生长速度与试样直径对定向凝固Ti-46Al-8Nb合金显微组织和硬度的影响

来源期刊:中国有色金属学报(英文版)2014年第12期

论文作者:刘国怀 李新中 张 元 陈瑞润 苏彦庆 郭景杰 傅恒志 王昭东 王国栋

文章页码:4044 - 4052

关键词:钛铝合金;定向凝固;生长速度;直径;相转变

Key words:TiAl alloy; directional solidification; growth rate; diameter; phase transition

摘 要:对Ti-46Al-8Nb(摩尔分数,%)合金进行布里奇曼型定向凝固实验,考察生长速度和试样直径对合金显微组织、相变路径和硬度的影响。结果表明,随着生长速度的增加和试样直径的减小,凝固过程由完全β相凝固转变为具有包晶反应的凝固过程,其最终显微组织为α2/γ层片及有α2/γ层片和B2相组成的多相组织。以上结果是由扩散和对流的减弱造成的溶质富集而引起的。包晶反应的发生往往导致严重的溶质偏析,其中溶质Al和Nb的偏析使得层片组织较为粗大。因此,在较高生长速度下发生包晶反应时,合金硬度值急剧下降,硬度曲线随着生长速度的增加呈不连续变化。严重溶质偏析导致的粗大层片组织也使得该成分合金的硬度低于其他TiAl基合金的硬度。

Abstract: Bridgman-type directional solidification experiments were conducted for Ti-46Al-8Nb (mole fraction, %) alloy. The effects of the growth rate and the diameter on the microstructure, phase transition and hardness of the alloy were investigated. The results show that with the increase of the growth rate and the decrease of the diameter, the fully β phase solidification changes to the peritectic solidification, and the final microstructure is composed of the α2/γ lamellar structure and a multiphase microstructure (B2 phase, α2/γ lamellar structure) respectively, which can be attributed to the solute enrichment resulting from the decreasing diffusion and convection ability. The occurrence of peritectic reaction at high growth rate promotes the solute segregation heavily and the coarse lamellar spacing in Al- and Nb-rich region, which greatly decreases the hardness values and leads to the discontinuity of the hardness curves with the increase of the growth rate. Comparatively, the Ti-46Al-8Nb alloy has lower hardness values than the other applied TiAl-based alloys in previous studies.

Trans. Nonferrous Met. Soc. China 24(2014) 4044-4052

Guo-huai LIU1, Xin-zhong LI2, Yuan ZHANG2, Rui-run CHEN2, Yan-qing SU2, Jing-jie GUO2, Heng-zhi FU2, Zhao-dong WANG1, Guo-dong WANG1

1. State Key Laboratory of Rolling and Automation, Northeastern University, Shenyang 110819, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 6 August 2013; accepted 4 November 2014

Abstract: Bridgman-type directional solidification experiments were conducted for Ti-46Al-8Nb (mole fraction, %) alloy. The effects of the growth rate and the diameter on the microstructure, phase transition and hardness of the alloy were investigated. The results show that with the increase of the growth rate and the decrease of the diameter, the fully β phase solidification changes to the peritectic solidification, and the final microstructure is composed of the α2/γ lamellar structure and a multiphase microstructure (B2 phase, α2/γ lamellar structure) respectively, which can be attributed to the solute enrichment resulting from the decreasing diffusion and convection ability. The occurrence of peritectic reaction at high growth rate promotes the solute segregation heavily and the coarse lamellar spacing in Al- and Nb-rich region, which greatly decreases the hardness values and leads to the discontinuity of the hardness curves with the increase of the growth rate. Comparatively, the Ti-46Al-8Nb alloy has lower hardness values than the other applied TiAl-based alloys in previous studies.

Key words: TiAl alloy; directional solidification; growth rate; diameter; phase transition

1 Introduction

TiAl-based alloys are highly promising for high temperature structural applications in aerospace and automotive industries due to their attractive properties, such as low density, high resistance to oxidation, high specific modulus and creep resistance [1-4]. However, the major obstacles such as room-temperature ductility, high-temperature strength and oxidation resistance above 800 °C have limited their practical applications as structural materials [5-8]. Recently, high-Nb TiAl alloys have been developed [9,10], in which the solute Nb can improve high-temperature resistance, lamellar structure stability and oxidation resistance [11,12]. Especially Ti-46Al-8Nb (mole fraction, %) intermetallic alloy developed within the pan-European IMPRESS project is both lightmass and creep resistant to high temperatures (~800 °C) [13,14], so being one of the advanced materials for turbines of aircraft engines and gas-burning power-generation plants. However, high Nb addition may change the TiAl phase diagram, leading to the solidification behavior different from that of binary TiAl alloy [15,16]. The complex solidification path and also subsequent solid-state transformation limit the understanding of microstructure development in Nb-additional TiAl alloys. Directional solidification is an appropriate technique to research solidification behavior of alloy under defined solidification conditions [17]. The solidification parameters (growth rate, temperature gradient and diameter) have a great effect on the microstructure evolution and the microsegregation, and further influence the mechanical properties, which have been investigated widely for different alloys [18-23]. Therefore, the study on the phase transition, microstructure evolution and interface morphology under different solidification parameters during the directional solidification is interest to further progress in commercial applications of Ti-46Al-8Nb alloy.

In addition, the Vickers hardness values can represent the strain hardening ability and the plastic deformation resistance, and further reflect the processing property of the materials. Especially there is a linear relationship between microhardness and yield stress, which promises the mechanical properties of directionally solidified TiAl ingots to be predicted from the Vickers hardness values [24]. Similar linear dependence of the yield stress on the hardness is also observed in wrought TiAl alloy with the fully lamellar structure. It appears that the microhardness analysis offers a relatively simple method to predict the mechanical properties of the materials. Recently, the hardness measurements have been taken for different TiAl alloys, and it is observed that the phase compositions in TiAl-based alloys have different contributions to the hardness with the change of the solidification conditions [25]. Therefore, it is necessary to find out the evolution of the microhardness with the varied microstructure under different solidification conditions in the directionally solidified Ti-46Al-8Nb alloy. Furthermore, the investigations of Vickers hardness are essential for the processing and potential applications of the TiAl alloys.

The aim of this study was to determine the microstructure, phase transition and hardness of the directionally solidified Ti-46Al-8Nb alloy under different solidification conditions. The evolution of the phase transition, the detailed microstructure and the interface morphology with the change of the diameter and the growth rate was investigated firstly, and then the selection diagrams for the solidification process and the final microstructure were obtained finally. A particular interest was focused on the effect of the phase components on Vickers hardness (HV) with the change of the solidification conditions.

2 Experimental

Intermetallic Ti-46Al-8Nb alloy with an actual composition of Ti-46.3Al-7.6Nb (mole fraction, %) was supplied in the form of cast cylindrical ingot, which was fabricated by the induction skull melting (ISM) under argon atmosphere. The samples were machined to rods with different diameters (1, 3 and 6 mm) and 100 mm in length by a spark machining. The Bridgman type apparatus was employed to produce the directionally solidified bar, and the details of the experiments were described in our previous work [19]. After growing 40 mm at selected growth rates (1-70 μm/s), the sample was quenched into the liquid Ga-In-Sn alloy to restore the solid-liquid interface. The temperature gradient (G=20 K/mm) was measured by W/Re thermocouples as described in Refs. [26,27]. After directional solidification, the longitudinal and transverse sections of the specimens were cut for the microstructure analysis performed by optical microscopy (OM) and scanning electron microscopy (SEM) equipped with an energy dispersive spectrometer (EDS). OM and SEM samples were prepared using standard metallographic techniques and etched with a solution of 10 mL HF + 10 mL HNO3 +180 mL H2O.

The hardness measurements of the directionally solidified Ti-46Al-8Nb alloy were made with a standardized Vickers test device at a load of 10 g and a dwell time of 10 s on the longitudinal section. The hardness values were the average of at least 10 measurements. The local hardness measurements along the dendrites were made at a load of 5 g and a dwell time of 10 s on the longitudinal section.

3 Results and discussion

3.1 Macrostructure

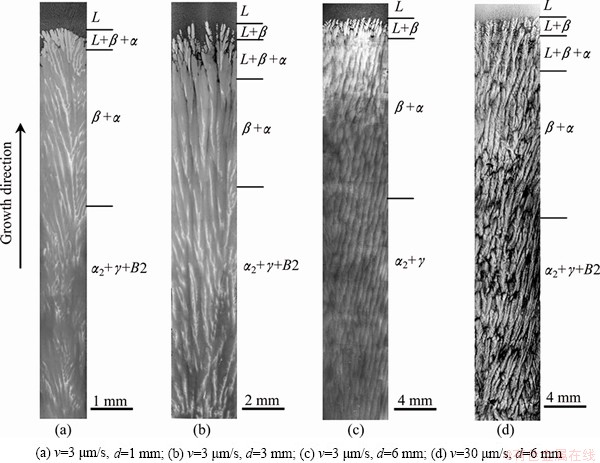

Figure 1 shows the macrostructures of directionally solidified Ti-46Al-8Nb alloy with different diameters at different growth rates after the directional solidification. The columnar grains are well aligned along the growth direction, and the number of the columnar grains depends directly on the solidification conditions and the position in the specimens, as shown in Fig. 1.

Interestingly, it is observed that the phase transition of the alloy evolves with the change of the diameter and the growth rate. As shown in Figs. 1(a) and (b), the typical peritectic reaction can be observed at the solid-liquid interface with diameters of 1 mm and 3 mm, and the peritectic interface is observed away from the β phase tip with the increase of the diameter. While a fully β solidification can be observed with the diameter up to 6 mm, as shown in Fig. 1(c). The change of the solidification path with the diameter can be attributed to the change of the diffusion and convection regime of the solutes during the directional solidification, and details analysis will be presented later. Additionally, it is also observed that the solidification path also changes with the increase of growth rate. As shown in Figs. 1(c) and (d), the solidification process with the fully β phase solidification at 3 μm/s changes to the peritectic solidification at 30 μm/s, which can be attributed to the fact that the increase of the growth rate corresponding to the rapid cooling rate leads to the L+β→β transus line shifting to lower Al direction, and the similar evolution of the solidification process with the increase of the growth rates occurs in the directionally solidified Ti-47.5Al-2.5Mo alloy [28].

3.2 Microstructure

3.2.1 Effect of diameter of sample on quenching interface and final microstructure

Fig. 1 Macrostructures of directionally solidified Ti-46Al-8Nb alloys with different diameters at different growth rates

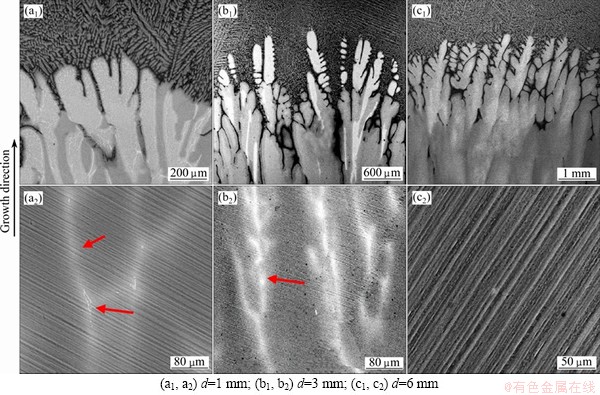

Figure 2 shows the morphologies of the solid-liquid interface and the corresponding final microstructures of the directionally solidified Ti-46Al-8Nb alloys with different diameters at a growth rate of 3 μm/s. The cellular and cellular-dendritic growths of primary β phase can be observed at the solid-liquid interface at the selected growth rate, as shown in Figs. 2(a1)-(c1). Particularly, the typical peritectic reaction is observed at the positions behind the β phase tips with small diameters of 1 and 3 mm, as shown in Figs. 2(a1) and (b1). While the fully β phase solidification is observed with the diameter of 6 mm, as shown in Fig. 2(c1). The occurrence of the peritectic reaction is mainly due to the enrichment of Al in the interdendritic liquid during the growth of primary β phase, which is connected with the process of the diffusion and convection with different diameters [21,22]. According to TRIVEDI et al [22], for a given system, the fluid velocity is characterized by Rayleigh number (Ra) which, for a fixed horizontal temperature gradient (△T), is given by

(1)

(1)

where μ is the kinematic viscosity; αL is the thermal diffusivity of the liquid; βT is the coefficient of density varying with temperature; g is the gravity vector; d is the diameter of the sample. The Rayleigh number is proportional to gd4 for a fixed horizontal temperature gradient. Then, the values of Ra will increase with the increase of the diameter, and correspondingly the effect of the convection in the melt during the directional solidification will increase with the increase of the diameter, which may decrease the solute enrichment in the interdendrite during the growth of primary phase. Therefore, the solute Al enrichment at the solid-liquid interface will decrease gradually with the increase of the diameter. The occurrence of the peritectic reaction can be observed only with the small diameters, and the peritectic interface will be away from the solid-liquid interface gradually with the increase of the diameter. Furthermore, for the specimen with a diameter of 6 mm the solute enrichment cannot support the occurrence of the peritectic reaction, and then the fully β phase solidification should be observed in the directionally solidified Ti-46Al-8Nb alloy.

As shown in Figs. 2(a2) and (b2), the complex multiphase material (B2 phase and α2/γ lamellar phase) is observed in the final microstructure with diameters of 1 and 3 mm, while the final microstructure of α2/γ lamellar phase is observed with the diameter of 6 mm, which suggests that the change of the solidification process with the diameter leads to different final microstructures. The precipitation of B2 phase can be connected with the enrichment of the β-stabilizer Nb during the phase transition, in which the peritectic reaction leads to the retained β phase richened in Nb to be distributed in the core of dendrites due to the growth of peritectic α phase, and further enrichment of Nb in the retained β phase due to the β→α transformation may lead to the stabilization of β phase to the ordered B2 phase. But for the sample with a diameter of 6 mm the enrichment of solute Nb in primary β phase decreases due to the strong convection and diffusion regime during the solidification, which cannot promote the high-temperature β phase stabilization to be B2 phase during the further β→α transformation. Additionally, low growth rate also promotes the distribution homogeneity of the solute Nb during the phase transformation. Then the light block B2 phase cannot be observed in the directional solidified Ti-46Al-8Nb alloy when the diameter of the sample is 6 mm.

Fig. 2 Solid-liquid interface morphologies (a1-c1) and final microstructures (a2-c2) of directionally solidified Ti-46Al-8Nb alloys with different diameters at growth rate of 3 μm/s

3.2.2 Effect of growth rate on quenching interface and final microstructure

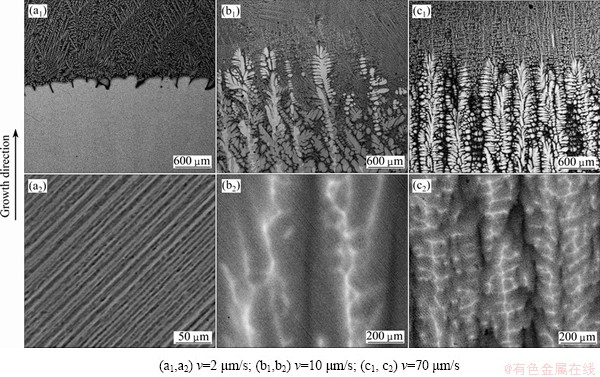

Figure 3 shows the quenching interface morphologies and corresponding final microstructures of the directional solidified Ti-46Al- 8Nb alloys with a diameter of 3 mm at different growth rates. Shallow cellular growth of single β phase is observed at a growth rate of 2 μm/s, and the final microstructure is composed of a fully α2/γ lamellar structure, as shown in Figs. 3(a1) and (a2). The regular dendritic growth can be observed at growth rates of 10 and 70 μm/s respectively, which are accompanied with sequent peritectic reaction during the solidification, and the final microstructures are composed of the α2/γ lamellar structure and the retained β (B2) phase. At low growth rates corresponding to low cooling rate, the solute elements can diffuse completely and are distributed homogeneously during the phase transformation, and then the solute enrichment cannot promote the occurrence of the peritectic reaction and the precipitation of B2 phase. While during the dendritic growth at high growth rates, the solute Al in the interdendritic liquid from the growth of primary β phase can reach a supersaturated solution due to the rapid cooling rate and promotes the occurrence of the peritectic reaction. The further growth of peritectic α phase may lead to the β-stabilizer element Nb richened in the retained β phase to be distributed in the core of the dendrite, and finally B2 phase originating from the stabilization of Nb-riched β phase can be observed in the final microstructure.

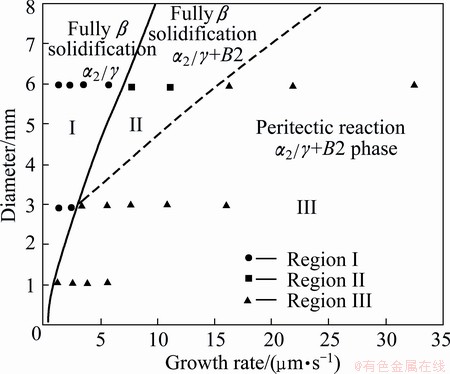

3.2.3 Selection diagram for solidification process and final microstructure

Through the analysis above, the phase transformation evolves with the change of the sample diameter and the growth rate, which leads to the variety of the final microstructures. Figure 4 shows the summary of the effect of the growth rate and the diameter on the solidification process and the final microstructure of the directionally solidified Ti-46Al-8Nb alloy. It can be seen that the fully β phase growth and the final α2/γ lamellar structure in final microstructure can be obtained at large diameters and low growth rates, as shown by region Ⅰ in Fig. 4. The increase of the growth rate can promote the precipitation of B2 phase, and then the final microstructure consisting of α2/γ and B2 phases can be observed during the single β phase growth, as shown by region II in Fig. 4. While at small diameters and high growth rates the peritectic reaction and the multiphase microstructure (α2/γ lamellar structure and B2 phase) in final microstructure can be observed, as shown by region III in Fig. 4.

Fig. 3 Solidi-liquid interface morphologies (a1-c1) and final microstructures (a2-c2) of directionally solidified Ti-46Al-8Nb alloys with diameter of 3 mm at different growth rates

Fig. 4 Selection diagram for solidification process and final microstructure of directionally solidified Ti-46Al-8Nb alloy

Obviously, the increase of the growth rate leads to the L+β→β transus line shifting to lower Al content during the directional solidification, which promotes the solidification process changing from the fully β phase solidification to the peritectic reaction. Additionally, the high growth rates corresponding to the rapid cooling rates promote the solute enrichment resulting from the decrease of the diffusion ability, and further the Nb enrichment from the β→α transition may promote the high-temperature β phase stabilization to be B2 phase. Simultaneously, the decrease of the diameter may decrease the diffusion and convection of the solutes in the melt, which promotes the solute Al enrichment in the interdendritic region, leading to the occurrence of the peritectic reaction. The further development of the peritectic reaction will lead to severe solute segregation and the multiphase microstructure (α2/γ lamellar structure and B2 phase) in final microstructure. The discrepancy of the phase components in the final microstructures due to the difference of the phase transformation has a great effect on the mechanical properties of the alloys, and detailed analysis will be presented below.

3.3 Microhardness

During the directional solidification of alloys, the solidification parameters, temperature gradient (G), growth rate (v) and diameter of specimen (d), have a great effect on the microstructure characteristics of the alloys, and further influence the mechanical properties [29]. Additionally, the microhardness has a linear relationship with the yield stress for the directionally solidified TiAl alloy and further takes the performance of the processing to fabricate the components, which promises the mechanical properties to be predicted simply [24,30]. Therefore, the microhardness under different solidification conditions was investigated for the directionally solidified Ti-46Al-8Nb alloy, and the microhardness values were compared with those obtained in previous works in other TiAl based alloys [19,24,31].

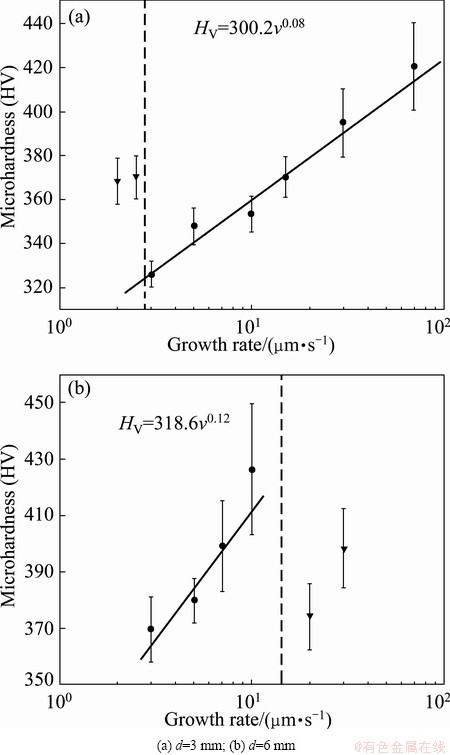

Figure 5 shows the evolutions of Vickers hardness with the increase of the growth rate for the directionally solidified Ti-46Al-8Nb alloys with diameters of 3 and 6 mm respectively. When the diameter is 3 mm, the hardness values are high at low growth rates (≤2 μm/s), and there is no B2 phase in the final microstructure through the analysis above. However, the discontinuity of the hardness curves can be observed at a growth rate of 3 μm/s, and the peritectic reaction occurs accompanied with the precipitation of plenty of B2 phase. Then, the hardness values increase with the increase of the growth rate, which can be attributed to the refined lamellar structure due to the rapid cooling rate, as shown in Fig. 5(a). The relationship between the microhardness HV and the growth rate (v) (>2 μm/s) is obtained by using linear regression analysis, which is given as

HV=300.2v0.08 (2)

The regression coefficient of this fit is R2=0.95. The exponent value of the growth rate is fitted to be 0.08, which is in good agreement with 0.10 obtained by FAN et al [19] for Ti-43Al-3Si (mole fraction, %) alloy. In addition, the exponent value is smaller than 0.14 obtained by LAPIN et al [24] for Ti-46Al-2W-0.5Si (mole fraction, %) alloy and 0.15 obtained by FAN et al [31] for Ti-46Al-0.5W-0.5Si (mole fraction, %) alloy.

Fig. 5 Variation of microhardness as function of growth rate for directionally solidified Ti-46Al-8Nb alloys with different diameters

Compared with the alloy with a diameter of 3 mm, the occurrence of peritectic reaction accompanied with plenty of B2 phase cannot be observed until the growth rate reaches up to 20 μm/s for the directional solidified Ti-46Al-8Nb alloy with a diameter of 6 mm. Correspondingly, it can be observed that the discontinuity of the hardness curves occurs at high growth rate of 20 μm/s, and then the hardness values increase with the increase of the growth rate, as shown in Fig. 5(b). At lower growth rates (v<20 μm/s), the hardness values also increase with the increase of the growth rate. The relationship between HV and v (<20 μm/s) is obtained by using linear regression analysis, which is given as

HV=318.6v0.12 (3)

The regression coefficient of this fitting equation is R2=0.95. The exponent value of the growth rate is fitted to be 0.12, which is larger than 0.08 when the diameter of the specimen is 3 mm, and the discrepancy between the exponents of the specimen with different diameters can be attributed to the change of the solidification conditions leading to different phase compositions. In addition, the exponent value is close to 0.14 obtained by LAPIN in et al [24] for Ti-46Al-2W-0.5Si alloy and 0.15 obtained by FAN et al [31] for Ti-46Al-0.5W-0.5Si alloy.

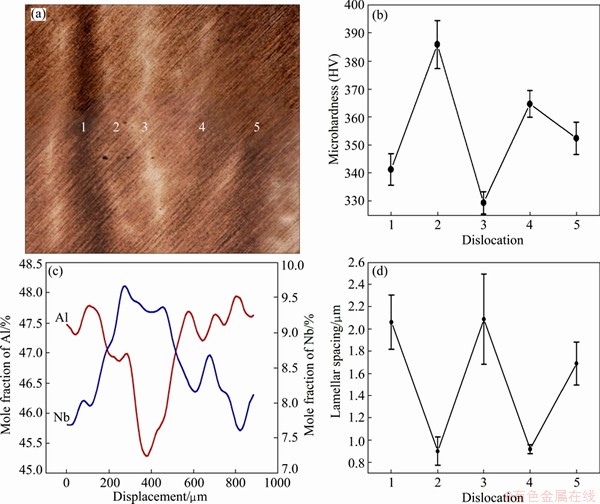

Fig. 6 Final microstucture (a) and variation of microhardness (b), solute content (c) and lamellar spacing (d) along spotting colummar crystal at growth rate of 5 μm/s for directionally solidified Ti-46Al-8Nb alloy

Through the analysis above, it is interesting to see that the occurrence of the peritectic reaction accompanied with plenty of B2 phase can deteriorate the microhardness greatly, and the discrepancy of the phase components under different solidification conditions has effect on the hardness curve directly. Therefore, particular attention has been paid to the effect of the phase components and the inhomogeneous micro- structure on the microhardness of the alloy. Figure 6 shows the evolution of the microhardness of different regions around the dendrite in the final microstructure of the directionally solidified Ti-46Al-8Nb alloy. The hardness curve develops in the type of “wave shape”, which shows that the hardness values are small in the interdendritic region and in the core of the dendrite, while they are large between them, as shown in Figs. 6(a) and (b). The evolution of the hardness can be attributed to the variability of the inhomogeneous phase compositions and the microsegregation leading to a scatter of the mechanical properties. As shown in Fig. 6(c), quantitative EDS analysis shows that Al is rich in the interdendrite, and Nb is rich in the core of the dendrite. The inhomogeneity of the solute elements promotes the discrepancy of phase compositions in the final microstructure. Microstructure observations reveal that the elongated B2 phase (ordered β-phase) is observed in the core of the dendrite due to the Nb enrichment, which induces the coarse lamellar structure and is detrimental to the microhardness, as shown in Fig. 6(d). In addition, the solute Al enrichment in the interdendritic region can also cause the increase of the lamellar spacing and decrease of the microhardness, as shown in Figs. 6(b) and (d). Therefore, the “wave shape” of the microhardness around the dendrite can be obtained due to the inhomogeneity of the phase components and the microstructure in the directional solidified Ti-46Al-8Nb alloy.

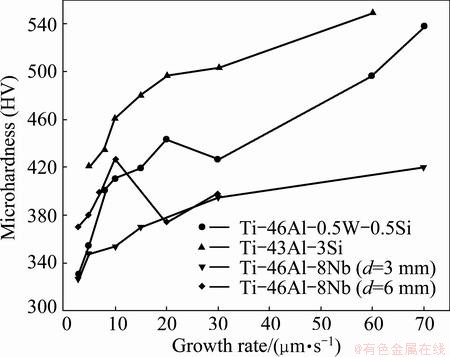

Figure 7 shows the variation of the Vickers hardness with the increase of the growth rate in different TiAl-based alloys during the directional solidification in our studies. All the values of Vickers hardness increase with the increase of the growth rate, in which the hardness values of Ti-46Al-8Nb alloy are smaller than those of Ti-46Al-0.5W-0.5Si and Ti-43Al-3Si alloys. The discrepancy of the hardness can be attributed to different phase compositions and microstructures resulting from the addition of the β-stabilizer elements. The enrichment of Nb during the directional solidification can promote the precipitation of B2 phase and lead to the coarse lamellar structure in Nb-riched region. Additionally, the discrepancy of hardness can also be influenced by the volume fraction of γ phase [32]. In fact, the Vickers hardness of α2 phase is about with HV 500, while that of γ phase is in the order of HV 200, and then the depleted-Al TiAl alloys with large volume fraction of α2 phase own high hardness values according to the lever rule. Therefore, the Ti-46Al-8Nb alloys with high Al and the β-stabilizer Nb contents in this study own lower hardness values than the other TiAl alloys.

Fig. 7 Variation of microhardness of different directionally solidified TiAl-based alloys as function of growth rate

In addition, it can be seen that the hardness values of the alloy with a diameter of 6 mm are higher than those with a diameter of 3 mm for the directional solidified Ti-46Al-8Nb alloy at low growth rates (≤10 μm/s), while both the hardness values tend to be identical at high growth rates. The results above can be attributed to the effect of the peritectic reaction leading to the severe solute segregation with the change of the solidification conditions. At the selected growth rates, the peritectic solidification can be observed for the directionally solidified Ti-46Al-8Nb alloy with a diameter of 3 mm, which leads to the small hardness values due to the severe solute segregation. When the diameter is 6 mm, the fully β phase growth and the α2/γ lamellar structure can be observed at low growth rates, and correspondingly high hardness values can be obtained. The high growth rates corresponding to the occurrence of peritectic reaction deteriorate the hardness to be identical to that with the diameter of 3 mm. Through the results above, it can be found that the inhomogeneity of solutes Al and Nb in TiAl-Nb alloy can decrease the hardness greatly, and then the low growth rate and large specimen diameter should be taken to avoid the solute enrichment in the directionally solidified Ti-46Al-8Nb alloy.

4 Conclusions

1) The increase of the diameters promotes the diffusion and convection in the melt during the solidification, which leads to the peritictic solidification to the fully β phase solidification, and correspondingly the final microstructure of a multiphase microstructure (B2 phase and α2/γ lamellar structure) changes to the α2/γ lamellar structure.

2) The increase of the growth rate leads to the solute enrichment due to the decrease of the diffusion ability, leading to the fully β phase solidification changing to the peritectic solidification, and correspondingly the final microstructure of the α2/γ lamellar structure changes to a multiphase microstructure (B2 phase and α2/γ lamellar structure).

3) The occurrence of the peritectic reaction leads to severe solute segregation, in which the enrichment of solutes Al and Nb which induces the coarse lamellar structure can deteriorate the hardness values greatly, and then the hardness curve is discontinuous with the increase of the growth rates due to the occurrence of the peritectic reaction.

References

[1] KIM Y W. Effects of microstructure on the deformation and fracture of γ-TiAl alloys [J]. Mater Sci Eng A, 1995, 192-193: 519-533.

[2] LIU Z C, LIN J P, LI S J, CHEN G L. Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys [J]. Intermetallics, 2002, 10: 653-659.

[3] LIU G H, LI X Z, SU Y Q, CHEN R R, GUO J J, FU H Z. Microstructure and microsegregation in directionally solidified Ti-46Al-8Nb alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1342-1349.

[4] WU X H. Review of alloy and process development of TiAl alloys [J]. Intermetallics, 2006, 14: 1114-1122.

[5] DIMIDUK D M. Gamma titanium aluminide alloys—An assessment within the competition of aerospace structural materials [J]. Mater Sci Eng A, 1999, 163: 281-288.

[6] XIAO S L, TIAN J, XU L J, CHEN Y Y, YU H B. Microstructures and mechanical properties of TiAl alloy prepared by spark plasma sintering [J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 1423-1427.

[7] LIU J, LUAN Q D, WANG X G, PENG L M. Microstructural and high temperature deformation characterization of Ti-45Al-3Nb-(Cr, Mn, Mo, Sc) alloy [J]. Mater Sci Eng A, 2010, 527: 7658-7662.

[8] YAMAGUCHI M, JOHNSON D R, LEE H N, INUI H. Directional solidification of TiAl-base alloys [J]. Intermetallics, 2000, 8: 511-517.

[9] SUN H F, LI X W, FENG J, FANG W B. Characterization of TiAl-based alloy with high-content Nb by powder metallurgy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 491-495.

[10] BEDDOES J, CHEN W R, ZHAO L. Precipitation of β particles in a fully lamellar Ti-47Al-2Nb-1Mn-0.5W-0.5Mo-0.2Si (at.%) alloy [J]. J Mater Sci, 2002, 37: 621-627.

[11] QIU C Z, LIU Y, HUANG L, LIU B, ZHANG W, HE Y H, HUANG B Y. Tuning mechanical properties for beta (B2)-containing TiAl intermetallics [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 2593-2603.

[12] YOSHIHARA M, MIURA K. Effects of Nb addition on oxidation behavior of TiAl [J]. Intermetallics, 1995, 3: 357-363.

[13] JARVIS D J, VOSS D. IMPRESS integrated project—An overview paper [J]. Mater Sci Eng A, 2005, 413-414: 583-591.

[14] KARTAVYKH A, GINKIN V, GANINA S, REX S, HECHT U, SCHMITZ B, VOSS D. Convection-induced peritectic macro- segregation proceeding at the directional solidification of Ti-46Al-8Nb intermetallic alloy [J]. Mater Chem Phys, 2011, 126: 200-206.

[15] NAKAMURA H, TAKEYAMA M, YAMABE Y, KIKUCHI M. Phase equilibria in TiAl alloys containing 10 and 20 at% Nb at 1473 K [J]. Scripta Materialia, 1993, 28: 997-1002.

[16] LEONARD K J, VASUDEVAN V K. Phase equilibria and solid state transformations in Nb-rich Nb-Ti-Al intermetallic alloys [J]. Intermetallics, 2000, 8: 1257-1268.

[17] KURZ W, FISHER D J. Fundamentals of solidification [M]. Aedermannsdorf: Trans Tech Publications, 1989.

[18] KAYA H,  Dependency of microindentation hardness on solidification processing parameters and cellular spacing in the directionally solidified Al based alloys [J]. J Alloys Compd, 2009, 478: 281-286.

Dependency of microindentation hardness on solidification processing parameters and cellular spacing in the directionally solidified Al based alloys [J]. J Alloys Compd, 2009, 478: 281-286.

[19] FAN J L, LI X Z, SU Y Q, GUO J J, FU H Z. The microstructure parameters and microhardness of directionally solidified Ti-43Al-3Si alloy [J]. J Alloys Compd, 2010, 506: 593-599.

[20] HU X W, LI S M, LIU L, FU H Z. Research on lamellar structure and microhardness in directionally solidified ternary Sn-40.5Pb- 2.6Sb eutectic alloy [J]. J Alloys Compd, 2010, 493: 116-121.

[21] KERR H W, KURZ W. Solidification of peritectic alloys [J]. International Materials Reviews, 1996, 41: 129-164.

[22] TRIVEDI R, MIYAHARA H, MAZUMDER P, SIMSEA E, TEWARI S N. Directional solidification microstructures in diffusive and convective regimes [J]. Journal of Crystal Growth, 2001, 222: 365-379.

[23] KARMA A, RAPPEL W J, FUH B C, TRIVEDI R. Model of banding in diffusive and convective regimes during directional solidification of peritectic systems [J]. Mater Trans A, 1998, 29: 1457-1470.

[24] LAPIN J, ONDRUS L, NAZMY M. Directional solidification of intermetallic Ti-46Al-2W-0.5Si alloy in alumina moulds [J]. Intermetallics, 2002, 10: 1019-1031.

[25] DING X F, LIN J P, ZHANG L Q, WANG H L, HAO G J, CHEN G L. Microstructure development during directional solidification of Ti-45Al-8Nb alloy [J]. J Alloys Compd, 2010, 506: 115-119.

[26] FAN J L, LI X Z, SU Y Q, GUO J J, FU H Z. Effect of growth rate on microstructure parameters and microhardness in directionally solidified Ti-49Al alloy [J]. Mater Des, 2012, 34: 552-558.

[27] LIU D M, LI X Z, SU Y Q, GUO J J, FU H Z. Microstructure evolution in directionally solidified Ti-(50, 52)at%Al alloys [J]. Intermetallics, 2011, 19: 175-181.

[28] KIM M C, OH M H, LEE J H, INUI H, YAMAGUCHI M, WEE D M. Composition and growth rate effects in directionally solidified TiAl alloys [J]. Mater Sci Eng A, 1997, 239-240: 570-576.

[29]  U, MARASLI N. Dependency of eutectic spacings and microhardness on the temperature gradient for directionally solidified Sn-Ag-Cu lead-free solder [J]. Mater Chem Phys, 2010, 119: 442-448.

U, MARASLI N. Dependency of eutectic spacings and microhardness on the temperature gradient for directionally solidified Sn-Ag-Cu lead-free solder [J]. Mater Chem Phys, 2010, 119: 442-448.

[30] LAPIN J,  L, BAJANA O. Effect of Al2O3particles on mechanical properties of directionally solidified intermetallic Ti-46Al-2W-0.5Si alloy [J]. Mater Sci Eng A, 2003, 360: 85-95.

L, BAJANA O. Effect of Al2O3particles on mechanical properties of directionally solidified intermetallic Ti-46Al-2W-0.5Si alloy [J]. Mater Sci Eng A, 2003, 360: 85-95.

[31] FAN J L, LI X Z, SU Y Q, GUO J J, FU H Z. Dependency of microhardness on solidification processing parameters and microstructure characteristics in the directionally solidified Ti-46Al-0.5W-0.5Si alloy [J]. J Alloys Compd, 2010, 504: 60-64.

[32] PERDRIX F, TRICHRT M F, BONNENTIEN J L, CORNET M, BIGOT J. Influence of cooling rate on microstructure and mechanical properties of a Ti-48Al alloy [J]. Intermetallics, 1999, 7: 1323-1328.

刘国怀1,李新中2,张 元2,陈瑞润2,苏彦庆2,郭景杰2,傅恒志2,王昭东1,王国栋1

1. 东北大学 轧制技术与连轧自动化国家重点实验室,沈阳 110819;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

摘 要:对Ti-46Al-8Nb(摩尔分数,%)合金进行布里奇曼型定向凝固实验,考察生长速度和试样直径对合金显微组织、相变路径和硬度的影响。结果表明,随着生长速度的增加和试样直径的减小,凝固过程由完全β相凝固转变为具有包晶反应的凝固过程,其最终显微组织为α2/γ层片及有α2/γ层片和B2相组成的多相组织。以上结果是由扩散和对流的减弱造成的溶质富集而引起的。包晶反应的发生往往导致严重的溶质偏析,其中溶质Al和Nb的偏析使得层片组织较为粗大。因此,在较高生长速度下发生包晶反应时,合金硬度值急剧下降,硬度曲线随着生长速度的增加呈不连续变化。严重溶质偏析导致的粗大层片组织也使得该成分合金的硬度低于其他TiAl基合金的硬度。

关键词:钛铝合金;定向凝固;生长速度;直径;相转变

(Edited by Wei-ping CHEN)

Foundation item: Projects (51071062, 51274077, 51271068) supported by the National Natural Science Foundation of China; Project (2011-P03) supported by Open Fund of State Key Laboratory of Mold and Die Technology of Huazhong University of Science and Technology; Project (HIT. NSRIF. 2013002) supported by the Fundamental Research Funds for the Central Universities, China; Project (2011CB605504) supported by the National Basic Research Program of China

Corresponding author: Guo-huai LIU; Tel: +86-24-83686739; E-mail: liuguohuai007@163.com

DOI: 10.1016/S1003-6326(14)63567-6