Nanostructured Al-Zn-Mg-Cu alloy synthesized by cryomilling and spark plasma sintering

CHEN Han-bin(陈汉宾)1, TAO Kai(陶 凯)2, YANG Bin(杨 滨)2, ZHANG Ji-shan(张济山)2

1. No.59 Institute of China Ordnance Industry, Chongqing 400039, China;

2. State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing,

Beijing 100083, China

Received 23 September 2008; accepted 17 January 2009

Abstract: Nanocrystallized Al-10.0%Zn-3.0%Mg-1.8%Cu (mass fraction) alloy powder was prepared by cryomilling, and then the nanostructured powder was consolidated into bulk material by spark plasma sintering (SPS). The microstructural evolution and phase transformation were studied. A supersaturated face-centered cubic solid solution is formed after cryomilling for 10 h, and the average grain size is 28 nm. Two typical nanostructures of the bulk nanostructured alloy are observed: primarily equiaxed grains with size of 150 nm, and occasionally occurring sub-micron grains up to 500 nm. Two types of MgZn2 particles precipitate during consolidation. One is the sub-micron particles distributed along the boundaries of the powders, and the other is fine particles with size of several nanometers in the matrix, especially at the boundaries of sub-micron grains. These second phase particles can be completely dissolved into matrix by proper solid solution treatment.

Key words: cryomilling; spark plasma sintering; nanostructured Al-Zn-Mg-Cu alloy; microstructural evolution; second phase

1 Introduction

Precipitation-strengthened 7xxx series Al alloys are well applied in aeronautical field due to their excellent mechanical properties[1], which are greatly influenced by the morphology and distribution of precipitates. Usually, optimizing heat treatment[2-4], increasing the content of major alloying elements[5-6], and reducing grain size[7-8] are employed to enhance the mechanical properties of these alloys. Thereby, techniques such as spray-forming[6-7] and powder metallurgy[8-9] are widely used. However, the grain size of materials obtained from these techniques is in the range of micro-scale. The potential for enhancing the mechanical properties of structural materials by reducing grain size to nanosize has attracted considerable interests in recent years. Thus, preparation of these aluminum alloys with nanocrystallines is worthy to pay attention.

Now, mechanical alloying is the main approach to fabricate nanocrystalline metal and alloy powders. However, some difficulties arise during ball milling ductile metals and their alloys due to the relatively stronger tendency of powder particles to adhere to container walls and sinter to form large millimeter-sized particles, which arise from re-welding conducted by localized high temperature. The introduction of cryogenic liquid media during milling, namely cryomilling, can effectively solve this problem[10]. Recently, cryomilling has been noted to produce nanocrystalline aluminum and its alloy powders[10-14]. And hot/cold isostatic pressing and extrusion are usually employed to consolidate these nanocrystalline powders to bulk nanostructured materials[15-20]. However, prohibiting rapid grain growth during conventional consolidations is still a challenge. The previous investigations demonstrated that the average grain size was normally increased by 130%-250% during extrusion following hot isostatic pressing process as extrusion changed the arrangement of the dispersions that pinned the grain boundaries[18]. Furthermore, the milled or cryomilled multi-phase nanocrystalline alloy powders with a high content of alloying elements are all in the state of supersaturated solid solution. Precipitation occurs when these powders are subjected to thermal consolidation. The velocity of the precipitates is higher than that of the coarse crystal counterparts due to the high energy and the shorter diffusion path in nanocrystalline materials. In the conventional thermal consolidation process, the precipitates coarsen excessively owing to the relative higher temperature and long time. These coarse precipitates reduce the mechanical properties and increase the difficulty in heat treatments. Spark plasma sintering(SPS) is a novel technique for rapidly sintering powders. It can fabricate bulk nanostructured materials with a relatively low temperature and very short time[21-22]. Surface activation of powder particles in SPS is conducted by pulsed current, which contributes to the powders densification.

The purpose of this work is to prepare nanostructured Al-Zn-Mg-Cu alloy by cryomilling and SPS, and to investigate in detail the microstructure evolution and second phase transformation behavior in the nanostructured highly-alloyed Al-Zn-Mg-Cu alloy during cryomilling and SPS.

2 Experimental

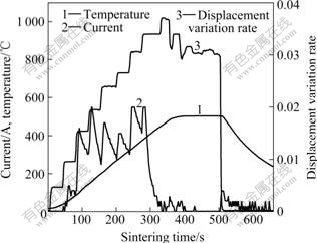

Spray-atomized Al-Zn-Mg-Cu (10.0 Zn, 3.0 Mg, 1.8 Cu, and balance Al, mass fraction, %) powder with a particle size less than 40 μm was mechanically milled in a liquid nitrogen environment for 3-10 h, and the impeller was operated at 200 r/min. The stainless steel balls with a diameter of 6.4 mm were used as the grinding media with the ball-to-powder mass ratio of 25?1. Then, 8 g cryomilled powder was placed in a cylindrical graphite die with a diameter of 20 mm. Before sintering, the powder in the die was cold pressed through the punches by a jack. The pressed powder was consolidated using a SPS-3.20-MK-V SPS apparatus under vacuum of 10 Pa. The sintering was assisted with the uniaxial pressure of 30 MPa and the heating rate of 100 ℃/min. The density of the SPSed samples is 2.934 g/cm3. The sample was kept at the maximal temperature of 500 ℃ for 120 s. The temperature, current, and displacement variation rate as function of time were recorded, as shown in Fig.1. Some samples were solid solution treated at 445 ℃, 30 min+470 ℃, 30 min, then quenched into ambient water.

Fig.1 Temperature, current, and displacement variation rate in SPS consolidation as function of sintering time

The morphologies of powders and bulk samples were investigated with ZEISS-SUPRA55 field emission gun (FEG) scanning electron microscope (SEM). The grain size was measured by X-ray diffractometry (XRD) and transmission electron microscopy (TEM). X-ray diffraction measurements were conducted on a PHILIPS APD-10 X-ray diffractometer equipped with a graphite monochromator using Cu Kα radiation. The grain size was measured utilizing the integral breadth technique, subtracting background and correcting for Kα2 and instrumental broadening. Five diffraction peaks were used to determine the grain size through calculation of peak broadening using linear fitting method[21]. Transmission electron microscopy (TEM) observations were performed using a HITACHI H-800 microscope operated at 160 kV.

3 Results and discussion

3.1 Microstructural evolution of as-atomized alloy powder during cryomilling

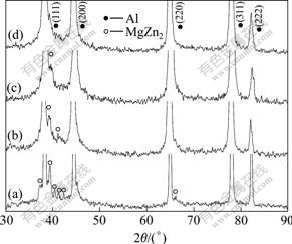

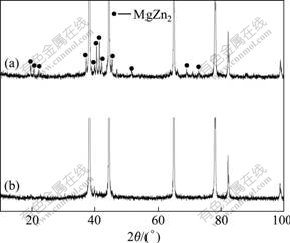

Fig.2 reveals the structural evolution of the as- atomized alloy powder during cryomilling. It can be seen that Al diffraction peaks became weaker and broader with the increase of cryomilling time, indicating that the grain size of the alloy decreased and the microstrain increased. Moreover, grain refinement process was combined with the formation of supersaturated solid solution. The diffraction peaks of MgZn2 phase presented in the XRD pattern of the spray-atomized powder, as shown in Fig.2(a). It is worth noting that MgZn2 could be dissolved into the α(Al) lattice gradually during cryomilling, as shown in Figs.2(b)-(d). A supersaturated face-centered cubic solid solution was fabricated after cryomilling for 10 h, as shown in Fig.2(d). Besides, the diffraction peaks shifted toward lower diffraction angles with the increase of cryomilling time, which also illuminated that the MgZn2 dissolved into the Al lattice. The lattice constants of as-atomized and as-cryomilled powders determined by XRD patterns were about 0.4058 and 0.4062 nm, respectively, which were slightly larger than the lattice constant of the pure Al (0.4049 nm).

Fig.2 XRD patterns of Al-10.0Zn-3.0Mg-1.8Cu alloy powders: (a) As-atomized; (b) Cryomilled for 3 h; (c) Cryomilled for 6 h; (d) Cryomilled for 10 h

It is well known that mechanical alloying is capable of forming supersaturated solid solutions due to the local high temperature and enhanced diffusion within the highly deformed structure. However, extremely low temperature during cryomilling can restrain the diffusion. Previous study had testified that solid solution was not formed via directly cryomilling elemental powders[23]. Concerning the pre-alloyed systems, ZHOU et al[10] found that Mg and Sc atoms of the as-atomized Al-Mg-Sc alloy powder dissolved in the fcc Al lattice by analyzing the lattice constant of the cryomilled powder. Our results further revealed that the second phases in the aluminum alloy with high content of alloying elements can dissolve into the matrix to form a supersaturated solid solution during cryomilling. The formation of supersaturated solid solution was probably attributed to the peculiar nanostructure formed during cryomilling. Though low temperature makes against the diffusion of alloying element, it depresses the ductility of aluminum alloy powders, which contributes to the production of intensive interfacial defects by the impingement between milling balls and powder particles. As a result, the activation energies of diffusion decrease due to the conducted severe distortion of lattice. Furthermore, the nanocrystalline alloy powder prepared by cryomilling is characterized by a high density of dislocations and non- equilibrium state, both of which facilitate the diffusion.

3.2 Microstructures of alloy powders

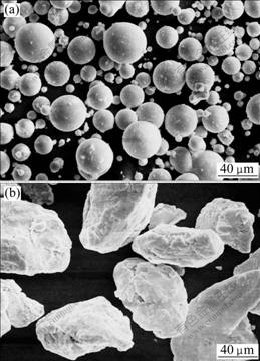

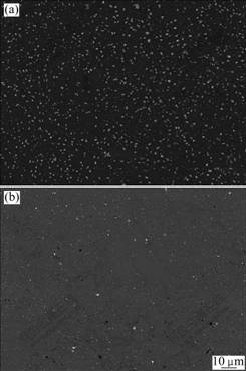

Cryomilling, similar to the conventional mechanical alloying process, includes the following stages: flattening, fracturing, and welding of constituent materials. The as-atomized Al-Zn-Mg-Cu alloy powder particles were subjected to severe mechanical deformation by colliding with milling balls during cryomilling. In this procedure, the morphology of particles as well as the microstructure changed. Fig.3 shows the variations of the particle morphology of the as-atomized powder and the cryomilled powder. The as-atomized powder particles were spherical with diameter below 40 μm, as shown in Fig.3(a). After 10 h cryomilling, the morphology of particles changed from regular spherical shape to irregular and flaky shape with crevices and pores, and the size of particles increased to 70 μm, as shown in Fig.3(b).

Fig.3 SEM morphologies for Al-10.0Zn-3.0Mg-1.8Cu alloy powders: (a) As-atomized; (b) Cryomilled for 10 h

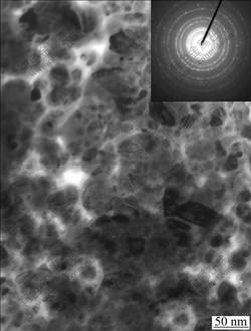

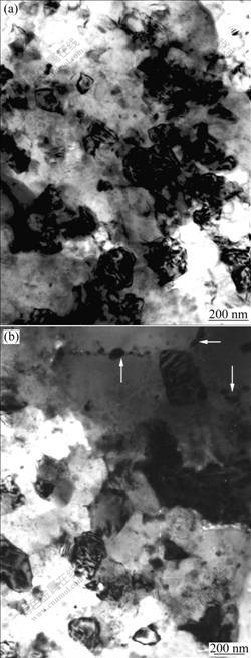

Moreover, extremely small nanocrystalline grains were yielded after 10 h cryomilling. The characterization of grain size on these cryomilled powders was performed by X-ray diffraction measurement and TEM measurement. The values of volume-averaged crystallite size(d) and root-mean-square(rms) strain 1/2 of the cryomilled Al-Zn-Mg-Cu alloy powders were 28 nm and 1×10-3, respectively, which were examined by analyzing the broadening of XRD peaks and the angular dependence from Fig.2(d). Fig.4 shows the TEM image for the cryomilled powder. The equiaxed grains were randomly distributed. The values of grain size by two methods were consistent with each other. The corresponding selected-area diffraction (SAED) pattern showed a continuous ring pattern, which indicated a nanocrystalline structure. ZHOU et al[10-11] reported that subdivision is the major mechanism in the development of fine-grain microstructure by mechanical attrition at cryogenic temperature, and grain rotation and boundary sliding mechanisms[24] cannot be ruled out.

Fig.4 TEM image for as-cryomilled Al-10.0Zn-3.0Mg-1.8Cu alloy powder with SAED pattern inserted

3.3 Microstructure of SPS-processed sample

The cryomilled nanocrystalline aluminum alloy powders are in nonequilibrium state. During consolidating by SPS, the separation of the second phase from supersaturated solid-solution and grain growth occurred. The XRD pattern for the SPS-processed bulk Al-Zn-Mg-Cu alloy sample is presented in Fig.5(a), from which one can see that the second phase particles, η (MgZn2), precipitated during the consolidation process. These second phase particles disappeared after solid solution treatment of 445 ℃, 30 min+470 ℃, 30 min, as shown in Fig.5(b). Fig.6(a) shows the backscattered SEM image of the SPS-processed sample, where a lot of white spots with size of submicron distributed along the boundaries of powder. These coarse second phase particles in the matrix were believed to affect the mechanical properties. Therefore, proper solid solution treatment should be performed to eliminate these coarse second phase particles. Fig.6(b) displays the BSE image of the heat treated sample, in which nearly all the coarse second phase particles are dissolved into the matrix. EDS analysis indicated that a few residual white spots in Fig.6(b) were alumina particles due to oxidation during solid solution treatment. The results of XRD and backscattered SEM indicated that the second phase particles still precipitated from the matrix of the cryomilled powders during SPS, and these second phase particles could be dissolved using proper solid solution treatments.

Fig.5 XRD patterns of Al-10.Zn-3.0Mg-1.8Cu alloy: (a) SPS- processed; (b) Solid solution treatment after 445 ℃, 30 min+ 470 ℃, 30 min

Fig.6 Back scattered SEM images of Al-10.0Zn-3.0Mg-1.8Cu alloy: (a) SPS-processed sample; (b) Solid solution treated sample

When comparing the XRD spectrum of the SPS sample with that of the cryomilled powder (Fig.2(d)), it was noted that the intensity of diffraction peaks was reduced after SPS, indicating that grain growth or microstrain release occurred during SPS. Fig.7(a) shows the representative microstructure of the bulk sample. The appearance of the grains was equiaxed with the average grain size of 100-150 nm (determined by measuring 250 individual grains). It was worth noting that some coarse grains with the maximum size up to 500 nm were also observed occasionally in the SPS-processed sample, as shown in Fig.7(b). On the other hand, a number of fine second phase particles were observed in the grain interior and at the grain boundaries. The noticeable characteristic was that some bigger second phase particles precipitated on sub-micron grain boundaries, as marked by arrows in Fig.7(b).

Fig.7 TEM images showing microstructure of bulk nanostructured Al-10.0Zn-3.0Mg-1.8Cu alloy: (a) Fine-grained area; (b) Sub-micron-grained zone

Although SPS is a hopeful consolidation technique to retain the nanostructure of powders, grain growth rate under the SPS is much higher than that under other hot consolidations. LI and GAO[25] attributed this phenomenon to two aspects. The applied pressure accelerated the dynamic grain growth and the spark discharge increased the surface activity of the particle. But this phenomenon did not occur in the case of vacuum hot pressing of the above mentioned aluminum alloy powders at the same temperature. Thereby, it is suggested that spark discharge is the primary factor, which accelerates the grain growth in this special sintering process. The effect of pulsed current on grain growth has not been well understood. Joule heating, mass transport enhancement due to electromigration or defect generation, and clean grain boundaries by plasma were suggested to contribute to the effect of pulsed current on grain growth[26]. The local high current density at these contact points of powders results in extremely high temperature due to Joule heating, leading to melting or severe grain growth in these regions. Moreover, the surface activity of powders by spark discharge accelerates the surface diffusion and makes the grains grow quickly. The activation energy of grain growth is reduced considerably by the improved grain surfaces, hence the grain growth is difficult to avoid during SPS. In one word, SPS is an effective method for synthesizing bulk nanostructured metals and alloys, but the densification mechanism of SPS process needs to be further investigated.

4 Conclusions

1) Nanostructured Al-Zn-Mg-Cu alloy powder with an average grain size of approximately 28 nm was synthesized by cryomilling for 10 h.

2) A bulk nanostructured alloy was consolidated by SPS at 500 ℃ for 2 min. Two types of microstructures were observed in the bulk samples: primarily, a random dispersion of equiaxed grains with an average grain size of 100-150 nm, and occasionally, sub-micron grains with diameter of 300-500 nm.

3) A few of MgZn2 particles in spray-atomized powder could be gradually dissolved into the α(Al) lattice to form the supersaturated solid solution after cryomilling for 10 h. Two types of MgZn2 particles precipitated during SPS. One was the submicron particles distributing along the boundaries of the cyromilled powder, and the other was fine particles with size of several nanometers in the matrix, especially at the boundaries of sub-micron grains. These second phase particles could be completely dissolved into matrix by proper solid solution treatment.

References

[1] WU Y L, FROES F H, ALVAREZ A, LI C C, LIU J. Microstructure and properties of a new super-high-strength Al-Zn-Mg-Cu alloy C912 [J]. Mater Des, 1997, 18: 211-215.

[2] Engdahl T, Hansen V, Warren P J, Stiller K. Investigation of fine scale precipitates in Al-Zn-Mg alloys after various heat treatments [J]. Mater Sci Eng A, 2002, 327: 59-64.

[3] Sha G, Cerezo A. Early-stage precipitation in Al-Zn-Mg-Cu alloy (7050) [J]. Acta Mater, 2004, 52: 4503-4516.

[4] Chen Kang-hua, Huang Lan-ping. Strengthening-toughening of 7xxx series high strength aluminum alloys by heat treatment [J]. Trans Nonferrous Met Soc China, 2003, 13(3): 484-490.

[5] Srivatsan T S. An investigation of the cyclic fatigue and fracture behavior of aluminum alloy 7055 [J]. Mater Des, 2002, 23: 141-151.

[6] Wang F, Xiong B, Zhang Y, Zhang Z, Wang Z, Zhu B, Liu H. Microstructure and mechanical properties of spray-deposited Al-Zn-Mg-Cu alloy [J]. Mater Des, 2007, 28: 1154-1158.

[7] Jenabali Jahromi S A. Creep behavior of spray-cast 7xxx aluminum alloy [J]. Mater Des, 2002, 23: 169-172.

[8] de Sanctics M. Structure and properties of rapidly solidified ultrahigh strength Al-Zn-Mg-Cu alloys produced by spray deposition [J]. Mater Sci Eng A, 1991, 141: 103-121.

[9] Kim W J, Higashi K, Kim J K. High strain rate superplastic behaviour of powder-metallurgy processed 7475Al+0.7Zr alloy [J]. Mater Sci Eng A, 1996: 261: 170-177.

[10] Zhou F, Nutt S R, Bampton C C, Lavernia E J. Nanostructure in an Al-Mg-Sc alloy processed by low-energy ball milling at cryogenic temperature [J]. Metall Mater Trans A, 2003, 34: 1985-1992.

[11] Zhou F, Witkin D, Nutt S R, Lavernia E J. Formation of nanostructure in Al produced by a low-energy ball milling at cryogenic temperature [J]. Mater Sci Eng A, 2004, 375/377: 917- 921.

[12] Tellkamp V L, Lavernia E J. Processing and mechanical properties of nanocrystalline 5083 Al alloy [J]. Nanostruct Mater, 1999, 12: 249-252.

[13] Lee Z, Witkin D B, Radmilovic V, Lavernia E J, Nutt S R. Bimodal microstructure and deformation of cryomilled bulk nanocrystalline Al-7.5Mg alloy [J]. Mater Sci Eng A, 2005, 410/411: 462-467.

[14] Park Y S, Chung K H, Kim N J, Lavernia E j. Microstructural investigation of nanocrystalline bulk Al-Mg alloy fabricated by cryomilling and extrusion [J]. Mater Sci Eng A, 2004, 374: 211-216.

[15] Dogan C P, Rawers J C, Govier R D, Korth G. Mechanical processing, compaction, and thermal processing of [alpha]-Fe powder [J]. Nanostruct Mater, 1994, 4: 631-644.

[16] Groza J R, Dowding R J. Nanoparticulate materials densification [J]. Nanostruct Mater, 1996, 7: 749-768.

[17] Pagounis E, Talvitie M, Lindroos V K. Consolidation behavior of a particle reinforced metal matrix composite during HIPing [J]. Mater Res Bull, 1996, 31: 1277-1285.

[18] Witkin D B, Lavernia E J. Synthesis and mechanical behavior of nanostructured materials via cryomilling [J]. Prog Mater Sci, 2006, 51: 1-60.

[19] Omori M. Sintering, consolidation, reaction and crystal growth by the spark plasma system (SPS) [J]. Mater Sci Eng A, 2000, 287: 183-188.

[20] Ye J, Ajdelsztajn L, Schoenung J M. Bulk nanocrystalline aluminum 5083 alloy fabricated by a novel technique: Cryomilling and spark plasma sintering [J]. Metall Mater Trans A, 2006, 37: 2569-2579.

[21] Jiang H G, RUhle M, Lavernia E J. On the applicability of the X-ray diffraction line profile analysis in extracting grain size and microstrain in nanocrystalline materials [J]. J Mater Res, 1999, 14: 549-559.

[22] Huang B, Perez R J, Lavernia E J, Luton M J. Formation of supersaturated solid solutions by mechanical alloying [J]. Nanostruct Mater, 1996, 7: 67-79.

[23] Huang B, Perez R J, Lavernia E J. Grain growth of nanocrystalline Fe-Al alloys produced by cryomilling in liquid argon and nitrogen [J]. Mater Sci Eng A, 1998, 255: 124-132.

[24] Perez R J, Huang B, Lavernia E J. Thermal stability of nanocrystalline Fe-10 (mass fraction, %) Al produced by cryogenic mechanical alloying [J]. Nanostruct Mater, 1996, 7: 565-572.

[25] Li W, Gao L. Rapid sintering of nanocrystalline ZrO2(3Y) by spark plasma sintering [J]. J Eur Ceram Soc, 2000, 20: 2441-2445.

[26] Paris S, Gaffet E, Bernard F, Munir Z A. Spark plasma synthesis from mechanically activated powders: A versatile route for producing dense nanostructured iron aluminides [J]. Scripta Mater, 2004, 50: 691-696.

Foundation item: Project(2002AA302502) supported by the Hi-tech Research and Development Program of China; Project(20050008016) supported by the Research Fund for the Doctoral Program of Higher Education, China

Corresponding author: CHEN Han-bin; Tel: +86-10-62333351; E-mail: hanbinchen@yahoo.com.cn

DOI: 10.1016/S1003-6326(08)60415-X

(Edited by YANG Bing)