文章编号: 1004-0609(2005)08-1155-07

铸态及快淬态无钴AB5型贮氢合金的循环稳定性

张羊换1, 2, 王国清1, 董小平2, 郭世海1, 任江远2, 王新林1

(1. 内蒙古科技大学 材料学院, 包头 014010; 2. 钢铁研究总院 功能材料研究所, 北京 100081)

摘 要: 对AB5型LaxMm1-x(NiMnSiAlFe)4.9(x=0, 0.45, 0.75, 1.00, 摩尔分数)贮氢合金进行了快淬处理, 研究了La含量及快淬工艺对合金微观结构及电化学循环稳定性的影响。 结果表明: La含量的增加对铸态合金的循环稳定性没有明显影响, 但使快淬态合金的循环稳定性下降, 且快淬处理能显著提高合金的循环稳定性。 当La替代量从0增加到1.00时, 经300次充放循环后, 铸态合金的容量保持率(Rh)从59.2%增加到59.8%; 16m/s淬速快淬态合金的容量保持率从83.9%下降到65.0%。 对于x=0.45的合金, 当淬速从0(铸态被定义为淬速等于0)增加到28m/s时, 容量保持率从59.8%增加到75.8%。

关键词: 无钴AB5型贮氢合金; 快淬工艺; 微观结构; 循环稳定性 中图分类号: TG139.7

文献标识码: A

Cycle stability of Co-free AB5-type hydrogen storage alloy

prepared by casting and rapid quenching

ZHANG Yang-huan1, 2, WANG Guo-qing1, DONG Xiao-ping2,

GUO Shi-hai1, REN Jiang-yuan2, WANG Xin-lin1

(1. School of Materials, Inner Mongolia University of Science and Technology,Baotou 014010, China;

2. Institute of Functional Material Research,Central Iron and Steel Research Institute, Beijing 100081, China)

Abstract: In order to improve the electrochemical cycle stability of the Co-free AB5-type hydrogen storage alloy, Co-free LaxMm1-x(NiMnSiAlFe)4.9 (x=0, 0.45, 0.75, 1.00, mole fraction) hydrogen storage alloys were treated by rapid quenching. The effects of the substituting Mm with La and the quenching rate on the microstructure and the electrochemical cycle stability of the as-cast and quenched alloys were investigated. The obtained results show that the influence of substituting Mm with La on the cycle stability of the as-cast alloys is insignificant, but its influence on that of the as-quenched alloys is notable, and rapid quenching can remarkably enhance the cycle stability of the alloys. When the amount of substituting Mm with La increases from 0 to 1.00, the capacity retaining rate (Rh) of as-cast alloys increases from 59.2% to 59.8% after 300 charge-discharge cycles with the current density of 300mA/g, and for the as-quenched (16m/s) alloy, it decreases from 83.9% to 65.0%. When the quenching rate increases from 0 (the as-cast is defined as the quenching rate of 0m/s) to 28m/s, the capacity retaining rate (Rh) of La0.45 alloy increases from 59.8% to 75.8%.

Key words: Co-free AB5-type hydrogen storage alloy; rapid quenching; microstructure; cycle stability

AB5型稀土系贮氢电极合金具有室温及常压下可逆吸放大量氢以及易活化和反应速度快等优点而被广泛用作Ni-MH电池的负极材料[1, 2]。 然而, 最近几年, 由于锂离子电池的迅猛发展, Ni/MH电池受到了巨大的冲击和挑战。 一方面是由于锂离子电池具有更高的质量(或体积)能量密度; 另一方面, 在现有技术条件下生产的Ni/MH电池在价格上无法与铅酸电池抗衡。 因此, 提高贮氢合金的电化学性能, 降低其生产成本就成为Ni/MH电池能否在竞争中取胜的关键。 在典型的AB5贮氢合金中, Co含量约为10%(质量分数), 其成本约占合金原材料总成本的40%~50%。 因此很多研究旨在降低合金的Co含量[3-11], 但Co对AB5型贮氢合金的电化学循环稳定性起着举足轻重的作用[12]。 因此如何提高低钴贮氢合金的电化学稳定性, 成为低钴无钴AB5型贮氢合金研究的焦点。 研究表明[13-15], 通过成分设计及快淬处理, 可使低钴AB5型贮氢合金获得具有微晶、 纳米晶、 非晶混合结构的特殊微观组织, 这种结构的贮氢合金具有良好的初始活化性能和优异的电化学循环稳定性。 本文作者研究了快淬工艺对AB5型无钴LaxMm1-x-(NiMnSiAlFe)4.9(x=0, 0.45, 0.75, 1.0)贮氢合金循环稳定性的影响。

1 实验

1.1 合金的制备

实验合金用1kg级真空中频感应电炉熔炼, 经铜模浇铸后获得母合金锭。 将部分母合金重熔后进行单辊快淬处理, 获得淬速分别为10、 16、 22和28m/s的快淬态合金, 淬速以铜辊表面线速度表示。 实验合金的成分为LaxMm1-x(NiMnSiAlFe)4.9(x=0, 0.45, 0.75, 1.00), 对应La替代量x, 合金编号为La0, La0.45, La0.75, La1.00。 制备合金所用Ni、 Mn、 Si、 Al、 Fe、 La等原材料的纯度均高于99.7%, Mm为富铈的混合稀土(23.70%La, 55.29%Ce, 5.31%Pu, 15.70%Nd, 质量分数), 纯度为99.85%。

1.2 实验电极制备及循环稳定性测试

铸态及快淬态合金经机械破碎后获得径小于61μm的合金粉末。 将1g合金粉与1g镍粉和少许聚乙烯醇(PVA)充分混合, 在35MPa的压力下制成直径为15mm的圆片, 干燥4h后放入6mol/L KOH溶液中浸泡24h, 然后把电极片固定在开口式三电极电池负极镍片引线上, 进行循环稳定性测试。 测试系统的正极为Ni(OH)2/NiOOH, 参比电极为Hg/HgO, 电解液为6mol KOH水溶液。 取负极和参比电极之间的电压为放电电压。 每次循环以恒定电流过充约30%, 间隔15min后, 恒电流放电至-0.500V。 在300mA/g电流密度下, 测试合金的循环稳定性, 测试环境温度保持30℃。

1.3 微观结构分析

铸态合金样品直接研磨抛光, 用60%HF溶液浸蚀。 快淬样品用环氧树脂镶嵌后制样, 用扫描电镜(SEM)和光学显微镜观察合金的形貌。 将合金研磨成粒度为50μm以下的粉末, 用D/max/2400 X射线衍射仪测试合金的相结构及晶格参数, 射线源为CuKα1, 电流为160mA, 电压为40kV, 扫描速度为10(°)/min。 用无水酒精分散粉末合金试样, 用TEM观察试样的晶粒形貌并确定其晶态。 用扫描电镜观察合金电化学循环前后的形貌变化, 揭示电极合金的失效机理。

2 结果与讨论

2.1 微观结构

2.1.1 微观组织及形貌

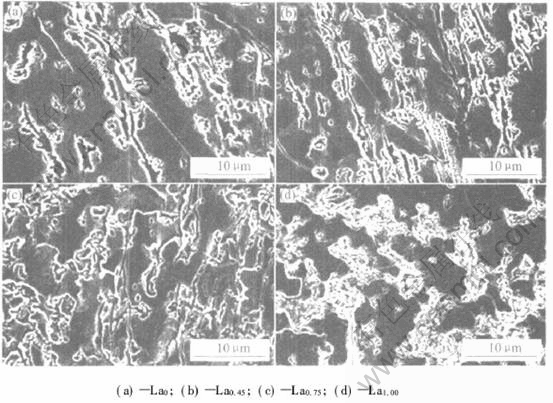

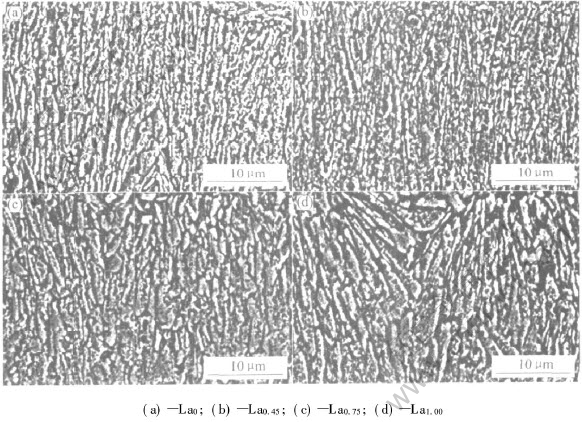

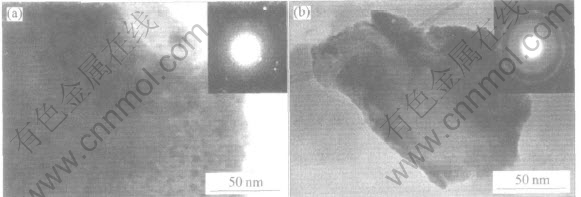

用扫描电镜观察了铸态及快淬态无钴合金的形貌, 结果如图1和2所示。 从图1可以看出, 合金的铸态组织比较粗大, 而且合金的成分均匀性较差。 La替代量的增加对合金的铸态形貌有较明显的影响, 随La替代量的增加, 合金的富La主相由分散分布转变为集中分布。 经10m/s淬速快淬后, 合金形貌发生了巨大的变化。 与铸态组织相比, 快淬态合金的晶粒显著细化, 成分偏析基本消除。 晶粒的形态由铸态的树枝晶向柱状晶转化。 值得注意的是, 随La替代量的增加, 快淬态合金的晶粒明显粗化。 说明La的变化对非平衡结晶过程的形核和长大过程有明显影响。 而且, 随La含量的增加, 合金柱状晶粒的取向发生改变, 其一致性变差。 用透射电镜观察了快淬态La0.45合金的微观组织形貌, 并用微区衍射分析了不同淬速下合金的晶态, 结果如图3所示。 从图3可以看出, 当淬速为16m/s时, 合金的形貌具有微晶特征, 微区衍射斑也反映出合金具有晶体的特征。 当淬速达到28m/s时, 微区衍射斑表明了合金中存在一定数量的非晶相, 出现了非晶化趋势。

图1 铸态合金的微观形貌

Fig.1 Morphologies of as-cast alloys

图2 淬速为10m/s快淬态合金的微观形貌

Fig.2 Morphologies of as-quenched alloys at quenching rate of 10m/s

图3 快淬态La0.45合金的形貌及微区衍射分析

Fig.3 TEM morphologies and SAD pattern of as-quenched La0.45 alloy

2.1.2 相组成及相结构

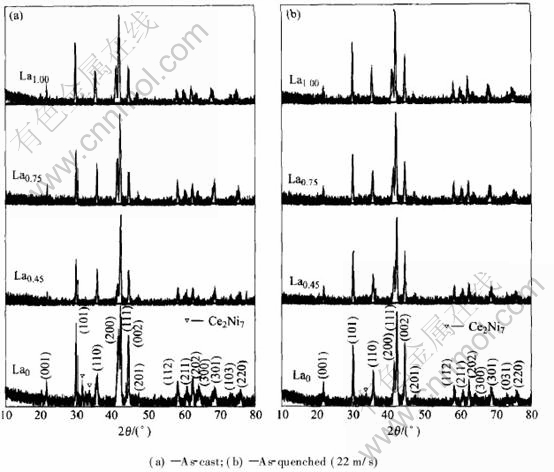

用X射线衍射仪测定了铸态及淬速22m/s快淬态La0, La0.45, La0.75, La1.00合金的相组成及相结构, 结果如图4所示。 从图4可以看出, 铸态La0合金具有双相结构, 主相为CaCu5相, 第二相为Ce2Ni7相。 La替代的La0.45合金中Ce2Ni7相消失。 继续增加La替代量, 合金的相组成及相结构没有显著变化, 但 (002)衍射峰的强度明显减弱。 说明La的加入影响合金在结晶过程中的晶体取向。 经 22m/s快淬后, 不同合金的衍射谱较为一致, 说明在快淬态下, La替代量对合金的晶体结构影响较小。 由晶面(101), (110), (200), (111) 和(002)衍射峰计算得到铸态和22m/s快淬合金的点阵常数, 并根据公式V=a2c sin60计算合金的晶胞体积, 结果列于表1。 从表1可以看出, 随La替代量的增加, 铸态及快淬态合金的晶格常数(a轴)及晶胞体积均增大。

图4 铸态及快淬态合金的X射线衍射谱

Fig.4 XRD patterns of as-cast and quenched alloys

2.2 循环稳定性

2.2.1 La含量对循环稳定性的影响

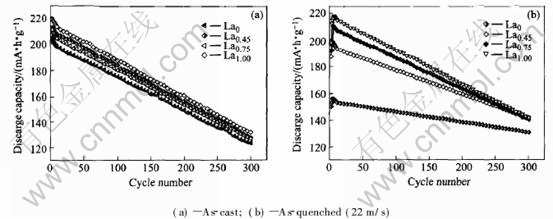

铸态及快淬态合金循环次数与放电容量的关系如图5所示。 从图5可以看出, 铸态合金的曲线斜率几乎看不出区别, 但快淬态合金的曲线斜率随La含量的增加而显著增大。 说明La含量的增加对铸态合金的循环稳定性影响较小, 但对快淬态合金的循环稳定性影响显著。 引入容量保持率(Rh)评价合金的循环稳定性。

图5 铸态及快淬态合金的循环次数与放电容量的关系

Fig.5 Relationships between cycle number and discharge capacity of alloys

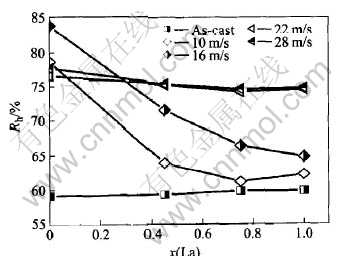

以300mA/g电流密度充放电时, 最大容量为表示为C300, max, 经过300次循环时的容量为C300, 300, 则容量保持率Rh=C300, 300/C300, max×100%。 La替代量与铸态及快淬态合金容量保持率的关系如图6所示。 从图6可以看出, 对于铸态合金, 容量保持率随La含量的变化很小。 当淬速为22和28m/s时, 随La替代量的增加, 容量保持率略有下降。 当淬速为10和16m/s时, La的替代量增加使合金的容量保持率显著下降。 说明在此淬速范围, La的替代量增加对合金的循环寿命不利。

表1 铸态及快淬态合金主相的晶格常数和晶胞体积

Table 1 Lattice constants and cell volumes of main phase in as-cast and quenched alloys

图6 La含量与容量保持率(Rh)的关系

Fig.6 Relationships between La content and capacity retaining rate(Rh)

2.2.2 淬速对循环稳定性的影响

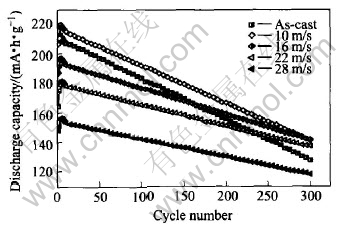

铸态及快淬态La0.45合金循环次数与放电容量的关系如图7所示。 从图7可以看出, 快淬态的曲线斜率明显小于铸态的, 且曲线的斜率随淬速的增加而显著较小, 说明快淬可以显著提高合金的循环寿命。

图7 铸态及快淬态La0.45合金的循环次数与容量的关系

Fig.7 Relationships between cycle number and discharge capacity of as-cast and quenched La0.45 alloy

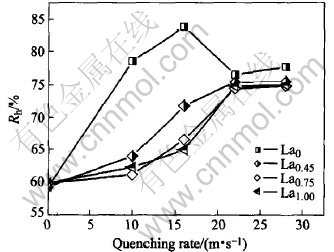

淬速与容量保持率及容量衰减率的关系如图8所示。 从图8可以看出, 合金的容量保持率均随淬速的增加而增加。 值得注意的是, 淬速为0和28m/s时, 所有合金具有相近的容量保持率。 说明在铸态下, La含量的变化对合金的循环稳定性影响较小。 而在高淬速下, 合金的循环稳定性的决定因素是淬速。 而当淬速为10和16m/s时, 不同成分合金的容量保持率差异较大, 说明在此淬速范围内, 合金的循环稳定性是由成分和淬速共同决定的。

图8 淬速与合金容量保持率的关系

Fig.8 Relationships between quenching rate and capacity retaining rate(Rh) of alloy

文献[16]的研究结果证实, 导致贮氢合金容量衰减的主要原因是合金在充放电过程中的氧化和粉化。 合金的循环稳定性主要取决于氢原子进入间隙位置导致的晶格应变大小和合金本身的抗粉化能力。 La替代使晶胞间隙半径增大对提高合金的抗粉化能力有利。 间隙半径越大, 氢原子进入间隙引起的晶格畸变越小, 合金的循环寿命越长。 但La替代使合金的抗腐蚀氧化能力下降, 总的结果是La替代对铸态合金的电化学循环稳定性影响较小。 La替代使得中等淬速(10和16m/s)快淬态合金的循环寿命下降, 其原因是La替代导致快淬态合金的晶粒粗化(图2), 使合金的抗粉化的能力下降。 在高淬速(≥22m/s)下, 获得微晶和一定数量非晶相的混合结构, 这种结构对合金的抗粉化能力起决定性作用, 因此, La替代对高淬速快淬态合金的循环寿命的影响较小。 快淬使合金循环寿命大幅度增加的原因是由于快淬导致的晶粒细化和非晶相的形成。 合金的抗粉化能力主要取决于合金的强韧性。 晶粒细化和非晶相的形成可以提高合金的强韧性, 使合金的抗粉化能力提高, 从而提高合金的循环寿命[17]。 非晶相的形成可以进一步增加合金在腐蚀性电解液中的耐蚀性, 使合金的循环寿命进一步提高。

3 结论

1) La替代量增加对铸态及高淬速快淬态合金的循环寿命影响较小, 但使中等淬速(10和16m/s)快淬态合金的循环寿命明显降低。 当La的替代量x从0增加到1时, 淬速为16m/s的快淬态合金的容量保持率从83.92%下降到64.97%。 而淬速为28m/s的快淬态合金的容量保持率从77.78%下降到74.90%。 La替代Mm使快淬态合金的晶粒粗化, 这是La替代Mm使快淬态合金循环寿命下降的主要原因之一。

2) 快淬处理可以显著改变无钴LaxMm1-x-(NiMnSiAl Fe)4.9(x=0, 0.45, 0.75, 1.00, 摩尔分数)贮氢合金的微观结构, 使合金的成分均匀化, 晶粒显著细化, 晶粒的形态由铸态的树枝晶向柱状晶转化。

3) 快淬处理可大幅度提高合金的循环寿命, 且循环寿命随淬速的增加而增加。 晶粒细化和非晶相的形成是快淬态合金循环寿命提高的主要原因。

REFERENCES

[1] Uehara I, Sakai T, Ishikawa H. The state of research and development for applications of metal hydrides in Japan[J]. J Alloys and Comp, 1997, 253-254: 635-641.

[2] Wang Q D, Chen C P, Lei Y Q. The recent research, development and industrial applications of metal hydrides in the Peoples Republic of China[J]. J Alloys and Comp, 1997, 253-254: 629-634.

[3] LI Ping, ZHANG Yang-huan, WANG Xin-lin, et al. Research of Mm(NiMnAlCu)4.9Co0.2 hydrogen storage alloys prepared by cast and rapidly quenched[J]. J Power Sources, 2003, 124: 285-292.

[4] Cocciantelli J M, Bernard P, Fernandez S, et al. The influence of Co and various additives on the performance of MmNi4.3-xMn0.33Al0.4Cox hydrogen storage alloys and Ni/MH prismatic sealed cells[J]. J Alloys and Comp, 1997, 253-254: 642-647.

[5] LI Ping, WANG Xin-lin, ZHANG Yang-huan, et al. Research of low-Co AB5 type rare-earth-based hydrogen storage alloy electrodes[J]. J Alloys and Comp, 2003, 354(1-2): 310-314.

[6] HU Wei-kang. Effect of microstructure, composition and non-stoichiometry on electrochemical properties of low-Co rare-earth nickel hydrogen storage alloys[J]. J Alloys and Comp, 1998, 279(2): 295-300.

[7] HU Wei-kang, KIM Dong-myung, JANG Kuk-jin, et al. Studies on co-free rare-earth-based hydrogen storage alloys[J]. J Alloys and Comp, 1998, 269(1-2): 254-258.

[8] LI Ping, WANG Xin-lin, ZHANG Yang-huan, et al. Research on electrochemical characteristics and microstructure of Mm(NiMnAl)4.9Co0.2 rapidly quenched alloy[J]. J Alloys and Comp, 2003, 353(1-2): 278-282.

[9] HU Wei-kang, Lee H, Kim D M, et al. Electrochemical behaviors of low-Co Mm-based alloys as MH electrodes[J]. J Alloys and Comp, 1998, 268(1-2): 261-265.

[10] HU Wei-kang. Studies on cobalt-free AB5-type hydrogen storage alloys[J]. J Alloys and Comp, 1999, 289(1-2): 299-305.

[11] JIANG Li-jun, ZHAN Feng, BAO De-you, et al. Low cost AB5-type hydrogen storage alloys for a nickel-metal hydride battery[J]. J Alloys and Comp, 1995, 231(1-2): 635-638.

[12] Chartouni D, Meli F, Züttel A, et al. The influence of cobalt on the electrochemical cycling stability of LaNi5-based hydride forming alloys[J]. J Alloys Comp, 1996, 241(1-2): 160-166.

[13] LI Chuan-jian, WANG Xin-lin, LI Xiu-mei, et al. The hydrogen storage properties of MmNi3.8Co0.6-Mn0.55Ti0.05 compounds prepared by conventional and melt-spinning techniques[J]. Electrochemica Acta, 1998, 43: 1839-1842.

[14] ZHANG Yang-huan, CHEN Mei-yan, WANG Xin-lin, et al. Effect of boron additive on the cycle life of low-Co AB5-type electrode consisting of alloy prepared by cast and rapid quenching[J]. J Power Sources, 2003, 125: 273-279.

[15] ZHANG Yang-huan, CHEN Mei-yan, WAN Xin-lin, et al. Microstructure and electrochemical characteristics of Mm(Ni, Co, Mn, Al)5Bx(x=0-0.4) hydrogen storage alloys prepared by cast and rapid quenching[J]. Electrochima Acta, 2004, 49(7): 1161-1168.

[16] Sakai T, Oguro K, Miyamura H, et al. Some factors affecting the cycle lives of LaNi5 based alloy electrodes of hydrogen batterys[J]. J Less-Common Metals, 1990, 161: 193-202.

[17] 张羊换, 陈梅艳, 王新林, 等. 硼对稀土系AB5型贮氢合金微观结构及电化学性能的影响[J]. 中国有色金属学报, 2004, 14(4): 580-586.

ZHANG Yang-huan, YANG Mei-yan, WANG Xin-lin, et al. Effect of boron additive on microstructures and electrochemical properties of rare earth-based AB5 hydrogen storage alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 580-586.

基金项目: 国家自然科学基金资助项目(50131040); 内蒙古自然科学基金资助项目(200408020706)

收稿日期: 2005-01-16;

修订日期: 2005-06-15

作者简介: 张羊换(1959-), 男, 教授, 博士.

通讯作者: 张羊换, 教授; 电话: 010-62187570; E-mail: zyh59@yahoo.com.cn; zhangyh59@163.com

(编辑 龙怀中)