文章编号:1004-0609(2016)-04-0782-08

基于CAFE模型的镍基合金定向凝固过程显微组织模拟

张 璞1,侯 华1,赵宇宏1,靳玉春1,赵宇辉2,眭怀明3

(1. 中北大学 材料科学与工程学院,太原 030051;

2. 河北工业职业技术学院 机电工程系,石家庄 050091;

3. 扬州峰明金属制品有限公司,扬州 225117)

摘 要:采用CAFE模型(Cellular automata finite element method)模拟第二代镍基高温合金CMSX4凝固过程中的晶粒生长,并探讨浇注温度和冷却速度对凝固组织的影响。结果表明:凝固开始时,首先在铸锭底部会形成一层取向随机的细小等轴晶,由于晶粒间的竞争生长,晶粒数目减小,晶粒尺寸增大,<001>晶向与热流方向偏离角较大的晶粒逐渐被偏离角较小的晶粒淘汰。浇注温度的提高会使晶粒尺寸变大、晶粒数目变小,而冷却速度的升高却会使晶粒尺寸变小,与理论分析一致。

关键词:镍基合金;CMSX4合金;CAFE法;定向凝固;组织演化

中图分类号:TG146.15 文献标志码:A

凝固过程的显微组织模拟是指在晶粒尺度上对铸件凝固过程进行模拟,通过对铸件凝固过程的微观模拟只需做少量实验即可预测铸件凝固组织和力学性 能[1-3]。CAFE模型是其中一种微观模拟方法,是GANDIN等[4-5]基于晶体凝固模型,在CA方法中引入晶粒的晶体学取向和枝晶尖端生长动力学,并与有限元热流计算方法相结合,形成的元胞自动机-有限元模型。其特征是:凝固区域首先用较粗的网格来计算温度场,在此网格内,划分成更细而均匀的节点,在其中采用CA模型进行形核与生长计算,CA节点是自动生成的。该方法可以模拟外层等轴晶与柱状晶的竞争生长、柱状晶区的形成、晶粒边界的取向与热梯度之间的关系、柱状晶向等轴晶的CET (Columnar to equiaxed transition)转变、在非等温温度场中的等轴晶粒的形状等[6-7]。

CAFE模型的应用是比较广泛的,卜晓兵等[8]采用CAFE模型,对同一铸件不同尺寸的Al-2%Cu合金凝固显微组织进行三维模拟及预测,并引入空位形成能对固相扩散系数进行了优化,发现当铸件直径增大时,柱状晶占总晶体比例铸件减少,等轴晶所占比例铸件增大,且随着换热系数的增大,同一铸件不同直径的铸件凝固组织中柱状晶组织比例显著增大。仲红刚等[9]使用CAFE模型预测水平单向凝固实验中,Al-4.5%Cu合金试样的温度场和显微组织模拟,结果表明CAFE模型可以较准确地预测柱状晶向等轴晶转变(CET)位置和等轴晶晶粒尺寸。张华等[10]对不同工艺下Al-Si合金A104的凝固组织进行了三维模拟及预测,并进行了热态验证实验,发现模拟结果与实验结果基本吻合,能够较为准确地反映出等轴晶和柱状晶的分布位置、比例和大小。MOHSEN等[11]比较了CAFE模型以及PFFE模型(Phase field finite element model)模拟Al-3%Cu合金单晶凝固过程中的等轴晶生长过程的模拟结果,结果表明,CAFE模型比PFFE模型更有效率,特别是在模拟晶粒尺寸方面。RAVINDRA等[12]改进了CAFE模型,并模拟了FSW(Friction stir welding)过程中晶粒尺寸的分布,并通过对比发现模拟结果与实验结果相吻合。

本文作者采用CAFE模型模拟了第二代镍基高温合金CMSX4定向凝固过程中的枝晶生长,研究了凝固过程中晶粒的转变、粗化、竞争生长等现象,以及浇注温度和冷却速度对凝固过程的影响。

1 CAFE模型

1.1 宏观模型

温度场的模拟是进行微观凝固组织模拟的前提,采用有限元(FE)法求解热传导微分方程,三维宏观温度场热传导控制方程[13]为

(1)

(1)

式中:T为热力学温度;ρ为密度;c为比热容;λ为导热系数;L为凝固潜热。凝固潜热的释放是金属凝固过程区别于一般导热过程的特点,是连接宏微观现象、进行宏微观耦合模拟的一个纽带,潜热的释放直接由微观范畴的晶粒形核、生长来确定,同时枝晶生长释放的结晶潜热反馈到温度场计算中去,在本模型中对结晶潜热的处理采用热焓法[14]。

1.2 微观模型

1.2.1 形核模型

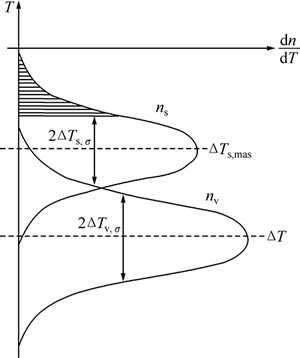

凝固过程中枝晶的形核有均匀形核和非均匀形核两种,而显微组织的数值模拟过程对非均匀形核的处理有2种方法:瞬时形核和连续形核。为了更准确地反映实际情况,并考虑到凝固过程中其他凝固条件对最终晶粒大小和晶粒形态分布的影响,本研究中采用GANDIN等[4-5]提出的基于高斯分布的连续形核模型,图1所示为体与面的非均匀形核高斯分布曲线[10]。

图1 液体表面与体内的形核高斯分布函数[10]

Fig. 1 Nucleation site distribution for nuclei formed at chill surface and in bulk of liquid[10]

假设形核现象发生在一系列不同的形核位置上,采用连续而非离散的分布函数dn/dΔT来描述形核密度的变化,其中,dn是由过冷度ΔT增加引起的晶粒密度增加。在某一过冷度ΔT时所形成的晶粒的密度n(ΔT)可由该分布曲线的积分求得:

(2)

(2)

取高斯分布得:

(3)

(3)

式中:n(ΔT)是过冷度ΔT时的晶核密度,ΔT=TL-T (TL为液相线温度);NS为最大形核密度;ΔTN和ΔTσ分别为合金的最大形核过冷度和标准方差过冷度。

1.2.2 生长模型

生长模型采用由KURZ等[15]提出的枝晶尖端生长动力学模型,即KGT(Kurz-Givoanola-Trivedi)模型[16],选择该模型的原因在于:一方面该模型描述了快速凝固过程中强制性尖端的生长,确立了晶粒生长速度和过冷度的关系;另一方面考虑了在高的凝固速度下溶质陷落、扩散系数随温度的变化关系,以及有曲率和动力学效应对过冷度的贡献,其具体如下:

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

(8)

(8)

式中:ΔTc、ΔTt、ΔTK、ΔTr分别为溶质扩散引起的过冷度、热扩散引起的过冷度、动力学过冷度和固/液界面引起的曲率过冷度。对绝大多数合金而言,ΔTt、ΔTK、ΔTr通常可以忽略,固近似有ΔT=ΔTc;Ω为溶质过饱和度;R为枝晶尖端半径;Gc为枝晶前沿液相中的溶质浓度梯度;G为浓度梯度;Γ为Gibbs-Thompson系数;m为液相线斜率;Pe为溶质的Peclet数;Iv(Pe)为Peclet数的Ivantsov函数;ξc为 Peclet数的函数,在低速生长时取1;D为液相内的溶质扩散系数;v为枝晶尖端生长速度[17]。

由于KGT模型是针对二元合金,本模型中采用等当量法对其扩展,使其适应任意多元合金,扩展后的模型包括:

(9)

(9)

(10)

(10)

(11)

(11)

式中:ci、mi、ki分别为各种元素在合金中的质量分数、液相线斜率和溶质的平衡分配系数。

联合式(4)~(11),最终可得枝晶尖端生长速度v和过冷度ΔT之间简化的关系式为

(12)

(12)

式中:a2、a3分别为多项式系数,是与合金相关的常数;ΔT为枝晶尖端的过冷度。

2 CA与FE模型的耦合

有限元法(FE)是一种用较简单的问题替代复杂问题得到一个近似解的方法,它将求解域看成是由许多称为有限元的小的互连子域组成,对每一单元假设一个合适的(较简单的)近似解,然后推导求解这个域总的满足条件(如结构的平衡条件),从而得到问题的解,本模拟中,应用FE法模拟计算宏观上凝固过程中的温度场变化。元胞自动机法(CA)是一个时间、空间以及系统都离散化的动力学系统,是一种随机数学模型,在一个元胞自动机模型中,体系由有限个元胞组成,时间由离散化的一定间隔的时间步组成,每个元胞的所有可能状态也是独立划分的,分为有限个分立的状态,本模拟中主要应用CA法模拟计算微观上晶粒的形核与生长变化。

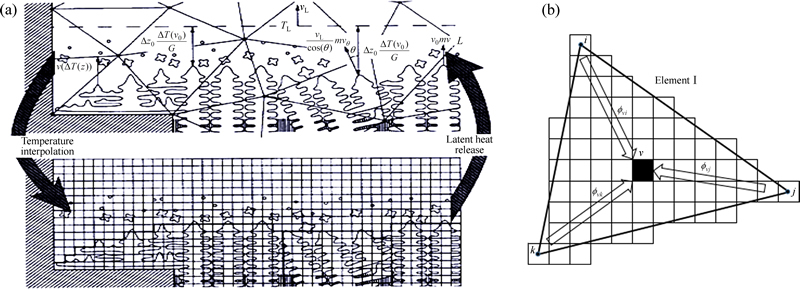

为了将FE和CA法耦合到一个模型中,并且引入凝固潜热的影响,确保显微组织是温度场的函数,为此定义了FE节点和CA元胞之间的插值因子,如图2所示。中心在有限元网格的CA元胞v与有限元节点i、j、k之间分别具有非零的插值因子 、

、 、

、 。这些因子结合FE节点的温度就可以确定网格中元胞处的温度。在节点处采用同样的插值因子对树枝晶形核、生长过程释放的潜热求和,更新节点温度[18-19]。

。这些因子结合FE节点的温度就可以确定网格中元胞处的温度。在节点处采用同样的插值因子对树枝晶形核、生长过程释放的潜热求和,更新节点温度[18-19]。

3 CAFE模型的计算方法

CAFE模型计算过程如下:在宏观范围内,模型基于热流计算,忽略熔体内的对流,采用有限元法及热焓法和隐式格式求解热流方程;在微观范围内,考虑枝晶尖端动力学和晶粒范围内的溶质扩散,建立形核和生长模型,计算等轴枝晶晶粒的形成;在某个时间步长内,当过冷度满足形核条件时,此单元的某些节点开始形核,其生长取向是从一系列随机取向族中选取的。

计算开始时合金的温度高于液相温度,所有元胞被状态因子i=0 (液态)标记。在某个时间步长时,过冷度满足形核条件,此单元的某些节点形核、状态因子转换为整数(i≠0)。晶粒的生长算法是完全确定的,在计算中,假定枝晶按照尖端动力学方式生长,择优取向的生长方向是<001>方向,且与母胞的保持一致。

晶粒生长是基于八面体[111]面,每个生长的元胞赋予整数状态因子(iv≠0)。计算时,在相邻元胞中至少有一个是液态。生长的八面体和元胞v(iv≠0)捕获相邻元胞μ(iv=0),被捕获的相邻元胞μ状态因子数转化为元胞v的状态因子数,并且与元胞v相关的新的八面体开始生长,只要元胞周围被糊状区包围,元胞停止生长[20-22]。

图2 CAFE耦合模型及FE节点与CA节点关系示意图

Fig. 2 Coupled model of CAFE (a) and relationship between FE mesh and CA cells (b)

4 镍基高温合金的显微组织模拟

4.1 模拟参数的确定

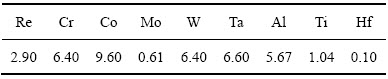

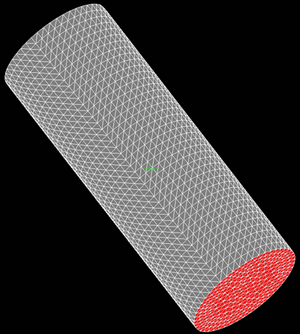

本模拟中采用第二代镍基高温合金CMSX4[22],液相线温度为1381 ℃,固相线温度为1329 ℃,金属液的浇注温度为1401 ℃。合金化学成分见表1。根据其化学成分可以计算出枝晶尖端生长速度的多项式系数,α2=1.710×10-3,α3=7.863×10-4。且模型中需要输入的参数ΔTs,max=5 K、ΔTs,σ=1 K、ns,max=1×107 m-3、ΔTv,max=5 K、ΔTv,σ=1 K、nv,max=1×108 m-3(面形核参数下标为s,体形核参数下标为v)。采用的试样尺寸为d30 mm×80 mm,对其进行实体造型,并进行网格剖分,网格尺寸为2 mm×2 mm×2 mm,得其节点数为5953,单元数为28050。图2所示为网格剖分示意图。自动生成CA节点,元胞尺寸为10μm×10μm×10μm。在试样的底部(图3中红色区域)设定水冷区,试样顶部设定一个发热保温冒口(防止试样顶部产生缩孔缩松),试样的四周设定为绝热区,使试样中只存在一个自上而下的温度梯度,使熔体定向凝固。

表1 CMSX4第二代镍基高温合金的化学成分

Table 1 Chemical compositions of second generation nickel- based superalloy CMSX4 (mass fraction, %)

图3 试样网格剖分示意图

Fig. 3 Schematic diagram of specimen mesh generation

4.2 CMSX4合金定向凝固过程显微组织模拟

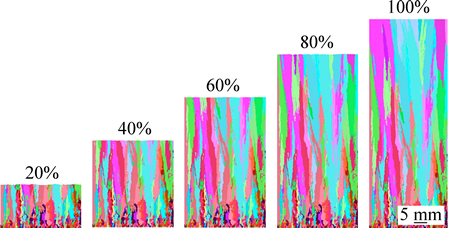

图4所示为凝固过程进行到20%、40%、60%、80%和100%时的纵向切面晶粒生长模拟图。其中不同颜色代表不同取向的晶粒。从图4可以看出,随着凝固的进行,晶粒从底部开始沿着热流的反方向形核长大,底部的等轴晶组织逐渐长大并向定向柱状晶组织转变,其中只有一小部分定向柱状晶组织会一直长大。

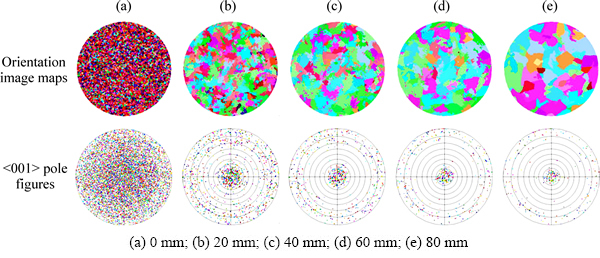

为了详细地分析模拟结果,从试样底部开始每20 mm的高度做一个切面,即切面(a)~(e),并做出各切面的晶粒生长模拟图以及相应的<001>取向极图。从图5(a)~5(e)中各切面晶粒生长模拟图可以观察到,凝固开始时,首先在试样底部出现了一层细小且取向随机分布的等轴晶区,随着凝固的进行(即距试样底部距离的增大),切面处的晶粒数目逐渐减少,晶粒尺寸逐渐增大。图6所示为晶粒度与距试样底部距离之间的关系曲线。由图6可知,在距试样底部0~10 mm范围内的晶粒度急剧减少,从7.787×106 m-2减小到1.181×106 m-2,而在距试样底部10~80 mm范围内的晶粒度减少的速度明显减慢,从1.181×106 m-2减小到1.296×105 m-2。这是由于在试样底部形成的大量取向随机分布的等轴晶间的竞争生长较为激烈,随着距试样底部距离的增加,横截面上的晶粒数量逐渐减少,取向相互接近,使得晶粒间的竞争生长变得缓慢,从而晶粒数量减少的速度也减慢。

图7所示为平均取向偏差与距试样底部距离之间的关系曲线。从图5(a)~(e)所示的极图和图7可以看出,铸锭底部的晶粒位向杂乱排列且无方向性,而随着凝固的进行,<001>晶向与热流方向偏离角较大的晶粒逐渐被偏离角较小的晶粒淘汰,平均取向偏差逐渐减小,趋向于10°,且在最后凝固的切面上(见图5(e)),<001>晶向与热流方向之间的偏离角大部分处于15°以内,平均偏离角12.207°。这是由于在凝固过程中,枝晶的生长具有择优取向,只有那些与温度梯度方向一致的的晶粒才会长大,而其他偏离温度梯度方向的晶粒则会在生长过程中逐渐被择优取向的晶粒所淘汰。在铸锭的凝固过程中,z轴方向上的温度梯度最大,散热最快,即z轴方向上的晶粒生长速度最大,由于晶粒间的竞争生长机制,使它们最快地长大,达到其他晶粒前沿,阻碍了其他取向晶粒的长大。

图4 凝固过程进行到20%、40%、60%、80%、100%时的纵向切面晶粒生长模拟图

Fig. 4 Schematic diagram showing simulation of grain growth of longitudinal section when solidification process to 20%, 40%, 60%, 80%, 100%

图5 试样不同位置处横截面的晶粒生长模拟图以及相应的<001>取向极图

Fig. 5 Predicted grain structure of orientation image maps and corresponding <001> pole figures of cross-sections at different distances from base of specimen

图6 晶粒度与距试样底部距离之间的关系曲线

Fig. 6 Grain density as function of distance from base of specimen

图7 平均取向偏差与距试样底部距离之间的关系曲线

Fig. 7 Average deviations as a function of distances from base of specimen

4.3 浇注温度对显微组织的影响

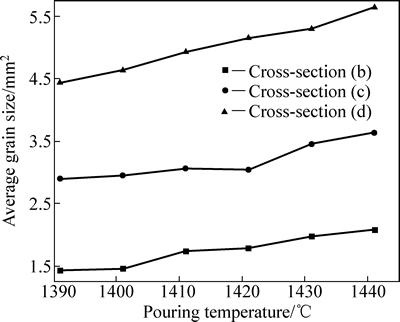

图8所示为图5中各浇注温度下切面(b)、(c)、(d)处的平均晶粒尺寸图。从图8可知,随着浇注温度的升高,试样凝固组织中的柱状晶比例逐渐增大,晶粒尺寸明显变大,发生晶粒粗化,且距试样底部的距离越高,粗化现象越明显。这是由于随着浇注温度的提

图8 各浇注温度下(b),(c),(d)切面平均晶粒尺寸图

Fig. 8 Average grain size of cross-sections (b), (c), (d) at different casting temperatures

高,液体的过冷度将会减小,由式(12)可知,等轴晶生长速度减小。另外,浇注温度的提高,使得熔体形核率减小,结晶时间变长,从而抑制了等轴晶的生长,温度梯度又比较大,促进了柱状晶区的发展,同时由于晶核的极大减少,使得晶粒组织必然变得粗大。

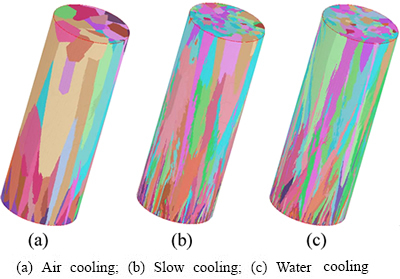

4.4 冷却强度对显微组织的影响

通过在试样底部设立空冷区、缓冷区和水冷区来研究不同冷却速度对试样显微组织的影响,界面换热系数分别为10、2500、5000 W/(m2·K)。由图9可得,在空冷下形成的晶粒较为粗大,数目比较少,而在冷却速度较大的缓冷、水冷下,晶粒尺寸比较小,晶粒数目较多。这是由于在空冷下,冷却换热系数较小,在试样底部形核的晶粒数量很少,导致其晶粒尺寸较大。而在水冷和缓冷下,当冷却强度增大时,增强了形核力,晶粒形核位置和形核率,使晶粒细化,这与凝固理论相一致。并且缓冷和空冷条件下形成的晶粒均匀度较高。

图9 空冷、缓冷、水冷3种冷却速度下试样组织模拟结果

Fig. 9 Simulation results of samples under three kinds of cooling rate

5 结论

1) 第二代镍基CMSX4合金凝固时,晶粒沿着热流的反方向开始形核长大,首先在试样底部形成一层细小且取向随机分布的等轴晶区。随着凝固的进行,试样底部的晶粒逐渐长大,晶粒数目减少,<001>晶向与热流方向偏离角较小的晶粒逐渐淘汰了其他晶粒,取向趋于一致,在最后成形的切面上,偏离角大部分处于15°以内。

2) 浇注温度的提高,使得熔体形核率减小,结晶时间变长,从而抑制了等轴晶的生长,促进了柱状晶区的发展,同时由于晶核的极大减少,使得晶粒组织必然变得粗大,晶粒数目减少。

3) 由于冷却强度的提高引起的形核率等的增加,使得可以通过提高冷却速度细化凝固过程中形成的晶粒。

REFERENCES

[1] GANDIN C A, CHARBON C, RAPPAZ M. Stochastic modeling of solidification grain structure[J]. ISIJ International, 1995, 35: 651.

[2] ZAEEM M A, YIN H, FELICELLI S D. Modeling dendritic solidification of Al-3%Cu using cellular automaton and phase-field methods[J]. Applied Mathematical Modelling, 2013, 37(5): 3495-3503.

[3] 张红伟, NAKAJIMA K, 王恩刚, 赫冀成. Al-Si合金宏观偏析、凝固组织演变的元胞自动机-控制容积法耦合模拟[J]. 中国有色金属学报, 2012, 22(7): 1883-1895.

ZHANG Hong-wei, NAKAJIMA K, WANG En-gang, HE Ji-cheng. Simulation of macrosegregation and solidification microstructure evolution for Al-Si alloy by coupled cellular automaton-finite volume model[J]. The Chinese Journal of Nonferrous Metals, 2012, 21(7): 1883-1895.

[4] GANDIN C H A, RAPPAZ M. Probabilistic modeling of microstructure formation in solidification processes[J]. Acta Metallurgy Material, 1993, 39(2): 345.

[5] GANDIN C H A, RAPPAZ M. A coupled finite element-cellular automaton model for the predict ion of dendritic grain structure in solidification processes[J]. Acta Metallurgy Material, 1994, 40(7): 2233.

[6] 王 松, 谢 明, 王塞北, 付作鑫, 沈 月, 杜文佳, 薄存继. 基于CAFE法的Cu-Cr-Zr-Ag合金凝固组织模拟[J]. 贵金属, 2013, 34(3): 50-54.

WANG Song, XIE Ming, WANG Sai-bei, FU Zuo-xin, SHEN Yue, DU Wen-jia, BO Cun-ji. Simulation of solidified microstructures of Cu-Cr-Zr-Ag alloy based on CA-FE method[J]. Precious Metals, 2013, 34(3): 50-54.

[7] JING Cai-liang, XU Zhi-gang, WANG Ying, WANG Wan-jun. Simulation on solidification structure of 72A tire cord steel billet using CAFE method[J]. China Foundry, 2012, 9(1): 53.

[8] 卜晓兵, 李落星, 张立强, 朱必武, 王水平. Al-Cu合金凝固微观组织的三维模拟及优化[J]. 中国有色金属学报, 2011, 21(9): 2195-2201.

BU Xiao-bing, LI Luo-xing, ZHANG Li-qiang, ZHU Bi-wu, WANG Shui-ping. Three-dimensional numerical simulation and optimization of solidification structure of Al-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2195-2201.

[9] 仲红刚, 曹 欣, 陈湘茹, 张捷宇, 翟启杰. Al-Cu合金水平单向凝固组织预测及实验观察[J]. 中国有色金属学报, 2013, 23(10): 2792-2799.

ZHONG Hong-gang, CAO Xin, CHEN Xiang-ru, ZHANG Jie-yu, ZHAI Qi-jie. Numerical and experimental investigation of solidification structure in horizontal directional solidification process of Al-Cu Alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(10): 2792-2799.

[10] 张 华, 倪红卫, 陈光友, 成日金, 刘吉刚. Al-Si合金凝固组织的三维模拟及预测[J]. 过程工程学报, 2009, 9(1): 92-96.

ZHANG Hua, NI Hong-wei, CHENG Guang-you, CHENG Ri-jin, LIU Ji-gang. Three-dimensional numerical simulation and prediction of solidification structure of Al-Si alloy[J]. The Chinese Journal of Process Engineering, 2009, 9(1): 92-96.

[11] MOHSEN A Z, HEBI Y, SERGIO D F. Modeling dendritic solidification of Al-3%Cu using cellular automaton and phase-field methods[J]. Applied Mathematical Modelling, 2013, 37: 3495-3503.

[12] RAVINDRA S S, GANESH N R, SUMITESH D. Cellular automata finite element(CAFE) model to predict the forming of friction stir welded blanks[J]. Computational Materials Science, 2012, 58: 87-100.

[13] SAUNDERS N, MIODOWNIK A P. Calculation of phase diagrams: A comprehensive guide[J]. London: Oxford University Press, 1998: 33.

[14] 庞瑞鹏, 王福明, 张国庆, 李长荣. 基于3D-CAFE法对430铁素体不锈钢凝固热参数的研究[J]. 金属学报, 2013, 49(10): 1234-1242.

PANG Rui-peng, WANG Fu-ming, ZHANG Guo-qing, LI Chang-rong. Study of solidification thermal parameters of 430 ferrite stainless steel based on 3D-CAFE method[J]. Acta Metallurgica Sinica, 2013, 49(10): 1234-1242.

[15] KURZ W, GIOVANOLA B, TRIVEDI R. Theory of microstructural development during rapid solidification[J]. Acta Metall Mater, 1986, 34(5): 823-830.

[16] 王金龙, 赖朝彬, 王福明, 张炯明, 任 嵬. CAFE模型机理及应用[J]. 钢铁研究学报, 2009, 21(10): 60-63.

WANG Jin-long, LAI Chao-bin, WANG Fu-ming, ZHANG Jiong-ming, REN Wei. Mechanism and application of CAFE method[J]. Journal of Iron and Steel Research, 2009, 21(10): 60-63.

[17] 宋迎德, 郝 海, 古松伟, 张爱民, 张兴国. 枝晶生长速度对微观组织数值模拟的影响研究——Ivantsov函数近似方法的确定[J]. 铸造技术, 2011, 32(1): 34--38.

SONG Ying-de, HAO Hai, GU Song-wei, ZHANG Ai-min, ZHANG Xing-guo. Research on the microstructure simulation determination of the approximation of Ivantsov Function[J]. Foundry Technology, 2011, 32(1): 34-38.

[18] 王金龙, 王福明, 李长荣, 程慧静. 基于CAFE法优化易切削钢9SMn28锰硫比[J]. 热加工工艺, 2009, 38(5): 10-13.

WANG Jin-long, WANG Fu-ming, LI Chang-rong, CHENG Hui-jing. Optimization of rate of manganese to sulfur for free-cutting steel 9SMn28 based on CAFE methods[J]. Hot Working Technology, 2009, 38(5): 10-13.

[19] ZHU M F, HONG C P. A modified cellular automaton model for the simulation of dendritic growth in solidification of alloys[J]. ISIJ International, 2001.

[20] 王永聚, 付建华, 闫红红, 张家齐. 42CrMo钢环件凝固过程与组织的变化数值模拟[J]. 热加工工艺, 2012, 41(19): 50-52.

WANG Yong-ju, FU Jian-hua, YAN Hong-hong, ZHANG Jia-qi. Numerical simulation on solidification process and structure changes of 43CrMo steel ring casting[J]. Hot Working Technology, 2012, 41(19): 50-52.

[21] YANG Zhi-jun, ZHAO Xiao-hua, KOU Hong-chao, LI Jin-shan, HU Rui, ZHOU Lian. Numerical simulation of temperature distribution and heat transfer during solidification of titanium alloy ingots in vacuum arc remelting process[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(10): 1957-1962.

[22] SEO S M, KIM I S, LEE J H, JO C Y, MIYAHARA H, OGI K. Grain structure prediction of Ni-base superalloy castings using the cellular automaton-finite element method[J]. Materials Science and Engineering A, 2007, 449(13):713-716.

Microstructure simulation during directional solidification of nickel-based alloy based on CAFE model

ZHANG Pu1, HOU Hua1, ZHAO Yu-hong1, JIN Yu-chun1, ZHAO Yu-hui2, SUI Huai-ming3

(1. College of Materials Science and Engineering, North University of China, Taiyuan 030051, China;

2. Department of Electrical Engineering, Hebei College of Industry and Technology, Shijiazhuang 050091, China;

3. Yangzhou Feng Ming Metal Products Company Limited, Yangzhou 225117, China)

Abstract: CAFE model was adopted to simulate the grain growth during solidification process of the second generation nickel-based superalloy CMSX4, and then the influences of casting temperature and cooling rate on the solidification structure were discussed. The results show that at the beginning of solidification, a layer of fine equiaxed grains with random orientation forms first. Due to the competition between the grain growth, the number of grains decreases, the grain size increases, and the grains with bigger deviation angle of the <001> crystal orientation deviating from the direction of heat flow are gradually eliminated by the grains with small deviation angle. The increase of pouring temperature will make the grain size bigger, the number of crystal grains decreases, while the increase of cooling rate can make the grain size smaller. The results are consistent with the theoretical analysis.

Key words: nickel-based alloy; CMSX4 alloy; CAFE method; directional solidification; structure evolution

Foundation item: Project(2014DFA50320) supported by International Cooperation of Ministry of Science and Technology of China; Projects(51204147, 51274175) supported by the National Natural Science Foundation of China; Project(2013-81) supported by the Scientific Research Fund for Homecoming Students of Shanxi Province, China; Project(2013081017) supported by International Science and Technology Cooperation of Shanxi Province, China

Received date: 2015-04-09; Accepted date: 2015-09-13

Corresponding author: ZHAO Yu-hong; Tel: +86-15035172958; E-mail: zyh388@sina.com

(编辑 龙怀中)

基金项目:科技部国际科技合作项目(2014DFA50320);国家自然科学基金资助项目(51204147,51274175);山西省回国留学人员科研资助项目(2013-81);山西省国际科技合作项目(2013081017)

收稿日期:2015-04-09;修订日期:2015-09-13

通信作者:赵宇宏,教授,博士;电话:15035172958;E-mail:zyh388@sina.com