DOI: 10.11817/j.issn.1672-7207.2015.04.002

环冷机偏析布料研究

田万一1, 2,张家元 1,戴传德2,张小辉3,王建平2

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 中冶长天国际工程有限公司,湖南 长沙,410007;

3. 昆明理工大学 冶金与能源工程学院,云南 昆明,650093)

摘要:以提高环冷机的余热利用量为目标,对环冷机的布料工艺进行优化研究,并研制实现新型布料工艺的设备。基于多孔介质模型和局部非热平衡双能量方程模型建立环冷机内烧结矿冷却过程的仿真模型,利用该仿真模型对环冷机不同分层布料工况下烧结矿冷却过程进行数值仿真试验研究。研究结果表明:按粒径由料面至底部为“中—小—大”分布的工况余热利用量最大,比常规工况提高14.05%。以此工况条件下台车内料层分布状态为理想目标布料状态,着手进行偏析布料斗的设计研发,并且对研制的偏析布料斗进行半工业化试验研究。偏析布料斗在环冷机布料过程中具有较好的偏析布料效果,并且偏析布料状态为理想目标布料状态。

关键词:环冷机;余热利用;数值仿真;偏析布料

中图分类号:TF046.4;TK11+5 文献标志码:A 文章编号:1672-7207(2015)04-1182-07

Segregation feeding on sinter circular cooler

TIAN Wanyi1, 2, ZHANG Jiayuan1, DAI Chuande2, ZHANG Xiaohui3, WANG Jianping2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Zhongyechangtian International Engineering Co. Ltd., Changsha 410007, China;

3. Faculty of Metallurgical and Energy Engineering,

Kunming University of Science and Technology, Kunming 650093, China)

Abstract: To improve waste heat utilization of circular cooler, the optimization research of loading process was studies, and the equipment of the new type loading process was made. A numerical model was developed on the basis of porous medium model and local non-equilibrium thermodynamics model, and the numerical simulation of sinter cooling process with different layer-loadings on segregation feeding was carried out. The results show that the waste heat utilization is the largest when the distribution of particle size is “middle—small—big” (from surface to bottom of sintered bed),this is the optimal condition, and the waste heat utilization is 14.05% larger than that of the normal condition. The design and experimental of segregation feeding chute were based on the optimal condition. The segregation feeding chute plays a good segregation effect on loading process, whose segregation status is the target segregation status.

Key words: sinter circular cooler; waste heat utilization; numerical simulation; segregation feeding

烧结工序能耗在钢铁企业中是仅次于炼铁的第二大耗能工序,环式冷却机(环冷机)由于具有连续作业性好、效率高等特点被广泛应用于烧结矿冷却过程,而该过程中产生的废气余热占烧结工序能耗的19%~35%[1]。因此,在保证烧结矿冷却效果的前提下,如何提高环冷机的余热回收利用率是科技工作者关注的焦点[2-5],现代烧结系统也越来越多地考虑了对烧结矿冷却过程的余热利用[6-7]。理论研究和工程实践表明,环冷机的运行和操作参数对烧结矿的冷却及环冷机废气的余热利用有重要影响[8-10],而这些参数的形成会受到布料方式的影响。传统均匀给料斗与环冷机台车形成垂直交料关系,但由于环冷机台车内外侧线速度不一致,烧结矿的粒径不一,在自然堆积过程中会形成不均匀布料,导致环冷机台车内烧结矿在不同的区域和高度上的孔隙率和粒度出现不同的分布情况,从而影响烧结矿的冷却过程和对废气的余热利用。对烧结矿进行分层布料以及相应的偏析布料技术的开发能改善和优化环冷机操作参数[11],因此,为研究不同操作参数对烧结矿冷却过程和废气余热利用的影响,以及根据烧结机破碎筛分粒径对烧结矿的分层分布偏析布料进行研究。本文基于某钢铁公司360 m2烧结机和配套的396 m2环冷机,对烧结矿冷却过程建立数学模型,按烧结机破碎筛分后的粒径统计进行分层布料数值仿真,并进行与分层分布最优参数相适应的偏析布料试验研究,设计和开发偏析布料斗。

1 计算模型

1.1 物理模型

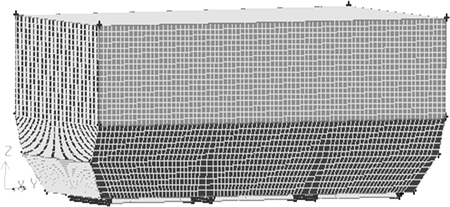

对某钢铁企业396 m2环冷机的余热利用区进行分析。根据台车几何尺寸建立物理模型,考虑到对分层布料的仿真计算,将台车在高度方向上划分为上、中、下3层,每层的高度按照烧结矿破碎筛分后的粒径统计确定。对整个计算区域采用结构化网格划分,对流动换热较强、梯度较大的区域采用网格加密,网格系统如图1所示。

对台车的运行和流动、换热过程进行以下假设:

1) 环冷机运行工况稳定,各操作参数均为恒定值;

2) 忽略烧结矿颗粒间、气体内部的辐射换热;

3) 烧结矿颗粒内外温度一致,内部无温度梯度。

图1 环冷机台车网格系统

Fig. 1 Grid of sinter cooler trolley

1.2 数学模型

环冷机台车内的烧结矿块(颗粒)形状极不规则,粒径不同,气流在台车内的流动和换热过程非常复杂,难以对其进行精确的数学描述和仿真计算,对流动和换热按照颗粒粒径的统计平均化处理是目前常用的方法[12-13]。在这种处理方式下,烧结块可视为多孔介 质[14]。在多孔介质条件下,气体流过烧结矿产生的黏膜性阻力系数(α)与惯性阻力系数(C2)在多孔介质条件下可用Ergun方程计算[15-16]:

(1)

(1)

(2)

(2)

式中:f为孔隙率;dp为烧结矿粒径,m。由于在烧结矿冷却过程中,气体和固体之间始终存在温度差,故对台车内气、固换热采用局部非热力学平衡双能量方程模型[17-19]。对烧结矿固体床层和冷却空气分别建立能量方程。

固相:

(3)

(3)

气相:

(4)

(4)

式中:ρs,ρf为固相和气相的密度,kg/m3;cs为固相比热,J/kg;cpf为气相的比定压热容,J/kg;λs和λf分别为固相和气相的导热系数,W/(m·K);Ts和Tf分别为固相和气相温度,K;hv为固相和气相间的单位体积对流换热系数,J/(m3·s·K); 和

和 分别为固相和气相的产生热,W/m3;下标s为固相,f为气相。

分别为固相和气相的产生热,W/m3;下标s为固相,f为气相。

基于流体动力学计算软件FLUENT进行仿真计算。对于气体在烧结矿床层中的湍流流动采用标准k-ε湍流模型计算;对压力-速度耦合采用SIMPLE算法;对湍动能、湍流耗散率的离散采用二阶迎风格式;对Ts和Tf采用自定义标量(UDS)进行定义;对能量方程的非稳态项、源项采用自定义函数(UDF)进行定义。

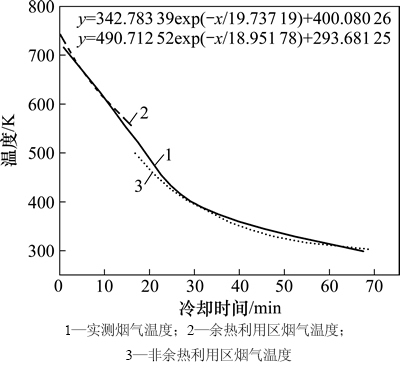

1.3 模型验证

图2所示为利用上述模型对环冷机冷却过程进行仿真,通过origin软件对仿真和实测试验数据进行拟合得到的出口截面空气温度随冷却时间的变化拟合曲线。从图2可以看出:仿真结果与实测试验结果拟合较好。

图2 出口截面上烟气平均温度与冷却时间的关系

Fig. 2 Relationship between cross-section average flue gas temperature in outlet and cooling time

2 分层布料仿真

2.1 初始条件与分层布料工况

所计算的区域位于余热利用区,对于入口,采用速度入口边界,速度根据流量计算,入口风温为404 K;根据测试得到台车挡板的热流密度为436 W/m2,出口相对压力为0。

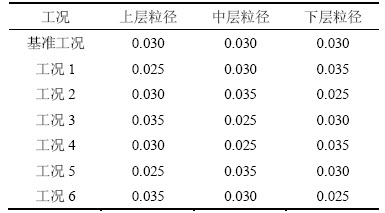

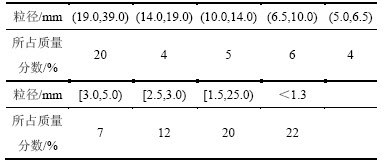

以均匀布料时的工况作为基准工况,根据烧结矿破碎筛分后的粒径统计确定3层高度,在不改变料层孔隙率和冷却气体流量的情况下,3种粒径不同的分布共有6种工况,如表1所示。其中料层孔隙率为0.4,料层总厚度为1.4 m,入口气体流量为650 000 m3/h。

2.2 计算结果及分析

经过计算得到各工况的出口风温如表2所示。针对各工况的余热利用量进行对比分析。余热利用量为在一定气体流量条件下出口气流与入口气流的热值之差。各工况的余热利用量如表2所示。

由表2可知:按照不同粒径进行分层布料的各种工况下,环冷机台车出口风温和余热利用量比基准工况下均有所提高;余热利用区的出口风温越高,说明在相同的时间内气流从料层内带走的热量越多,料层的降温速度越快,环冷机生产效率也越高,其中按下层最大粒径、中层最小粒径的布料方式的出口风温最高,余热利用量最大,相对于基准工况提高了14.05%。因此,本文以该种布料方式为目标布料方式,设计开发出偏析布料斗,并进行试验研究。

表1 分层布料计算工况

Table 1 Simulation condition of layered-feeding m

3 偏析布料试验研究

前述数值仿真试验结果证明:环冷机最佳的料层分布状态为粒径大的烧结矿布置在台车底部,粒径小的布置在台车在中部,粒径中等的布置在台车顶部,即为目标分布状态。要使环冷机布料后台车内烧结矿料层分布为目标分布状态,则需要相应的布料设备,设备要具有几个特点:1) 布料设备具有偏析功能;2) 料层分布状态为目标分布状态;3) 布料设备结构简单、性能可靠。偏析布料斗的开发针对上述特点进行,其中上述前2个特点是关键,偏析布料斗的偏析性能决定了分层布料的状态和效果。

3.1 偏析布料斗工作原理

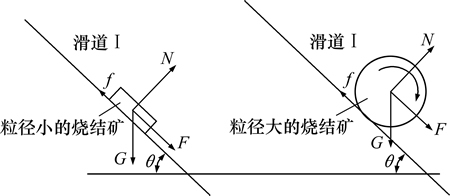

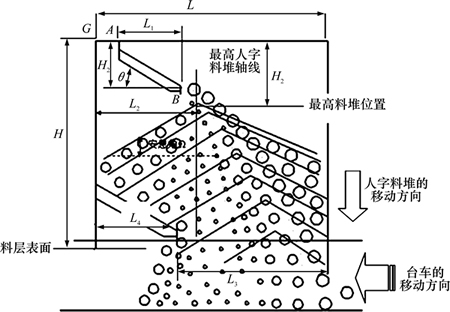

偏析布料斗是利用不同粒径烧结矿在布料过程中的运动方式和速度的不一致性以及料堆在堆积过程中堆积规律来实现偏析布料功能的,并且使偏析布料后的烧结矿分布状态为目标分布状态。

表2 出口风温和余热利用量

Table 2 Outlet air temperature and waste heat utilization

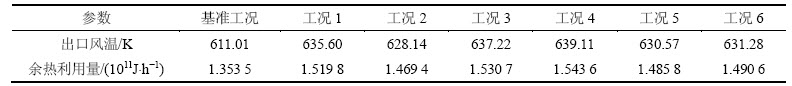

图3所示为烧结矿受力分析图,图4所示为偏析布料斗的截面图。烧结矿经入料口进入偏析布料斗后,先进入滑道I。滑道I采用斜板设计,烧结矿在重力作用下下滑并逐渐加速离开滑道I,在这个过程中,粒径不同的烧结矿运动状态不同。在不考虑烧结矿颗粒随机碰撞的条件下,烧结矿从偏析布料斗入料口进入滑道I直至离开滑道I过程中,烧结矿的受力分析如图3所示。对粒径不同的烧结矿进行受力分析,在重力G和滑道I支承力作用下,烧结矿产生1个沿着滑道I平面向下的分力F,粒径小的烧结矿形状一般呈片状、盘状和针状等,当其受到的向下分力大于摩擦阻力f时,烧结矿将发生向下的滑动,设摩擦系数为μ1;粒径较大的烧结矿形状一般为球状或接近于球状,在重力、支承力和摩擦力的共同作用下,不仅产生了1个向下的滑动力F,同时也产生1个向下的较大转矩M,使粒径大的烧结矿向下滚动。可见:粒径大的烧结矿的运动状态是以滚动运动为主;同时伴有部分滑动运动,是一种混合运动,设其当量摩擦因数为μ2,则有μ2<μ1。

图3 烧结矿受力分析

Fig. 3 Force analysis of sinter

图4 烧结矿偏析形成过程

Fig. 4 Process of sinter segregation

当烧结矿运动至滑道I的末端也就是图4中的B点处时,根据能量守恒原理则,有

(5)

(5)

其中:

(6)

(6)

式中:vB为滑道Ⅰ末端B点的速度,m/s;vA为滑道Ⅰ入口的A点的速度,m/s;H1为滑道Ⅰ的垂直高度,m;m为烧结矿自身的质量,kg;μ为滑道Ⅰ与烧结矿的摩擦因数;θ为滑道Ⅰ与水平面夹角。

由(5)式可知:由于进入滑道时烧结矿速度vA是相同的,故烧结矿在离开滑道I末端时的速度取决于烧结矿与滑道I的摩擦因数μ;烧结矿的速度vB随摩擦因数μ的增大而减小,并且呈线性关系。由于粒径大的烧结矿呈混合运动状态,故其当量摩擦因数μ2将远小于粒径小的烧结矿纯滑动状态的摩擦因数μ1,粒径越大的烧结矿到达B点时的速度越大。

烧结矿在脱离滑道I后将作抛物线运动,由于烧结矿在B点初速度不同,故形成了不同的颗粒流线轨迹,即粒径较大的烧结矿落在较远处,粒径较小的烧结矿落在较近处,形成物料堆按粒径前大后小的现象;随着人字形烧结矿堆高度逐渐增加,烧结矿堆的顶点逐渐左移,直到烧结矿堆达到最大高度,在这个过程中,烧结矿将从烧结矿堆顶端不断的落到偏析布料斗内没烧结矿的区域。与滑道I的受力状态相似,烧结矿不同颗粒粒径物料在烧结矿堆上的运动状态同样不同,在烧结矿堆逐渐升高的过程中,粒径大的烧结矿将从烧结矿堆的顶部滚落,而粒径小的烧结矿只能逐渐滑动下落。当烧结矿料堆达到一定高度时,粒径大的烧结矿被抛到了离滑道I最远的一侧,而粒径中等和粒径小的烧结矿由于其初始速度不足够大,将不能被抛到图4中烧结矿堆右边,粒径中等的烧结将滚落到图中偏析布料斗的最左边区域,这样就形成了烧结矿堆右侧以粒径大的烧结矿为主,左侧以粒径中等的烧结矿为主,粒径小的烧结矿分布在偏析布料斗的中间区域的偏析效果。

在“人”字堆形成之前,由于没有“人”字烧结矿堆的阻挡,粒径中等的烧结矿不会滚落到图中偏析布料斗的左边,所以,偏析布料斗内不会有目标理想效果。

当“人”字形烧结矿堆形成后,烧结矿不断从滑道I滑落,同时台车沿图示方向移动,偏析料斗中的烧结矿将按从右到左的顺序依次进入环冷机台车内部,从而形成了“下层粒径大-中层粒径小-上层粒径中等”的料层断面结构。在正常情况下,环冷机是在人字堆形成后连续运行的。

3.2 试验方案及结果分析

偏析布料斗在投入工业化生产试验之前,对偏析布料斗进行半工业化试验,验证其实际使用的偏析效果。

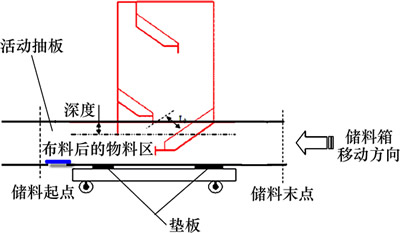

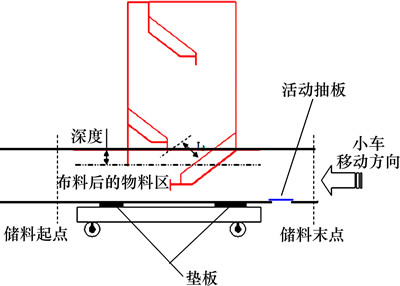

如图4所示,利用相似原理,试验设备的尺寸按实际工业化生产用偏析布料斗尺寸的1/4设计制造,料斗容积为1.35 m3。偏析布料斗通过挂耳安装在立架上,烧结矿储料箱置于移动的平板车上,两者组成模拟环冷机运行过程中的台车,平板车可在钢轨上自由移动。在立架上搭建操作平台和起吊料箱支架,支架上和起吊箱上的孔套通过活动销轴连接实现起吊箱的前端翻转,利用吊车吊起料箱后端吊钩可将矿料沿入料口倾入,这样模拟烧结矿进入偏析布料斗的过程。烧结矿储料箱底部设置活动抽板,抽开活动板后,抽板上部的物料将被放空,从而在其两侧形成物料断层。此断层展示的即为偏析布料断面,通过观察断面物料粒径的分布情况可判断料斗偏析布料效果。试验所用物料为工业生产用烧结矿,烧结矿温度为常温,烧结矿经过筛分取样统计,烧结的粒度组成如表3所示。

表3 物料的粒度dp组成

Table 3 Gradation composition of materials

试验方案是根据前述偏析布料斗“人”字堆形成前后具有不同偏析效果来拟定的。试验分2部分,分别模拟“人”字烧结矿堆形成之前和形成之后偏析布料斗在环冷机台车内的布料情况。

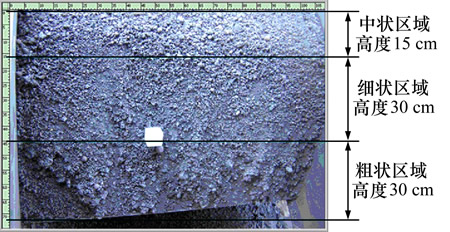

试验一的操作示意图如图5所示。试验的主要目的是考察在形成最高“人”字形烧结矿堆前偏析布料斗内的烧结矿在储料箱中的粒径分布情况,具体步骤为:将烧结矿从偏析布料口倒入,物料将落在移动储料箱内,由于物料倒入较少,在偏析布料斗内未形成“人”字形烧结矿堆,检验此时移动储料箱内的烧结矿料层分布情况;当烧结矿倒入后,打开图5中的活动抽板,将会看到移动储料箱内的料层分布情况。图6所示为试验方案一所形成的偏析布料断面图。

由图6可知:在烧结矿没有形成最高“人”字形烧结矿堆之前,其分层效果不理想;在底部“人”字形烧结矿堆的形成过程中,粒径较大的物料从料斗出口后板向下滚动并逐渐堆积,粒径中等的物料直接从料斗出口前板出来并逐渐堆积,而料斗出口的中间位置为细颗粒物料区域;随着“人”字形料堆的高度逐渐增加,储料车起点位置部分区域被物料覆盖,使得物料沿储料车的长度方向从左至右形成了粒径为“中—小—大”的分布状态,而不是沿高度方向从料面到底部形成这样的分布状态,所以,此时还没有达到分层布料的效果,即在布料开始阶段进入储料车的物料不会产生偏析布料的效果。

图5 试验一操作示意图

Fig. 5 Operation diagram of Experimental 1

图6 试验一料层断面图

Fig. 6 Cross section of sintered bed in Experimental 1

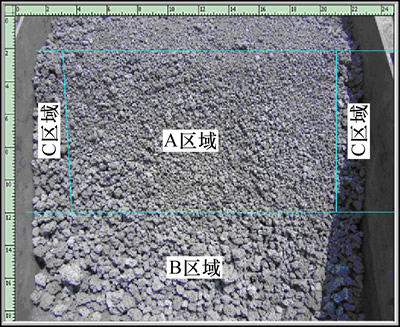

试验方案二的主要目的是考察在形成最高“人”字形烧结矿堆后偏析布料斗中的烧结矿在储料箱中的料层分布情况。由前述分析可知:随着偏析布料斗烧结矿的增加,“人”字形烧结矿堆将逐渐增高;随着入料的继续进行,平板车不断向前推进,此时,会形成稳定的分层布料效果,因此,该试验从储料箱中部开始到活动抽板尾部结束。该方案示意图如图7所示。图8所示为试验方案二所形成的偏析布料断面。

由图8可知:对移动储料箱的烧结矿料层断面进行统计,则烧结矿料层从料面到底部的粒度分布状态为“中—小—大”,比例分别为20%:40%:40%,呈现出一定的偏析效果。但结合表3所示的粒径分布可知:粒径较小的料层高度偏大,即在中间粒径较小的料层中,部分粒径中等和较大的物料混存于其中,没有偏析出来。图9所示为储料箱前部自然安息斜面。

由图9可知:前部B区域主要是粒径较大的烧结矿堆积,含有少部分粒径中等的烧结矿,C区域是粒径较大和中等的烧结矿堆积,A区域主要是粒径中等与较小的烧结矿堆积,表层主要是粒径中等的烧结矿堆积;另一方面,考虑到安息角的影响,A区域和C区域的物料会逐渐滚落到底部B区域,故此图中A区域以粒径较小的烧结矿为主是正常现象。

图7 试验二操作示意图

Fig. 7 Operation diagram of Experimental 1

图8 试验二料层断面图

Fig. 8 Cross section of sintered bed in Experimental 2

图9 试验二储料箱前部自然安息斜面

Fig. 9 Nature repose slope in front of sintered bed in Experimental 2

从试验结果可以看出:偏析布料斗在其内部“人”字形烧结矿堆形成后也就是环冷机正常运行状态的情况下具有较好的偏析效果,并且其偏析形成的分层布料状态为目标布料状态,即前述仿真试验中最优工况下的布料状态。

4 结论

1) 基于多孔介质模型和双能量方程模型建立了烧结矿冷却过程的数学模型,通过对其仿真结果与测试结果的比较证明了其合理性。利用该模型对基准工况和各种分层布料工况进行仿真试验研究,发现分层布料工况下余热利用量比基准工况的大,其中按粒径分布状态为从料面到底部为“中—小—大”的工况余热利用量最大,比基准工况提高了14.05%。

2) 利用物料运动特性和动力特性确定偏析布料斗的偏析原理,在此基础上开发出偏析布料斗,使其具有偏析分层布料效果,并且分层布料状态为目标布料状态即最优布料状态。对偏析布料斗进行了半工业化试验,证明偏析布料斗在环冷机正常运行的情况下具有较好的偏析分层布料功能,能够实现环冷机台车内部“中—小—大”的偏析分层布料目标。

参考文献:

[1] 张欣, 温治, 娄国锋, 等.高温烧结矿气-固换热过程数值模拟及参数分析[J]. 北京科技大学学报, 2011, 33(3): 339-345.

ZHANG Xin, WEN Zhi, LOU Guofeng, et al. Numerical simulation and parameters analysis on the gas-solid heat transfer process of high temperature sinter[J]. Journal of University of Science and Technology Beijing, 2011, 33(3): 339-345.

[2] 冀留庆, 林学良. 烧结机废气余热利用[J]. 工业安全与环保, 2009, 35(12): 16-17.

JI Liuqing, LIN Xueliang. Waste gas recovery of sintering machine[J]. Industrial Safety and Environmental Protection, 2009, 35(12): 16-17.

[3] 张春霞, 齐渊洪, 严定鎏, 等. 中国炼铁系统的节能与环境保护[J]. 钢铁, 2006, 41(11): 1-5.

ZHANG Chunxia, QI Yuanhong, YAN Dingliu, et al. Energy-saving and environmental protection of ironmaking system in China[J]. Iron and Steel, 2006, 41(11): 1-5.

[4] 叶匡吾. 我国烧结能耗现状和节能对策[J]. 烧结球团, 1997, 22(5): 11-12.

YE Kuangwu. Significance of energy saving of sintering and technical measures[J]. Sintering and Pelletizing, 1997, 22(5): 11-12.

[5] Caputo A C, Cardarelli G, Pelagagge P M. Analysis of heat recovery in gas-solid moving beds using a simulation approach[J]. Applied Thermal Engineering, 1996, 16(1): 89-99.

[6] 蔡九菊, 董辉, 杜涛, 等. 烧结过程余热资源分级回收与梯级利用研究[J]. 钢铁, 2011, 46(4): 88-92.

CAI Jiuju, DONG Hui, DU Tao, et al. Study on grade recovery and cascade utilization of waste heat from sintering-cooling process[J]. Iron and Steel, 2011, 46(4): 88-92.

[7] ZHANG Xiaohui, CHEN Zhuo, ZHANG Jiayuan, et al. Simulation and optimization of waste heat recovery in sinter cooling process[J]. Applied Thermal Engineering, 2013, 54(1): 7-15.

[8] 董辉, 力杰, 罗远秋, 等. 烧结矿冷却过程的实验研究[J]. 东北大学学报(自然科学版), 2010, 31(5): 689-692.

DONG Hui, LI Jie, LUO Yuanqiu, et al. Experimental study on cooling process of sinter[J]. Journal of Northeastern University (Natural Science), 2010, 31(5): 689-692.

[9] 潘鹤, 金永龙, 马洛文, 等. 冷却制度对烧结矿性能的影响[J]. 钢铁, 2007, 42(11): 5-8.

PAN He, JIN Yonglong, MA Luowen, et al. Study of influence of cooling conditions on properties of sinters[J]. Iron and Steel, 2007, 42(11): 5-8.

[10] Leong J C, Jin K W, Shaiu J S, et al. Effect of sinter layer porosity distribution on flow and temperature fields in a sinter cooler[J]. International Journal of Minerals, Metallurgy and Materials, 2009, 16(3): 265-272.

[11] 周胜良, 刘相佩, 戴传德, 等. 环冷机布料方法及装置: 中国, 201010144395.4[P]. 2010-04-12.

ZHOU Shengliang, LIU Xiangpei, DAI Chuande, et al. Method and apparatus for feeding materials in sinter circular cooler: China, 201010144395.4[P]. 2010-04-12.

[12] Pelagagge P M, Caputo A C, Cardarelli G. Optimization criteria of heat recovery from solid beds[J]. Applied Thermal Engineering, 1997, 17(1): 57-64.

[13] Pelagagge P M, Caputo A C, Cardarelli G. Comparing heat recovery schemes insolid beds cooling[J]. Applied Thermal Engineering, 1997, 17(11): 1045-1054.

[14] Hinkley J, Waters A G, Litster J D. An investigation of pre-ignition air flow in ferrous sintering[J]. International Journal of Mineral Processing, 1994, 42(1/2): 37-52.

[15] 张小辉, 张家元, 戴传德, 等. 烧结矿冷却过程数值仿真与优化研究[J]. 化工学报, 2011, 62(11): 3081-3087.

ZHANG Xiaohui, ZHANG Jiayuan, DAI Chuande, et al. Optimal and simulation of sinter cooling process[J]. CIESC Journal, 2011, 62(11): 3081-3087.

[16] 刘伟, 范爱武, 黄晓明. 多孔介质传热传质理论与应用[M].北京: 科学出版社, 2006: 28-32.

LIU Wei, FAN Aiwu, HUANG Xiaoming. Porous media theory and application of heat and mass transfer[M]. Beijing: Science Press, 2006: 28-32.

[17] 李菊香, 涂善东. 考虑局部非热平衡的流体层流横掠多孔介质中恒热流平板的传热分析[J]. 化工学报, 2010, 61(1): 10-14.

LI Juxiang, TU Shandong. Heat transfer of laminar flow over a plate embedded in porous medium with a constant heat flux under local non equilibrium condition[J]. CIESC Journal, 2010, 61(1): 10-14.

[18] 陶斌斌, 杨历, 刘春元. 多孔介质干燥的非平衡热力学模型[J]. 河北工业大学学报, 2005, 34(1): 109-112.

TAO Binbin, YANG Li, LIU Chunyuan. Porous Media’s drying model of non-equilibrium thermodynamics[J]. Journal of Hebei University of Technology, 2005, 34(1): 109-112.

[19] Prat M. Recent advances in pore-scale models for drying of porous media[J]. Chemical Engineering Journal, 2002, 86(1/2): 153-164.

(编辑 陈灿华)

收稿日期:2014-05-10;修回日期:2014-07-23

基金项目(Foundation item):国家重大产业技术开发专项基金资助项目([2009]1717)(Project ([2009]1717) supported by the National Major Industrial Technology Development Special Fund)

通信作者:张家元,博士,教授,从事钢铁冶金过程节能研究;E-mail:zjyzhq@csu.edu.cn