2 Macro picture of fracture appearance

1.2 断口微观分析

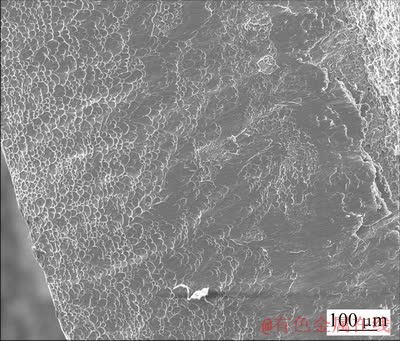

1区断面与2、3区台阶侧面微观形貌相似,如图3~5所示。1区断面表面不平整,有大量的磨损痕迹(如图1),局部有明显的扇形韧窝,2和3区台阶断面从表面沿深度方向均出现拉长的扇形韧窝花样,且越靠近内部,韧窝拉长越明显。2和3区台阶拐角处(如图6所示)有多层起伏面,可见二次裂纹。1区端面存在裂纹源(如图4箭头所示),裂纹源深度较浅,其他3个区域的断面在外圆和端面均未见裂纹源。1区断面通过能谱分析靠近表面处的含氧量约为0.172%略高于基体材料。2、3和4区平断面如图7所示,断口为准解理+少量韧窝,属于塑性断裂[9]。

图3 螺栓1区断面形貌

Fig. 3 Fracture appearance of section 1 of bolt

图4 1区断面裂纹源

Fig. 4 Fracture appearance of section 1 of crack initiated area

图5 台阶侧面形貌

Fig. 5 Step fracture appearance

1.3 结果分析

根据断口分析结果,可以判定螺栓裂纹源位于1区的头部端面。在拉伸应力加载过程中裂纹首先沿1区的2个尖端呈U型在表面和深度2个方向扩展,以剪切型为主。1区深度方向裂纹扩展速度最快,首先失稳,失稳之后造成2区和3区的裂纹扩展方向发生变化,断面由剪切型变成张开型(2和3区台阶断面和1区断面有明显垂直的扇形或椭圆形韧窝,可以判定初期裂纹在剪切力的作用下扩展,2个断面在同一平面内相对运动)。最终断裂发生在4区,断面完全为准解理+小韧窝[10]。

图6 台阶拐角处形貌

Fig. 6 Step transition fracture image

图7 平断面准解理+小韧窝

Fig. 7 Planar tesile fracture of quasicleavage and dimple

2 微观组织及化学成分分析

2.1 头部微观组织

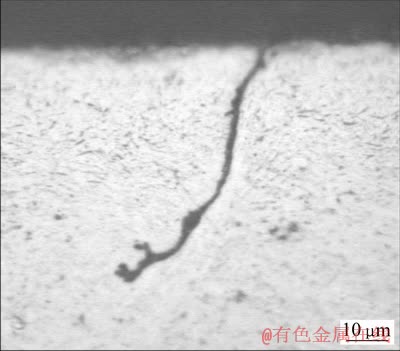

选取若干件同一批次螺栓,沿纵截面剖开,经过磨削抛光腐蚀,观察头部端面的金相组织。经观察发现,螺栓头部端面单侧均存在微裂纹缺陷(如图8所示),裂纹尖端分叉,产生二次裂纹,缺陷深度为50~100 μm,缺陷位置基本在光杆外圆投影的靠内处。头部镦锻流线基本沿变形轮廓分布,零件内部组织为等轴初生α+含有针状α的β转变体,等轴晶粒度约为10级,初生α相体积分数为40%~60%。根据标准要求,螺栓显微组织无异常。可以判定,断裂失效是由头部端面的不连续性缺陷造成的。

图8 头部端面微裂纹

Fig. 8 Micro crack in bolt head

2.2 化学成分分析

Ti6Al4V钛合金原材料及镦锻后H和O含量如表1所示。用于加工此种螺栓的Ti6Al4V钛合金棒材的化学成分在标准要求的合格范围内。为进一步判断化学成分变化产生的影响,对零件镦锻前后的H和O含量(如表1所示)进行了测试。从2组测试数据可以看出:镦锻后的零件氧含量略有升高,氢含量略有下降,但均在合格要求范围内(w(H)≤0.015%,w(O)≤0.2%)。

表1 Ti6Al4V钛合金H和O含量(质量分数)

Table 1 H and O compositions of Ti6Al4V titanium alloy (mass fraction, %)

3 工艺调试

3.1 镦锻工艺调试

在排除镦锻模具破损和润滑不当的情况下,此种头部端面微裂纹产生的最主要原因为材料塑性变形能力不佳。由于镦锻时材料要经过塑性变形,较大的变形量会导致在有应力集中的地方产生开裂或微裂纹。为了提高材料的塑性变形能力,一般做法是提高镦锻加工时的温度,加强材料自身流动性。为此,调试工艺时,分别将镦锻前的感应加热温度上调了10~80 ℃。加工后的零件沿纵向剖开并进行金相分析,观察结果表明头部端面的微裂纹仍然存在,深度未见明显减小。因此推断微裂纹缺陷应该是在截断步骤产生或者是原材料本身固有的。

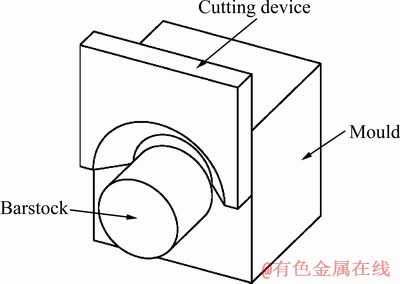

3.2 截断装置检查

Ti6Al4V棒材的截断装置如图9所示,在检查过程中发现切刀的装配出现了问题。由于装配间隙过大,致使棒料在截断时,切口不整齐(如图10(a)所示),因此,出现了突起的边缘。根据经验推断,可以认为冲头接触棒材坯料的初期,截断面突出的部分会被折断撕裂形成微裂纹(如图10(b)),随后在沉头面镦锻成形时裂纹埋入头部端面(如图10(c))使损伤闭合,形成极为细小的微裂纹缺陷,以至于荧光渗透检测也很难发现。

图9 截断机构示意图

Fig. 9 Schematic diagram of cutting device

图10 微裂纹产生过程示意图

Fig. 10 Micro crack production process

4 工艺改进

根据上述分析,对棒材截断装置进行了重新装配调整。调整后,镦锻后螺栓相同部位微裂纹深度大大缩小,成品件几乎未见微裂纹,抗拉强度性能指标也满足合格要求。经过后期对截断装置的多次测试和总结后发现,这种截断装置由于设计的缘故,对于直径大于6 mm的棒材很难保证其切口平整,并且在加工直径小于6 mm的棒材时,也要经常维护和打磨切刀。

为了弥补这种截断装置的设计缺陷,对于直径较大的螺栓,可以适当提高螺栓头部成形高度。因为螺栓头部一般很难一次镦锻到精确尺寸,工艺设计时,在保证头部承载面角度的情况下,头部高度会留有一定加工余量,成形之后用车床加工去掉余高,若裂纹深度小于加工余量则成品件头部端面不会出现裂纹。

5 结论

1) 螺栓产生的这种沉头面穿孔脱离失效源于头部端面的微裂纹。

2) 头部微裂纹的产生原因为坯料截断面不平整,通过安装调整截断装置的切刀间隙,可以有效减小头部端面的微裂纹深度。

3) 对于直径较大的螺栓,可以适当提高头部成形高度,以便在后加工时消除端面裂纹。

REFERENCES

[1] 王鼎春. 高强钛合金的发展及应用[J]. 中国有色金属学报, 2010, 20(1): 958-963.

WANG Ding-chun. The development and application of high strength titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 958-963.

[2] WU Cheng-bao, YANG He, FAN Xiao-guang, SUN Zhi-chao. Dynamic globularization kinetics during hot working of TA15 titanium alloy with colony microstructure[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 1963-1969.

[3] 沙爱学, 王庆如, 李兴无. 航空用高强度结构钛合金的研究及应用[J]. 稀有金属, 2004, 28(1): 239-242.

SHA Ai-xue, WANG Qing-ru, LI Xing-wu. Research and application of high-strength titanium alloys used in airplane structure[J]. Chinese Journal of Rare Metal, 2004, 28(1): 239-242.

[4] JOHN F, LIANG Z, STACEY N, LUKE H. Properties and microstructure of Ti-555(Ti-5Al-5Mo-5V-3Cr-0.6Fe) for fasteners[C]// Ti-2007 Science and Technology. Tokyo: The Japan Institute of Metals, 2007: 1263-1266.

[5] 赵庆云, 徐 锋. 航空紧固件用钛合金的研究进展[J]. 中国有色金属学报, 2010, 2(10): 1021-1023.

ZHAO Qing-yun, XU Feng. Research progress of titanium alloy for aerospace fasteners[J]. The Chinese Journal of Nonferrous Metals, 2010, 2(10): 1021-1023.

[6] 赵庆云, 刘风雷, 刘华东. 世界先进航空紧固件进展[J]. 航空制造技术, 2009(3): 54-56.

ZHAO Qing-yun, LIU Feng-lei, LIU Hua-dong. Development of advanced aerospace fastener[J]. Aeronautical Manufacturing Technology, 2009(3): 54-56.

[7] 张庆玲, 王庆如, 李兴无. 航空用钛合金紧固件选材分析[J]. 材料工程, 2007(1): 11-14.

ZHANG Qing-ling, WANG Qing-ru, LI Xing-wu. Materials selection analysis for titanium alloy fasteners in aviation industry[J]. Journal of Materials Engineering, 2007(1): 11-14.

[8] 吴连生, 刘正义, 许麟康, 张静江. 机械装备失效分析图谱[M]. 广州: 广东科技出版社, 1990: 273-275.

WU Lian-sheng, LIU Zheng-yi, XU Lin-kang, ZHANG Jing-jiang. Failure analysis of mechanical equipment[M]. Guangzhou: Guangdong Science and Technology Press, 1990: 273-275.

[9] 朱铭德, 沈一诺. 高强度钛合金螺栓断裂失效分析[J]. 理化检验—物理分册, 2008(8): 446-450.

ZHU Ming-de, SHEN Yi-nuo. Fracture analysis of the titanium alloy bolt with high strength[J]. Physical Testing and Chemical Analysis Part A: Physical Testing, 2008(8): 446-450.

[10] 张 栋, 钟培道, 陶春虎, 雷祖圣. 失效分析[M]. 北京: 国防工业出版社, 2013: 94-113.

ZHANG Dong, ZHONG Dao-pei, TAO Chun-hu, LEI Zu-sheng. Failure analysis[M]. Beijing: National Defense Industry Press, 2013: 94-113.

(编辑 何运斌)

基金项目:长江学者和创新团队发展计划基金资助项目(IRT0720)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:姚 罡,工程师,硕士;电话:010-85701055;E-mail: miuke0083@139.com