DOI:10.19476/j.ysxb.1004.0609.2017.06.08

La-Mg-Ni-Cu系Mg2Ni型合金气态贮氢动力学

高金良1,尚宏伟2,李亚琴2,袁泽明2,赵栋梁2,张羊换2

(1.微山钢研稀土材料有限公司,济宁 277600;

2.钢铁研究总院 功能材料研究所,北京 100081)

摘 要:为了改善Mg2Ni型合金的气态贮氢动力学性能,在合金中添加少量La,并用快淬工艺制备La-Mg-Ni-Cu系Mg2Ni型(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20) (摩尔分数,x %)合金。采用XRD、SEM及HRTEM分析铸态及快淬态合金的微观结构;采用全自动Sieverts测试仪测试合金的气态吸放氢动力学;采用差热分析仪测试不同加热速率下合金的放氢DSC曲线,并用Kissinger方程计算合金的放氢激活能。建立动力学与La含量及淬速的关系。结果表明:添加La不改变合金的主相Mg2Ni相,但导致第二相La2Mg17和LaMg3相出现,第二相的量随La含量的增加而增加。添加La和快淬有助于合金形成纳米晶-非晶结构,降低放氢激活能,从而改善放氢动力学。当La含量x从0增加到20时,铸态合金的放氢激活能 从73.18 kJ/mol下降到60.41 kJ/mol,而30m/s的快淬态合金的

从73.18 kJ/mol下降到60.41 kJ/mol,而30m/s的快淬态合金的 值从66.16 kJ/mol下降到50.50 kJ/mol。

值从66.16 kJ/mol下降到50.50 kJ/mol。

关键词:Mg2Ni型合金;快淬;添加La;气态吸放氢动力学;放氢激活能

文章编号:1004-0609(2017)-06-1132-08 中图分类号:146.4 文献标志码:A

对化石燃料的过度依赖一直困扰着人类发展,研发并使用可再生清洁能源势在必行。氢能储量丰富、无温室气体排放、储能密度高,被认为是最理想的清洁能源[1]。用氢能替代石油作为交通运输的能源是减少化石燃料消耗以及控制碳排放的有效方法[2]。由于氢的特殊性,氢的贮存必须兼备安全和高能量密度的特点。相比于高压气态贮氢、液化贮氢等方式,金属氢化物贮氢是最安全的贮氢方式,但现有类型的贮氢合金储能密度有限,没有一种合金能达到美国能源部(DOE)对贮氢容量的要求[3]。镁基贮氢合金可以满足车载贮氢系统对储能密度的要求,MgH2的理论贮氢量可达7.6%(质量分数), Mg2NiH4达3.6%,Mg2CoH5达4.5%,Mg2FeH6达5.4%[4]。但镁基金属氢化物吸放氢动力学性能差,严重地制约了其应用发展。

为实现镁基贮氢合金的应用,研究者做了大量工作[5-6]。总体来看,合金化法和成分替代能够使合金结构纳米化,从而降低Mg—H键强,最终降低氢化物的稳定性[7]。用稀土元素Nd部分替代Mg[8]和添加过渡族金属(Ni, Ti, Fe, Al, Co)[9-12]能明显降低金属氢化物的热稳定性,从而改善动力学性能。另外,镁基贮氢合金的吸放氢动力学对结构非常敏感[13],特别是减小晶粒尺寸至远低于微米级时能显著提高其吸放氢性能[14]。KUMAR等[15]报道,超细微观结构(<100 nm)可使Mg2Ni合金的放氢温度降低100 K,即从573 K降低到473 K。很多方法都可以制备超细微观结构,也就是纳米晶-非晶镁基合金[16-17],比如机械球磨[18]、快淬[19]、氢化燃烧合成法[20]、等通道角挤压(ECAP)[21]等。在诸多方法中,快淬工艺由于可控性高、成本低廉,最适合大规模制备高纯度且成分均匀的纳米晶-非晶镁基合金。

前期研究表明[22-24],Nd和Y替代Mg可在一定程度上改善Mg2Ni合金的贮氢动力学性能,但Nd和Y在稀土资源中含量较少,价格贵。本文作者利用稀土中含量较高的La替代Mg,用真空快淬技术制备了具有纳米晶-非晶结构的Mg2Ni型(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金,并研究了La含量及快淬对合金结构及气态贮氢动力学的影响。

1 实验

1.1 合金制备

合金成分为(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)。采用对应La含量的x将合金编号为La0、La5、La10、La15、La20。合金按设计成分配料后,用真空中频感应熔炼炉熔炼。为防止Mg的挥发,在熔炼过程中施加0.04 MPa氦气作为保护气。液态合金注入铜模冷却后获得母合金铸锭。将200 g合金铸锭装入底部开狭缝的石英管,利用电磁感应加热熔化后,在上端施加一定压力的气体使金属熔液通过底部狭缝喷射到高速旋转的铜辊表面,获得快淬态薄带。淬速用旋转铜辊的表面线速度表示,分别为10、20、30和40 m/s。

1.2 微观结构表征

用XRD (D/max/2400)分析了铸态及快淬态合金的相结构;用离子减薄法将快淬合金薄带制备成薄膜样品,用透射电镜TEM (JEM-2100F) 观察其形貌,并用电子衍射(ED)分析了合金的晶态。

1.3 气态贮氢动力学测试

用全自动Sieverts测试仪测试了合金的气态吸放氢动力学曲线。测试前,先将铸锭合金进行机械粉碎,筛选48~75 μm间的粉末进行测试。称量1 g样品放入反应室,并反复吸放氢直至完全活化。在达到稳定状态后,在523 K下测试吸放氢动力学曲线。测量时,吸氢初始氢压为2 MPa,放氢初始压为1×10-4 MPa。

1.4 DSC曲线及激活能计算

合金粉末饱和吸氢后,用差热分析仪(NETZSCH STA 449F3)测试氢化物在5、10、15和20 K/min加热速率下的放氢DSC曲线。加热温度区间为303~973 K。根据Kissinger方程计算了氢化物的分解激活能。

2 结果与讨论

2.1 微观结构表征

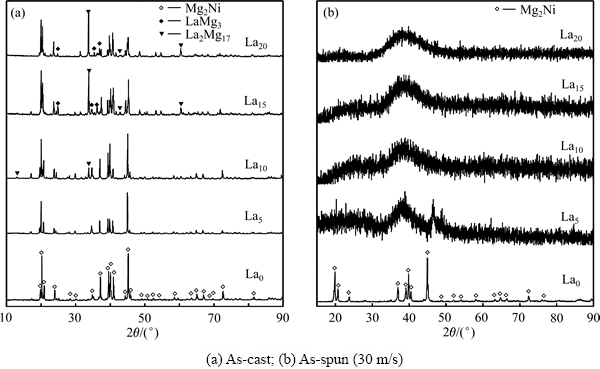

图1所示为铸态及快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的XRD衍射谱。由图1(a)可以看出,添加La没有改变合金的主相Mg2Ni相,但导致了第二相La2Mg17和LaMg13相的形成。第二相的相丰度随La含量的增加而增加。由图1(b)可以看出,快淬态La0合金具有典型的晶态衍射峰,而快淬含La合金具有典型的非晶峰。这表明添加La有利于提高合金在快淬过程的非晶形成能力。

图1 铸态及快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的XRD谱

Fig. 1 XRD patterns of as-cast and spun alloys

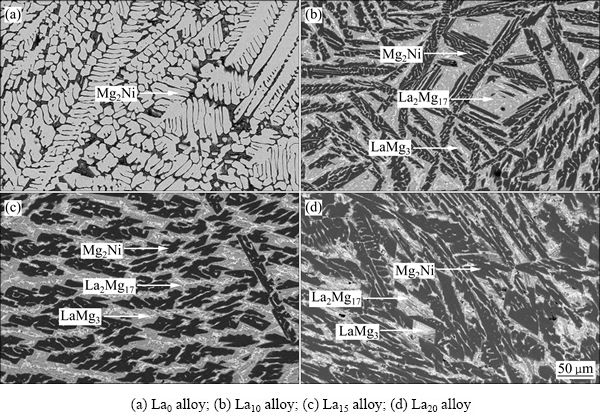

图2所示为铸态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金SEM像。由图2(a)可以看出,不含La的合金具有明显的单相结构,为典型的树枝晶形貌。添加La使铸态合金的形貌发生明显改变,而且除了主相Mg2Ni相外,还出现了第二相La2Mg17和LaMg3相。第二相的相丰度及分布随La含量的增加明显变化,如图2(b),(c),(d)所示,这与XRD分析的结果一致。

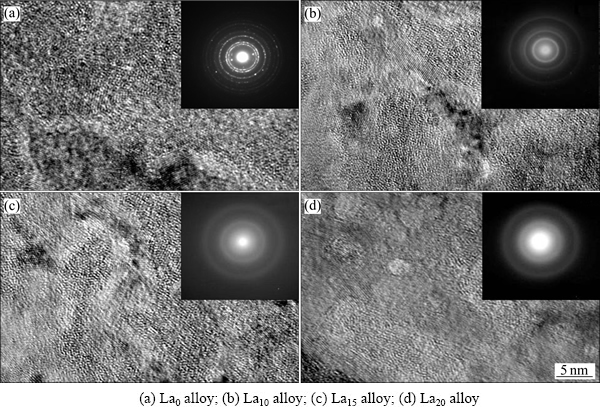

图3所示为30 m/s快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的高分辨透射电镜(HRTEM)形貌及选区电子衍射(SAED)环。在30 m/s淬速下,La含量的改变对合金的形貌及晶态产生了明显的影响。如图3(a)所示,快淬态La0合金为纳米晶结构,尽管晶体出现明显的混乱排列,但没有出现非晶相。对比图3(b)、(c)、(d)可以看出,随着La含量的增加,纳米晶不断减少而非晶相显著增加。SAED衍射环也说明了这一结论,表明添加La能明显提高合金在快淬过程中的非晶形成能力。

图2 铸态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的SEM像

Fig. 2 SEM images of as-cast alloys

图3 快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的TEM像及电子衍射环(ED)

Fig. 3 TEM images and ED patterns of as-spun (30 m/s) alloys

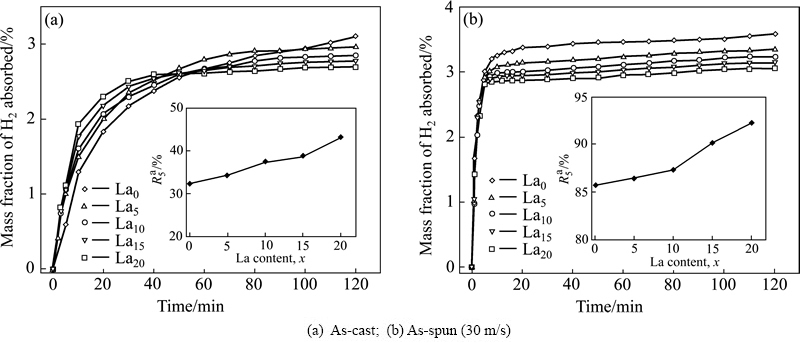

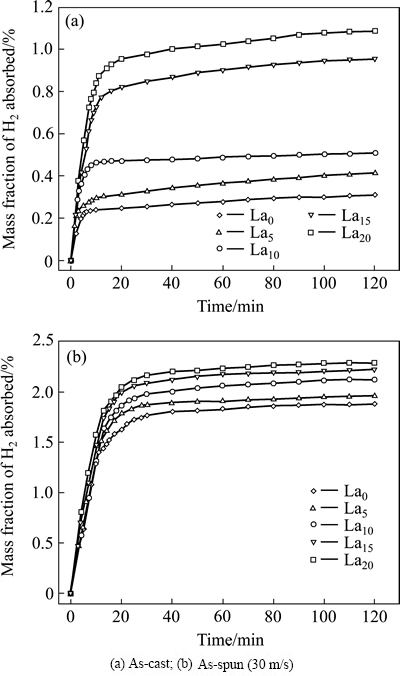

图4 铸态及快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的气态吸氢动力学曲线

Fig. 4 Hydrogen absorption kinetic curves of as-cast and spun (Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20) alloys

2.2 气态吸放氢动力学

图4所示为铸态及快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的气态吸氢动力学曲线。初始阶段,铸态及快淬态合金显示了极快的吸氢速率。当合金中的氢浓度达到一定量时,吸氢速率明显下降,并随着吸氢时间的延长,缓慢地达到饱和状态。需要注意的是,合金的饱和吸氢量随La含量的增加而减少,这主要是由于La的添加使主相Mg2Ni相减少。为了说明La含量的影响,用给定时间的吸氢量与饱和吸氢量的比值来衡量合金的吸氢动力学,用 表示,且

表示,且 。其中:

。其中: 和

和 分别为吸氢时间为100 min 和t min时的吸氢量。实验结果表明,所有合金的

分别为吸氢时间为100 min 和t min时的吸氢量。实验结果表明,所有合金的 值均大于其饱和吸氢量的98%。因此,将

值均大于其饱和吸氢量的98%。因此,将 值近似地作为合金的饱和吸氢量。基于图4的数据,建立了

值近似地作为合金的饱和吸氢量。基于图4的数据,建立了 (t=5)与La含量的关系,如图4中嵌图所示。当x从0增加到20时,铸态合金的

(t=5)与La含量的关系,如图4中嵌图所示。当x从0增加到20时,铸态合金的 值从32.3%上升到43.1%,如图4(a)中嵌图所示,而30 m/s快淬态合金的

值从32.3%上升到43.1%,如图4(a)中嵌图所示,而30 m/s快淬态合金的 值从85.7%增加到92.2%,如图4(b)中嵌图所示。对比图4(a)、(b)发现,对于给定的La含量,快淬态合金的

值从85.7%增加到92.2%,如图4(b)中嵌图所示。对比图4(a)、(b)发现,对于给定的La含量,快淬态合金的 值远大于铸态合金的,这表明快淬处理有利于提高合金的吸氢动力学。也就是说,合金的吸氢动力学除与其成分密切相关外,还对其微观结构非常敏感。La对吸氢动力学的作用主要与晶胞体积增大及第二相的形成相关,晶胞体积增大降低了吸氢时的体积膨胀,使扩散激活能下降;第二相的存在可能对吸氢反应具有一定的催化作用,这些均对氢的扩散有利。快淬提高吸氢动力学归因于快淬导致的晶粒细化。组织细化产生大量的新晶粒和晶界,这些都为氢扩散提供了良好的通道。

值远大于铸态合金的,这表明快淬处理有利于提高合金的吸氢动力学。也就是说,合金的吸氢动力学除与其成分密切相关外,还对其微观结构非常敏感。La对吸氢动力学的作用主要与晶胞体积增大及第二相的形成相关,晶胞体积增大降低了吸氢时的体积膨胀,使扩散激活能下降;第二相的存在可能对吸氢反应具有一定的催化作用,这些均对氢的扩散有利。快淬提高吸氢动力学归因于快淬导致的晶粒细化。组织细化产生大量的新晶粒和晶界,这些都为氢扩散提供了良好的通道。

图5 铸态及快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的放氢动力学曲线

Fig. 5 Hydrogen desorption kinetic curves of as-cast and spun (Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20) alloys

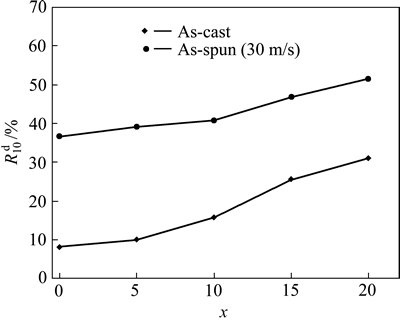

图5所示为铸态及快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的放氢动力学曲线,可以看出,添加La明显改善合金的放氢能力,放氢量及放氢动力学均随La含量的增加而增加。为了建立放氢动力学与La含量之间的关系,用给定时间的放氢速率来表示放氢动力学,并以 表示。计算方法为:

表示。计算方法为:

。其中,

。其中, 为吸氢时间为100 min的吸氢量;

为吸氢时间为100 min的吸氢量; 为t min的放氢量。基于图5的数据,可以建立

为t min的放氢量。基于图5的数据,可以建立 (t =10)与La含量的关系,如图6所示。可以看出,合金的放氢动力学随La含量的增加而增加。当x从0增加到20时,铸态合金的

(t =10)与La含量的关系,如图6所示。可以看出,合金的放氢动力学随La含量的增加而增加。当x从0增加到20时,铸态合金的 值从8.2%上升到31.1%, 30 m/s快淬态合金的

值从8.2%上升到31.1%, 30 m/s快淬态合金的 值从36.7%增加到51.5%。由图6可以看出,对于给定的La含量,快淬态合金的

值从36.7%增加到51.5%。由图6可以看出,对于给定的La含量,快淬态合金的 值远大于铸态合金的。这意味着快淬处理有利于改善合金放氢动力学。众所周知,氢化物的热稳定性以及氢在合金中的扩散能力是合金放氢动力学的决定因素。添加La改善合金放氢动力学主要源于两个方面。首先,添加La降低了合金氢化物的热稳定性,从而提高其放氢能力[25-26]。其次,添加La提高了合金在快淬过程的非晶形成能力。由于非 晶/纳米晶结构具有良好的放氢能力,所以快淬改善放氢动力学显然是与形成纳米晶-非晶结构相关。据文献报道,高的比表面积以及大量晶界有利于放氢反应的进行[27]。ZALUSKI等报道[28],当晶粒尺寸减小到纳米尺度时,可使多晶Mg2Ni型合金的放氢温度降到473 K以下。

值远大于铸态合金的。这意味着快淬处理有利于改善合金放氢动力学。众所周知,氢化物的热稳定性以及氢在合金中的扩散能力是合金放氢动力学的决定因素。添加La改善合金放氢动力学主要源于两个方面。首先,添加La降低了合金氢化物的热稳定性,从而提高其放氢能力[25-26]。其次,添加La提高了合金在快淬过程的非晶形成能力。由于非 晶/纳米晶结构具有良好的放氢能力,所以快淬改善放氢动力学显然是与形成纳米晶-非晶结构相关。据文献报道,高的比表面积以及大量晶界有利于放氢反应的进行[27]。ZALUSKI等报道[28],当晶粒尺寸减小到纳米尺度时,可使多晶Mg2Ni型合金的放氢温度降到473 K以下。

图6 铸态及快淬态(30 m/s)(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的 值与淬速的关系

值与淬速的关系

Fig. 6 Evolutions of  values of as-cast and spun (30 m/s) La0 and La15 alloys with spinning rate

values of as-cast and spun (30 m/s) La0 and La15 alloys with spinning rate

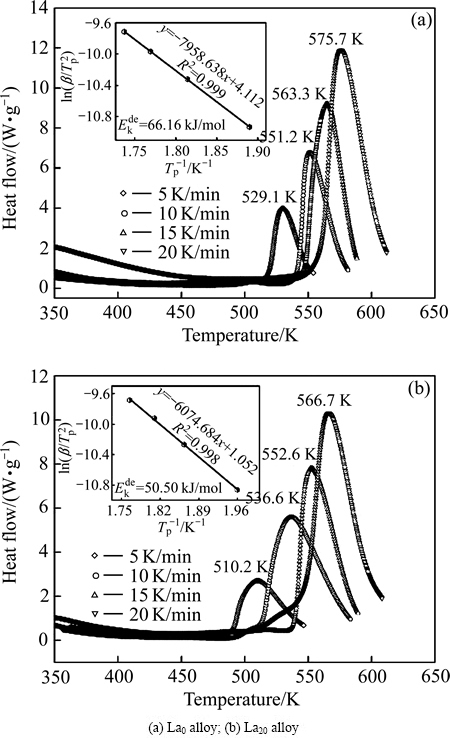

2.3 放氢激活能

气-固反应的激活能代表反应必须克服的能垒,是气-固反应动力学的决定因素。就放氢反应来说,其激活能为放氢过程的总能量之和。应用Kissinger方法计算了放氢反应的激活能,并通过研究添加La和快淬对激活能的影响来揭示放氢反应的动力学机理。Kissinger方程如下[23]:

(1)

(1)

式中: 是放氢激活能;

是放氢激活能; 是加热速率;Tp是DSC曲线峰值温度;R是摩尔气体常数。为了满足方程(1)所要求的条件,用DSC测试饱和吸氢状态下试验合金的放氢反应曲线,加热速率分别为5、10、15和20 K/min。作为典型的代表,图7给出了30 m/s快淬态La0和La20合金的DSC曲线。从图7中可以看到,在不同的加热速率下,DSC曲线有非常类似的放热峰,说明反应具有相同的过程。同时可以发现,对于特定的加热速率,相对于La0合金,La20合金的放热峰明显朝低温方向偏移。这表明添加La可以改善放氢动力学。基于图7的数据,应用方程(1)的对数转换,可以获得近似为线性的Kissinger曲线,如图7中嵌图所示。从Kissinger曲线的斜率计算得到了放氢反应激活能,并建立了激活能与La含量之间的关系,如图8所示。

是加热速率;Tp是DSC曲线峰值温度;R是摩尔气体常数。为了满足方程(1)所要求的条件,用DSC测试饱和吸氢状态下试验合金的放氢反应曲线,加热速率分别为5、10、15和20 K/min。作为典型的代表,图7给出了30 m/s快淬态La0和La20合金的DSC曲线。从图7中可以看到,在不同的加热速率下,DSC曲线有非常类似的放热峰,说明反应具有相同的过程。同时可以发现,对于特定的加热速率,相对于La0合金,La20合金的放热峰明显朝低温方向偏移。这表明添加La可以改善放氢动力学。基于图7的数据,应用方程(1)的对数转换,可以获得近似为线性的Kissinger曲线,如图7中嵌图所示。从Kissinger曲线的斜率计算得到了放氢反应激活能,并建立了激活能与La含量之间的关系,如图8所示。

图7 30 m/s快淬态La0和La20合金的DSC及Kissinger曲线

Fig. 7 DSC and Kissinger curves of as-spun (30 m/s) La0 and La20 alloys

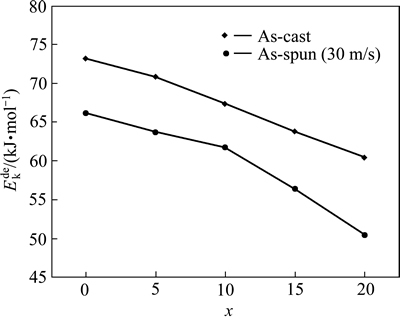

很明显,放氢反应激活能随La含量的增加而减小。当x从0增加到20时,铸态合金的 值从73.18 kJ/mol下降到60.41 kJ/mol,而30m/s的快淬态合金的

值从73.18 kJ/mol下降到60.41 kJ/mol,而30m/s的快淬态合金的 值从66.16 kJ/mol下降到50.50 kJ/mol。值得注意的是,对于给定的La含量,快淬态合金的

值从66.16 kJ/mol下降到50.50 kJ/mol。值得注意的是,对于给定的La含量,快淬态合金的 值明显低于铸态合金的,表明快淬有利于降低合金放氢反应的阻力而增加其驱动力。综上所述,添加La及快淬处理降低放氢反应激活能是其改善合金放氢动力学的真正驱动力。

值明显低于铸态合金的,表明快淬有利于降低合金放氢反应的阻力而增加其驱动力。综上所述,添加La及快淬处理降低放氢反应激活能是其改善合金放氢动力学的真正驱动力。

图8 铸态及30 m/s快淬态合金的放氢激活能随La含量的变化

Fig. 8 Evolution of the hydrogen desorption activation energy of as-cast and spun (30 m/s) (Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20) alloys with La content

3 结论

1) 研究了铸态及快淬态(Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20)合金的结构及吸放氢动力学性能。结果发现,添加La不改变合金的主相Mg2Ni相,但形成第二相La2Mg17和LaMg3相。快淬态合金具有纳米晶-非晶结构,且添加La明显提高合金在快淬过程中的非晶形成能力。

2) 添加La明显改善合金的气态吸放氢动力学,吸氢速率( )和放氢速率(

)和放氢速率( )均随La含量的增加而增加。当x从0增加到20时,铸态合金的

)均随La含量的增加而增加。当x从0增加到20时,铸态合金的 值从32.3%上升到43.1%,30 m/s快淬态合金的

值从32.3%上升到43.1%,30 m/s快淬态合金的 值从85.7%增加到92.2%;铸态合金的

值从85.7%增加到92.2%;铸态合金的 值从8.2%上升到31.1%,30 m/s快淬态合金的

值从8.2%上升到31.1%,30 m/s快淬态合金的 值从36.7%增加到51.5%。

值从36.7%增加到51.5%。

3) 用Kissinger方法计算了合金的放氢反应激活能,添加La及快淬处理引起的激活能下降,当x从0增加到20时,铸态合金的 值从73.18 kJ/mol下降到60.41 kJ/mol,而30 m/s的快淬态合金的

值从73.18 kJ/mol下降到60.41 kJ/mol,而30 m/s的快淬态合金的 值从66.16 kJ/mol下降到50.50 kJ/mol。放氢反应激活能下降,是放氢动力学改善的真正驱动力。

值从66.16 kJ/mol下降到50.50 kJ/mol。放氢反应激活能下降,是放氢动力学改善的真正驱动力。

REFERENCES

[1] 房文斌, 张文丛, 于振兴, 王尔德. 镁基储氢材料研究进展[J]. 中国有色金属学报, 2002, 12(5): 853-862.

FANG Wen-bin, ZHANG Wen-cong, YU Zheng-xing, WANG Er-de. Recent development of Mg-based hydrogen storage material[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(5): 853-862.

[2] MORI D, HIROSE K. Recent challenges of hydrogen storage technologies for fuel cell vehicles[J]. International Journal of Hydrogen Energy, 2009, 34(10): 4569-4574.

[3] KLEBANOFF L E, KELLE J O. 5 Years of hydrogen storage research in the U.S. DOE metal hydride center of excellence (MHCoE)[J]. International Journal of Hydrogen Energy, 2013, 38(11): 4533-4576.

[4] XU Chen-chen, XIAO Xue-zhang, SHAO Jie, LIU Lang-xia, QIN Teng, CHEN Li-xin. Effects of Ti-based additives on Mg2FeH6 dehydrogenation properties[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(3): 791-798.

[5] CHEN Chao-yi, CHEN Hui-lin, MA Ya-qin, LIU Jing. Hydrogen desorption kinetics mechanism of Mg-Ni hydride under isothermal and non-isothermal conditions[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 160-166.

[6] Lu Wen-chun, OU Shih-fu,LIN Ming-hong, WONG Man-fang. Hydrogen absorption/desorption performance of Mg-AL alloys synthesized by reactive mechanical milling and hydrogen pulverization[J]. Journal of Alloys and Compounds, 2016, 682: 318-325.

[7] 张 健, 华熳煜, 毛 聪, 龙春光, 周惦武. MgH2的表面稳定性及其解氢热力学的第一性原理研究[J].中国有色金属学报, 2013, 23(3): 896-792.

ZHANG Jian, HUA Man-yu, MAO Cong, LONG Chun-guang, ZHOU Dian-wu. First-principles study on structural stability and dehydrogenation thermodynamics of MgH2 surface[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 786-792.

[8] SONG Wen-jie, LI Jin-shan, ZHANG Tie-bang, HOU Tie-bang, KOU Hong-chao, XUE Xiang-yi, HU Rui. Microstructure and hydrogenation kinetics of Mg2Ni-based alloys with addition of Nd, Zn and Ti[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3677-3684.

[9] ZHANG Yang-huan, SONG Chun-hong, REN Hui-ping, LI Zhi-gang, HU Feng, ZHAO Dong-liang. Enhanced hydrogen storage kinetics of nanocrystalline and amorphous Mg2Ni-type alloy by substituting Ni with Co[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 2002-2009.

[10] 曹中秋, 王 婷, 边 静, 张 辉, 张国英. (Mg58Al42)0.9Ni0.1储氢合金的制备及其电化学性能[J]. 中国有色金属学报, 2009, 19(10): 1854-1859.

CAO Zhong-qiu, WANG Ting, BIAN Jing, ZHANG Hui, ZHANG Guo-ying. Preparation and electrochemical properties of (Mg58Al42)0.9Ni0.1 hydrogen storage alloy[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(10): 1854-1859.

[11] 李松林, 刘 燚, VARIN R A, 刘怀菲, 崔建民, 陈仕奇. 球磨方式对纳米晶Mg2FeH6储氢材料合成与放氢性能的影响[J].中国有色金属学报, 2008, 18(1): 42-47.

LI Song-lin, LIU Yi, VARIN R A, LIU Huai-fei, CUI Jian-min, CHEN Shi-qi. Effect of ball milling methods on synthesis and desorption properties of nanocrystalline Mg2FeH6 hydrogen storage materials[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 42-47.

[12] WANG Yao, ZENG Xiao-qin, ZOU Jian-xin, LI De-jiang, WU Xiao-mei, DING Wen-jiang. Microstructure characterization and hydrogen desorption behaviors of Mg-Al-H powders prepared by reactive milling in hydrogen[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(10): 3112-3118.

[13] TERESIAK A, GEBERT A, SAVYAK M, UHLEMANN M, MICKEL C, MATTERN N. In situ high temperature XRD studies of the thermal behaviour of the rapidly quenched Mg77Ni18Y5 alloy under hydrogen[J]. Journal of Alloys and Compounds, 2005, 398(1/2):156-164.

[14] SADHASIVAM T, STERLIN LEO HUDSO M, PANDEY S K, ASHISH B, MILIND K S, GURUNATHAN K, SRIVASTAVA O N. Effects of nano size mischmetal and its oxide on improving the hydrogen sorption behaviour of MgH2[J]. International Journal of Hydrogen Energy, 2013, 38(18): 7353-7362.

[15] HIMA KUMAR L, VISWANATHAN B, SRINIVASA MURTH S. Hydrogen absorption by Mg2Ni prepared by polyol reduction[J]. Journal of Alloys and Compounds, 2008, 461(1/2): 72-76.

[16] 宁向梅, 黄金亮, 贾淑果, 殷 镖, 张兴渊. Al 对Mg-Cu-Y 合金非晶形成能力及热稳定性的影响[J]. 中国有色金属学报, 2013, 23(7): 1805-1811.

NING Xiang-mei, HUANG Jin-liang, JIA Shu-guo, YIN Biao, ZHANG Xing-yuan. Effect of Al on glass forming ability and thermal stability of Mg-Cu-Y alloys[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1805-1811.

[17] 邱克强, 杨君宝, 尤俊华, 任英磊. Mg-Zn-Ca 合金的非晶形成能力及力学性能[J]. 中国有色金属学报, 2011, 21(8): 1828-1833.

QIU Ke-qiang, YANG Jun-bao, YOU Jun-hua, REN Ying-lei. Glass-forming ability and mechanical properties for Mg-Zn-Ca alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1828-1833.

[18] ZALUSKA A, ZALUSKI L, STROM-OLSEN J O. Synergy of hydrogen sorption in ball-milled hydrides of Mg and Mg2Ni[J]. Journal of Alloys and Compounds, 1999, 289(1/2): 197-206.

[19] SPASSOV T, RANGELOVA V, NEYKOV N. Nanocrystallization and hydrogen storage in rapidly solidified Mg-Ni-RE alloys[J]. Journal of Alloys and Compounds, 2002, 334(1/2): 219-223.

[20] GU Hao, ZHU Yun-feng, LI Li-quan. Effect of La/Ni ratio on hydrogen storage properties of Mg-Ni-La system prepared by hydriding combustion synthesis followed by mechanical milling[J]. International Journal of Hydrogen Energy, 2008, 33(12): 2970-2974.

[21] JORGE A M Jr, PROKOFIEV E, LIMA G F, RAUCH E, VERON M,  BOTTA W, KAWASAKI M, LANGDON T G. An investigation of hydrogen storage in a magnesium-based alloy processed by equal-channel angular pressing[J]. International Journal of Hydrogen Energy, 2013, 38(20): 8306-8312.

BOTTA W, KAWASAKI M, LANGDON T G. An investigation of hydrogen storage in a magnesium-based alloy processed by equal-channel angular pressing[J]. International Journal of Hydrogen Energy, 2013, 38(20): 8306-8312.

[22] ZHANG Yang-huan, XU Sheng, ZHAI Ting-ting, YANG Tai, YUAN Ze-ming, ZHAO Dong-liang. Hydrogen storage kinetics of nanocrystalline and amorphous Cu-Nd-added Mg2Ni-type alloys[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3524-3533.

[23] ZHANG Yang-huan, YANG Tai, BU Wen-gang, CAI Ying, ZHANG Guo-fang, ZHAO Dong-liang. Effect of Nd content on electrochemical performances of nanocrystalline and amorphous (Mg24Ni10Cu2)100-xNdx (x=0-20) alloys prepared by melt spinning[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3668-3676.

[24] ZHANG Yang-huan, HAN Zhong-gang, YUAN Ze-ming, YANG Tai, QI Yan, ZHAO Dong-liang. Electrochemical properties of nanocrystalline and amorphous Mg-Y-Ni alloys applied to Ni-MH battery[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3736-3746.

[25] SPASSOV T,  U. Hydrogenation of amorphous and nanocrystalline Mg-based alloys[J]. Journal of Alloys and Compounds, 1999, 287(1/2): 243-250.

U. Hydrogenation of amorphous and nanocrystalline Mg-based alloys[J]. Journal of Alloys and Compounds, 1999, 287(1/2): 243-250.

[26] ERIC A L. Hydrogen storage measurements in novel Mg-based nanostructured alloys produced via rapid solidification and devitrification[J]. International Journal of Hydrogen Energy, 2011, 36(17): 10787-10796.

[27] SPASSOV T,  U. Thermal stability and hydriding properties of nanocrystalline melt-spun Mg63Ni30Y7 alloy[J]. Journal of Alloys and Compounds, 1998, 279(2): 279-286.

U. Thermal stability and hydriding properties of nanocrystalline melt-spun Mg63Ni30Y7 alloy[J]. Journal of Alloys and Compounds, 1998, 279(2): 279-286.

[28] ZALUSKI L, ZALUSKA A,  J O. Nanocrystalline metal hydrides[J]. Journal of Alloys and Compounds, 1997, 70(2): 253-254.

J O. Nanocrystalline metal hydrides[J]. Journal of Alloys and Compounds, 1997, 70(2): 253-254.

Gaseous storage hydrogen kinetics of La-Mg-Ni-Cu system Mg2Ni type alloys

GAO Jin-liang1, SHANG Hong-wei2, LI Ya-qin2, YUAN Ze-ming2, ZHAO Dong-liang2, ZHANG Yang-huan2

(1. Weishan Cisri-Eare Earth Materials Co., Ltd., Jining 277600, China;

2. Department of Functional Material Research, Central Iron and Steel Research Institute, Beijing 100081, China)

Abstract: In order to improve the gaseous hydrogen storage kinetics of Mg2Ni type alloys, a small quantity of La was added to alloys, and the La-Mg-Ni-Cu system Mg2Ni type (Mg24Ni10Cu2)100-xLax (x=0, 5, 10, 15, 20) (mole fraction, x %) alloys were prepared by rapid quenching. The structures of the as-cast and quenched alloys were analyzed by XRD, SEM and HRTEM. The gaseous hydrogen absorption and desorption kinetics of alloys were tested by a fully automatic Sieverts equipment. Hydrogen desorption DSC curves of alloys were tested at different heating rates by a differential thermal analyzer, and the activation energy of alloys was calculated by using the equation of Kissinger. The relationship between the kinetics and La content and quenching rate was established. The results show that adding La doesn’t change the Mg2Ni major phase, however, leads to the formation of the second phases including La2Mg17 and LaMg3 phases. The phase abundance of the second phases increases with increasing the La content. Increasing La content and quenching rate are helpful to form the nanocrystalline and amorphous structure, and reducing the hydrogen desorption activate energy, thus improving the hydrogen desorption kinetics for Mg2Ni type alloys. The hydrogen desorption activation energy reduces from 73.18 kJ/mol to 60.41 kJ/mol and 66.16 kJ/mol to 50.50 kJ/mol for the as-cast alloy and as-spun alloy (30 m/s), respectively.

Key words: Mg2Ni type alloy; rapid quenching; adding La; gaseous hydrogen absorption-desorption kinetics; hydrogen desorption activation energy

Foundation item: Project(51471054) supported by the National Natural Science Foundation of China

Received date: 2016-04-12; Accepted date: 2016-08-31

Corresponding author: GAO Jin-liang; Tel: +86-537-5032188; E-mail: zhangyh59@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51471054)

收稿日期:2016-04-12;修订日期:2016-08-31

通信作者:高金良,高级工程师,博士;电话:0537-5032188;E-mail: zhangyh59@163.com