文章编号:1004-0609(2011)01-0131-07

制动过程中热应力对C/C复合材料磨损表面形貌的影响

徐惠娟,易茂中,熊 翔,黄伯云,梁月明,郭 瑞

(中南大学 粉末冶金国家重点实验室, 长沙 410083)

摘 要:以炭纤维针刺整体毡为预制体,经化学气相渗透和树脂浸渍增密方式得到C/C复合材料。采用有限元分析软件,模拟飞机在正常着陆条件下,刹车盘在制动过程中的热应力分布,并研究热应力对C/C复合材料磨损表面形貌的影响。结果表明:热应力是由于摩擦热的不均匀分布引起的。在摩擦表面外径处温度较高,产生的热应力较大,最大值约为3.15 MPa;而在靠近内径处温度较低,热应力较小,约为1.78 MPa。内、外径处热应力的差异导致磨损表面具有两种不同的组织形貌;靠近外径处的磨损表面比较粗糙,摩擦膜不完整,颜色暗淡,为“暗带”的组织形貌,摩擦性能较差;而靠近内径处的磨损表面光滑,摩擦膜连续稳定,颜色明亮,为“亮带”的组织形貌,摩擦性能较好。

关键词:C/C复合材料;有限元;热应力;磨损表面

中图分类号:TB 332 文献标志码:A

Effect of thermal stress on worn surface morphology of C/C composites during braking

XU Hui-juan, YI Mao-zhong, XIONG Xiang, HUANG Bai-yun, LIANG Yue-ming, GUO Rui

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract:The thermal stress field of C/C composites with needled carbon fiber perform densified by chemical vapor infiltration and impregnating resin was simulated by finite element method in simulating normal landing. And the effect of thermal stress on the worn surface morphology was investigated. The results show that the thermal stress is caused by the existence of the non-uniform frictional heat on the contact surface. The temperature and thermal stress near the outer diameter of the friction surface are higher than those near the inner diameter. The maximum thermal stress near the outer diameter is 3.15 MPa and the thermal stress near the inner diameter is 1.78 MPa. Two different worn surface appearances can be observed on the sample because of the thermal stress distribution. The higher thermal stress near the outer diameter induces the rough and dull surface morphology named ‘dark band’, which has worse friction property. While the thermal stress near the inner diameter is lower, the surface is smooth and allows the maintenance of uniform and bright friction film named ‘bright band’, which has better friction property.

Key words: C/C composites; finite element; thermal stress; worn surface

C/C复合材料由于具有耐高温、热膨胀系数小、导热性能优良、强度高、摩擦性能良好以及磨损较低等优点,已广泛应用于航空航天及军事领域[1-2]。作为飞机刹车材料,C/C复合材料与钢相比具有密度低和热物理、力学性能良好等优点,它的密度仅为1.7~1.9 g/cm3,为钢的1/4~1/5,可以使飞机质量减少几百公斤;它不仅制动性能优良,而且使用寿命是金属刹车盘的数倍,是当今最理想的飞机刹车材料[3-4]。

C/C复合材料的摩擦磨损性能不仅与基体炭的种类、纤维取向、纤维的体积分数及能载水平有关,还与摩擦表面的温度及热应力等因素有关[5-9]。不同结构的基体炭表现出不同的摩擦磨损特性,粗糙层热解炭具有较好的摩擦性能,高能下摩擦因数衰减小;在摩擦表面不同取向的纤维会形成不同的摩擦层,产生不同的磨损率,当纤维体积分数超过30%时,磨损量显著增加;粗糙层热解炭结构的C/C复合材料在制动过程中产生的磨屑尺寸随着能载水平的增加急剧减小,在不同的能载水平下,其摩擦磨损特性不同。总之,影响C/C复合材料摩擦磨损性能的因素很多,有材质本身的因素,也有试验条件的影响。

制动盘在制动过程中将动能转化成热能,摩擦表面的温度从室温迅速上升到几百甚至上千度[10]。这个迅速升温的过程通常会对摩擦性能产生两方面的影响:一方面是使吸附在摩擦表面的水气、氧等解吸附,摩擦因数升高;另一方面是摩擦表面温度的升高会增加磨屑层的变形能力,更高的温度还会引起碳结构的削弱,导致更多的磨屑产生,使摩擦因数降低[11]。在高速制动条件下即当制动能量较高时,磨损表面会出现亮带及暗带光学组织。这是摩擦热分布不均匀及表面热应力不等引起的[9],由于在实验中很难测定制动盘的热应力,其对C/C复合材料摩擦磨损性能的影响不能通过实验来验证。本文作者通过采用有限元软件模拟计算实验室试环在制动过程中的瞬态温度场和热应力场的变化,分析温度对热应力场的影响以及热应力对C/C复合材料磨损表面形貌的影响,并研究其形成不同磨损表面形貌的机理。

1 实验

1.1 样件制备

以炭纤维针刺整体毡为预制体,经化学气相渗透和树脂浸渍增密,其基体炭为粗糙层结构的热解炭和树脂炭,最终经过2 000 ℃热处理,样件的密度为1.87 g/cm3。

1.2 热物性能测定

将制得的C/C复合材料加工成d 14 mm×30 mm的样件,采用铜卡计混合法在ZBY-800型中温比热仪上进行室温到800 ℃比热容的测试。将制得的C/C复合材料分别沿平行和垂直炭纤维叠层方向加工成 d 10 mm×4 mm的样件,采用激光闪光法,在JR-3型热物性测定仪上测定样件室温到800 ℃的轴向和径向热扩散率α,根据比热容和热扩散率计算导热系数。

热膨胀系数的测量使用日本理学公司生产的TAS 100型热分析仪。测量样件的尺寸为3 mm×4 mm×20 mm,测量过程中以氩气作为保护气体,测量温度从室温到800 ℃,升温速率为3 ℃/min。

1.3 摩擦磨损性能测试

本实验采用缩比样件模拟飞机在正常着陆条件下的能载水平,在MM-1000摩擦试验机上采用摩擦热冲击方法进行环-环制动实验。样件的长纤维排布方向平行于摩擦表面,实验开始之前,将样件在磨床上磨平,确保动、静环摩擦面的平行度达到要求。样件的几何形状为外径75 mm,内径45 mm,厚17.5 mm的圆环。实验参数为:压力0.6 MPa,线速度25 m/s,惯量0.3 kg·m2。多次重复进行制动实验直至摩擦因数稳定为止,在实验过程中记录制动力矩和摩擦因数曲线。

1.4 摩擦表面形貌观察

制动实验结束后,用数码相机拍摄磨损表面形貌的宏观照片,在JSM-5600LV型扫描电子显微镜下观察样件磨损表面的微观形貌,并采用KH-7700三维视频显微镜观察样件磨损表面的三维形貌。

2 温度场、热应力场的模拟仿真

2.1 有限元模型

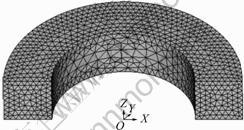

考虑到制动试环的结构对称性,取半个试环进行分析,并进行简化处理。采用耦合单元SOLID5建立模型,划分网格,进行热-应力耦合分析,得到有限元模型如图1所示。模型的内径为45 mm、外径为75 mm,厚度为17.5 mm。

2.2 热传导方程

根据传热学理论,对于无内热源的各向异性材料,热传导方程如下[12]:

(1)

(1)

式中:T为温度;t为热传导时间;ρ为材料密度;c为材料比热容;kx、ky、kz分别为材料在x、y、z方向的热导率。

图1 样件的三维有限元模型

Fig.1 Three-dimensional finite element model of sample

2.3 位移约束

位移约束又称DOF约束,是对模型在空间的自由度的约束。本实验中由于样件原本是一个完整的圆环,为了计算方便,模拟时只取半个圆环。为了保证试环所对称半圆环计算的准确性,需约束其纵截面处的自由度,取uy=0,即限制物体在垂直于两个纵截面方向上的位移,如图2所示。

图2 样件施加的位移约束

Fig.2 Displacement constraint on sample

2.4 热应力的计算

物体A和B相对摩擦滑动时产生的摩擦热以及摩擦体内部的热传导使物体各部分温度发生变化,物体由于热变形将产生线应变α(T-T0),其中:α为物体材料的热膨胀系数;T为弹性体内任一点现时的温度;T0为初始温度。由于物体受到约束且各部分的温度变化不均匀,物体的热变形不能自由进行,在物体中产生应力。物体由于温度变化引起的应力称为“热应力”[13]。当弹性物体的温度场已经求得时,就可以进一步求出弹性体各部分的热应力。热应力的计算公式为

σ = α E ( T - T0 ) (2)

式中:σ为热应力,MPa;α为热膨胀系数;E为弹性模量,GPa;T0为初始温度,℃;T为某时刻温 度,℃。

3 结果与讨论

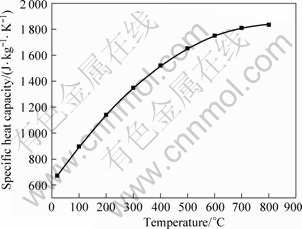

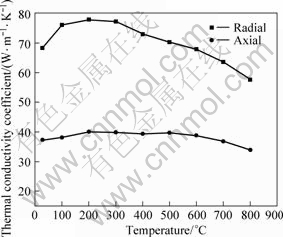

3.1 样件的热物性能

图3~5所示分别为样件的热物性能测试结果。由图3可知,C/C复合材料的比热容随着温度升高而增大。图4所示为样件在径向和轴向的导热系数,由图4可知,样件径向的导热系数大于轴向的导热系数,这是因为平行方向炭纤维取向占优势,而炭纤维是导热的主要因素[14];且无论在径向还是轴向,随着温度的升高,样件的导热系数先增大,在200 ℃达到最大值,随后逐渐减小。LUO等[15]对C/C复合材料在900 ℃以下导热系数与温度的关系进行研究后发现:对于

图3 比热容随温度的变化曲线

Fig.3 Curve of specific heat capacity vs temperature

图4 导热系数随温度变化曲线

Fig.4 Curves of thermal conductivity coefficient vs temperature

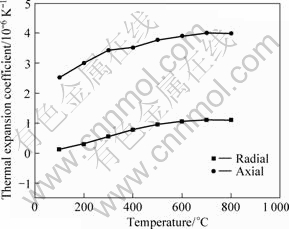

图5 热膨胀系数随温度变化曲线

Fig.5 Curves of thermal expansion coefficient vs temperature

组织结构好、结晶度高的样件,随着温度的升高,热导率逐渐降低;而对于结晶度低的样件,热导率则变化平缓;结晶度介于两者之间的样件,导热系数先有一个升高的阶段,到达一定值后逐渐降低。本实验的样件是以粗糙层热解炭为主,添加少量低织构树脂炭,其结晶度介于高织构和低织构之间,所以导热系数先升高,到达一定值后逐渐降低。图5所示为材料的热膨胀系数随温度的变化曲线。由图5可知,C/C复合材料的热膨胀系数很小,随着温度升高,材料的热膨胀系数逐渐增大,且轴向热膨胀系数大于径向热膨胀系数, 这主要是由于材料的热膨胀性能与其晶体大小的关系不大,而受晶体方向的影响较大[16]。

3.2 温度场和热应力场的计算

图6所示为样件在制动过程中的最高热应力分布云图和对应的温度场分布云图。从图6(a)可以看出:样件在径向和轴向均存在热应力梯度,径向的热应力梯度小于轴向的热应力梯度,摩擦表面的热应力最大,且摩擦表面从内径到外径方向,热应力增加显著,摩擦表面内径处的热应力最小,为1.78 MPa;摩擦表面外径处的热应力最大,为3.15 MPa,发生时间为制动开始后的第2.1 s。当热应力达到最大值时,相应的温度场分布云图如图6(b)所示。由图6(b)可见,样件在径向和轴向均存在明显的温度梯度,轴向的温度梯度比径向的温度梯度大,摩擦表面外径处的温度最高,其对应处的热应力也最大。

图7所示为样件在轴向和径向热应力随时间的变化曲线。图7(a)所示为样件中径处轴向热应力随时 间的变化曲线。由图7(a)可知,在制动初始阶段,摩

图6 样件在制动过程中的最高热应力分布云图和对应的温度场分布云图

Fig.6 Highest thermal stress field (a) and corresponding temperature field (b) distribution of sample during braking

擦表面的热应力迅速上升,在2 s左右达到最大值,随后快速下降,下降速度高于其他3个位置的热应力下降速度;距摩擦表面不同厚度处的热应力随时间的变化相近,热应力均随着制动过程的进行缓慢上升,在4~5 s时达到最大值,之后缓慢下降,其最大值远小于摩擦表面热应力的最大值,摩擦表面的热应力与样件内部的热应力相差很大,而样件内部不同厚度处的热应力差别较小。图7(b)所示为样件摩擦表面内、中及外径处的热应力随时间的变化曲线。由图7(b)可知:3个位置处的热应力均在制动初始阶段快速上升,在2 s左右达到最大值,随后快速下降;内、中及外径处的热应力变化趋势相近,外径处的热应力最大、内径处的最小,内、中及外径处的热应力梯度比轴向热应力梯度小,这主要与摩擦表面的内、中及外径处的温度梯度、热膨胀量及约束较小有关。

3.3 磨损表面形貌特征

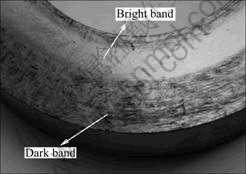

在模拟飞机正常着陆条件的制动过程中,样件磨损表面形成了两种不同的形貌,如图8所示。由图8

图7 样件在不同方向热应力随时间的变化

Fig.7 Variation of thermal stress in different directions with time: (a) Axial direction; (b) Radial direction

可看出,在靠近内径处磨损表面比较光滑,由于镜面反射颜色明亮,为灰白色,称为“亮带”;而靠近外径处磨损表面则比较粗糙,发生漫反射而颜色暗淡,称为“暗带”。在亮带区形成了比较完整的摩擦膜;暗带区凹凸不平,没有形成摩擦膜或者摩擦膜被破坏,这主要是由于样件在制动过程中温度分布不均匀及接触面热膨胀不等引起的。

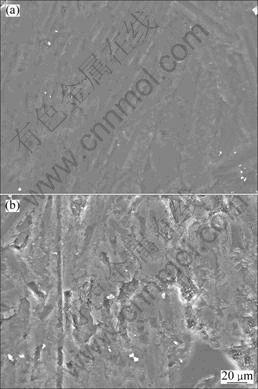

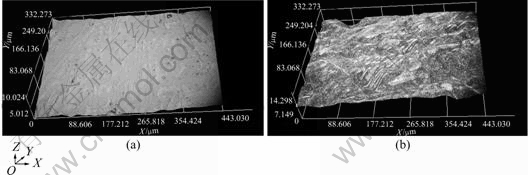

图9所示为样件磨损表面亮带和暗带处的SEM像。由图9可以看出:磨损表面的亮带处形成了一层比较完整、连续、致密及较薄的摩擦膜,整个表面比较光滑;而磨损表面的暗带处凹凸不平,没有完整的摩擦膜形成,磨屑在表面堆积变形后形成了粗糙、较厚及松散的磨屑层。图10所示为磨损表面的亮带和暗带部位的3D形貌图。由图10可见,磨损表面的亮带部位平整光滑,暗带部位高低起伏不平。亮带部位的磨损表面的高度差约为2.0 μm;暗带部位的磨损表面的高度差较大,约为3.9 μm,是亮带部位磨损表面高

图8 样件磨损表面的宏观形貌

Fig.8 Macroscopical morphology of worn surface of sample

图9 样件磨损表面亮带和暗带处的SEM像

Fig.9 SEM images of bright (a) and dark (b) bands on worn surface of sample

度差的近1倍。

样件在制动过程中外径处的线速度大于内径处的线速度,外径处产生的热流密度大于内径处产生的热流密度。同时,由于制动时间短,外径处温度迅速升高,且温度升高速度远大于热量传递速度,从而在径向和轴向产生了较大的温度梯度,使温度高的区域向温度低的区域膨胀。但由于受到约束而不能自由进行,因此,在温度高的区域产生压应力,样件外径处的 接触应力较大,容易破坏由磨屑被压制而形成的连

图10 磨损表面亮带和暗带部位的3D形貌

Fig.10 3D morphologies of surface of bright (a) and dark (b) bands on worn surface of sample

续的摩擦膜,从而无法形成光滑连续的摩擦膜,在外径处形成形貌为颗粒状且比较粗糙的暗带,此时的摩擦磨损机制类似于磨粒磨损,磨损较大;在内径处的温度较低,热应力较小,不容易破坏由磨屑形成的连续的摩擦膜,磨损较小,较容易形成完整的摩擦膜而呈光滑的亮带形貌。

4 结论

1) C/C复合材料样件在径向和轴向均存在热应力梯度,径向热应力梯度小于轴向热应力梯度,摩擦表面的热应力最大,且摩擦表面从内径到外径方向,热应力显著增大,摩擦表面内径处的热应力最小,为1.78 MPa,摩擦表面外径处的热应力最大,为3.15 MPa。

2) 正常着陆条件试验后,C/C复合材料样件在其磨损表面形成了两种不同的组织形貌:在靠近外径处,磨损表面形成了粗糙的暗带;而在靠近内径处,磨损表面形成了光滑的亮带。

3) 研究表明:在制动过程中的热应力分布对磨损表面的形貌有直接影响,磨损表面外径处高的热应力导致较厚、松散磨屑层暗带形貌的形成;而磨损表面内径处形成的致密、较薄的摩擦膜亮带形貌与内径处较小的热应力有关。

References

[1] KATARZYNA P B, ANDERSON K B, SZYMANSKI T, KRKOSKA M, FILIP P. Thermal analysis of bulk carbon-carbon composite and friction products derived from it during simulated aircraft braking[J]. Carbon, 2007, 45(3): 524-530.

[2] 易茂中, 葛毅成, 黄伯云. 不同基体炭结构的C/C复合材料摩擦表面特性和摩擦磨损机理[J]. 中国有色金学报, 2006, 16(6): 929-936.

YI Mao-zhong, GE Yi-cheng, HUANG Bai-yun. Characteristics of wear surface morphology and wear mechanism of C/C composite with different matrix carbons[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 929-936.

[3] 熊 翔, 黄伯云, 徐惠娟, 吉冬英, 彭剑昕. 针刺毡C/C 复合材料磨擦制动压力和速度特性[J]. 复合材料报, 2003, 20(3): 42-46.

XIONG Xiang, HUANG Bai-yun, XU Hui-juan, JI Dong-ying, PENG Jian-xin. Friction and wear behaviors of C/C composite from needled felt at different braking pressures and speeds[J]. Acta Materiae Compositae Sinica, 2003, 20(3): 42-46.

[4] XIONG Xiang, LI Jiang-hong, HUANG Bai-yun. Impact of brake pressure on the friction and wear of carbon/carbon composites[J]. Carbon, 2007, 45(9): 2692-2716.

[5] XIONG Xiang, HUANG Bai-yun, LI Jiang-hong, XU Hui-juan. Friction behaviors of carbon/carbon composites with different pyrolytic carbon texture[J]. Carbon, 2006, 44(3): 463-467.

[6] HUTTON T J, JOHNSON D, MCENANEY B. Effects of fiber orientation on the tribology of a model carbon-carbon composite[J]. Wear, 2001, 249(8): 647-655.

[7] 徐惠娟, 熊 翔, 黄伯云, 彭剑昕, 李江鸿. 不同能载水平下C/C复合材料的摩擦特性[J]. 中南工业大学学报: 自然科学版, 2003, 34(3): 221-224.

XU Hui-juan,XIONG Xiang,HUANG Bai-yun, PENG Jian-xin, LI Jiang-hong. Friction properties of C/C composites in different energy condition[J]. Journal of Central South University Technology: Natural Science, 2003, 34(3): 221-224.

[8] 左劲旅, 张红波, 李江鸿, 熊 翔. 纤维体积分数对C/C复合材料摩擦磨损性能的影响[J]. 中南大学学报: 自然科学版, 2005, 36(4): 555-559.

ZUO Jin-lü,ZHANG Hong-bo, LI Jiang-hong, XIONG Xiang. Effect of fiber volume fraction on friction and wear properties of C/C composites[J]. Journal of Central South University: Natural Science, 2005, 36(4): 555-559.

[9] YEN B K, ISHIHARA T. The surface morphology and structure of carbon-carbon composites in high-energy sliding contact[J]. Wear, 1994, 174(1/2): 111-117.

[10] KIM D J, LEE Y M, PARK J S, SEOK C S. Thermal stress analysis for a disk brake of railway vehicles with consideration of the pressure distribution on a frictional surface[J]. Material Science and Engineering A, 2008, 483/484(15): 456-459.

[11] MATSUI A, YASUTAKE A. Improvement of tribological properties of C/C composites at high temperature[J]. Tribology Transactions, 1998, 41(1): 124-128.

[12] 王勋成, 邵 敏. 有限单元法基本原理和数值方法[M]. 北京: 清华大学出版社, 1996: 438.

WANG Xun-cheng, SHAO Min. Basic theory and numerical methods of finite element method[M]. Beijing: Tsinghua University Press, 1996: 438.

[13] GAO C H, LIN X Z. Transient temperature field analysis of a brake in a non-axisymmetric three-dimensional model[J]. Journal of Materials Processing Technology, 2002, 129(3): 513-517.

[14] 李江鸿, 熊 翔, 巩前明, 黄伯云. 不同基体炭C/C复合材料的摩擦磨损性能[J]. 中国有色金属学报, 2005, 15(3): 446-451.

LI Jiang-hong, XIONG Xiang, GONG Qian-ming, HUANG Bai-yun. Friction and wear properties of carbon/carbon composites with different matrix carbon[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 446-451.

[15] LUO Rui-ying, LIU Tao, LI Jing-song, ZHANG Hong-bo, CHEN Zhi-jun, TIAN Guang-lai. Thermophysical properties of carbon/carbon composites and physical mechanism of thermal expansion and thermal conductivity[J]. Carbon, 2004, 42(14): 2887-2895.

[16] ZHAO Jian-guo, LI Ke-zhi, LI He-jun, WANG Chuang. The influence of thermal gradient on pyrocarbon deposition in carbon/carbon composites during the CVI process[J]. Carbon, 2006, 44(4): 786-791.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2006CB600906); 国家高技术研究发展计划资助项目(2009AA034301)

收稿日期:2010-08-02;修订日期:2010-09-29

通信作者:徐惠娟,副研究员;电话:0731-88836929;E–mail: xuhj1@126.com