基于FEA的拼焊板轿车中立柱拉延成形

刘晓晶,刘朋会,秦海斌,李峰,王聪

(哈尔滨理工大学 材料科学与工程学院,黑龙江 哈尔滨,150040)

摘要:运用DYNAFORM软件,对轿车侧围激光拼焊板中立柱进行冲压成形有限元数值模拟研究。通过观察成形极限图和厚度分布图对零件进行成形缺陷分析。针对成形结果中出现的拉裂、起皱和减薄等缺陷问题,采用调整成形工艺参数以及设置等效拉深筋的方法改善使成形结果,并根据仿真分析的结果,提出改进及优化工艺的方案。利用数值模拟过程中优化的工艺参数,进行实际零件的拉延成形实验,得到了质量较好的成形零件。研究结果表明:拼焊板焊缝模型的选取、板坯及工具网格的划分直接影响数值模拟的精度;冲压速度、压边力和拉深筋等工艺参数的选取直接影响零件的拉延成形,尤其是通过对拉深筋阻力的调节,平衡了材料的流动,解决了用调节压边力的方法无法解决的拼焊板零件成形问题。

关键词:拼焊板;拉深筋;拉延成形;数值模拟

中图分类号:TG386 文献标志码:A 文章编号:1672-7207(2012)08-2973-06

Drawing process of tailor welded blank car center pillar based on FEA

LIU Xiao-jing, LIU Peng-hui, QIN Hai-bin, LI Feng, WANG Cong

(School of Materials Science and Engineering, Harbin University of Science and Technology, Harbin 150040, China)

Abstract: The finite element numerical simulation for the drawing process of laser tailor welded blank car center pillar was researched using software DYNAFORM. By observing the forming limit diagram (FLD) and thickness diagram and analyzing the defects of the forming parts, the forming result were improved by means of adjusting some parameters and setting equivalent draw beads to avoid some defects such as rupture, wrinkling and thinning. Improving and optimizing process was proposed based on the simulation results. Using the optimized parameters used in simulation process, the drawing experiment was carried out, and good quality experimental forming parts were obtained. The results show that selection of weld model and mesh generation of blank and tools can directly affect the simulation accuracy; parameters such as drawing velocity, blank holder force and draw bead can affect the drawing result. Especially, material flow is balanced through regulating draw beads and it solves the problem which can’t be solved by adjusting the blank holder force in laser tailor welded blank forming process.

Key words: tailor welded blanks; draw bead; drawing; numerical simulation

拼焊板(tailor welded blanks,TWBs)成形技术是指将2块以上具有不同的厚度、材质和表面涂层的板料焊接在一起,进行冲压成形[1-2]。在车身覆盖件制造中采用拼焊板,可以有效地改善结构件的力学性能,提高零件的刚度和抗冲击性,减少装配零件的数量及减轻质量,最大限度地提高材料利用率,降低整车生产成本。所以,激光拼焊板零件已广泛用在如门板、纵梁、底板、立柱以及板坯超大的零件设计中[3-4]。同一般的冲压件相比,拼焊板汽车覆盖件具有形状复杂、表面质量要求较高、结构尺寸较大、多为空间曲面、相互配合的协调性要求较高等特点[5-6]。拼焊板材料的成形也有其自身的一些特点:一方面,由于不同的板厚差和不同的板料强度组合使得拼焊板材料的成形性能下降;另一方面,在成形过程中焊缝的移动、板料的不均匀变形和起皱等也是影响拼焊板材料成形的重要因素。针对上述特点,目前国内外对拼焊板的研究主要集中在拼焊板成形性能、拼焊板焊缝移动控制、拼焊板起皱问题、拼焊板冲压成形有限元建模等几个方面[7-9]。例如,Young等[10]分析了有拉深筋时盒形件的焊缝移动问题;Saunders[11]分析了焊缝位置、强度和厚度比等对焊缝移动的影响,上海交通大学模具CAD国家研究中心提出了板料成形前的板料形状优化方案[12]。Zhao等[13]利用有限元数值模拟的方法,考虑计算精度和计算效率,对不同的有限元模型进行了比较分析,建议采用不考虑热影响区的三维壳单元模型对拼焊板的成形过程进行模拟。对于复杂的拼焊板汽车覆盖件成形工艺的研究较少。因此,有必要针对复杂的拼焊板汽车覆盖件,研究影响其成形的各个因素及其与成形极限的关系,为合理设计拼焊板零件和确定合理的冲压成形工艺提供依据。本文作者应用DYNAFORM软件,针对轿车侧围中立柱,进行冲压成形有限元数值模拟研究。通过成形过程数值模拟仿真,对成形极限图和厚度分布图进行分析,针对成形结果中出现的拉裂、起皱和减薄等缺陷问题,通过调整部分工艺参数,主要通过设置等效拉深筋的方法使成形结果得到改善,并根据仿真分析的结果,提出改进和优化工艺的设计方案。

1 焊缝的处理问题

板料先经过裁剪,再用焊接的方法拼焊在一起而组成拼焊板,因此普通拼焊板由母材、热影响区和焊缝区3部分组成:如果2块板是用激光焊接的方法焊接在一起,那么,焊缝区和热影响区的宽度比较窄,在整个板料面积中所占的比例很小。但是,由于焊接过程中热循环的作用,焊缝处晶粒会长大,容易产生魏氏组织,造成焊缝处晶粒粗大现象,进而导致焊缝区塑性和韧性的下降,因此,焊缝区和热影响区的材料力学性能与母材相比有很大的差别。

目前,模拟拼焊板零件成形的方法主要有2种[14]:一是考虑焊缝的形状和尺寸、焊缝区和热影响区处马氏体的含量,细划分焊缝附近区域的有限元网格,建立精确的焊缝模型;二是忽略焊缝的类型,只考虑焊缝的位置,焊缝和热影响区由一排梁单元或者壳单元网格来表示,或者仅采用刚性连接处理。

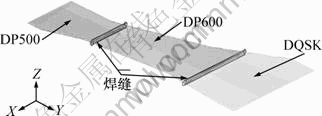

与单一板料相比,拼焊板的抗拉强度和屈服强度都有所增大,材料的硬化指数和延伸率则有所减小,拼焊板冲压成形过程中板平面内的变形可以分解为纵向变形和横向变形。在纵向,由于焊缝处材料的硬度比母材高,而延展率又远比母材的低,所以,在焊缝处容易发生破裂;在横向,由于焊缝处材料的屈服强度远高于母材的抗拉强度,因此,在横向上焊缝区域几乎不会发生塑性变形,变形仅发生在母材上,导致材料较弱的一侧容易发生破裂。研究表明[15]:当焊缝区域面积相对整个板料面积很小时,焊缝对母材的影响比较小,可以忽略焊缝类型,只考虑焊缝的位置。本文针对轿车侧围中立柱进行冲压成形模拟研究,零件形状如图1所示。由于板料是采用激光焊接的方法拼焊在一起,焊缝比较窄,在成形模拟过程中,板料采用BT壳单元,薄侧材料和厚侧材料在焊接处的单元相同,因此,考虑采用刚性连接,忽略焊缝类型,只考虑焊缝的位置,这样焊缝两侧母材相连接处的网格节点就拥有相同的平动和转动自由度。

图1 轿车中立柱零件模型

Fig.1 Model of center pillar of the car

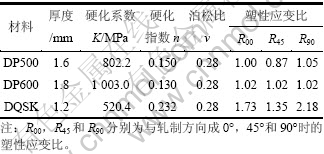

2 轿车侧围立柱有限元数值模拟

本文所研究的轿车侧围中立柱拼焊板板坯由3块钢板激光焊接而成的,3块板的材料分别为高强钢DP500,DP600和低碳钢DQSK,都选用36号各向异性材料,屈服函数符合Hill屈服准则,其材料性能参数如表1所示,焊缝采用刚性连接。板坯及焊缝位置示意图如图2所示。

在划分板坯网格时,工件的最小圆角至少由3个网格构成,也就是说,最小圆角处的网格尺寸在网格细化2次的情况下约等于R,网格的整体保证无畸变、尖锐角等质量较差的网格,以四边形网格为主,在特殊情况下有三角形单元时,尽量保证是等边三角形。板料网格单元采用全阶积分壳单元,法向积分点个数取7个,以避免沙漏现象,并提高数值模拟的精度。

表1 材料性能参数

Table 1 Parameters of material properties

图2 中立柱拼焊板板坯及焊缝位置模型

Fig.2 Model of TWBs blank and position of welding

根据零件的形状用DYNAFORM软件创建凹模,并划分工具网格。在划分工具网格时,保证工具网格以最大程度地贴合曲面实体为原则,适当增大网格的长宽比例,采用BT壳单元,法向积分点个数取1。考虑到本次模拟实验用的高强钢板的强度较高、塑性较差,因此,尽可能降低拉深深度,以便于成形。凹模创建完成后,再从凹模上偏置出凸模和压边圈。拼焊板冲压成形有限元数值模拟模型如图3所示。

图3 拼焊板冲压成形有限元数值模拟模型

Fig.3 Numerical simulation model of part

利用DYNAFORM软件自带的自动设置功能进行成形分析设置,初步设定虚拟冲压速度为1 m/s,冲压行程曲线为梯形,压边力为300 kN,毛坯零件层之间的接触类型为自动面到面接触。在完成设置之后,进行动画演示,以确定各个工具的运动情况,然后提交计算。

3 模拟仿真结果及分析

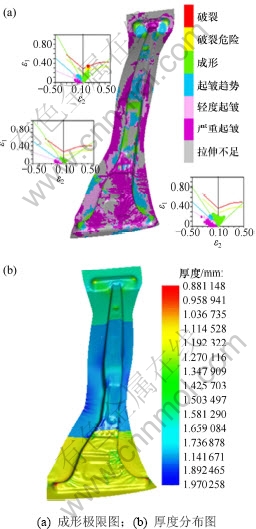

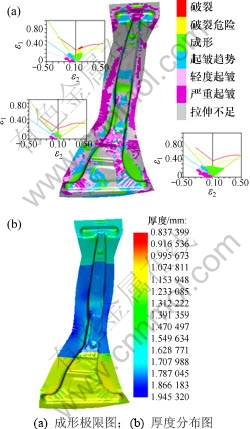

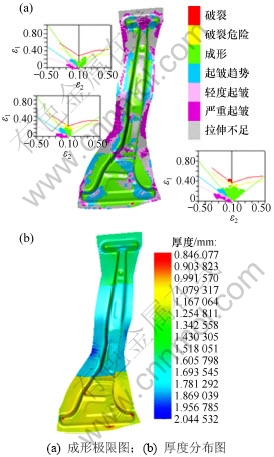

初步模拟后板料的成形极限图与厚度分布图如图4所示。

从图4可以看出:零件底部局部未被充分拉延;零件的两端和边缘部位出现破裂和起皱现象,有些部位还严重起皱;在零件的4个尖角处,减薄现象比较严重。这些缺陷问题会影响到零件的几何精度、表面质量和力学性能。通过减小压边力可以避免零件被减薄;设置等效拉深筋可以在板料易流动的部位局部增加进料阻力,在难流动部位局部减小进料阻力,这样就平衡了材料的流动,合理地改变了变形区板材的受力状态;适当降低冲压速度也有利于板料的变形。

图4 零件的成形极限图与厚度分布图

Fig.4 FLD and thickness distribution of part

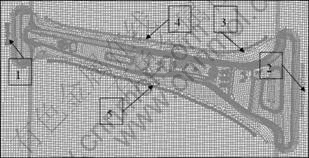

根据以上分析,对冲压成形模拟的部分工艺参数进行调整:压边力调整为200 kN;虚拟冲压速度调整为500 mm/s。1~5号等效拉深筋设置如图5所示,在本次模拟中1共设置5条等效拉深筋,完全锁定的拉深筋阻力如表2所示。1号、2号和3号拉深筋的主要作用是增加坯料两端的进料阻力,从而控制零件两端的起皱问题;4号和5号拉深筋主要用于改善零件底部拉延不充分的区域。拉深筋的阻力可以方便、灵活地进行调节,这样就弥补了拼焊板零件成形时对压边力调节不足的问题。在修改了这些参数、重点设置了拉深筋之后,再次进行成形模拟,成形极限图和厚度分布图如图6所示。

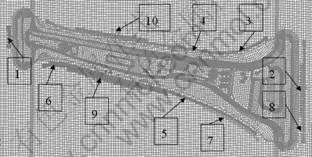

从图6可以看到:通过调整压边力、虚拟冲压速度以及设置等效拉深筋,零件的破裂情况基本消除,起皱的范围大幅度缩小,但零件边缘和底部两端部位还有少量起皱,底部还存在小面积的未被充分拉延的区域。要解决此种缺陷问题,可在虚拟冲压速度和压边力不变的前提下,调整拉深筋的布局及拉深筋的阻力,以平衡材料的流动,使板坯的成形得到优化。考虑到零件比较复杂,底部有大量的突起和凹陷等不易成形部位,而且零件各处的拉深深度不一致,3块板坯的成形性能相差比较大,零件各处板坯在流动过程中所需的力也不一样,因此,需要分段调整板坯的进料阻力。重新布置拉深筋,新增加5条拉深筋,并调整各个拉深筋的参数。分别增加1号和2号拉深筋的阻力,并增设8号拉深筋,以解决零件两端的起皱问题;为了使零件底部拉延更充分一点,增设6号和7号拉深筋,并增加3号、4号和5号拉深筋的阻力;9号和10号拉深筋所在的部位零件的拉深深度比较浅,这个部位需要加大进料阻力。调整后的等效拉深筋1~10号布置示意图如图7所示,各拉深筋的参数如表3所示。

图5 等效拉深筋的布置示意图

Fig.5 Position of equivalent draw beads

表2 完全锁定的各个拉深筋的阻力

Table 2 Resistances of draw beads N

图6 调整工艺参数后的成形极限图和厚度分布图

Fig.6 FLD and thickness distribution after process parameters improvement

表3 调整后的完全锁定的各个拉深筋的阻力

Table 3 Resistance of draw beads after improvement N

图7 调整后的拉深筋布置示意图

Fig.7 Position of draw beads after improvement

拉深筋阻力主要由Weidemann建立的著名的拉深筋阻力模型(如式(1)所示)确定,由于建立该力学模型时,忽略了材料的硬化特性、各向异性,并且做了部分理想的假设等,所以,实际拉深筋阻力是在该模型的计算基础上反复模拟调试得出的。

(1)

(1)

式中:t为板料的初始厚度;ω为拉深筋的长度;μ为摩擦因数;σs为屈服强度;ψ为板料弯曲角;Rg和Rb为拉深筋的肩部和底部半径;P为单位长度上的等效压边力。

再次调整工艺参数后的成形极限图和厚度分布图如图8所示。从图8可以看出:成形零件的起皱情况得到了控制,零件底部基本上被拉开,而且没有出现破裂情况,减薄和增厚也在允许的范围之内,因此,成形质量较好,说明在模拟仿真过程中修改拉深筋的布局和参数起到了优化成形的效果。

图8 再次调整工艺参数后的成形极限图和厚度分布图

Fig.8 FLD and thickness distribution after second process parameters improvement

依据模拟分析结果,通过实际零件的成形实验,加工出的零件产品如图9所示。从图9可见:依据数值模拟过程中设置的工艺参数加工出来的中立柱零件,成形质量较好,没有出现破裂、起皱及较严重的回弹及扭曲问题,在经过切边及冲孔工序之后,符合装配要求。通过实际拉延成形实验发现:有限元数值模拟结果对零件加工具有参照性,可指导实际生产。

图9 加工出的轿车侧围中立柱零件图

Fig.9 Center pillar of car produced in factory

4 结论

(1) 对于像轿车侧围中立柱这种大型的激光拼焊板零件,由于激光焊接的质量比较好,焊缝相对于整个零件来说比较窄,对成形的影响比较小,因此在数值模拟中可以不考虑焊缝模型,只考虑焊缝的位置。

(2) 在成形模拟中,冲压速度、压边力和拉深筋等工艺参数的调整对拼焊板零件成形的影响较大。本文通过对拉深筋阻力的调节,平衡了材料的流动,解决了用调节压边力的方法无法解决的拼焊板零件成形过程问题,并且在实际生产中比较容易操作和实施。将模拟方案应用于实际零件的成形,得到了质量较好的轿车侧围零件。

(3) 拉深筋设置及调节措施为:

① 拉深筋要与材料流动方向垂直,筋的走向与其对应的凹模口形状一致,通常由凹模入口轮廓线偏置而成,筋线与凹模口的距离为25 mm左右。

② 对于拼焊板零件,拉深筋采用分段调节的方法,在强度较低、塑性较好、材料较容易流动的板坯位置应该设置较大阻力的拉深筋,而在强度较高、塑性较差、材料不容易流动的板坯位置应该设置较小阻力的拉深筋或不设置拉深筋。

③ 在容易起皱的部位设置局部的短筋调整进料阻力;在拉延深度大的直线部分,设置拉深筋,在拉延深度大的圆弧部分,不设置拉深筋;当拉延深度相差较大时,在深的部位不设拉深筋,浅的部位设拉 深筋。

参考文献:

[1] Ghoo B Y, Keum Y T, Kim Y S. Evaluation of the mechanical properties of welded metal in tailored steel sheet welded by CO2 laser[J]. Journal Materials Processing Technology, 2001, 113(1/2/3): 692-698.

[2] 陈炜, 杨继昌, 林忠钦. 拼焊板在车身覆盖件制造中的应用[J]. 汽车工程, 2003, 25(1): 82-87.

CHEN Wei, YANG Ji-chang, LIN Zhong-qin. A study on application of tailor-welded blank to car body closure panels manufacturing[J]. Automotive Engineering, 2003, 25(1): 82-87.

[3] 田浩彬, 林建平, 刘瑞同, 等. 汽车车身轻量化及其相关成形技术综述[J]. 汽车工程, 2005, 27(3): 381-384.

TIAN Hao-bin, LIN Jian-ping, LIU Rui-tong, et al. A review on ultralight auto body and related forming technologies[J]. Automotive Engineering, 2005, 27(3): 381-384.

[4] 王春燕. 激光拼焊板制轿车整体侧围内板成形关键技术的研究[D]. 长春: 吉林大学汽车工程学院, 2008: 1-4.

WANG Chun-yan. Study on key technology of drawing formability for automotive body inner side panel made of tailor welded blank[D]. Changchun: Jilin University. School of Automotive Engineering, 2008: 1-4.

[5] 崔令江. 汽车覆盖件冲压成形技术[M]. 北京: 机械工业出版社, 2003: 6.

CUI Ling-jiang. Technique of sheet metal forming for automotive body panels[M]. Beijing: Mechanic industry Press, 2003: 6.

[6] 崔令江. 汽车覆盖件冲压变形趋向性控制[J]. 材料科学与工艺, 2004, 12(4): 375-378.

CUI Ling-jiang, Control of deforming trend in auto cover stamping process[J]. Material Science and Technology, 2004, 12(4): 375-378.

[7] 蒋浩民, 陈新平. 激光拼焊板拉延成形焊缝移动优化控制[J]. 材料科学与工艺, 2004, 12(5): 512-514.

JIANG Hao-min, CHEN Xin-ping. Optimized control of weld movement in the drawing process of laser tailored welded blanks[J]. Material Science and Technology, 2004, 12(5): 512-514.

[8] 翁孟超, 杨志强. 基于Dynaform的拼焊板冲压成形压边方法研究[J]. 锻压技术, 2007, 32(2): 33-36.

WENG Meng-chao, YANG Zhi-qiang. Research on blank holder methods of tailor-welded blanks in stamping based on Dynaform[J]. Forging and Stamping Technology, 2007, 32(2): 33-36.

[9] 林建平, 孙东继. 汽车用拼焊板国内外研究进展[J]. 汽车技术, 2007(8): 1-5.

LIN Jian-ping, SUN Dong-ji. Development of research in tailor welded blanks used in auto industry[J]. Automotive Engineering, 2007(8): 1-5.

[10] Young M H, Youho C. Characteristic of weld line movements for the deep drawing with draw beads of tailor welded blanks[J]. Journal of Materials Processing Technology, 2001, 111(1/3): 164-169.

[11] Saunders F I. Forming of tailor welded blanks[M]. Ohio: The Ohio State University, 1994: 10-20.

[12] 唐炳涛, 赵震, 陈军, 等. 板料冲压成形中坯料优化设计方法研究[J]. 金属成形工艺, 2004, 22(2): 58-60.

TANG Bing-tao, ZHAO Zhen, CHEN Jun, et al. The study of blank optimization methods for sheet metal forming parts[J]. Journal of Netshape Forming Engineering, 2004, 22(2): 58-60.

[13] Zhao K M, Chun B K, Lee J K. Finite element analysis of tailor welded blanks[J]. Finite Elements in Analysis and Design, 2001, 37: 117-130.

[14] 张福祥, 陈炜, 杨继昌, 等. 拼焊板在盒形件拉深过程中的焊缝移动研究[J]. 金属成形工艺, 2002(5): 33-36.

ZHANG Fu-xiang, CHEN Wei, YANG Ji-chang, et al. Research on welding line movement for TWB during square cup drawing[J]. Journal of Netshape Forming Engineering, 2002(5): 33-36.

[15] Ahmetoglu M A, Brouwers D, Shulkin L, et al. Deep drawing of round cups from tailor-welded blanks[J]. Journal of Materials Processing Technology, 1995, 53(3/4): 684-694.

(编辑 赵俊)

收稿日期:2011-09-20;修回日期:2011-12-20

基金项目:黑龙江省自然科学基金资助项目(E201102)

通信作者:刘晓晶(1966-),女,黑龙江哈尔滨人,博士,教授,从事模具CAD/CAPP/CAE及集成技术、板料液压成形技术及数值模拟研究;电话:0451-86392501;E-mail:lxj812@126.com