文章编号:1004-0609(2015)02-0423-07

多弧离子镀制备的CrCN涂层组织及摩擦磨损性能

陈 颢1, 2,叶育伟1, 3,王永欣3,李金龙3,羊建高2

(1. 江西理工大学 材料科学与工程学院,赣州 341000;

2. 江西理工大学 钨资源高效开发及应用技术教育部工程研究中心,赣州 341000;

3. 中国科学院 宁波材料技术与工程研究所 海洋新材料与应用技术重点实验室,宁波 315201)

摘 要:采用多弧离子镀技术在硅片和316L不锈钢上制备了CrN和CrCN涂层,利用扫描电镜(SEM)、电子能谱(EDS)、透射电镜(TEM)、X射线光电子能谱仪(XPS)对其表面形貌及成分进行表征,采用纳米压痕仪、划痕测试仪及摩擦磨损试验机测试涂层力学及摩擦学性能,观察试样磨损形貌,并分析其磨损机理。结果表明:较之于CrN涂层,所制备的CrCN涂层具有更均匀、致密的结构,与基体结合良好;涂层主要成分为Cr、C和N,其中C元素主要以sp2、sp3和C—Cr键的形式存在;CrCN涂层中由于强化相Cr7C3的产生和杂化C的形成等多种强化作用,显著提高了其硬度和耐摩擦磨损性能。

关键词:CrCN涂层;CrN涂层;显微组织;硬度;摩擦;磨损性能

中图分类号:TG146.1 文献标志码:A

Microstructure and tribological properties of CrCN coating prepared by arc ion plating

CHEN Hao1, 2, YE Yu-wei1, 3, WANG Yong-xin3, LI Jing-long3, YANG Jian-gao2

(1. School of Materials Science and Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. Engineering Research Center of High-efficiency Development and Application Technology of Tungsten Resources, Ministry of Education, Jiangxi University of Science and Technology, Ganzhou 341000, China;

3. Key Laboratory of Marine New Materials and Related Technology,

Ningbo Institute of Material Technology and Engineering, Chinese Academy of Sciences, Ningbo 315201, China)

Abstract: CrN and CrCN coating were prepared on single crystal Si and 316L stainless steel by arc ion plating. The surface morphology, microstructures, phase compositions and performance of the CrCN coating were characterized by SEM, EDS TEM, XRD, XPS, EDS, nanoindentation, scratch test and wear tester. The surface morphologies after wear were observed and the wear mechanism was discussed. The results show that CrCN coating has obvious flaws and better bond with the matrix than CrN coating. The composition of CrCN coating mainly contains Cr, C and N. sp2, sp3 and Cr—C bonds dominate in the carbon bonding. Because of the reinforced Cr7C3 particulate and the formation of hybrid carbon, the hardness, tribological properties and wear resistant of CrCN coating can be enhanced.

Key words: CrCN coating; CrN coating; microstructure; hardness; wear; tribological property

水环境中机械系统的关键摩擦副零部件同时承受摩擦和腐蚀的损伤,从而易引起零部件过早失效,然而,一些海洋设备中的关键摩擦零部件,如泵液压系统阀齿轮轴及螺旋桨必须直接用海水润滑[1-3]。恶劣的使用环境对摩擦零部件提出了严峻的挑战。因此,解决海洋摩擦零部件的摩擦学问题成为当务之急。在众多的硬质涂层当中,以Ti和Cr两种金属元素为基础开发的涂层种类最多,且研究最多、应用最广,构成了PVD过渡族元素化合物中最大的两个涂层体系,即Ti基和Cr基涂层体系。其中Cr基涂层因具有硬度高、内应力低、韧性好、耐磨性好、耐腐蚀性好及化学性能稳定等特点,已被运用于切削刀具、模具、汽车、餐具、防腐和装饰等领域[4-7]。其中物理气相沉积(PVD)法制备的CrN涂层因具有良好的结合强度、较高的硬度和较好的热稳定性,常被用于有耐磨要求的工件表面以延长其使用寿命[8-11]。然而,CrN涂层也存在一些缺陷,如在摩擦过程中摩擦因数较大,难以满足精密部件高速运行的工况环境要求[12-13],极大地限制了CrN涂层的应用范围[14]。因此,探讨既能保持CrN涂层的性能优点,又能降低其摩擦因数的研究成为了研究热点。涂层中以石墨结构存在的C元素能明显降低硬质涂层的摩擦因数。当CrN涂层中掺杂入C元素后,形成的CrCN涂层具有更高硬度、更好的耐磨性及耐腐蚀性能[15-17],具有极大的发展潜力。

迄今为止,很多研究者研究过 CrCN 涂层,但大部分研究集中于大气及水环境[18-21],未对其在海水环境下的摩擦学性能进行研究,且缺少对其相应的摩擦磨损机理进行深入探讨。本文作者采用多弧离子镀技术制备出CrN和CrCN涂层,较之于CrN涂层,重点研究了C元素对CrCN涂层组织结构、力学性能及摩擦学性能的影响,并对涂层在不用环境介质下的摩擦磨损机理进行了探讨。

1 实验

1.1 涂层制备工艺及设备

实验采用中科院宁波材料所的Hauzer Flexicoat F850多弧离子镀膜设备,在单晶硅和316L不锈钢基材上分别制备CrN和CrCN涂层。主要制备流程为除油除氧化层→离子清洗→Cr过渡层→CrN→CrCN沉积。

基材单晶硅和316L不锈钢在放入真空镀膜室前先用石油醚除去油脂,再浸泡在丙酮中用超声波清洗,以除去其表面杂质,提供涂层附着强度。镀膜温度为350 ℃,真空度为4×10-5 Pa,用Ar等离子体对基材清洗以清除表面的氧化物及其它污染物;采用高纯铬靶沉积Cr过渡层,以提高涂层与基底之间的结合强度;沉积CrN和CrCN涂层时,氮气流量为400 mL/min,靶电流为60 A,沉积偏压为-130 V。沉积CrCN涂层时,为保证C含量逐渐增加,乙炔流量从5 mL/min逐渐增加到40 mL/min。

1.2 分析及测试手段

样品制备完成后,沿涂层的垂直方向切取截面并制得金相试样,试样经王水深腐蚀后,在AXISUTLTRADLD多功能电子能谱仪、D8 Advance X射线衍射仪、OXFORO-X-Max电子能谱仪(EDS)、Tecnai F20透射电子显微镜、S4800冷场发射扫描电 镜上分析涂层的显微组织和物相组成;利用Revetest划痕测试系统和纳米压痕仪对涂层力学性能进行表征。并采用美国CETR公司生产的UMT-3多功能摩擦磨损试验机进行摩擦实验。d=3 mm的YG-6硬质合金球(94%WC+6%Co(质量分数),硬度约为14 GPa,弹性模量约为650 GPa)作为摩擦配副,在不同环境介质(空气、去离子水、海水)下进行球-盘往复式滑动摩擦。摩擦磨损试验条件如下:载荷5 N、频率5 Hz、时间30 min。

2 结果与分析

2.1 涂层组织及形貌

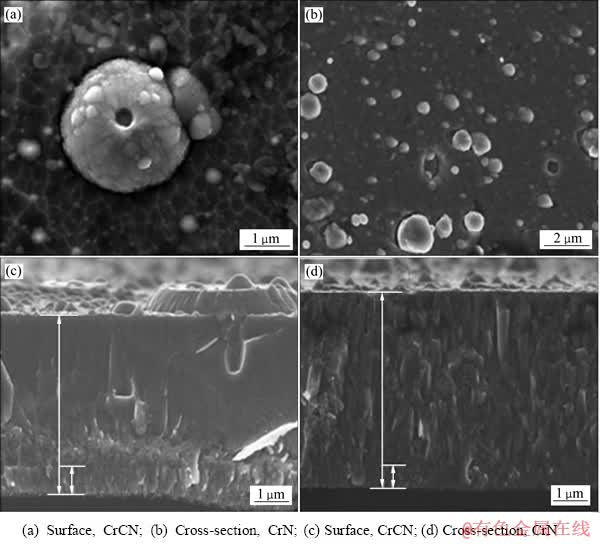

图1所示为在单晶硅上制备的CrN和CrCN涂层的表面和横截面形貌。由图1可见,较之于CrN涂层,均匀沉积的CrCN涂层结构较为致密,无裂纹、气孔等缺陷。两种涂层表面均有典型多弧离子镀涂层所存在的大液滴特征(见图1(a)中白色颗粒);不同之处在于CrCN涂层表面有清晰的网格状结构,这是涂层形成过程中元素偏聚所致。涂层从Cr过渡层到CrCN涂层具有梯度渐变特征(见图1(b)),两种涂层的沉积速率相近,CrCN涂层的整体厚度约为4.13 μm,其中Cr过渡层厚度约为0.648 μm。

图2所示为CrN和CrCN涂层的XRD谱。由图2可知,CrCN涂层中主要有7个衍射峰,分别为在40°附近的CrN(111)、CrN(200)、Cr7C3(421);在60°附近的CrN(220)和 C3N4(311);以及80°附近的CrN(222)和CrN(311)。较之于CrN涂层,CrCN涂层中产生了Cr7C3(421)和C3N4(311)。新相的形成主要是由于CrN中晶格的N或Cr原子被掺入的C原子所取代,形成置换固溶体。而被取代的原子半径与C 原子半径不同,必然会在 C 原子附近局部范围内造成不对称晶格畸变[4],打乱了晶体正常的生长,改变了涂层的择优取向。

图1 CrN和CrCN涂层表面及截面形貌

Fig. 1 Microstructures of surface and cross-section of CrN and CrCN coatings

图2 CrN和CrCN涂层XRD谱

Fig. 2 XRD patterns of CrN and CrCN coating

为探索C元素在CrCN涂层中的存在形式,对CrCN涂层进行XPS测试,其结果如图3所示。由图3(a)可知,涂层主要成分为Cr、C和N。局部检测到微量O,其原因是由于基底表面上存在尚未处理完全的氧化层。在刻蚀期间用Ar轰击涂层表面以及镀膜期间填充了Ar,所以检测到微量的Ar。图3(b)所示为CrCN涂层中C 1s精细峰的Gaussian拟合图,由图3(b)可见,C 1s精细谱有两个明显的谱峰, 其中一个明显谱峰在283 eV附近,经拟合分析后可知,C元素与Cr元素形成一定数量的C—Cr键,结合图2中XRD分析可知,C—Cr键对应的相为Cr7C3。另一个谱峰在285 eV附近,经拟合分析后可知,C元素大部分是以金刚石结构的sp3杂化键和石墨结构的sp2杂化键存在。杂化C的存在阻碍了 CrCN 纳米晶粒的生长,最终使涂层的晶粒尺寸不断减小,在 XRD谱上表现为衍射峰的宽化和弱化。

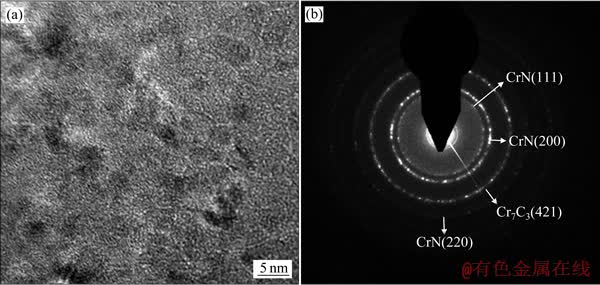

图4所示为CrCN涂层表面的TEM像和选区的电子衍射谱。由图4可见,多弧离子镀CrCN涂层表面晶粒均匀细小,在图4(a)中,清晰可辨的晶格之间夹杂有部分晶格不明显甚至没有晶格的无序组织,说明CrCN涂层内部除细小的多晶晶粒外,还夹杂部分类似非晶的无序结构,有可能在涂层局部形成微区的纳米晶-非晶镶嵌结构,对提高涂层的力学性能有重要意义。在图4(b)中,衍射图谱呈同心圆环,4个较明显的衍射环分别对应CrN(111)、CrN(200)、Cr7C3(421)和CrN(220),与XRD及XPS的分析结果相吻合。

图3 CrCN涂层的XPS谱

Fig. 3 XPS spectra of CrCN coating

图4 CrCN涂层的TEM像和衍射花样

Fig. 4 TEM image(a) and diffraction pattern(b) of CrCN coating

2.2 涂层纳米硬度及结合力

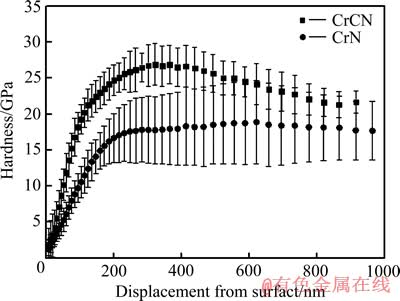

对在316L不锈钢基体上制备的CrN和CrCN涂层硬度进行测量。图5所示为从涂层表面到基体材料的纳米压痕硬度曲线。由图5中的曲线可以看出,在近表面200~400 nm区域存在一个硬度平台区域,该平台区域所对应的硬度为两种涂层的硬度。其中CrN涂层的硬度约为17.5 GPa,CrCN涂层的硬度约为25 GPa。较之于CrN涂层,由于强化相Cr7C3的产生和杂化C的形成等多种强化作用,显著提高了CrCN涂层的硬度。

图5 CrN和CrCN涂层纳米硬度

Fig. 5 Hardness of CrN and CrCN coatings

图6所示为在316L不锈钢基体上制备的CrN和CrCN涂层的结合力及划痕形貌图。从图6可知,由于C元素的掺入,涂层的临界载荷出现小幅上升,较之于CrN涂层声波信号至120 N附近发出明显的声信号,CrCN涂层在130 N附近出现了类似现象,且所对应的划痕形貌开始产生轻微裂纹。临界载荷的提高主要是由于C元素掺入,使得涂层形成致密的微观结构,能有效抑制裂纹的萌生和扩展。

图6 CrN和CrCN涂层的结合力及划痕形貌示意图

Fig. 6 Binding force and scratch morphology of CrN and CrCN coating

2.3 涂层摩擦学性能

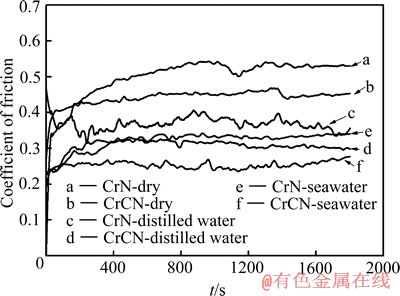

图7所示为316L不锈钢上沉积CrN和CrCN涂层在不同环境(大气、去离子水、海水)下的摩擦因数曲线及磨损率。试验表明:所有测试CrCN涂层均未被磨穿,CrN涂层在大气、去离子水、海水环境中摩擦因数分别为0.52、0.36、0.32; CrCN涂层在大气、去离子水、海水环境中摩擦因数分别为0.45、0.3、0.25。就摩擦介质而言,两种涂层的摩擦因数呈现出相同的变化规律,即在大气、去离子水、海水环境下依次降低。形成此规律的原因在于摩擦过程中去离子水和海水起到润滑剂的作用,显著降低涂层的摩擦因数;较之于去离子水环境,海水中的Ca2+和Mg2+能够在摩擦界面处生成CaCO3和Mg(OH)2,从而达到更好的润滑效果[22]。就两种涂层而言,CrCN涂层在3种摩擦介质下均表现出比CrN涂层较低的摩擦因数。主要原因是由于C元素掺入后在涂层内形成了具有石墨结构的sp2键,在摩擦过程中,能有效地降低摩擦界面的剪切应力,降低摩擦因数。

图7 CrN和CrCN涂层在不同环境下的摩擦因数

Fig. 7 Friction coefficients of CrN and CrCN coating under different environments

图8所示为316L不锈钢上沉积CrN和CrCN膜在不同环境下的磨损率。由图8可知,就两种涂层而言,和摩擦因数的规律相同,即CrCN涂层在3种摩擦介质下均表现出比CrN涂层较低的磨损率。主要原因在于C元素掺入使得涂层结构更致密,硬度增大,不利于裂纹的形成和产生。就摩擦介质而言,两种涂层在大气环境下的磨损率最大,海水环境下的次之,去离子水环境下的最小。在去离子水环境下,由于水的润滑和降温作用,磨损率急剧下降;而在海水环境下,由于海水中Cl-的腐蚀作用,在摩擦过程中容易使涂层新鲜表面暴露出来,加剧磨损,同时引起更多的缺陷,加快腐蚀速率,使得涂层的磨损率高于去离子水环境下的磨损率。综上所述,海水环境下,CrCN较CrN能表现出更好的摩擦学性能。

图8 CrN和CrCN涂层在不同环境下的磨损率

Fig. 8 Wear rates of CrN and CrCN coatings under different environments

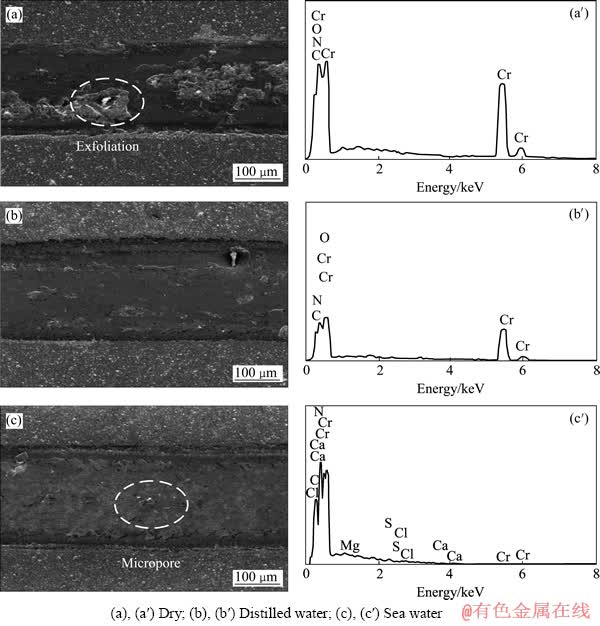

为进一步研究CrCN涂层与WC摩擦配副对磨时的磨损机理,利用SEM分别观测在不同环境下对磨后CrCN涂层的磨痕形貌(见图9),并采用EDS分析磨痕表面的元素成份。由图9(a)可见,干摩擦条件下,样品磨损表面塑性变形严重,表面上布满块状磨屑脱落的痕迹和许多即将脱落的磨屑,磨屑在摩擦过程中被反复碾压,容易划伤表面,加剧磨损。在大气环境中,CrCN涂层的磨损机制主要表现为粘着磨损和磨料磨损。另外,磨痕成分主要以Cr、C和N为主,有少量O存在,说明在摩擦过程中涂层有一定程度的氧化。

图9 不同环境下CrCN涂层表面磨损形貌及EDS谱

Fig. 9 Morphologies((a), (b), (c)) and EDS spectra((a′), (b′), (c′)) of worn surface of CrCN coating under different environments

由图9(b)可见,在去离子水环境中,磨痕表面形貌与干摩擦有显著不同,磨痕表面较光滑,无明显的微坑和粘着物质。由于去离子水在摩擦过程中容易形成水膜,起到了润滑减摩的作用,减少磨削粘着现象的发生,同时,涂层表面也发生了一定程度的氧化,但是相对于大气环境中,氧化程度明显降低,这主要是由于水隔绝了空气,使得摩擦环境中的含氧量下降。磨损机制以磨料磨损为主。

另外,由图9(c)可见,海水环境中的磨痕表面特征相对于去离子水环境下又发生了明显变化,磨痕表面有细小微坑出现和少许白色物质,分析认为这些微坑可能是摩擦过程中由海水的腐蚀作用导致的,这些微坑在摩擦过程中容易形成腐蚀通道,使得腐蚀液直接进入到涂层内部,加剧磨损。白色物质除了膜层自身的材料外,还存在S、Mg和Ca等成份,S、Mg和Ca主要来自于海水中。这些摩擦产物在摩擦过程中起到边界润滑作用,加之海水本身的流体润滑作用,进一步降低了摩擦磨损,其磨损机制以腐蚀磨损和磨料磨损为主。

3 结论

1) 采用多弧离子镀技术,通过控制涂层成分和操作条件,在单晶硅和316L不锈钢基材上制备CrN和CrCN涂层。与CrN涂层相比,CrCN涂层与基体结合较好,结合力达到130 N。

2) 较之于CrN涂层,CrCN涂层主要成分为Cr、C和N。碳元素主要以sp2、sp3杂化键和Cr7C3的形式存在,由于强化相Cr7C3的产生和杂化C的形成等多种强化作用,显著提高了CrCN涂层的硬度及耐磨性能。

3) 涂层摩擦磨损性能显著依赖于测试介质,较之于CrN涂层,CrCN涂层在大气、去离子水、海水环境中的摩擦因数及磨损率均较低,表现出更优异的摩擦磨损性能。

REFERENCES

[1] CUI G J, BI Q L, ZHU S Y, YANG J, LIU W M. Tribological properties of bronze-graphite composites under sea water condition[J]. Tribology International, 2012, 53(8): 76-86.

[2] NIE S L, HUANG G H, LI P W. Tribological study on hydrostatic slipper bearing with annular orifice damper for water hydraulic axial piston motor[J]. Tribology International, 2006, 39(11): 1342-1354.

[3] CHEN Jun, YAN Feng-yuan. Tribocorrosion behaviors of Ti-6Al-4V and Monel K500 alloys sliding against 316 stainless steel in artificial seawater[J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1356-1365.

[4] 许俊华, 曹 峻, 喻利花. 磁控溅射制备TiCN复合膜的微结构与性能[J]. 中国有色金属学报, 2012, 22(11): 3123-3128.

XU Jun-hua, CAO Jun, YU Li-hua. Microstructure and properties of TiCN composite films prepared by magnetron sputtering[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3123-3128.

[5] ZHANG G A, WANG L P, WANG S C, YAN P X, XUE Q J. Structure and mechanical properties of reactive sputtering CrSiN films[J]. Applied Surface Science, 2009, 255(8): 4 425-4429.

[6] KAO W H, SU Y L, YAO S H. Tribological property and drilling application of Ti-C:H and Cr-C:H coating on high-speed steel substrates[J]. Vacuum, 2006, 80(6): 604-614.

[7] BEWILOGUA K, COOPER C V, SPEPECHT C, SCHRODERA J, WITTORFA R, GRISCHKE M. Effect of target material on deposition on deposition and properties of metal-containing DLC (Me-DLC) coatings[J]. Surface and Coating Technology, 2000, 132(2/3): 275-283.

[8] 孔 明, 岳建玲, 李戈扬. 陶瓷硬质纳米多层膜研究进展[J].无机材料学报, 2010, 25(2): 113-119.

KONG Ming, YUE Jian-ling, LI Ge-yang. Research development of hard ceramic nanomultilayer films[J]. Journal of Inorganic Materials, 2010, 25(2): 113-119.

[9] 王建鹏, 李 伟, 刘 平, 马凤仓, 刘新宽, 陈小红, 何代华. Si 含量对 CrN/TiSiN 纳米多层膜显微结构和力学性能的影响[J]. 中国有色金属学报, 2014, 24(3): 739-744.

WANG Jian-peng, LI Wei, LIU Ping, MA Feng-cang, LIU Xin-kuan, CHEN Xiao-hong, HE Dai-hua. Influence of Si content on microstructure and mechanical property of CrN/TiSiN nanomultilayered films[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 739-744.

[10] 陈 灵, 曾德长, 邱万奇, 董小虹, 黎炳雄, 黄拿灿. TiAlCrN和TiAlCrN/CrN复合膜的微观结构与力学性能[J]. 中国有色金属学报, 2009, 19(9): 1608-1612.

CHEN Ling, ZENG De-chang, QIU Wan-qi, DONG Xiao-hong, LI Bing-xiong, HUANG Na-can. Microstructure and mechanical properties of TiAlCrN and TiAlCrN/CrN composite coatings by arc ion plating[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1608-1612.

[11] MENDIBIDE C, STEYER P, FONTAINE J, GOUDEAU P. Improvement of the tribological behaviour of PVD nanostratified TiN/CrN coatings: An explanation[J]. Surface and Coatings Technology, 2006, 201(7): 4119-4124.

[12] SINGH V, PALSHIN V, TITTSWORTH R C, MELETIS E I. Local structure of composite Cr-containing diamond-like carbon thin films[J]. Carbon, 2006, 44(7): 1280-1286.

[13] 王 静, 张广安, 王立平. 金属复合对CrN薄膜的结构及摩擦磨损性能的影响[J]. 密封与润滑, 2005, 33(5): 30-32.

WANG Jing, ZHANG Guang-an, WANG Li-ping. The influence of metal alloyed on the structure and wear properties of CrN coatings[J]. Lubrication Engineering, 2005, 33(5): 30-32.

[14] STALLARD J, YANG S, TEER D G. The friction and wear properties of CrN, graphit-ic and dymon-ic coatings in air and under oil lubrication[J].Transactions of Materials and Heat treatment, 2004, 25(10): 858-860.

[15] CHIM Y C, DING X Z, ZENG X T, ZHANG S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc[J]. Thin Soild Films, 2009, 517(17): 4845-4849.

[16] 牛仕超, 余志明, 代明江, 林松盛, 侯惠君, 李洪武. 中频磁控溅射沉积梯度过渡Cr/CrN/CrNC/CrC 膜的附着性能[J]. 中国有色金属学报, 2007, 17(8): 1307-1312.

NIU Shi-chao, YU Zhi-ming, DAI Ming-jiang, LIN Song-sheng, HOU Hui-jun, LI Hong-wu. Adhesion of Cr/CrN/CrNC/CrC graded interlayer deposited by MF-magnetron sputtering[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1307-1312.

[17] BAI L J, ZHU X D, XIAO J M, HE J W. Study on thermal stability of CrTiAlN coating for dry drilling[J]. Surface & Coatings Technology, 2007, 201(9/11): 5257-5260.

[18] 胡鹏飞, 蒋百灵, 李洪涛. 碳掺杂对CrN镀层显微硬度与组织结构的影响[J]. 真空科学与技术学报, 2012, 32(2): 158-162.

HU Peng-fei, JIANG Bai-ling, LI Hong-tao. Hardness enhancement of CrN coatings by C-doping[J]. Chinese Journal of Vacuum Science and Technology, 2012, 32(2): 158-162.

[19] 胡鹏飞, 蒋百灵, 李洪涛. 碳靶电流对CrCN镀层摩擦因数的影响[J]. 功能材料, 2011(1): 175-181.

HU Peng-fei, JIANG Bai-ling, LI Hong-tao. Influence of carbon target current on friction coefficient of CrCN coating[J]. Journal of Functional Materials, 2011(1): 175-181.

[20] WARCHOLINSKI B, GILEWICZ A, RATAJSKI J, KUKLINSKI Z, ROCHOWICZ J. An analysis of macroparticle-related defects on CrCN and CrN coatings in dependence of the substrate bias voltage[J]. Vacuum, 2012, 86: 1235-1239.

[21] WARCHOLINSKI B, GILEWICZ A. Effect of substrate bias voltage on the properties of CrCN and CrN coatings deposited by cathodic arc evaporation[J]. Vacuum, 2013, 90: 145-150.

[22] CHEN B B, WANG J Z, YAN F Y. Friction and wear behaviors of several polymers sliding against gcr15 and 316 steel under the lubrication of sea water[J]. Tribology Letters, 2011, 42(1): 17-25.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51161008,51464013);国际热核聚变(ITER)计划专项(2011GB110002);江西省高等学校科技落地计划项目(KJLD12072)

收稿日期:2014-04-17;修订日期:2014-10-28

通信作者:陈 颢,教授,博士;电话:15970796661;E-mail: chenhao_168168@163.com