DOI:10.11817/j.ysxb.1004.0609.2021- 42057

金刚石颗粒表面磁控溅射镀膜及热处理工艺

王长瑞1, 2,田 威1,胡俊山1,李 波1,李鹏程1,林铁松2,廖文和1

(1. 南京航空航天大学 直升机传动技术重点实验室, 南京,210016;

2. 哈尔滨工业大学先进焊接与连接国家重点实验室, 哈尔滨, 150001)

摘 要:金刚石颗粒表面镀膜和热处理可解决高导热金刚石/铜复合材料的界面润湿和结合问题,本文研究了金刚石颗粒表面磁控溅射镀覆改性金属 Mo 和 W以及不同热处理工艺对镀覆金刚石颗粒重量、表面形貌、微观组织和组成的影响规律。研究结果发现,磁控溅射后Mo镀层呈现麦粒状组织,而W镀层为球形状组织;在真空环境下热处理,随着热处理温度的增加会加速Mo或者W的升华速率,使得金刚石颗粒表面裸漏在热处理环境中而发生石墨化。在Ar环境下热处理,900 ℃时Mo或者W单质相还有残留,当温度升高到950 ℃时出现了石墨化现象,但热处理温度为1000 ℃时形成了致密的MoCx和WCx相,消除了石墨化现象,并获得了良好的热处理界面,为获得高导热性的金刚石/铜复合材料奠定基础。

关键词:金刚石/铜复合材料;热处理工艺;微观组织;金刚石石墨化;相组成

中图分类号:TF124 文献标志码:A

在战斗机、预警机、无人机等战略航空航天器高集成装备性能需求牵引下,新型雷达的芯片级和模块级电子设备向着功能一体化、尺寸小型化、结构紧凑化、高功率密度方向发展[1-5]。新型电子设备的热流密度大幅度增加,特别是核心芯片的热流密度由传统的200-300 W/cm2向着1000 W/cm2发展。超高的热流密度使得核心芯片的热控问题凸显,其使用寿命及可靠性呈指数型降低,高效散热成为核心芯片的“卡脖子”问题[6-8]。如何制备高导热的核心芯片热沉材料是解决卡脖子问题的核心技术之一,金刚石/铜具有较高的导热系数(>500 W/m·K),是传统热沉材料的2-3倍,低的热膨胀系数(与新型核心芯片非常匹配),是最佳新型热沉材料之一[9,10]。但金刚石和铜之间的润湿性极差,既不能形成固溶体,也不能形成碳化物,二者之间为简单的机械结合,界面存在孔洞、空隙, 导致界面结合很弱,界面上热载体的平均自由程大大降低,难以获得高导热系数的热沉[11-13]。

国内外研究人员通过电镀、化学镀、盐浴法、磁控溅射等方法在金刚石表面预镀Si、B、Ti、Cr和W等元素或对铜基体预合金化,来修饰复合材料界面,提高金刚石/铜复合材料的热导率。Raza等[14]采用微蒸镀法在金刚石颗粒表面镀覆Ni和Cr镀层,可以使样品的致密化程度提高,由于镀层与金刚石反应形成Cr7C3相,有利于界面结合,获得了高于无镀层金刚石/铜的导热系数。KITIWAN等[15]利用化学气相沉积在金刚石颗粒表面镀覆SiC镀层,可使烧结后的致密度达到98%以上。NUNES等[16]在金刚石/铜复合材料中通过机械合金化的方法加入0.1 wt% Cr,可以实现金刚石与铜的界面的有效结合,与SPS烧结相比,热挤压强化可以获得更均匀的组织。北京科技大学曲选辉研究团队[17]对盐浴法制备金刚石界面镀层进行了系统的研究,研究表明Cr7C3镀层促进了金刚石颗粒与铜基体的润湿性和界面结合,获得了致密的金刚石/铜复合材料。中科院宁波材料所江南等[18]采用前驱体原位生长的方法在金刚石颗粒表面制备B纳米线,有效提高了金刚石表面的接触面积及润湿性。UKHINA等[19]采用羰基钨和二茂镍为前驱体利用化学沉积方法在金刚石表面制备涂层。WU等[20] 利用COMSOL软件模拟了金刚石/铜复合材料内部的热通量,通过电镀制备了导热系数(Tc)和热膨胀系数(CTE)分别为614.87 W /(mK)和9.45×10 6 K-1的金刚石/铜复合材料。CHE等[21]通过改变钛和金刚石的体积分数在金刚石/铜界面形成碳化钛(TiC)和金属间化合物(Cu3Ti2)来获得良好的界面。将添加3 vol%Ti的金刚石/铜复合材料在945 ℃下SPS烧结保温5分钟,其导热系数高达670 W/(mK),为理论预测值的90%。相对于上述方法,磁控溅射法更有利于金刚石表面沉积均匀的镀层,可以通过超声振动确保镀层的均匀性,并通过控制镀膜时间控制镀层的厚度[22]。SANG [23],JIA[24]和XIN[25]采用磁控溅射法在金刚石颗粒表面进行镀W研究,获得了均匀的镀层和高导热的金刚石/铜复合材料,研究指出热处理后单质W发生相变,并在金刚石{100}和{111}晶面上的结合呈现一定的界面差异性。

但是目前对于不同热处理工艺下磁控溅射金刚石颗粒表面的微观组织与相组成等的演变规律研究较少,这也是确保后续获得高导热系数的关键因素之一。为此,本文研究不同热处理环境、温度与镀覆元素对界面的影响规律,为高导热金刚石/铜热沉的制备提供理论和工艺支撑。

1 实验材料与方法

1.1 实验材料

金刚石采用购买于郑州华晶金刚石股份有限公司80/100目的B60型金刚石,晶粒形貌、{111}晶面和{100}晶面如图1所示,根据FTIR分析测试其导热系数为1950W/m·K(数据由购买公司提供)。磁控溅射用Φ100mm×50mm的W和Mo靶材纯度为99.99%,购买于攀时(上海)高性能材料有限公司。

图1 原始金刚石颗粒形貌

Fig. 1 Morphology of original diamond particles

1.2 金刚石颗粒表面磁控溅射实验

在OUR500三靶磁控溅射镀膜机上进行了磁控溅射实验。沉积过程中,在0.5 Pa压力下进行流动Ar气氛保护,同时将金刚石衬底加热至300 ℃并保持30 min,磁控溅射工艺的电流和电压分别为1 A和500 V。在磁控溅射过程中,采用超声振动系统对金刚石颗粒进行振动,使金刚石颗粒在沉积过程中发生翻滚,确保每个颗粒的每个表面沉积的均匀性。

1.3 热处理工艺

为了获得性能一致的金刚石/铜复合材料,磁控溅射后的金刚石颗粒需要与铜粉进行混合。为了保证球磨混合后金刚石沉积层不被破坏而影响后续导热性能,需要对磁控溅射后的金刚石颗粒进行热处理。实验中对磁控溅射制备金刚石颗粒的W和Mo表面组织形貌和相组成及热处理工艺进行研究,具体热处理工艺为:(1)在真空环境(真空度为0.1 Pa)和常压Ar气氛两种条件下进行热处理;(2) 热处理温度为900 ℃、950 ℃、1000 ℃,热处理时间为1h。

1.4 分析测试

采用高精度天平和量具通过等体积法进行重量变化分析,利用德国BRUKER 原子力显微镜对热处理后的金刚石表面形貌进行AFM表征,采用日本SmartLab X射线衍射仪进行XRD物相分析,对热处理后的相变化进行研究,日本日立的REGULUS 8220 扫描电镜用来进行SEM和EDS观察。

2 结果与讨论

2.1 磁控溅射表面形貌

磁控溅射W和Mo后金刚石颗粒的表面组织形貌,如图2所示。磁控溅射后金刚石颗粒形貌与原始金刚石颗粒形貌相比没有明显的变化(图2a和图2b),都是棱角分明的正十四面体结构。通过局部放大图可以看出金刚石镀Mo表面(图2c)为麦粒状形貌,而金刚石镀W表面(图2d)为球形颗粒状形貌,两种颗粒表面都有尺寸0.2μm左右的团聚颗粒,主要是在磁控溅射过程中Mo和W的颗粒定向局部长大、团聚所致,但由于颗粒尺寸较小且少,不影响后续散热。通过EDS分析可以看出,磁控溅射后Mo(图2e)和W(图2f)元素在金刚石颗粒表面均匀分布,说明磁控溅射方法有利于Mo和W镀层的均匀化制备,并且为获得良好的表面质量和界面结合力提供了基础。

图2 磁控溅射后金刚石颗粒表面形貌

Fig. 2 Surface morphology of diamond particles after magnetron sputtering

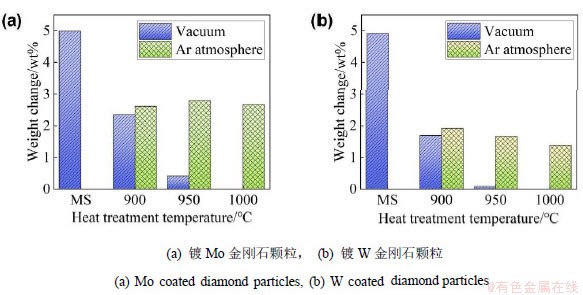

2.2 热处理后重量变化

对磁控溅射沉积Mo和W的金刚石颗粒分别在真空环境和Ar保护气氛下进行热处理的重量变化如图3所示。通过重量测量法计算磁控溅射沉积Mo和W的金刚石颗粒增重分别为4.99%和4.91%。镀Mo金刚石颗粒在真空环境下进行热处理时,随着热处理温度的升高,金刚石颗粒的重量逐渐降低,如图3a所示,主要是在真空环境下更利于金刚石颗粒表面镀覆的Mo发生升华现象而脱离金刚石表面,进而造成重量降低现象。但是在Ar保护气氛下,随着热处理温度的增加,镀Mo金刚石颗粒的重量变化不大,说明在Ar保护气氛下有效抑制了Mo的升华现象,在保证足够的Mo元素覆盖在金刚石颗粒表面的同时可保证界面镀覆元素与金刚石颗粒的稳定反应,以确保后续过程中与金刚石颗粒表面形成良好的接触,为散热性能的提升奠定基础。镀W金刚石颗粒在真空环境下进行热处理时的金刚石颗粒重量变化与镀Mo金刚石颗粒类似,如图3b所示,只是在真空环境下950℃热处理后,镀W金刚石颗粒重量已经接近于等体积的纯金刚石颗粒重量,说明此时金刚石界面镀覆的W元素已全部因升华而损失掉,在Ar保护气氛下热处理后,随着温度的增加,镀W金刚石颗粒的重量呈下降趋势,说明在Ar保护气氛下W元素的升华依然明显。

图3 不同热处理温度和气氛下重量变化

Fig. 3 Weight change under different heat treatment temperature and atmosphere

2.3 热处理后微观组织分析

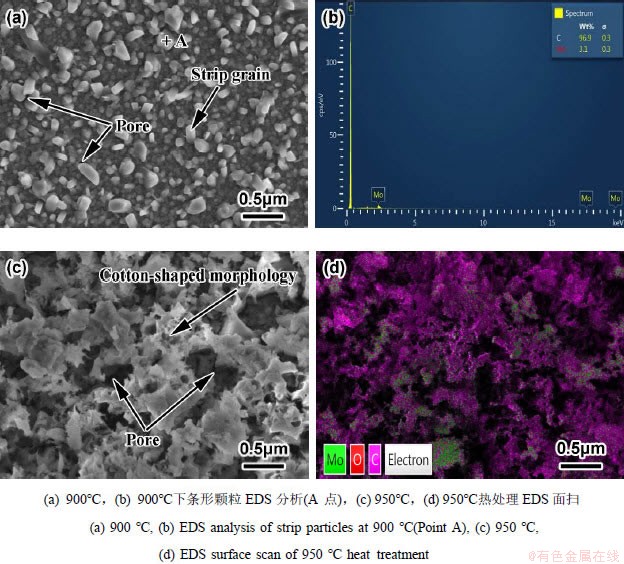

图4所示为真空气氛保护下,在不同温度下镀Mo金刚石颗粒的表面微观组织变化情况。可以看出在900℃下(图4a)金刚石颗粒几乎完全被形成的镀覆层覆盖,表面形貌由原来的由麦粒状(图2c)演变成0.1μm的颗粒和0.5μm以下的条形状颗粒组成,表面残存少量的空洞,通过EDS分析可知(图4b),条形状颗粒也主要是Mo元素为主,还有热处理过程中带入的少量O元素,说明在900℃热处理温度下,由于镀覆在金刚石颗粒表面Mo活化能的增加Mo晶粒发生再结晶,使得界面趋于明显,并在局部区域沿着垂直于金刚石颗粒表面生长而形成棱角分明的长条状形貌。当热处理温度升到950℃时(图4c),发现此时的金刚石表面变得凹凸不平,出现了大量的孔洞和类似于絮状的形貌,通过EDS面扫分析发现(图4d),此时界面残留少量的Mo元素,大部分的Mo元素由于真空环境和温度的升高气化速度增加,还未与金刚石界面反应而气化消失了。在Mo元素的气化,加上少量O元素的存在,使得金刚石颗粒表面形成局部真空和高温,反而加速了金刚石颗粒表面的石墨化,形成了凹凸不平的表面形貌[26,27]。说明在真空环境下对镀Mo金刚石颗粒进行热处理,不利于Mo与金刚石颗粒表面的反应,反而会加速金刚石颗粒表面的石墨化,形成絮状等凹凸不平的表面形貌。

图4 真空气氛、不同热处理温度下镀Mo金刚石颗粒的表面微观组织变化

Fig. 4 The surface microstructure changes of Mo coated diamond particles under vacuum atmosphere and different heat treatment temperature

图5所示为真空气氛保护下,在不同温度下镀W金刚石颗粒的表面微观组织变化情况。图5a为热处理温度为900 ℃时镀W金刚石颗粒的表面微观组织,相对于磁控溅射后的球形颗粒,真空热处理后颗粒尺寸发生了长大,颗粒尺寸增加2倍以上,形成了散点式连续纹理结构,其中含有大量的空洞,说明在此温度下W的升华速率大于W与金刚石界面反应速度,使得此温度下金刚石界面的W都升华掉而影响后续铜的界面润湿性能,进一步影响金刚石/铜复合材料的散热性能。当热处理温度升高到950℃时,金刚石颗粒表面只残存少量的镀层颗粒,此时随着烧结温度的升高,W元素升华进一步加剧,造成大量的W元素的损失,局部W元素与金刚石反应,并形成了局部W富集,使得镀层颗粒尺寸增加到0.5μm以上,通过EDS分析可知,颗粒中主要是W元素,其次为C元素,还有少量的O元素存在,详细的相组成在下一节进行介绍。此外,在镀层消失的金刚石颗粒表面整体界面比较平整,未出现图4c所示的凹凸不平的形貌,但是从图中可以看出,存在一些条形状或者片状的组织,EDS分析(图5d)显示主要是C元素,是因为在真空及高温环境下,金刚石表面发生石墨化所导致,这与文献[15、28]研究结果一致。

图5 真空气氛、不同热处理温度下镀W金刚石颗粒的表面微观组织变化

Fig. 5 The surface microstructure changes of W-coated diamond particles under vacuum atmosphere and different heat treatment temperatures

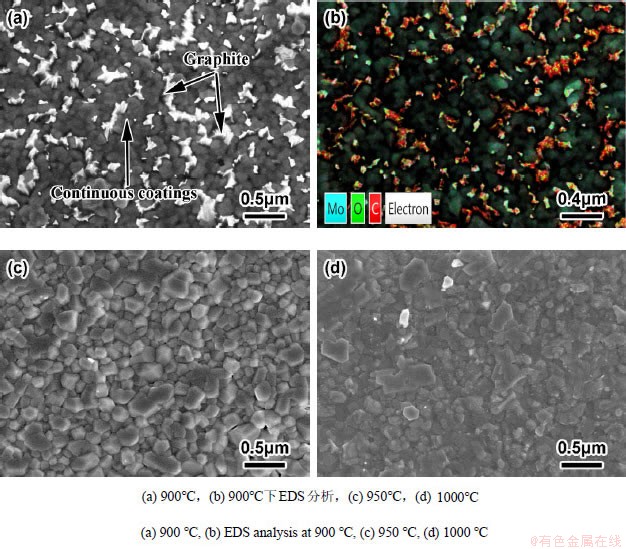

由图4和图5可知,真空环境下进行热处理不利于镀层与金刚石界面的反应,反而造成大量镀层的升华及金刚石表面的石墨化。为此,进一步研究了在Ar气氛保护下的热处理工艺。图6所示为Ar气氛保护下镀Mo金刚石颗粒的表面微观组织变化情况。当热处理温度为900 ℃时(图6a),金刚石颗粒表面有两种形貌,一种是灰色连续形貌,颗粒之间界面不分明,类似于融化后凝固态组织,通过EDS分析(图6b)显示主要为Mo元素,说明此形貌为连续的镀层形貌;另一种为白色显示的形貌,分布在镀层形貌的边界处,通过EDS分析(图6b)显示主要为C元素,可以看出金刚石颗粒表面还是分布着少量的O元素。说明在900 ℃热处理下,Mo镀层与金刚石颗粒表面进行较好的连接,并发生相关化学反应(下节讨论),增强的界面结合性能,但是由于Mo的高温升华,使得金刚石颗粒部分表面Mo完全消失,并且由于磁控溅射时引入了少量的O元素,使得此处暴漏在真空环境下的金刚石颗粒表面发生了石墨化,而形成了图6a中所示的白色形貌的石墨。当热处理温度升高到950 ℃时(图6c),可以看到金刚石颗粒表面形成了致密的、近球形的颗粒,尺寸在0.25μm左右,没有发现明显的气孔,说明在此温度下可以得到性能良好的热处理界面,有利于后续与铜结合后获得更高的散热性能和力学性能[29]。当热处理温度升高到1000 ℃时(图6d),金刚石界面颗粒发生再结晶和晶粒长大,出现了更多异常长大的颗粒,会造成界面形貌的不平整,影响后续与铜的界面融合,因此,在Ar气氛和950 ℃温度下进行热处理可以获得更好的界面。此外,微观组织变化趋势与图3a中Ar气氛热处理后颗粒重量变化一致,可以看出在900 ℃、950 ℃和1000 ℃热处理后重量变化不大,而在真空下进行热处理而重量变化明显。

图6 Ar气氛、不同热处理温度下镀Mo金刚石颗粒的表面微观组织变化

Fig. 6 Changes of surface microstructure of Mo coated diamond particles in Ar atmosphere at different heat treatment temperatures

图7所示为Ar气氛下,不同热处理温度下镀W金刚石颗粒的表面微观组织变化情况。当热处理温度为900 ℃时(图7a),此时大部分为球形颗粒,此处在0.1μm左右,还有少量的条形颗粒和气孔存在,通过EDS分析发现(图7b)主要含有W、C和少量的O元素,主要是由于部分镀层处W镀层聚集及与金刚石表面发生反应形成WCx,以及高温下W升华所致。当热处理温度升高到950 ℃时(图7c),镀层颗粒生长明显,尺寸增加到1mm左右,增加10倍以上,主要是温度升高增加了晶粒界面活化能,使得晶粒不断生长导致。但是由于晶粒增加迅速,再加上高温下W元素的升华,使得一些区域出现了mm级的大孔隙,镀层的完整性遭到了破坏,进而影响金刚石/铜复合材料的散热性能,产生这种现象的原因是在此温度下,W元素升华的速度大于W元素与金刚石颗粒界面反应的速度,使得不少W元素因高温而升华失去,一部分与金刚石界面反应形成WCx,而且高温下界面活化能增加,使得镀层再结晶速度增加,颗粒尺寸快速生长[30]。当热处理温度达到1000 ℃时(图7c),晶粒尺寸反而减小,主要是因为温度的升高,W与金刚石界面反应激活能增加,此时的反应温度大于W升华的温度,使得大多数的W与金刚石快速反应形成WCx,因升华而造成的W挥发很少,有利于形成良好的接触界面和提高金刚石/铜复合材料的散热性能。通过EDS分析(图7e和图7f),表面晶粒元素主要是W和C,也证明了上述分析。但是相对于Mo与金刚石颗粒的快速反应来说,W与金刚石颗粒的快速反应温度要更高一些,一般在1000 ℃以上[31]。在1000℃进行热处理时反应与升华同时存在,这是如图3b所示随着温度升高,金刚石颗粒重量逐步减少的原因,但减少不多。但是过高的温度(高于1000℃)会造成金刚石的石墨化反而影响散热,因此Ar气氛下1000℃为比较理想的热处理温度[32]。

图7 Ar气氛、不同热处理温度下镀W金刚石颗粒的表面微观组织变化

Fig. 7 The surface microstructure changes of W-coated diamond particles under Ar atmosphere and different heat treatment temperatures

通过上述分析可知,在真空环境下Mo和W元素的升华速率大于与金刚石界面反应的速率,随着温度升高,Mo和W加速升华,使得金刚石颗粒表面形成少量的MoCx,裸漏的金刚石由于高温和少量的O存在易于发生石墨化,不利于金刚石颗粒磁控溅射镀层的热处理。在Ar气氛保护下进行热处理时,Mo和W元素与金刚石界面反应的速率大于升华速率,更多的磁控溅射元素与金刚石界面形成WCx,只有少量的发生升华,可以得到致密化的镀层界面,使得金刚石与热处理环境有效的隔离,避免了石墨化,有利于获得高性能的金刚石/铜复合材料。Ar气氛下磁控溅射Mo和W镀层的最佳热处理温度分别为950 ℃,1000 ℃。

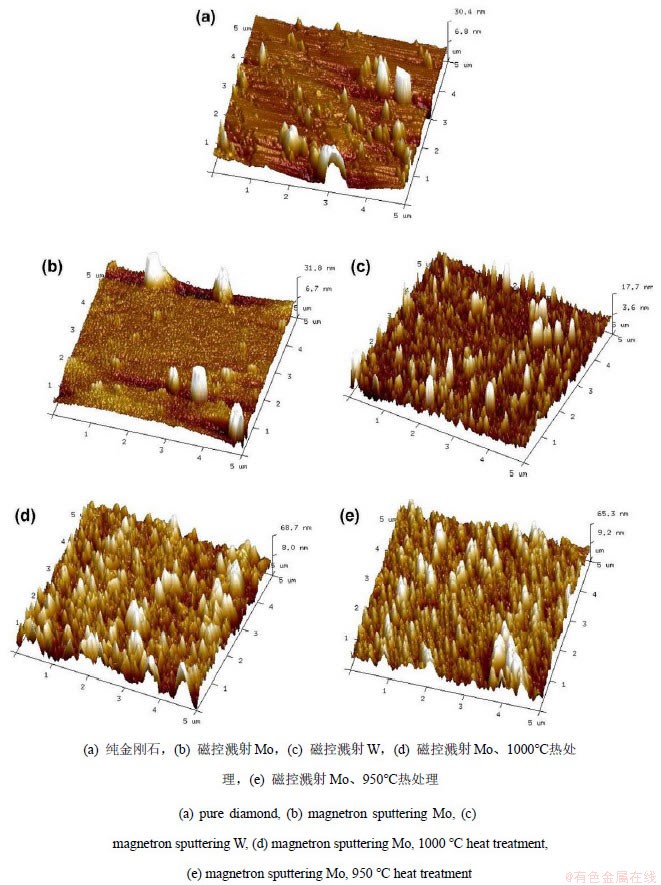

2.4 热处理前后表面形貌

图8所示为不同参数下金刚石颗粒AFM形貌。可以看出初始金刚石颗粒表面(图8a)整体比较平整,但是也有一些微米级的凸起,主要是由于金刚石制备过程中所致,但是其增加了金刚石的表面积,在进行磁控溅射时有利于镀层元素的沉积[33]。图8b和图8c所示为磁控溅射Mo和W之后的AFM表面,除了金刚石表面的凸起外,磁控溅射Mo的金刚石颗粒表面更为平滑,Mo晶粒尺寸小于100 nm左右,而磁控溅射W的金刚石颗粒表面呈现凹凸不平的锯齿状形貌,厚度在100 nm-500 nm之间,说明磁控溅射时,Mo元素更容易获得均匀的镀层,而W元素易于沿着垂直于金刚石颗粒表面的方向定向生长而形成凹凸不平的组织(图9)。磁控溅射Mo的金刚石颗粒在热处理以后(图8e),镀层形貌发生较大变化,主要是由于Mo与金刚石发生反应形成碳化物所致,此时的晶粒尺寸也增加到200 nm以上。而热处理后的W镀层(图8f)的形貌虽然发生了化学反应,整体形貌与磁控溅射形貌类似,但沿着垂直于金刚石表面的定向生长更为明显。图8e和图8f所示的热处理后AFM形貌表明,磁控溅射的单质元素与金刚石发生反应形成碳化物而增强界面结合能,而呈现凹凸不平的锯齿状形貌有利于镀层与金刚石颗粒的界面结合性能的提升[34]。

图8 不同参数下金刚石颗粒AFM形貌

Fig. 8 AFM morphology of diamond particles under different parameters

图9 镀W金刚石颗粒不同阶段镀层界面示意

Fig.9 Coating interface at different stages of Mo coated diamond particles

2.5 热处理前后相组成变化

磁控溅射Mo镀层金刚石颗粒在真空环境、不同热处理温度下的XRD分析如图10所示,可以看出磁控溅射后只有金刚石和Mo单质两种相组成,但是Mo的峰比较弱,在图2中所示均匀镀层的情况下,也再次说明镀覆的厚度很薄。在真空环境下进行900 ℃热处理后,金刚石的峰依然是主峰,此时已经出现Mo2C相,与文献[35]中一致,但Mo相的衍射峰变弱,一是与金刚石反应形成Mo2C相,二是在高温下Mo元素发生升华,两个因素共同造成了Mo衍射峰的变弱,在真空环境下进行950 ℃热处理后,Mo衍射峰消失,主要是金刚石和Mo2C相的衍射峰,但是由于为了满足高导热要求,镀层含量很少,镀层厚度在几百纳米级别,形成的Mo2C相较少,衍射峰不是特别明显,如图11所示。此时出现了石墨的衍射峰,这意味着在950 ℃时金刚石发生石墨化,此温度比Lei等[36]报道的800℃的石墨化温度高150℃,可能是此时处于真空环境,而且磁控溅射的镀层中O含量很少,使得相应的环境延缓了金刚石的石墨化。

图10 磁控溅射Mo镀层金刚石颗粒在真空环境、不同热处理温度下的XRD分析

Fig. 10 XRD analysis of Mo coated diamond particles by magnetron sputtering in vacuum environment at different heat treatment temperatures

图11 磁控溅射Mo镀层金刚石颗粒在真空环境、不同热处理温度下的XRD分析局部放大图

Fig.11 Local Enlargement of XRD analysis for Mo coated diamond particles by magnetron sputtering in vacuum environment at different heat treatment temperatures

图12所示为磁控溅射W镀层金刚石颗粒在真空环境、不同热处理温度下的XRD分析。磁控溅射后主要是金刚石和W相的衍射峰,在900 ℃时,出现了W2C和WC相,主要是由于W相与金刚石界面反应所致,其中W2C相的衍射峰强于WC相的衍射峰,在此温度下W元素的升华速率大,使得W2C和WC相的衍射峰比较弱。虽然相较于金刚石的{111}晶面,W镀层在金刚石的{100}晶面更利于沉积且结合力更强,相对来说{111}晶面上W元素更容易升华,如图13所示。但是金刚石{111}晶面上会生成W2C和WC相,而金刚石{100}晶面上主要是WC相[23]。当热处理温度升高到950℃时,由于W镀层的加速挥发,使得W2C和WC相的衍射峰进一步减弱,但是WC相的衍射峰强于W2C相的衍射峰,说明高温下更利于WC相的形成。WC相作为界面改性层的优越性在一定程度上是由于WC的导热系数大于W2C。但整体来说WC相含量较少,衍射峰不是很明显,因此,后续需要进一步合理的控制热处理工艺,确保WC相的形成。

图12 磁控溅射W镀层金刚石颗粒真空环境、热处理不同温度下的XRD分析

Fig. 12 XRD analysis of W coated diamond particles by magnetron sputtering in vacuum environment at different heat treatment temperatures

图13 磁控溅射W镀层金刚石颗粒在真空环境、900℃热处理后不同晶面组织形貌

Fig. 13 The morphology of different crystal planes of W-coated diamond particles by magnetron sputtering after heat treatment at 900 ℃ in vacuum

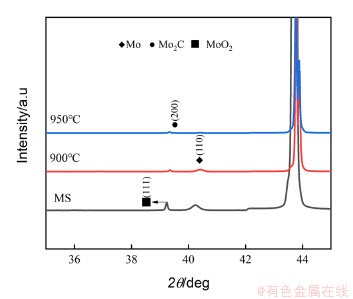

磁控溅射Mo镀层金刚石颗粒在Ar气氛环境、不同热处理温度下的XRD分析如图14所示。当热处理温度为900 ℃时,此时还有大量的Mo相存在,并生成了一定量的Mo2C,但是含量比较少,使得衍射峰比较弱。当热处理温度升高到950 ℃时,此时存在Mo相、Mo2C相,Mo2C相含量同样很少,衍射峰比较弱,但出现了新相Mo3C2。主要是由于MoCx相的类型很多,当温度升高到772 ℃时,MoCx可以转变成更稳定的Mo3C2相,在碳化钼的存在相中,Mo2C具有较强的金属性,共价键最强。此外,Mo2C的功函数只有3.4eV,其包裹在碳层内,则金刚石颗粒的电化学活性和稳定性会得到增强,因此精确控制碳化温度来调节Mo2C[37]。和图10类似,在950 ℃时出现了石墨衍射峰,说明此时金刚石发生了一定的石墨化,主要是因为此温度下Mo与金刚石的反应速率与Mo的升华速率相当,使得金刚石部分表面裸漏在热处理的环境中,再加上磁控溅射时引入的少量的O元素的存在,使得金刚石发生了石墨化。当热处理温度升高到1000 ℃时,Mo与金刚石的反应速率大于Mo的升华速率,使得金刚石颗粒表面快速形成了致密的MoCx相,实现了与外界环境的阻隔,此时并未发现石墨的衍射峰,说明有效阻止金刚石的石墨化。

图14 磁控溅射Mo镀层金刚石颗粒Ar气氛热处理不同温度下的XRD分析

Fig. 14 XRD analysis of magnetron sputtered Mo coated diamond particles heat treated in Ar atmosphere at different temperatures

磁控溅射W镀层金刚石颗粒在Ar气氛环境、不同热处理温度下的XRD分析如图15所示,在900 ℃进行热处理时,此时未发现WCx的衍射峰,说明在Ar气氛下此热处理温度较低,不利于W元素已金刚石进行反应。当热处理温度身高到950 ℃,此时出现了W2C和WC的衍射峰,但是由于含量较少,衍射峰不是很明显,而且和磁控溅射Mo镀层在Ar环境下一样,也出现了金刚石石墨化的现象,也是由于W的升华速率大于W与金刚石表面的反应速率,使得金刚石部分表面裸露在热处理环境中而发生石墨化。当热处理温度升高到1000 ℃时,只有金刚石、W2C和WC的衍射峰,说明此时W已与金刚石完全反应,形成了致密化的界面,并避免了金刚石石墨化。

图15 磁控溅射W镀层金刚石颗粒Ar气氛热处理不同温度下的XRD分析

Fig.15 XRD analysis of magnetron sputtered W coated diamond particles heat treated in Ar atmosphere at different temperatures

3 结论

(1) 磁控溅射后金刚石颗粒表面镀层均匀分布,镀Mo金刚石颗粒表面为麦粒状形貌,而镀W金刚石颗粒表面为球形颗粒状形貌。

(2) 在真空环境下热处理时金刚石颗粒表面镀覆的Mo和W单质发生升华现象而脱离金刚石表面,进而造成失重问题,在Ar环境进行热处理使得失重现象得以抑制,但镀W金刚石颗粒失重依然存在。

(3) 在真空环境下热处理时,随着温度的升高,大量的Mo和W升华,使得金刚石颗粒表面发生石墨化。在Ar气氛下进行热处理后,磁控溅射Mo和W的金刚石表面都形成致密、均匀的组织,满足后续制备高导热复合材料要求。

(4) 在真空环境下进行热处理,磁控溅射Mo的金刚石界面相组成主要是金刚石、石墨、Mo和Mo2C,磁控溅射W的金刚石界面相组成主要是金刚石、石墨、W、W2C和WC,不同温度下相组成不同,但是易于出现石墨化现象。而在Ar气氛下进行1000℃热处理后,磁控溅射Mo和W的金刚石表面形成MCx和WCx相。

(5) 在Ar气氛,950℃热处理后磁控溅射Mo的金刚石颗粒获得合适的镀覆效果,而磁控溅射W的金刚石颗粒在Ar气氛,1000℃热处理后获得合适的镀覆效果。

REFERENCES

[1] MOUSAVI S L, NAGHSHEHKESH N, AMIRNEJAD M, et al. Corrosion performance and tribological behavior of diamond-like carbon based coating applied on Ni-Al-bronze alloy [J]. Transactions of Nonferrous Metals Society of China, 2021, 31: 499-511.

[2] 方俊晓,陈庆军,高霁雯, 等. 掺杂Fe 基非晶合金调控Ni-金刚石/Al复合材料的导热性能[J]. 中国有色金属学报, 2021, 31(3):565-577.

FANG Jun-xiao, CHEN Qing-jun, GAO Wen-wen, et al. Control of thermal conductivity of Ni-Diamond/Al composite by doping Fe-based amorphous alloy [J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3):565-577.

[3] WANG C, TANG L, WANG H.Vibration Fracture Mechanism and Optimization Design of Array Power Supply for Near-Space SAR[J]. Shock and Vibration, 2020, 4917406.

[4] REN S, CHEN J, HE X, et al. Effect of matrix-alloying-element chromium on the microstructure and properties of graphite flakes/copper composites fabricated by hot pressing sintering[J]. Carbon 2018,127: 412-423.

[5] WANG C C, WANG X C, SUN F H. Fabrication and application of nano/microcrystalline composite diamond coated drawing dies using alternative carbon sources [J]. Transactions of Nonferrous Metals Society of China, 2018, 28(8):1602-1610.

[6] AN Z, XIONG D, FAN G, et al. Enhanced thermal conductivity of diamond/aluminum composites through tuning diamond particle dispersion[J]. Journal of Materials Science, 2018,53:6602-6612.

[7] ROSINSKI M, CIUPINSKI L, GRZONKA J, et al. Synthesis and characterization of the diamond/copper composites produced by the pulse plasma sintering (PPS) method[J]. Diamond & Related Materials, 2012,27-28:29-35.

[8] SOMMERS A, WANG Q, HAN X, et al. Ceramics and ceramic matrix composites for heat exchangers in advanced thermal systems-a review[J]. Applied Thermal Engineering. 2010,30:1277-1291.

[9] BEFFORT O, KHALID F, WEBER L, et al. Interface formation in infiltrated Al(Si)/diamond composites[J]. Diamond & Related Materials, 2006, 15:1250-1260.

[10] MIZUUCHI K, INOUE K, AGARI Y, et al. Processing of diamond-particle-dispersed silver-matrix composites in solid-liquid co-existent state by SPS and their thermal conductivity[J]. Composites Part B-Engineering. 2012,43:1445-1452.

[11] Zhang H, QI Y, LI J, et al. Effect of Zr content on mechanical properties of diamond/Cu-Zr composites produced by gas pressure infiltration[J]. Journal of Materials Engineering and Performance. 2018,27:714-720.

[12] ANDREY M, MIROSLAW J, Lukasz C, et al. Diamond–tungsten based coating–copper composites with high thermal conductivity produced by Pulse Plasma Sintering[J]. Materials & Design, 2015, 76:97-109.

[13] SHEN B, CHEN S L, SUN F H. Effect of deposition temperature on properties of boron-doped diamond films on tungsten carbide substrate [J]. Transactions of Nonferrous Metals Society of China, 2018,28(4): 729-738.

[14] Raza K, Khalid F. Optimization of sintering parameters for diamond–copper composites in conventional sintering and their thermal conductivity[J]. Journal of Alloys and Compounds, 2014,615:111-118.

[15] KITIWAN M, KATSUI H, GOTO T. Spark plasma sintering of SiC-coated large-size diamond powder[J]. Materials Today: Proceedings, 2017, 4:11453-11456.

[16] NUNES D, CORREIA J B, CARVALHO P A, et al. Production of Cu/diamond composites for first-wall heat sinks[J]. Fusion Engineering and Design, 2011,86: 2589-2592.

[17] KANG Q, He X, Ren S, et al. Preparation of copperediamond composites with chromium carbide coatings on diamond particles for heat sink applications[J]. Applied Thermal Engineering, 2013, 60 :423-429.

[18] BAI H, DAI D, YU J, et al. Architecting boron nanostructure on the diamond particle surface[J]. Applied Surface Science, 2014, 292(15):790-794.

[19] UKHINA A, BOKHONOV B, SAMOSHKIN D, et al. Morphological features of W- and Ni-containing coatings on diamond crystals and properties of diamond-copper composites obtained by Spark Plasma Sintering. Materials Today: Proceedings. 2017,4(11): 11396-11401.

[20] WU Y P, SUN Y N, LUO J B , et al. Microstructure of Cu-diamond composites with near-perfect interfaces prepared via electroplating and its thermal properties. Materials Characterization. 2019,150: 199-206.

[21] CHE Q L, CHEN X K, JI Y Q, et al. The influence of minor titanium addition on thermal properties of diamond/copper composites via in situ reactive sintering. Materials Science in Semiconductor Processing. 2015,30:104-111.

[22] 马如龙, 彭超群, 王日初, 等. Cu-金刚石复合镀层的制备[J]. 中国有色金属学报, 2015,25(12):3414-3421.

MA Ru-long, PENG Chao-qun, WANG Ri-chu, et al. Preparation of Cu-diamond composite coating by composite electroplating [J]. The Chinese Journal of Nonferrous Metals, 2015,25(12):3414-3421.

[23] SANG J, Yang W, ZHU J, et al. Regulating interface adhesion and enhancing thermal conductivity of diamond/copper composites by ion beam bombardment and following surface metallization pretreatment[J]. Journal of Alloys and Compounds, 2018,740:1060-1066.

[24] JIA J, BAI S, XIONG D, et al. Effect of tungsten based coating characteristics on microstructure and thermal conductivity of diamond/Cu composites prepared by pressueless infiltration[J]. Ceramics International, 2019,45:10810-10818.

[25] XIN L, TIAN X, YANG W, et al. Enhanced stability of the Diamond/Al composites by W coatings prepared by the magnetron sputtering method[J]. Journal of Alloys and Compounds, 2018,763:305-313.

[26] 郭晓光, 刘涛, 翟昌恒, 等. 过渡金属作用下的金刚石石墨化机理研究[J]. 机械工程学报, 2016, 52(20):23-29.

GUO Xiaoguang, LIU Tao, ZHAI Changheng, et al. Study on the Mechanism of Diamond Graphite with the Action of Transition Metals[J]. Journal of Mechanical Engineering, 2016, 52(20):23-29.

[27] Zhang C, Cai Z Y, Wang R C, et al. Microstructure and thermal properties of Al/W-coated diamond composites prepared by powder metallurgy[J]. Materials & Design,

2016, 95:39-47.

[28] Zhang H, Zhang J, Liu Y, et al. Unveiling the interfacial configuration in diamond/Cu composites by using statistical analysis of metallized diamond surface. Scripta Materialia,2018, 152:84-88.

[29] Chang G, Sun F, Duan J, et al. Effect of Ti interlayer on interfacial thermal conductance between Cu and diamond. Acta Materialia, 2018, 160:235-246.

[30] 曾婧, 彭超群, 王日初, 等. 电子封装用金属基复合材料的研究进展. 中国有色金属学报, 2015,25(12):3255-3270.

ZENG Jing, PENG Chao-qun, WANG Ri-chu, et al. Research and development of metal matrix composites for electronic packaging [J]. The Chinese Journal of Nonferrous Metals, 2015,25(12): 3255-3270.

[31] SANG J, ZHOU L, YANG W, et al. Enhanced thermal conductivity of copper/diamond composites by fine- regulating microstructure of interfacial tungsten buffer layer [J]. Journal of Alloys and Compounds, 2021,856:157440.

[32] 卢金斌,贺亚,张旺玺, 等. Ni-Cr-B-Si+Cu-P-Sn 复合钎料真空钎焊金刚石. 中国有色金属学报, 2015,25(12):3255-3270.

LU Jin-bin, HE Ya, ZHANG Wang-xi, et al. Vacuum brazing diamond with Ni-Cr-B-Si+Cu-P-Sn composite filler metal [J]. The Chinese Journal of Nonferrous Metals, 2016,26(3): 610-615.

[33] PAN Y, HE X, REN S, et al. Optimized thermal conductivity of diamond/Cu composite prepared with tungsten-copper-coated diamond particles by vacuum sintering technique[J]. Vacuum, 2018,153:74–81.

[34] Li J, Zhang Y, Zhang H, et al. The thermal cycling reliability of copper pillar solder bump in flip chip via thermal compression bonding[J]. Microelectronics Reliability, 2020,104:13543.

[35] KANG Q, HE X, REN S, et al. Effect of molybdenum carbide intermediate layers on thermal properties of copper–diamond composites[J]. Journal of Alloys and Compounds ,2013,576:380–385.

[36] LEI L, SU Y, BOLZONI L, et al. Evaluation on the interface characteristics, thermal conductivity, and annealing effect of a hot-forged Cu-Ti/diamond composite[J]. Journal of Materials Science & Technology, 2020,49:7–14.

[37] JIA L, LI C, ZHAO Y, et al. Interfacial engineering of Mo2C–Mo3C2 heteronanowires for high performance hydrogen evolution reactions[J]. Nanoscale, 2019,11: 23318.

Magnetron sputtering coating and heat treatment process of diamond copper particles

WANG Chang-rui1, 2, TIAN Wei1, HU Jun-shan1, LI Bo1, LI Peng-cheng1, LIN Tie-song2, LIAO Wen-he1

(1. National Key Laboratory of Science and Technology on Helicopter Transmission, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

2. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The surface coating and heat treatment of diamond particles can solve the problem of high performance interface wetting and combination of high thermal conductivity diamond/copper composites. In this paper, the effects of magnetron sputtering surface coating modified metals Mo and W and different heat treatment processes on the weight, surface morphology, microstructure and composition of coated diamond particles are studied. The results show that Mo coating presents wheat grain structure after magnetron sputtering, while W coating has spherical structure; In vacuum environment, with the increase of heat treatment temperature, the sublimation rate of Mo or W will be accelerated, and graphitization will occur on the surface of diamond particles when exposed to the environment of heat treatment. After heat treatment in Ar environment, at 900 ℃ Mo or W phase still remains, and graphitization occurs when the temperature rises to 950 ℃. However, dense MoCx and WCx phases are formed when the heat treatment temperature is 1000 ℃. The graphitization phenomenon is eliminated and a good heat treatment interface is obtained, which lays a foundation for obtaining diamond copper composites with good thermal conductivity.

Key words: Diamond/ copper composites;Heat treatment process;Microstructure;Diamond graphite;Phase composition

Foundation item: Project(52075250) supported by tthe National Natural Science Foundation of China, Project (AWJ-22M13) supported by State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Project (2020M683376) supported by the China Postdoctoral Science Foundation.

Received date: 2021-07-17

Corresponding author: TIAN Wei; Tel: +86-13851662331; E-mail: tw_nj@nuaa.edu.cn

基金项目:国家自然科学基金(52075250); 先进焊接与连接国家重点实验室开放课题研究基金(AWJ-22M13); 中国博士后科学基金(2020M683376)

收稿日期:2021-07-17

通信作者:田威,教授,博士;电话:13851662331;E-mail:tw_nj@nuaa.edu.cn