镀镍SiC颗粒增强AZ61镁合金复合材料的显微组织和力学性能

来源期刊:中国有色金属学报(英文版)2019年第9期

论文作者:郭苏庆 王日初 彭超群 蔡志勇 董翠鸽

文章页码:1854 - 1863

关键词:镁基复合材料;表面镀镍SiC颗粒;界面结合;力学性能;表面改性

Key words:AZ61 matrix composites; Ni-coated SiCp; interface bonding; mechanical properties; surface modification

摘 要:采用粉末冶金加热挤压工艺制备SiCp/AZ61复合材料,为了改善复合材料的界面结合性能,在SiCp表面化学镀覆镍-磷涂层。分析镍涂层对复合材料显微组织和力学性能的影响。结果表明,SiC颗粒表面镀镍后在复合材料中分布更均匀,镀镍复合材料缺陷较少。在烧结过程中镍涂层与镁基体反应形成Mg2Ni界面化合层。与未镀覆复合材料相比,镀镍复合材料的致密度从97.9%增加到98.4%,并且随着SiC颗粒体积分数的增加,镀镍复合材料的硬度增加得更快。拉伸实验结果表明,当SiC颗粒的体积分数为9%时,镀镍复合材料具有较高的伸长率,拉伸强度从320 MPa增加到336 MPa,表明镍涂层能提高界面结合强度和性能。此外,分析SiCp/AZ61复合材料的断口形貌。

Abstract: In order to improve the interface bonding of SiCp/AZ61 composites prepared by powder metallurgy followed by hot extrusion, the electroless plating of Ni-P coating on SiCp was carried out. The influence of Ni coating on microstructure and mechanical properties of the composites was analyzed. The results show that SiC particles distribute more uniformly in the composites after surface Ni plating and there are fewer defects in Ni-coated composite. The Ni coating reacts with the magnesium matrix forming the Mg2Ni interfacial compound layer during the sintering process. The relative density of the composite increases from 97.9% to 98.4% compared with uncoated one and the hardness of the Ni-coated composite increases more rapidly as the volume fraction of SiCp increases. The tensile test results show that the tensile strength increases from 320 to 336 MPa when the volume friction of SiC particle is 9% and the Ni-coated composites have larger elongation, indicating that Ni coating improves the interfacial bonding strength and the performance of the composites. In addition, the fracture properties of SiCp/AZ61 composites were analyzed.

Trans. Nonferrous Met. Soc. China 29(2019) 1854-1863

Su-qing GUO, Ri-chu WANG, Chao-qun PENG, Zhi-yong CAI, Cui-ge DONG

School of Materials Science and Engineering, Central South University, Changsha 410083, China

Received 6 January 2019; accepted 4 July 2019

Abstract: In order to improve the interface bonding of SiCp/AZ61 composites prepared by powder metallurgy followed by hot extrusion, the electroless plating of Ni-P coating on SiCp was carried out. The influence of Ni coating on microstructure and mechanical properties of the composites was analyzed. The results show that SiC particles distribute more uniformly in the composites after surface Ni plating and there are fewer defects in Ni-coated composite. The Ni coating reacts with the magnesium matrix forming the Mg2Ni interfacial compound layer during the sintering process. The relative density of the composite increases from 97.9% to 98.4% compared with uncoated one and the hardness of the Ni-coated composite increases more rapidly as the volume fraction of SiCp increases. The tensile test results show that the tensile strength increases from 320 to 336 MPa when the volume friction of SiC particle is 9% and the Ni-coated composites have larger elongation, indicating that Ni coating improves the interfacial bonding strength and the performance of the composites. In addition, the fracture properties of SiCp/AZ61 composites were analyzed.

Key words: AZ61 matrix composites; Ni-coated SiCp; interface bonding; mechanical properties; surface modification

1 Introduction

Magnesium and its alloys have attracted great interest for structural applications in the aerospace, automotive, military, and electronics industries due to their light weight, high specific strength, superior machinability, damping capacity and recycling capacity in comparison to conventional unreinforced materials [1-3]. Silicon carbide particle (SiCp) is widely used as reinforcement in metal matrix composites (MMCs) owing to its high hardness, strength, elastic modulus, corrosion resistance, wear resistance, high temperature resistance and low price [4-7]. The demand for light-weight materials with enhanced mechanical properties has fueled research aimed at further improvements in the design of SiCp/Mg composites.

Among the many factors that may affect the mechanical performance of SiCp/Mg composites, the properties of the reinforcement (i.e., size, morphology, volume fraction, and distribution, etc.) and the interface of reinforcement-matrix play critical roles. Inspection of the published literature shows that increasing the volume frication of the SiC particles contributed to increase in strength with a sacrifice in ductility while reducing the size of the SiC particles resulted in higher yield strength and tensile strength of the composite in the same time [8,9]. All of these are based on the premise that the SiC particles are evenly distributed and the interface is well bonded [10,11]. Great efforts have been made to improve the interface bonding of the metal matrix composites. This effort mainly focuses on adding alloying elements, optimizing the preparation process, and modifying the surface. Surface modification of SiC particles is an effective approach to improve the interface wettability because it can prevent excessive interfacial reaction and improve the formability of the composites. Coating and high-temperature oxidation are common ways used in surface modification. It is confirmed that the surface oxidation of SiC particles can effectively remove the impurities, contaminants and intergranular water, thus making a positive impact on the properties of SiCp/Mg composites. However, the effect of high-temperature oxidation is adversely affected by the agglomeration of SiC particles at high temperature. Surface coating significantly improves the wettability between the magnesium matrix and SiC particles via coating a metal layer on the surface of SiC [12-14]. The interfacial bounding as well as the mechanical properties of SiC reinforced metal-based composites is significantly improved after coating the surface of SiC particles with metal layer.

However, less work has been performed on the microstructures and mechanical properties of Ni-coated SiC, and the research associated with the AZ61 matrix composites has also been rarely reported. Therefore, it is of great significance to investigate the influence of the Ni-coating on the SiCp surface on the properties of SiCp/AZ61 composites.

In this work, a Ni layer is plated on the surface of SiCp by electroless plating method. And then Ni-coated SiCp reinforced AZ61 magnesium composites are prepared by powder metallurgy and their microstructure and properties are compared to AZ61 magnesium composites reinforced with SiCp without Ni-coating. The morphology of the SiC particles, the microstructure characteristics and the mechanical properties of SiCp/AZ61 composites are discussed in detail in this work.

2 Experimental

2.1 Raw materials

The gas-atomized AZ61 alloy powders (Weihao, China) with an average size of 40 μm were used as matrix. Chemical composition of the AZ61 alloy powders is listed in Table 1. The α-SiC particles (Huarong Ceramics, China) with purity of 99.99% and an average size of 14 μm were used as reinforcement.

Table 1 Chemical composition of AZ61 powders (wt.%)

2.2 Surface modification of SiCp

Before the electroless plating of Ni-P coating, the SiC particles were processed for cleaning and activation using the following procedure:

(1) Cleaning and microscopic roughening in HF acid for 10 min;

(2) Sensitizing in a solution containing stannous chloride (SnCl2) and HCl for 30 min;

(3) Activating using a palladium chloride (PdCl2) solution for 30 min.

Distilled water was used between the different treatment stages to prevent contamination of the solutions. Furthermore, the particles were discontinuously stirred gently and maintained in an ultrasonic bath to enhance the chemical process.

The electroless Ni-coating deposition bath was developed with formulations used in Refs. [15-17]. The bath composition contains nickel sulphate (25 g/L) as a Ni source, sodium hypophosphite (25 g/L) as a reducing agent, sodium citrate (7.5 g/L) as a complexing agent and stabilizer. Sodium hydroxide solution was added as a pH adjustment. The electroless plating was carried out at 358 K by continuous stirring and the pH was adjusted to 7 using sodium hydroxide solution.

2.3 Preparation of SiCp/AZ61 composites

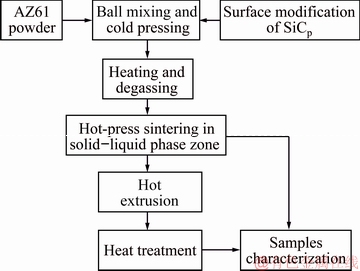

Figure 1 shows a process flow diagram for preparing SiCp/AZ61 composites. The AZ61 powders and Ni-coated SiCp were ball-mixed at 200 r/min for 30 min with a ball-to-powder mass ratio of 10:1. The mixed powders were compressed in a cemented carbide die with a diameter of 32 mm at room temperature. The pressure was 200 MPa and the dwell time was 2 min. Then, the as-received compacts were heated in a vacuum furnace and concurrently hot-press sintered at 773 K under a pressure of 45 MPa for 30 min and the temperature was monitored and controlled by a laser infrared thermometer. The hot-pressed specimens were extruded at 593 K with an extrusion ratio of 10:1. The extruded samples became bars with a diameter of 10 mm. Finally, the extruded specimens were solution- treated at 623 K for 2 h followed by water quenching, and then artificially aged at 453 K for 24 h. For comparative analysis, the SiCp/AZ61 composites with the original SiC particles were prepared under the same processing and aging condition.

Fig. 1 Process flow for preparing SiCp/AZ61 composites

2.4 Materials characterization

The density of the composites was measured by Archimedes method using an accurate balance (1 mg). The hardness of the material was measured using an HBS-62.5-type Brinell hardness tester with a 5 mm-diameter steel ball under a load of 62.5 kg, and the dwell time was 30 s. The X-ray diffraction (XRD) was performed using a D/max-vb 2500 diffractometer with Cu Kα radiation at a scanning speed of 4 (°)/min to detect the phase composition. Detailed microstructures were investigated by optical microscopy. The optical microstructure samples were prepared by sectioning and polishing of the corresponding plane and then etched by alcohol solution containing 4% of nitric acid (volume fraction). The microstructures such as the distribution of the Ni-coated SiCp in the AZ61 matrix were observed using a scanning electron microscope (SEM, Quanta- 200) equipped with an energy dispersive spectrometer (EDS). Electron probe microanalysis (EPMA; JXA8230) was used to demonstrate the distribution of intermetallic phases on the composite samples. The tensile tests at room temperature were conducted using an Instron MTS 810 mechanical testing machine at a loading rate of 0.2 mm/min.

3 Results and discussion

3.1 Characteristics of SiC particles

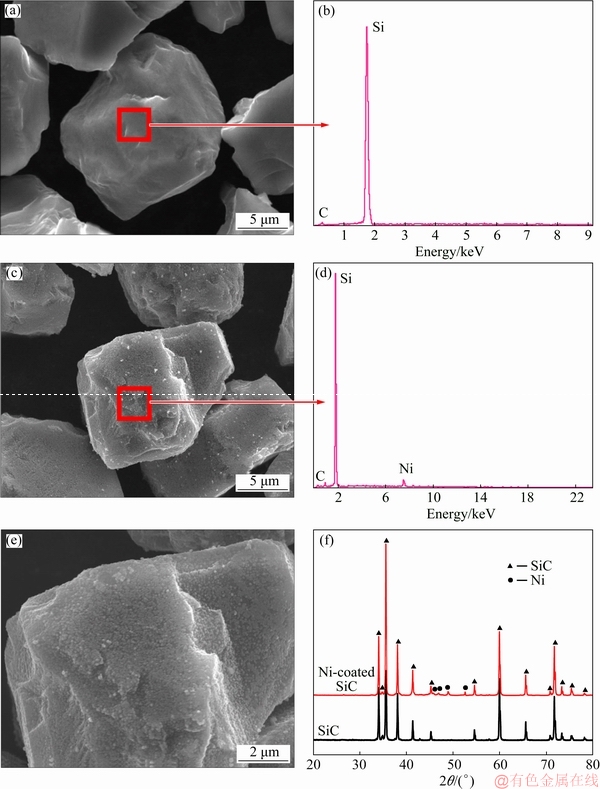

Fig. 2 SEM micrographs of uncoated (a) and Ni-coated (c, e) SiCp, and corresponding EDS results (b, d), XRD patterns of Ni-coated and uncoated SiCp (f)

Figure 2 shows the surface morphologies and corresponding EDS spectra of the SiCp with and without Ni-coating. Compared with the original SiCp, the Ni-coated SiCp is glossy and some tiny particles on the surface are observed. It can be observed from Fig. 2(e) that the surface becomes coarser. Additionally, the corresponding EDS spectra show that the Ni element is observed besides the silicon and carbide elements on the surface of the Ni-coated SiCp which means that the surface composition of SiCp has changed. Figure 2(f) shows the XRD patterns of the SiCp with and without Ni coating. It can be seen that Ni and SiC phases exist on the surface of the Ni-coated SiCp, which could be concluded that a pure Ni layer was plated on the surface of SiCp.

3.2 Microstructures of SiCp/AZ61 composites

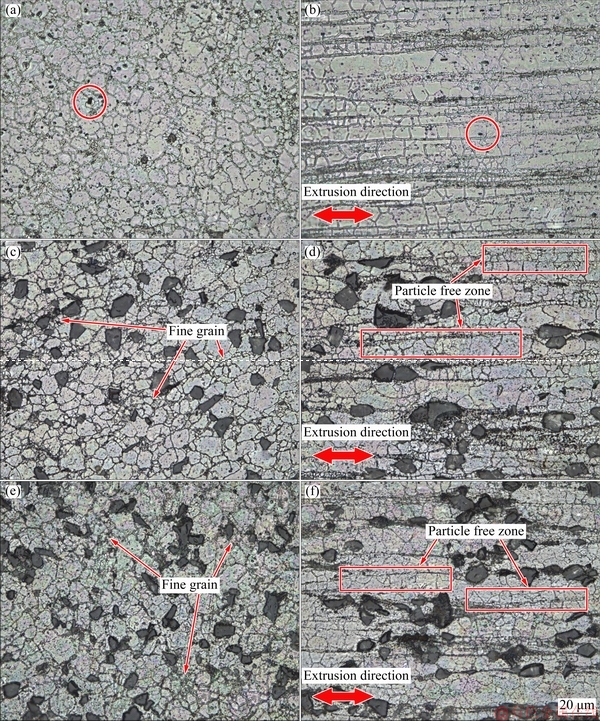

Figure 3 shows the optical micrographs of the hot extruded AZ61 alloys and SiCp/AZ61 composites after hot extrusion. It can be seen that the larger second phase particles in the AZ61 matrix alloy are distributed at the grain boundaries and crystals, as shown in the circle in Figs. 3(a) and (b). The Mg17Al12 phase in SiCp/AZ61 composites after hot extrusion breaks into smaller particles under the shear stress field of the matrix alloy and SiC particles. It can be observed that the SiCp particles distribute uniformly on the transversal section. However, the particles are mainly distributed along the extrusion direction and the particle-free zones are exhibited, as shown in Figs. 3(c) and (e). The flow velocity of matrix is faster than that of SiCp during hot extrusion because the AZ61 alloy is soft and deformable while the SiCp is hard and non-deformable. The finer equiaxed grains with well-defined grain boundaries indicate that the dynamic recrystallization (DRX) occurred during hot extrusion [18].

Fig. 3 Optical micrographs of AZ61 alloy (a, b), uncoated (c, d) and Ni-coated (e, f) SiCp reinforced composites along transversal section (a, c, e) and longitudinal section (b, d, f) after hot extrusion

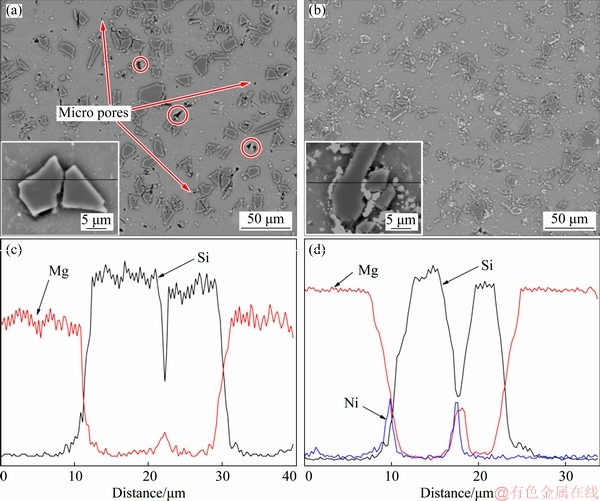

Figure 4 shows the microstructures and corresponding EDS results of the composites reinforced with 12 vol.% SiCp with and without Ni coating. It can be observed from Fig. 4 that there are micro-sized pores and obvious flaws around the uncoated SiCp. A lot of triangular-shape pits (as indicated by the red circles) are also observed. These pits may be ascribed to the abscission of the SiCp during polishing. This phenomenon indicates the interfacial bonding between the uncoated SiCp and the matrix is not strong enough. With the introduction of Ni-coated SiCp, little porosity or micro flaws are observed in the composite, as shown in Fig. 4(b). Additionally, the Ni coating is chemically stable after hot pressing followed by hot extrusion.

The direct contact between two SiC particles is observed from Fig. 4(a). However, a transition layer is present between two SiC particles as seen in Fig. 4(b). To verify the contact form and composition of the transition layer, the line scan was performed on the interfacial area and the results are shown in Figs. 4(c) and (d), respectively. It is observed that there is lack of matrix filling between the two SiC particles in Fig. 4(c). Therefore, it is reasonable to infer that stress concentration is easy to occur at the two particles when external load is applied, which leads to reduced strength of the composite. The line scan result of Fig. 4(d) shows that the Si content decreases between the particles and the Ni appears at the corresponding position. This result means that the Ni layer still adheres to SiCp after hot extrusion. It can be observed that the Ni layer results in the homogeneous distribution of SiCp in the AZ61 matrix and avoids direct contact between two or more particles. Therefore, the formation of microscopic cracks in the agglomerates is significantly reduced. It is generally known that the uniform dispersion of SiCp is beneficial for improving the strength and plasticity of the material.

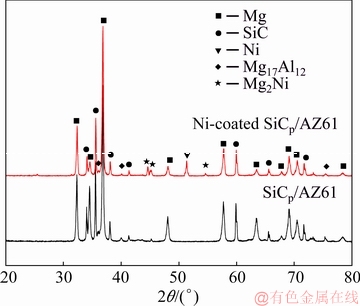

X-ray diffraction was carried out to figure out the bright phases distributed in the SiCp/AZ61 composites, and the results are shown in Fig. 5. Accordingly, no other phases are detected except Mg, SiC, and Mg17Al12 phases in the uncoated SiCp reinforced composite, which means that no interface reaction has occurred. However, Mg2Ni phase is detected in the Ni-coated SiCp reinforced composite, indicating that the Ni coating was reacted with the AZ61 matrix to from a chemical bonding at the interface. HASSAN and GUPTA [19] also found Mg2Ni phase at the interface in the Ni particles reinforced magnesium matrix composites. They suggested that the chemical interaction between Ni particle and magnesium matrix was beneficial for improving mechanical properties of the composites.

Fig. 4 SEM micrographs of composites reinforced with 12 vol.% uncoated (a) and Ni-coated (b) SiCp, and corresponding line scan results of uncoated (c) and Ni-coated (d) SiCp reinforced composites

Fig. 5 XRD patterns of composites reinforced with 12 vol.% uncoated and Ni-coated SiCp

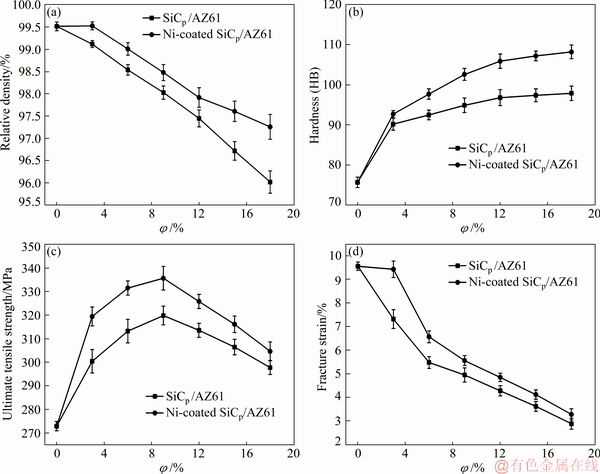

To investigate the distribution of intermetallic phases, BSE images and EPMA elemental quantitative analysis were performed on the samples after hot extrusion, and the results are shown in Fig. 6. As seen in Fig. 6(a), two kinds of phases were observed. The brighter phase, point 1 in Table 2, has a very high content of aluminum (about 87 at.%), which can be identified as pure aluminum phase considering the influence of high content of magnesium in the matrix. However, it may be noted that the Al phase is not observed in the XRD results in Fig. 5 due to the limitation of filtered X-ray radiation to detect the phases with less than 2 vol.% in a multiphase structure. The reason that the major phase contains small phases can be contributed to the Kirkendall effect caused by the difference of diffusion rates between Al and Mg atoms during annealing [20]. The intrinsic diffusion of Al is much faster than Mg in the second phase [21]. Therefore, Al can diffuse into the Mg phase leaving vacancies whereas Mg can hardly diffuse into the Al or Mg17Al12 phase. According to the analysis for quantitative assessment of the grey phase shown as point 2 in Fig. 6(a), the grey phases are most likely Mg17Al12 phases as revealed by the XRD results and atomic ratio. Point 3 is related to the AZ61 matrix and point 4 corresponds to SiCp, respectively. As depicted in Fig. 6(b), point 5 at the interface between the matrix and SiCp has relatively more Ni content, and point 6 can mostly be identified as mixed phases of Mg2Ni and Mg17Al12 based on the data in Table 2.

3.3 Mechanical properties

Fig. 6 BSE images and quantitative elemental analysis by EPMA techniques of uncoated SiCp/AZ61 (a) and Ni-coated SiCp/AZ61 (b) composites

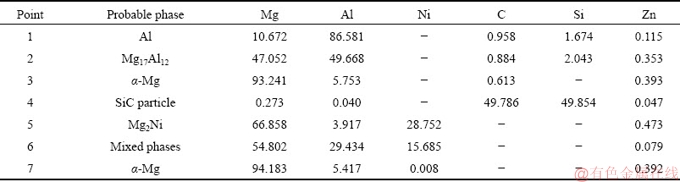

Table 2 EPMA results of points designated in Fig. 6 (at.%)

Fig. 7 Variations in relative density (a), hardness (b), ultimate tensile strength (c), and fracture strain (d) for AZ61 alloy reinforced with different volume fractions of uncoated and Ni-coated SiC particles

Figure 7 shows the relative density, hardness, ultimate tensile strength, and fracture strain of the AZ61 matrix composites reinforced with different volume fractions of SiCp with and without Ni coating, respectively. The relative density of the composites decreases with the increase in the volume fraction of SiCp. However, the composites with Ni-coated SiCp show a higher density than that with uncoated ones at the same content of SiCp. According to the result of differential thermal analysis, the solidus and liquidus temperatures of AZ61 alloy are 798 and 898 K, respectively [22]. Therefore, partial liquid phase is formed during hot-press sintering, which is beneficial for densification of the composites. By compared Fig. 4(a) with 4(b), the wetting between the AZ61 alloy and SiCp is significantly improved owing to the presence of Ni layer. The molten matrix could effectively spread on the surface of Ni-coated SiCp, and then most of the micro-pores and flaws are removed after sintering. This phenomenon results in a higher relative density of magnesium matrix composites reinforced with Ni-coated SiCp than the uncoated ones.

There is a significant increment in the hardness of the SiCp/AZ61 composites with the increase in volume fraction of reinforcement, as seen in Fig. 7(b). This enhanced hardness can be primarily attributed to: (1) the presence of relatively harder intermetallic and ceramic particles in the matrix [23,24], (2) a higher constraint to the localized matrix deformation during indentation. It should be noted that intermetallic is extremely hard relative to their pure components [25]. Higher concentration of reaction product and reinforcement particles causes a further increment of hardness. Additionally, the higher hardness of the Ni-coated SiCp/AZ61 composites is attributed to the presence of Mg2Ni phase.

It can be observed from Fig. 7(c) that the ultimate tensile strength (UTS) of the composites first increases and then decreases with the increase in the volume fraction of SiCp. The remarkable increase in the UTS at low volume fraction of SiCp (less than 9 vol.%) can be ascribed to: (1) the presence of uniformly distributed SiC particles, (2) effective transfer of applied tensile load to the uniformly distributed and well-bonded high strength reinforcement [26]. As observed from the cross-sectional microstructure of the hot-extruded composites in Fig. 4, the Ni coating is favorable for improving interfacial bonding due to the formation of Mg2Ni phase at the interface. Therefore, the composites reinforced with Ni-coated SiCp also show higher UTS than that with uncoated SiCp. However, the porosity of the composites increases with the increase in the volume fraction of SiCp, which leads to the sharp decrease in the UTS when the volume fraction of SiCp is more than 9 vol.%.

The fracture strain of the SiCp/AZ61 composites decreases with the increase in the content of SiCp as shown in Fig. 7(d). The reduction in fracture strain of the composites can be attributed to the presence of porosity and brittle second phases, such as Mg17Al12 and Mg2Ni, at the SiC particle/matrix interface as well as in the matrix. It may be noted that the presence of hard second phases in the matrix leads to the plastic incompatibility and acts as crack nucleation sites, which results in the reduction in ductility under the action of uniaxial tensile load [27].

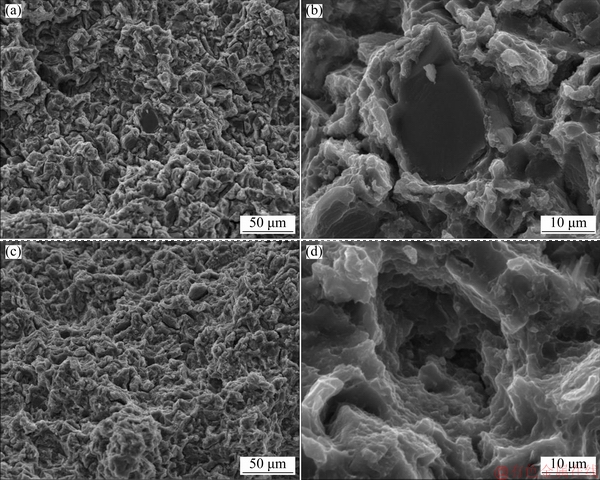

Fig. 8 Representative SEM micrographs of tensile fracture surfaces of AZ61 composites reinforced with 12 vol.% uncoated (a, b) and Ni-coated (c, d) SiCp

Generally, the changes of mechanical properties can be explained mainly by the mechanisms such as (1) Hall-Petch relationship due to grain refinement of dynamic recrystallization, (2) Orowan strengthening due to the presence of fine hybrid reinforcement/intermetallic phases, (3) elastic and coefficient of thermal expansion mismatch between matrix and reinforcements (αMg= 28.4×10-6 ℃-1, αSiC=4.7×10-6 ℃-1, αNi=13.0×10-6 ℃-1) and (4) effective load transfer from matrix to second phases [23].

3.4 Fractography

The tensile fracture surfaces of the AZ61 matrix composites reinforced with 12 vol.% SiCp are presented in Fig. 8. As observed from Fig. 8(a) few dimples were observed, which means that the fracture of composites reinforced with uncoated SiCp occurred by cleavage. Such fractography is attributed to the hexagonal crystal system (HCP) structure of magnesium that restricts the slip of the basal plane. Dislocations are easily entangled with each other in the process of deformation or blocked by grain boundaries. There is a large stress near the plug front and the stress concentration occurs rapidly. The stress concentration leads to the rapid de-bonding of SiCp from the AZ61 alloy matrix. Therefore, the interface separation is observed in the composite reinforced with uncoated SiCp as shown in Fig. 8(b). However, no apparent interface separation between the SiCp and matrix is observed on the fracture surface of the composites reinforced with Ni-coated SiCp as shown in Fig. 8(c). Moreover, there is a significant plastic deformation characterization on the fracture of the composite reinforced with Ni-coated SiCp. This result suggests that the formation of interfacial layer enhances the interfacial bonding strength between the SiCp and AZ61 alloy matrix. Therefore, the Ni coating on the surface of SiCp plays a role in transferring load from the matrix to the reinforcement under tensile stress.

4 Conclusions

(1) The Ni coating fabricated by electroless plating is beneficial for the wettability and interfacial bonding strength between the SiCp and AZ61 matrix. The Ni-coated SiCp particles uniformly distribute throughout the matrix and no particle agglomeration can be observed.

(2) Microstructural characterization of synthesized materials revealed that addition of SiC into AZ61 alloy matrix has refined grain size because of dynamic recrystallization after hot extrusion. Furthermore, SiCp helps to break the Mg17Al12 intermetallic phases into a large number of smaller particles in composite matrix.

(3) Room temperature mechanical characterization of Ni-coated SiCp/AZ61 composites revealed a significant increase in hardness, relative density, ultimate tensile strength and fracture strain than composites with the same addition of uncoated SiCp. Thus, Ni coating has definite potential to improve the mechanical properties of Ni-coated SiCp/AZ61 composites.

References

[1] WAN N A W M, SAJURI Z, MUTOH Y, MIYASHITA Y. Microstructure and mechanical properties of magnesium composites prepared by spark plasma sintering technology [J]. Journal of Alloys and Compounds, 2011, 509(20): 6021-6029.

[2] ATAYA S, EL-MAGD E. Quasi-static behavior of mg-alloys with and without short-fiber reinforcement [J]. Theoretical and Applied Fracture Mechanics, 2007, 47(2): 102-112.

[3] PARAMSOTHY M, HASSAN S F, SRIKANTH N, GUPTA M. Simultaneous enhancement of tensile/compressive strength and ductility of magnesium alloy AZ31 using carbon nanotubes [J]. Journal of Nanoscience and Nanotechnology, 2010, 10(2): 956-964.

[4] MALLICK A, TUN K S, GUPTA M. Deformation behaviour of Mg/Y2O3 nanocomposite at elevated temperatures [J]. Materials Science and Engineering A, 2012, 551: 222-230.

[5] YE Hai-zhi, LIU Xing-yang. Review of recent studies in magnesium matrix composites [J]. Journal of Materials Science, 2004, 39(20): 6153-6171.

[6] LIAO Wen-jun, YE Bing, ZHANG Li, ZHOU Hao, GUO Wei. Microstructure evolution and mechanical properties of SiC nanoparticles reinforced magnesium matrix composite processed by cyclic closed-die forging [J]. Materials Science and Engineering A. 2015, 642: 49-56.

[7] BALASUBRAMANIAN I, MAHESWARAN R , MANIKANDAN V, PATIL N, RAJA M A, SINGARI R M. Mechanical characterization and machining of squeeze cast AZ91D/SiC magnesium based metal matrix composites [J].Procedia Manufacturing, 2018,20: 97-105.

[8] DWIVEDI S P, SHARMA S, MISHRA RK. A comparative study of waste eggshells, CaCO3, and SiC-reinforced AA2014 green metal matrix composites [J]. Journal of Composite Materials, 2016, 51(17): 2407-2421.

[9] GU Lin, CHEN Ji-peng, XU Hui, ZHAO Wan-sheng. Blasting erosion arc machining of 20 vol.% SiC/Al metal matrix composites [J]. International Journal of Advanced Manufacturing Technology, 2016, 87(9-12): 2775-2784.

[10] INEM B, POLLARD G. Interface structure and fractography of a magnesium-alloy, metal-matrix composite reinforced with SiC particles [J]. Journal of Materials Science, 1993, 28(16): 4427-4434.

[11] MOLINS R, BARTOUT J D, BIENVENU Y. Microstructural and analytical characterization of Al2O3/(Al-Mg) composite interfaces [J]. Materials Science and Engineering A, 1991, 135(3): 111-117.

[12] GU Jin-hai, ZHANG Xiao-nong, QIU Yong-fu, GU Ming-yuan. Damping behaviors of magnesium matrix composites reinforced with Cu-coated and uncoated SiC particulates[J]. Composites Science and Technology, 2005, 65(11-12): 1736-1742.

[13] SANKARANARAYANAN S, SABAT R K, JAYALAKSHMI S, SUWAS S, GUPTA M. Effect of hybridizing micron-sized Ti with nano-sized SiC on the microstructural evolution and mechanical response of Mg-5.6Ti composite [J]. Journal of Alloys and Compounds, 2013, 575(15): 207-217.

[14] SHOEIB M, SOROR T Y, MAAMOUN M A, EL-BASIUNY M S. Aluminum metal-ceramic matrix composites reinforced by using electroless nickel plating on ceramic particles and fibers [J]. Materials Research Innovations, 2005, 9(2): 51-52.

[15] SUDAGAR J, LIAN Jian-she, SHA Wei. Electroless nickel, alloy, composite and nano coatings—A critical review [J]. Journal of Alloys and Compounds, 2013, 44(31): 183-204.

[16] CHEN Wan-ping, LI Long-tu, QI Jian-quan, WANG Yu, GUI Zhi-lun. Influence of electroless nickel plating on multilayer ceramic capacitors and the implications for reliability in multilayer ceramic capacitors [J]. Journal of the American Ceramic Society, 2010, 81(10): 2751-2752.

[17] CHEN Wen-ding, SUNG Yu, CHANG Chang-pin, CHEN Yann-cheng, GER Ming-der. The preparation of thermo-responsive palladium catalyst with high activity for electroless nickel deposition [J]. Surface & Coatings Technology, 2010, 204(14): 2130-2135.

[18] SHEN M J, WANG X J, LI C D, ZHANG M F. Effect of bimodal size sic particulates on microstructure and mechanical properties of AZ31B magnesium matrix composites [J]. Materials & Design, 2014, 52(2): 1011-1017.

[19] HASSAN S F, GUPTA M. Development of high strength magnesium based composites using elemental nickel particulates as reinforcement [J]. Journal of Materials Science, 2002, 37(12): 2467-2474.

[20] XIAO Lin, WANG Ning. Growth behavior of intermetallic compounds during reactive diffusion between aluminum alloy 1060 and magnesium at 573-673 K [J]. Journal of Nuclear Materials, 2015, 456: 389-397.

[21] BRENAN S, BERMUDEZ K, KULKARNI N S, SOHN Y. Interdiffusion in the Mg-Al system and intrinsic diffusion in β-Mg2Al3 [J]. Metallurgical and Materials Transactions A, 2012, 43(11): 4043-4052.

[22] OHNO M, MIRKOVIC D, SCHMID-FETZER R, Liquidus and solidus temperatures of Mg-rich Mg-Al-Mn-Zn alloys [J]. Acta Materialia, 2006, 54(15): 3883-3891.

[23] GUPTA M, LAI M O, SARAVANARANGANATHAN D. Synthesis, microstructure and properties characterization of disintegrated melt deposited Mg/SiC composites [J]. Journal of Materials Science, 2000, 35(9): 2155-2165.

[24] REDDY A L M, RAMAPRABHU S. Synthesis and characterization of magnetic metal-encapsulated multi-walled carbon nanobeads [J]. Nanoscale Research Letters, 2008, 3(2): 76-81.

[25] WESTBROO J H K, FLEISCHER R L. Intermetallic compounds, principles and practice: progress [M]. 3rd ed. New York: John Wiley & Sons, 2002.

[26] CHEN Biao, LI Shu-feng, IMAI H, JIA Lei, UMEDA J. Load transfer strengthening in carbon nanotubes reinforced metal matrix composites via in-situ tensile tests [J]. Composites Science and Technology, 2015, 113: 1-8.

[27] MEENASHISUNDARAM G K, SEETHARAMAN S, GUPTA M. Enhancing overall tensile and compressive response of pure Mg using nano-TiB2 particulates [J]. Materials Characterization, 2014, 94(8): 178-188.

郭苏庆,王日初,彭超群,蔡志勇,董翠鸽

中南大学 材料科学与工程学院,长沙 410083

摘 要:采用粉末冶金加热挤压工艺制备SiCp/AZ61复合材料,为了改善复合材料的界面结合性能,在SiCp表面化学镀覆镍-磷涂层。分析镍涂层对复合材料显微组织和力学性能的影响。结果表明,SiC颗粒表面镀镍后在复合材料中分布更均匀,镀镍复合材料缺陷较少。在烧结过程中镍涂层与镁基体反应形成Mg2Ni界面化合层。与未镀覆复合材料相比,镀镍复合材料的致密度从97.9%增加到98.4%,并且随着SiC颗粒体积分数的增加,镀镍复合材料的硬度增加得更快。拉伸实验结果表明,当SiC颗粒的体积分数为9%时,镀镍复合材料具有较高的伸长率,拉伸强度从320 MPa增加到336 MPa,表明镍涂层能提高界面结合强度和性能。此外,分析SiCp/AZ61复合材料的断口形貌。

关键词:镁基复合材料;表面镀镍SiC颗粒;界面结合;力学性能;表面改性

(Edited by Xiang-qun LI)

Foundation item: Project (CXZZ20140506150310438) support by the Science and Technology Program of Shenzhen, China; Project (2017GK2261) supported by the Science and Technology Program of Hunan, China; Project (2017zzts111) supported by the Fundamental Research Funds for the Central Universities of Central South University, China

Corresponding author: Cui-ge DONG; Tel: +86-18774852301; E-mail: dongcuige@csu.edu.cn

DOI: 10.1016/S1003-6326(19)65093-4