碳纤维增强碳化硅复合材料的力学性能与界面

来源期刊:中南大学学报(自然科学版)2000年第4期

论文作者:何新波 张新明 张长瑞 周新贵 周安郴

文章页码:342 - 345

关键词:Cf/SiC复合材料;显微结构;力学性能;界面

Key words:Cf/SiC composites; microstructures; mechanical properties; interfaces

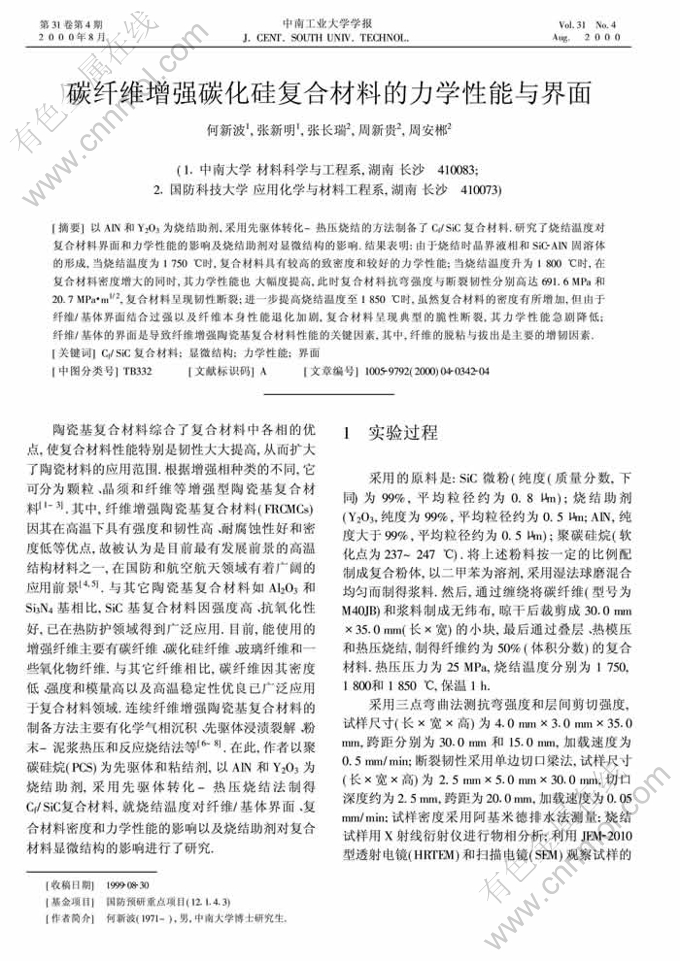

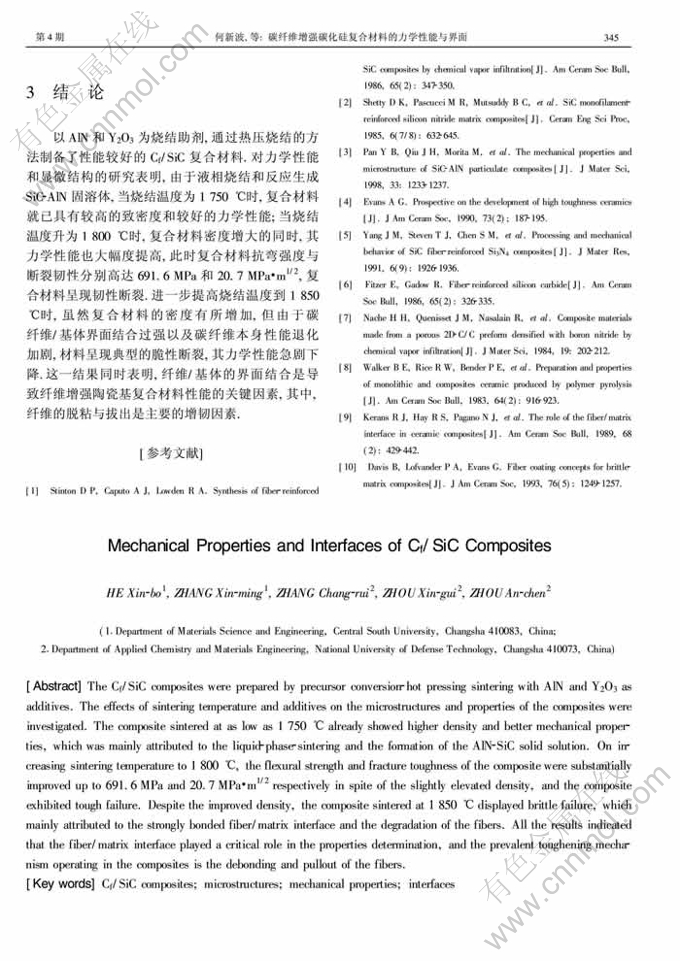

摘 要:以AlN和Y2O3为烧结助剂,采用先驱体转化-热压烧结的方法制备了Cf/SiC复合材料.研究了烧结温度对复合材料界面和力学性能的影响及烧结助剂对显微结构的影响.结果表明:由于烧结时晶界液相和SiC-AlN固溶体的形成,当烧结温度为1 750℃时,复合材料具有较高的致密度和较好的力学性能;当烧结温度升为1 800℃时,在复合材料密度增大的同时,其力学性能也大幅度提高,此时复合材料抗弯强度与断裂韧性分别高达691.6 MPa和20.7 MPa·m1/2,复合材料呈现韧性断裂;进一步提高烧结温度至1 850℃时,虽然复合材料的密度有所增加,但由于纤维/基体界面结合过强以及纤维本身性能退化加剧,复合材料呈现典型的脆性断裂,其力学性能急剧降低;纤维/基体的界面是导致纤维增强陶瓷基复合材料性能的关键因素,其中,纤维的脱粘与拔出是主要的增韧因素.

Abstract: The Cf/SiC composites were prepared by precursor conversion-hot pressing sintering with AlN and Y2O3 as additives. The effects of sintering temperature and additives on the microstructures and properties of the composites were investigated. The composite sintered at as low as 1 750℃already showed higher density and better mechanical properties, which was mainly attributed to the liquid-phase-sintering and the formation of the AlN-SiC solid solution. On increasing sinteringtemperature to 1 800℃, the flexural strength and fracture toughness ofthe compositewere substantially improved up to 691.6 MPa and 20.7 MPa·m1/2 respectively in spite of the slightly elevated density, and the composite exhibited tough failure. Despite the improved density, the composite sintered at 1 850℃ displayed brittle failure, which mainly attributed to the strongly bonded fiber/matrix interface and the degradation of the fibers. All the results indicated that the fiber/matrix interface played a critical role in the properties determination, and the prevalent tougheningmechanism operating in the composites is the debonding and pullout of the fibers.