镀钛SiC颗粒增强Al 2519复合材料的组织与力学性能

来源期刊:中国有色金属学报(英文版)2020年第4期

论文作者:董翠鸽 崔蕊 王日初 彭超群 蔡志勇

文章页码:863 - 871

关键词:Al 2519基复合材料;表面改性;镀钛SiC颗粒;粉末冶金;界面显微组织;力学性能

Key words:Al 2519 matrix composites; surface modification; Ti-coated SiCp; powder metallurgy; interfacial microstructure; mechanical properties

摘 要:采用真空蒸镀法对SiC颗粒(SiCp)表面进行镀Ti改性改善SiCp/Al复合材料界面结合,采用热压、挤压和热处理等方法制备镀Ti后SiCp和原始SiCp增强的Al 2519基复合材料。通过扫描电镜(SEM)和能谱仪(EDS)分析Ti镀层对复合材料组织与性能的影响。结果表明,致密沉积的Ti镀层与SiCp反应,在界面处形成TiC和Ti5Si3相;与用原始SiCp增强的复合材料相比,用Ti镀覆SiCp增强的复合材料表现出均匀且致密的显微组织且复合材料的相对密度和力学性能得到显著改善。体积分数为15%时,镀Ti后SiCp增强Al 2519复合材料的硬度、断裂应变和拉伸强度达到最优,分别为HB 138.5、4.02%和455 MPa。

Abstract: Ti-coated SiCp particles were developed by vacuum evaporation with Ti to improve the interfacial bonding of SiCp/Al composites. Ti-coated SiC particles and uncoated SiC particles reinforced Al 2519 matrix composites were prepared by hot pressing, hot extrusion and heat treatment. The influence of Ti coating on microstructure and mechanical properties of the composites was analyzed by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The results show that the densely deposited Ti coating reacts with SiC particles to form TiC and Ti5Si3 phases at the interface. Ti-coated SiC particle reinforced composite exhibits uniformity and compactness compared to the composite reinforced with uncoated SiC particles. The microstructure,relative density and mechanical properties of the composite are significantly improved. When the volume fraction is 15%, the hardness, fracture strain and tensile strength of the SiCp reinforced Al 2519 composite after Ti plating are optimized, which are HB 138.5, 4.02% and 455 MPa, respectively.

Trans. Nonferrous Met. Soc. China 30(2020) 863-871

Cui-ge DONG, Rui CUI, Ri-chu WANG, Chao-qun PENG, Zhi-yong CAI

School of Materials Science and Engineering, Central South University, Changsha 410083, China

Received 12 July 2019; accepted 16 February 2020

Abstract: Ti-coated SiCp particles were developed by vacuum evaporation with Ti to improve the interfacial bonding of SiCp/Al composites. Ti-coated SiC particles and uncoated SiC particles reinforced Al 2519 matrix composites were prepared by hot pressing, hot extrusion and heat treatment. The influence of Ti coating on microstructure and mechanical properties of the composites was analyzed by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The results show that the densely deposited Ti coating reacts with SiC particles to form TiC and Ti5Si3 phases at the interface. Ti-coated SiC particle reinforced composite exhibits uniformity and compactness compared to the composite reinforced with uncoated SiC particles. The microstructure,relative density and mechanical properties of the composite are significantly improved. When the volume fraction is 15%, the hardness, fracture strain and tensile strength of the SiCp reinforced Al 2519 composite after Ti plating are optimized, which are HB 138.5, 4.02% and 455 MPa, respectively.

Key words: Al 2519 matrix composites; surface modification; Ti-coated SiCp; powder metallurgy; interfacial microstructure; mechanical properties

1 Introduction

Aluminum matrix composites reinforced with silicon carbide particles (SiCp/Al) show good mechanical strength, stiffness, fatigue resistance, wear, and creep behavior, and have been widely applied in aerospace, aircraft, automotive and other industries [1-4]. However, the major problem encountered in SiCp/Al composites is the weak interface bonding between SiCp and aluminum alloy matrix [5,6]. A good interfacial bonding can avoid the stress concentration and result in the excellent mechanical properties of SiCp/Al composites. Improving the wettability and decreasing the melting point of Al matrix are the two main ways to mitigate this problem [7-9].

Adding alloy elements and surface modification are the common methods to improve the relative density and interface bonding of SiCp/Al composites. The addition of Mg and/or Si element decreases the melting point of Al alloy and improves the relative density of the Al matrix composites [10,11]. However, the mechanical properties of the composites are largely reduced when excessive amount of the alloy elements is added [12]. The electroless deposition of Ni or Cu on SiC particles is a popular surface modification method to improve the relative density and matrix strength of SiCp/Al composites [13]. Whereas, the coating could not improve the interfacial bonding since the coating layers diffuse into the Al alloy matrix during sintering [14,15]. Therefore, it is essential to develop a new coating that could not only enhance the relative density of composites but also improve the interfacial bonding strength. It is reported that Ti can react with SiCp and Al to form TiC and other metallic compounds such as Ti5Si3 and TiAl3 [16-18], which enlightens us to develop a suitable coating on the SiC particles. A Ti5Si3 coating has been prepared by salt-bath plating and improved the relative density and interfacial bonding of the composites [19-21]. However, the microstructure, mechanical properties, and mechanism of Ti-coated SiC particles reinforced Al 2519 matrix by powder metallurgy have not been fully investigated.

In this work, an evaporation method under vacuum atmosphere was used to form a new structure of a Ti layer on the surface of uncoated SiC particles. The structure of the Ti coating and the microstructure and mechanical properties of the Al 2519 matrix composites reinforced with different volume fractions of Ti-coated and uncoated SiC particles were investigated.

2 Experimental

2.1 Raw materials

Al 2519 alloy powder with an average size of 75 μm and purity of 99.9% was produced by gas atomization with N2 (Bolangsida Materials, China). Chemical composition of the as-received Al 2519 alloy powder is listed in Table 1. Conventional abrasive grade α-SiC particles (Huarong Ceramics, China) with an average size of 14 μm acted as the reinforcing phase. High-purity Ti powder (99.999%) with an average size of 75 μm was served as the raw material for the surface modification of SiC particles.

Table 1 Chemical composition of gas-atomized Al 2519 alloy powder (wt.%)

2.2 Process of Ti coating

The surface modification of SiC particles with Ti was performed using a diffusion method in a vacuum reactor. Before the coating process, the SiC particles were cleaned and activated by NaOH and dilute HNO3 solutions. The SiC particles were dipped into a 2.5 mol/L NaOH solution and a 10 wt.% HNO3 solution in a boiling condition and stirred for 20 min. Then, the SiC particles were dried in vacuum oven at 80 °C for 24 h. The dried SiC particle and Ti powder with the mass ratio of 1:2 added with 2 wt.% alcohol were mechanically mixed at low speed (approximately 50 r/min) for 8 h. The ball-to-powder mass ratio was 5:1 to ensure that the SiCp was fully surrounded by the Ti powder. The mixed powder was put into an alumina crucible and then heat-treated at 850 °C for 4 h in a vacuum of 1.0×10-3 Pa. After heat treatment, the Ti-coated SiC particles were obtained by mechanical sieving to exclude the Ti powder.

2.3 Preparation of SiCp /Al 2519 composites

The Al 2519 powder and (5-20) vol.% Ti-coated SiC particles were ball-mixed at 190 r/min for 10 h with a mass ratio of 10:1. After that, the mixed powder was die-pressed in a steel crucible with a diameter of 32 mm. The selected pressure was 57 MPa and the holding time was 2 min. The green compacts of about 70% relative density were then hot-pressing sintered at 550 °C under a pressure of 13 MPa for 1 h in vacuum atmosphere with a heating rate of 10 °C/min. The samples were extruded at 400 °C with an extrusion ratio of 9:1. Finally, the extruded samples were solution-treated at 525 °C for 1 h, followed by water quenching, and then artificially aged at 190 °C for 3 h and 150 °C for 24 h, successively. For comparison, Al 2519 alloy and SiCp/Al 2519 composites reinforced with uncoated SiC particles were prepared and followed by the identical processing and aging conditions.

2.4 Characterization

The density of the SiCp/Al 2519 composites was measured by Archimedes method using an accurate balance (1 mg). The X-ray diffraction (XRD) was performed using a D/max-vb 2500 diffractometer with Cu Kα radiation at a scanning speed of 2 (°)/min to detect the phase composition. The microstructures of the uncoated and Ti-coated SiC particles and SiCp/Al 2519 composites were detected using a scanning electron microscope (SEM, Quanta-200) equipped with an energy dispersive spectrometer (EDS). The tensile tests were carried out by an Instron MTS 810 mechanical testing machine at a loading rate of 0.2 mm/min. The micro-hardness of the material was measured using an HBS-62.5-type Brinell durometer with a 5 mm-diameter steel ball under a load of 62.5 kg for 30 s. The polarization curves were measured by sweeping the potential from -1.5 to -0.5 V at a scanning rate of 2 mV/s.

3 Results and discussion

3.1 Characteristics of Ti-coated SiCp

The SEM images and corresponding EDS spectra of the uncoated and Ti-coated SiC particles are shown in Fig. 1. From Fig. 1(a), the surface of uncoated SiC particles is neat and clean and the sharp angle is clearly observed. Compared with the uncoated SiC particles, the angle of Ti-coated SiC particles becomes smoother and a distinct Ti coating is observed, as seen in Fig. 1(b). From the magnified image, the surface of SiC particles is covered by uniform and dense Ti particles with a grain size of about 200 nm. Additionally, the corresponding EDS spectrum of the Ti-coated SiC particles shows that the Ti element is observed besides the Si and C elements on the surface of the SiC particles, as seen in Fig. 1(d).

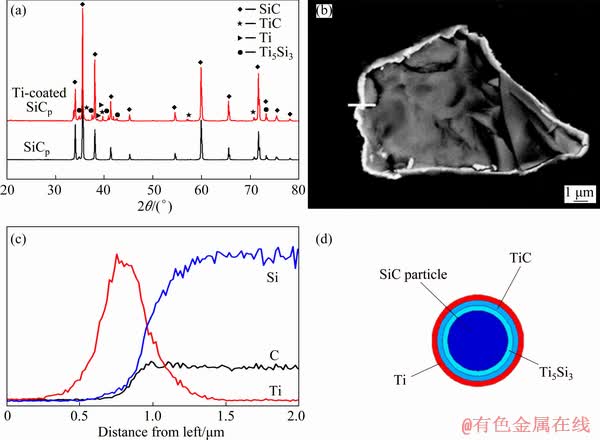

The XRD patterns of the Ti-coated SiC particles are shown in Fig. 2(a). It is observed that other than the Ti layer, Ti5Si3 and TiC phases also exist on the surface of the modified SiC particles. During the process of surface modification, Ti atoms were generated by volatilization from the Ti powders and then deposited on the surface of SiC particles under a vacuum of 1.0×10-3 Pa. Therefore, Ti5Si3 and TiC layers are generated according to the following reactions [22]:

SiC→Si+C (1)

Ti+C→TiC (2)

5Ti+3Si→Ti5Si3 (3)

The previous report suggested that the reaction between SiC and Ti is controlled by the atomic diffusion rate [23]. The smaller atomic radius results in the faster diffusion rate. So the diffusion rate of C is the fastest, that of Si is the second and that of Ti is the slowest. This indicates that the C atoms in SiC diffuse quickly to form TiC which is close to the Ti side because of the higher affinity of Ti to C than Si atoms [24]. With the increase of holding time, the Ti atoms diffuse to the surface of SiC particles to form Ti5Si3 beside the SiC side [25]. The variation of element concentration of Ti, Si, and C through the cross-section can be observed from the structure of Ti coating on SiC particles, as shown in Figs. 2(b) and (c). It is also observed that, the concentration of Ti first reaches a peak from the coating to the SiCp, while the corresponding concentrations of Si and C are almost zero. This result suggests that the outer layer is a pure Ti coating. While the concentration of C reaches a peak faster than that of Si, then decreases lightly with the increasing concentration of Si, indicating that the TiC phase is formed at first and then Ti5Si3. Therefore, the surface structure of Ti-coated SiC particles is SiC/Ti5Si3/TiC/Ti, from inner to outside, and the corresponding mechanism diagram of Ti-coated SiC particle is shown in Fig. 2(d).

Fig. 1 SEM images of uncoated (a) and Ti-coated (b) SiC particles and corresponding EDS results of point C (c) and point D (d) as marked

Fig. 2 XRD patterns (a) and cross-sectional microstructure (b) of Ti-coated SiC particles, collection of individual element concentration profiles (c), and surface structure of Ti-coated SiC particle (d)

3.2 Microstructures of SiCp/Al 2519 composites

The microstructures of Al 2519 matrix composites reinforced with (5-20) vol.% Ti-coated SiCp are presented in Fig. 3. As shown in Figs. 3(a)-(d), most of the Ti-coated SiC particles are well-distributed in the extruded SiCp/Al 2519 composites with different volume fractions. The mechanical properties of composites are influenced significantly by the distribution of ceramic particles and interface structure [26]. The homogeneous distribution of Ti-coated SiCp whose sharp corner is passivated results in uniform deformation and prevents stress concentration. It can be observed from Figs. 3(e) and (f) that, obvious pores and flaws exist at the interfaces of the composites reinforced with uncoated SiC particles. However, no apparent defects exist around the Ti-coated SiC particles. Therefore, it can be inferred that only a small interface adhesive force exists between the uncoated SiCp and the matrix, while the interfacial bonding is significantly improved when the Ti-coated SiC particles serve as reinforcement.

Figure 4 displays the magnified SEM images of the extruded SiCp/Al 2519 composites showing the contact between two SiC particles and the corresponding EDS line scanning map. As observed from Fig. 4(a), there is direct surface contact between two uncoated SiC particles in the aggregation area. The corresponding EDS line scanning map of Fig. 4(c) shows that the spectrum intensity of Al at the interface of the two particles is weak and the decrease of Si spectrum intensity is little. However, a transition layer (white phase) is observed in Fig. 4(b), which blocks the direct surface contact between two Ti-coated SiC particles. From the corresponding EDS line scanning map of Fig. 4(d), a sharp drop in the spectrum intensity of Si occurs between two particles and the spectrum intensity of Ti increases at the same position. This phenomenon indicates that the Ti coating still exists on the surface of SiC particles after consolidation and heat treatment. Therefore, the Ti coating could reduce the possibility of micro-crack formation at the particle agglomeration and contribute to the improvement of mechanical properties of the composites.

Fig. 3 Microstructures of Al 2519 matrix composites reinforced with 5 vol.% (a), 10 vol.% (b), 15 vol.% (c), and 20 vol.% (d) Ti-coated SiC particles and high magnification images of composites reinforced with 15 vol.% uncoated (e) and 15 vol.% Ti-coated (f) SiC particles

3.3 Properties of SiCp/Al 2519 composites

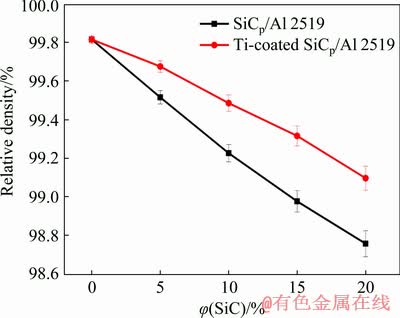

The relative density of the Al 2519 matrix composites reinforced with different volume fractions of SiC with and without Ti coating is shown in Fig. 5. It is observed that the relative density of the composites decreases with the increase in the volume fraction of SiC, but those with Ti-coated particles exhibit a higher density. Compared with the uncoated SiC particles, the wettability between the Al matrix and Ti-coated SiC particles is significantly improved, and the matrix could effectively spread on the surface of the Ti-coated particles [19]. Thus, most of the micro- pores and obvious flaws are highly reduced during hot pressing and extrusion, resulting in the improvement of relative density of the composites reinforced with Ti-coated SiC particles.

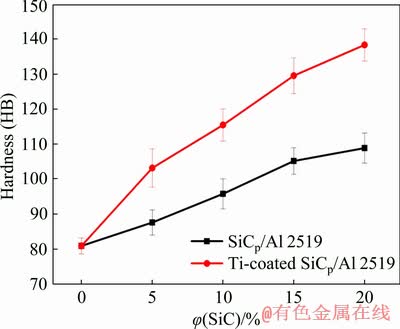

The hardness of the SiCp/Al 2519 composites reinforced with different volume fractions of SiC is shown in Fig. 6. It can be observed that there is a significant improvement in the hardness of Al 2519 alloy with the addition of SiC particles. The hardness of the SiCp/Al 2519 composites increases with the increase in volume fraction of SiC. The improvement of hardness is mainly attributed to the load transfer from matrix to SiCp [27] and the hard SiC particles prevent the plastic deformation of matrix. Additionally, the composites reinforced with Ti-coated particles exhibit higher hardness as compared with the composites reinforced with uncoated SiC because there is a good interface bonding between the Ti coating and matrix.

Fig. 4 Magnified SEM images of 15vol.%SiCp/Al 2519 composites showing contact between two uncoated (a) and Ti-coated (b) SiC particles and corresponding EDS line scanning maps (c, d), respectively

Fig. 5 Relative density of extruded SiCp/Al 2519 composites as function of volume fraction of SiC

Fig. 6 Hardness of extruded SiCp/Al 2519 composites as function of volume fraction of SiC

The ultimate tensile strength and fracture strain of the SiCp/Al 2519 composites reinforced with different volume fractions of SiC are shown in Fig. 7. The ultimate tensile strength increases first and then decreases with the increase in volume fraction of both Ti-coated and uncoated SiC particles. Generally, the strength of metal matrix composites increases gradually with the increase in volume fraction of reinforcement to a certain value and then decreases. However, the uniform dispersion of SiCp decreases and the porosity of composite increases with the increase in volume fraction of SiCp, leading to a decrease of the relative density. Thus, the existence of micropores easily produces stress concentration that decreases the tensile strength of the SiCp/Al 2519 composites [28,29]. The fracture strain of composites decreases with the increase in volume fraction of both Ti-coated SiCp and uncoated SiCp. Therefore, the best ultimate tensile strength would be achieved when the suitable volume fraction of reinforcement matches with uniform dispersion. Therefore, the Ti-coating on the surface of SiC particles improves the wettability, enhances the interface bonding strength, and reduces the micropores, thus enhancing the strength of composite.

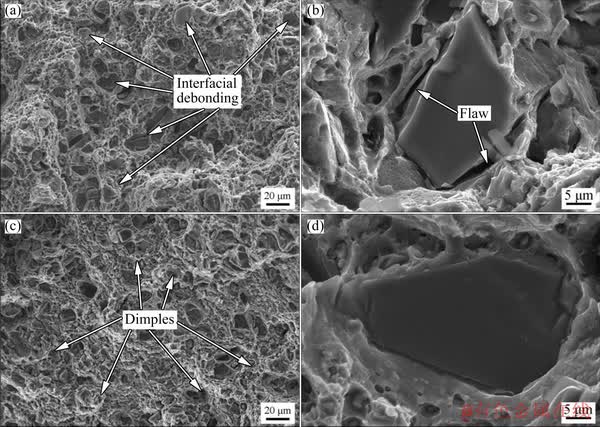

The above analysis is further confirmed by SEM images of the tensile fracture surfaces of the SiCp/Al 2519 composites reinforced with 15 vol.% Ti-coated and uncoated SiC particles, as shown in Fig. 8. It is observed from Figs. 8 (a) and (b) that, flaws between the SiCp and matrix and few dimples are presented in the composite reinforced with uncoated SiC particles, indicating that cleavage fracture and interface debonding occur under external pressure. However, the Ti-coated SiC particles combine closely with the matrix without flaws and a great many deep dimples are observed, as seen in Figs. 8(c) and (d).

Fig. 7 Tensile strength (a) and fracture strain (b) of extruded SiCp/Al 2519 composites as function of volume fraction

Fig. 8 Tensile fracture surfaces of Al 2519 matrix composites reinforced with uncoated SiCp (a, b) and Ti-coated SiCp (c, d)

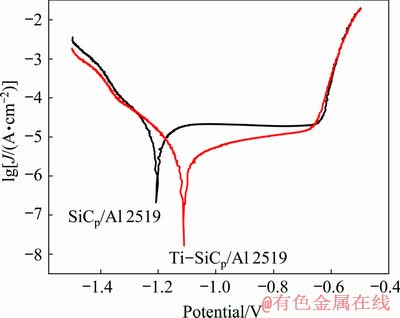

The potentiodynamic polarization curves of SiCp/Al 2519 composites in 3.5 wt.% NaCl solution before and after SiC particles are coated with Ti are shown in Fig. 9. Corrosion potential and corrosion current density of SiCp/Al 2519 composites are listed in Table 2. It can be seen that the composite material prepared by Ti-coated SiC is positively shifted compared with SiCp/Al 2519, and the corrosion current density is decreased, indicating that the corrosion rate of the material is also reduced, and the corrosion resistance is enhanced. Due to the good wettability of Ti and Al, the composites reduce the cracks and holes between SiC and Al during the sintering process, thereby improving the corrosion resistance.

Fig. 9 Polarization curves of 15vol.%SiCp/Al 2519 composites reinforced with uncoated SiCp and Ti-coated SiCp

Table 2 Corrosion potential and corrosion electrical density of 15vol.%SiCp/Al 2519 composites reinforced with uncoated SiCp and Ti-coated SiCp

4 Conclusions

(1) A dense Ti coating with fine grains is well created on the surface of SiC particles by plating in a vacuum reactor, and the structure of the interface is SiC/Ti5Si3/TiC/Ti.

(2) The presence of Ti coating on the surface of SiC particles improves the wettability between the SiC and matrix, resulting in a more homogeneous distribution of the SiC particles in the composites reinforced with Ti-coated particles.

(3) The relative density, hardness, fraction strain, and tensile strength are significantly increased in the composites reinforced with Ti-coated particles as compared with the uncoated ones owing to the uniform distribution, smooth shape of the Ti-coated SiCp and the reduced micro-pores. The hardness, fracture strain, and tensile strength of the Al 2519 composites reinforced with 15 vol.% Ti-coated SiCp reach the maximum values of HB 138.5, 4.02%, and 455 MPa, respectively. The corrosion potential and corrosion current density are -1.11 V and 5.38 μA/cm2, respectively.

References

[1] MONDAL D P, GANESH N V, MUNESHWAR V S, DAS S, RAMAKRISHNAN N. Effect of SiC concentration and strain rate on the compressive deformation behaviour of 2014Al-SiCp composite [J]. Materials Science and Engineering A, 2006, 433: 18-31.

[2] CHENG N P, LI C M, HUI Q, CHEN Z Q. Effect of particle surface treatment on the microstructure and property of SiCp/AA6066 composite produced by powder metallurgy [J]. Materials Science and Engineering A, 2009, 517: 249-256.

[3] EL-KADY OMYMA, FATHY A. Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites [J]. Materials & Design 2014, 54: 348-353.

[4] LIU Qiang, YE Feng, GAO Ye, LIU Shi-chao, YANG Hai-xia, ZHOU Zhi-qiang. Fabrication of a new SiC/2024Al co-continuous composite with lamellar microstructure and high mechanical properties [J]. J Alloys Compd, 2014, 585: 146-153.

[5] SLIPENYUK A, KUPRIN V, MILMAN Y, GONCHARUK V, ECKERT J. Properties of P/M processed particle reinforced metal matrix composites specified by reinforcement concentration and matrix-to-reinforcement particle size ratio [J]. Acta Mater, 2006, 54: 157-166.

[6] HASSANI A, BAGHERPOUR E, QODS F. Influence of pores on workability of porous Al/SiC composites fabricated through powder metallurgy + mechanical alloying [J]. J Alloys Compd, 2014, 591: 132-142.

[7] JIN Peng, XIAO Bo-lu, WANG Quan-zhao, MA Zong-yi, LIU Yue, LI Shu. Effect of hot extrusion on interfacial microstructure and tensile properties of SiCp/2009Al composites fabricated at different hot pressing temperatures [J]. Journal of Materials Science & Technology, 2011, 27: 518-524.

[8] WU Y F, KIM G Y, RUSSELL A M. Mechanical alloying of carbon nanotube and Al6061 powder for metal matrix composites [J]. Materials Science and Engineering A, 2012, 532: 558-566.

[9] WU Yu-feng, KIM Gap-yong. Carbon nanotube reinforced aluminum composite fabricated by semi-solid powder processing [J]. J Mater Process Technol, 2011, 211: 1341-1347.

[10] LUO Z. Crystallography of SiC/MgAlO/Al interfaces in a pre-oxidized SiC reinforced SiC/Al composite [J]. Acta Mater, 2006, 54: 47-58.

[11] SHI Z L, YANG J M, LEE J C, ZHANG Di, LEE H I, WU Ren-jie. The interfacial characterization of oxidized SiC(p)/2014 Al composites [J]. Materials Science and Engineering A, 2001, 303: 46-53.

[12] CONG Xiao-shuang, SHEN Ping, WANG Yi, JIANG Qi-chuan. Wetting of polycrystalline SiC by molten Al and Al-Si alloys [J]. Appl Surf Sci, 2014, 317: 140-146.

[13] GUO Su-qing, WANG Ri-chu, PENG Chao-qun, CAI Zhi-yong, DONG Cui-ge. Microstructures and mechanical properties of Ni-coated SiC particles reinforced AZ61 alloy composites [J]. Transactions of Nonferrous Metals Society of China, 2019, 29:1854-1863.

[14] LEON-PATINO C A, DREW R A L. Role of metal interlayers in the infiltration of metal–ceramic composites [J]. Curr Opin Solid State Mater Sci, 2005, 9: 211-218.

[15] WU Shu-sen, YOU Ya, AN Ping, KANNO T, NAKAE H. Effect of modification and ceramic particles on solidification behavior of aluminum-matrix composites [J]. Journal of Materials Science, 2002, 37: 1855-1860.

[16] ZHA M, WANG H Y, LI S T, LI S L, GUAN Q L, JIANG Q C. Influence of Al addition on the products of self- propagating high-temperature synthesis of Al-Ti-Si system [J]. Mater Chem Phys, 2009, 114: 709-715.

[17] YANG Hui, ZHOU Xiao-bing, SHI Wen, et al. Thickness- dependent phase evolution and bonding strength of SiC ceramics joints with active Ti interlayer [J]. J Eur Ceram Soc, 2017, 37: 1233-1241.

[18] NOMURA M, ICHIMORI T, IWAMOTO C, TANAKA S I. Structure of wetting front in the Ag-Cu-Ti/SiC reactive system [J]. Journal of Materials Science, 2000, 35: 3953-3958.

[19] YANG De-long, QIU Feng, ZHAO Wei-xing, SHEN Ping, WANG Hui-yuan, JIANG Qi-chuan. Effects of Ti-coating layer on the distribution of SiCP in the SiCP/2014Al composites [J]. Materials & Design, 2015, 87: 1100-1106.

[20] YANG De-long, QIU Feng, LEI Zong-kun, ZHAO Qing-long, JIANG Qi-chuan. The interfacial structure and mechanical properties of Ti5Si3-coated SiCP/Al2014 composites fabricated by powder metallurgy with hot pressing [J]. Materials Science and Engineering A, 2016, 661: 217-221.

[21] YANG De-long, QIU Feng, ZHAO Qing-long, JIANG Qi-chuan. Excellent compressive strength and ductility of Ti5Si3-coated SiCP/Al2014 composites [J]. J Alloys Compd, 2017, 698: 1086-1093.

[22] YANG De-long, QIU Feng, ZHAO Qing-long, WANG Lei, JIANG Qi-chuan. The abrasive wear behavior of Al2014 composites reinforced with Ti5Si3-coated SiCP [J]. Tribology International, 2017, 112: 33-41.

[23] NAKA M, FENG J C, SCHUSTER J C. Phase reaction and diffusion path of the SiC/Ti system [J]. Metallurgical and Materials Transactions A, 1997, 28: 1385-1390.

[24] GOTMAN I, GUTMANAS E Y, MOGILEVSKY P. Interaction between SiC and Ti powder [J]. J Mater Res, 1993, 8: 2725-2733.

[25] WANG Y H, ZHANG X H, ZANG J B, GE E B, ZHANG J H, CHENG X Z. Ti-coated SiC particle reinforced sintered Fe-Cu-Sn alloy [J]. Surf Coat Technol, 2011, 205: 4627-4631.

[26] ZHANG Long-liang, YANG De-long, QIU Feng, WANG Jin-guo, JIANG Qi-chuan. Effects of reinforcement surface modification on the microstructures and tensile properties of SiCp/Al2014 composites [J]. Materials Science and Engineering A, 2015, 624: 102-109.

[27] CHEN B, LI S F, IMAI H, JIA L, UMEDA J, TAKAHASHI M, KONDOH K. Load transfer strengthening in carbon nanotubes reinforced metal matrix composites via in-situ tensile tests [J]. Compos Sci Technol, 2015, 113: 1-8.

[28] YOUSIF A A, MOUSTAFA S F, EL-ZEKY M A, EL-SABBAHY F N. Alumina particulate/Cu matrix composites prepared by powder metallurgy [J]. Powder Metall, 2013, 46: 307-310.

[29] LEE Y F, LEE S L, CHUANG C L, LIN J C. Effects of SiCp reinforcement by electroless copper plating on properties of Cu/SiCp composites [J]. Powder Metall, 1999, 42: 147-152.

董翠鸽,崔 蕊,王日初,彭超群,蔡志勇

中南大学 材料科学与工程学院,长沙 410083

摘 要:采用真空蒸镀法对SiC颗粒(SiCp)表面进行镀Ti改性改善SiCp/Al复合材料界面结合,采用热压、挤压和热处理等方法制备镀Ti后SiCp和原始SiCp增强的Al 2519基复合材料。通过扫描电镜(SEM)和能谱仪(EDS)分析Ti镀层对复合材料组织与性能的影响。结果表明,致密沉积的Ti镀层与SiCp反应,在界面处形成TiC和Ti5Si3相;与用原始SiCp增强的复合材料相比,用Ti镀覆SiCp增强的复合材料表现出均匀且致密的显微组织且复合材料的相对密度和力学性能得到显著改善。体积分数为15%时,镀Ti后SiCp增强Al 2519复合材料的硬度、断裂应变和拉伸强度达到最优,分别为HB 138.5、4.02%和455 MPa。

关键词:Al 2519基复合材料;表面改性;镀钛SiC颗粒;粉末冶金;界面显微组织;力学性能

(Edited by Xiang-qun LI)

Foundation item: Project (CXZZ20140506150310438) supported by the Science and Technology Program of Shenzhen, China; Project (2017GK2261) supported by the Science and Technology Program of Hunan Province, China; Project (2017zzts111) supported by the Fundamental Research Funds for the Central Universities of Central South University, China

Corresponding author: Zhi-yong CAI; Tel: +86-18774852301; E-mail: csumsefph@126.com

DOI: 10.1016/S1003-6326(20)65260-8