静态阴极电弧蒸发制备的CrN涂层的结构和性能

来源期刊:中国有色金属学报(英文版)2019年第4期

论文作者:B. WARCHOLINSKI A. GILEWICZ A. S. KUPRIN I. V. KOLODIY

文章页码:799 - 810

关键词:氮化铬;电弧蒸发;相成分;粗糙度;硬度;磨损

Key words:chromium nitride; arc evaporation; phase composition; roughness; hardness; wear

摘 要:采用静态阴极电弧蒸发法,在基体面向等离子体源的正表面和其背面沉积CrN涂层。研究氮气压力对涂层的结构、相组成、力学性能和摩擦学性能的影响。分别用扫描电镜、接触轮廓仪和X射线衍射仪对涂层的形貌和结构进行表征,采用纳米压痕法对其力学性能进行研究,并采用球盘式摩擦计对涂层的摩擦磨损性能进行研究。结果表明,涂层沉积过程中氮气压力的增加将导致相变的发生,其顺序为Cr2N → Cr2N + CrN → CrN。与沉积在基体背面的涂层相比,沉积在基体正面的涂层的粗糙度更高,这主要是正面涂层中大颗粒的数量较多造成的。基体正面涂层的硬度和弹性模量也较高。研究还发现,涂层的附着力与磨损率呈反比关系。

Abstract: CrN coatings were deposited using cathodic arc evaporation in stationary system on the substrate surface faced to the plasma source and on the back surface. The effect of nitrogen pressure on the structure and phase composition, mechanical and tribological properties of the coatings was investigated. The coating morphology and structure were characterized using SEM and contact profilometry and X-ray diffractometry, respectively. Mechanical properties were studied by nanoindentation. The friction and wear properties of the coatings were investigated by ball-on-disk tribometer. An increase in nitrogen pressure during coating deposition results in phase transformation according to the relation Cr2N → Cr2N + CrN → CrN. The roughness of the coatings deposited on the front side of the substrate is higher than that on the back side, mainly due to larger number of macroparticles. The hardness and elastic modulus are also higher on the front side of the substrate. The adhesion and wear rate of the coatings have an inverse relationship.

Trans. Nonferrous Met. Soc. China 29(2019) 799-810

B. WARCHOLINSKI1, A. GILEWICZ1, A. S. KUPRIN2, I. V. KOLODIY2

1. Faculty of Technology and Education, Koszalin University of Technology, Koszalin 75-620, Poland;

2. National Science Center, Kharkov Institute of Physics and Technology, Kharkov, Ukraine

Received 18 July 2018; accepted 24 December 2018

Abstract: CrN coatings were deposited using cathodic arc evaporation in stationary system on the substrate surface faced to the plasma source and on the back surface. The effect of nitrogen pressure on the structure and phase composition, mechanical and tribological properties of the coatings was investigated. The coating morphology and structure were characterized using SEM and contact profilometry and X-ray diffractometry, respectively. Mechanical properties were studied by nanoindentation. The friction and wear properties of the coatings were investigated by ball-on-disk tribometer. An increase in nitrogen pressure during coating deposition results in phase transformation according to the relation Cr2N → Cr2N + CrN → CrN. The roughness of the coatings deposited on the front side of the substrate is higher than that on the back side, mainly due to larger number of macroparticles. The hardness and elastic modulus are also higher on the front side of the substrate. The adhesion and wear rate of the coatings have an inverse relationship.

Key words: chromium nitride; arc evaporation; phase composition; roughness; hardness; wear

1 Introduction

Due to good chemical, mechanical and tribological properties, PVD hard coatings based on transition metal nitride coatings are widely applied [1-3]. Chromium nitride coatings as one of them are characterized by high hardness and chemical inertness. They show excellent resistance in corrosive environments and in areas where friction is present [4]. Chromium nitride coatings can be prepared using different PVD methods, for example, by cathodic evaporation [5-11] or magnetron sputtering [12,13]. The deposition method and technological parameters strongly influence the chemical composition and microstructure. The increase in nitrogen pressure changes the phase structure of the coatings according to the relation Cr → Cr + Cr2N → Cr2N → Cr2N + CrN → CrN. Because of different chemical compositions, these phases exhibit different physical properties [6,12,14].

The above deposition methods have their advantages and disadvantages. The coatings formed using arc evaporation have better adhesion to the substrate, higher hardness and density. The magnetron sputtered coatings are characterized by a smooth surface without defects [15,16].

The disadvantage of the most common method of forming thin hard coatings, cathodic arc evaporation, is the large number of defects on the surface. The improvement of the surface quality can be obtained by using the so-called plasma filters [7]. They significantly reduce the number of the surface defects and the deposition rate of the coatings. Therefore, the studies are needed to achieve a smooth coating with comparable mechanical and tribological properties in a reasonable time. There are only a few works on this subject. The effect of deposition on the front and back surfaces in a stationary system is described, in our knowledge, for TiN [17] and ZrN [8] and partly for CrN [9,18,19] coatings. Such effect is observed, for example, for TiN, ZrN and TiAlN [8,17,18]. An additional effect is simultaneously observed: a significant increase in the deposition rate on the back side (with respect to the cathode) of the samples having diameter less than 50 mm [17]. The investigations of Ti-based coatings deposited using arc evaporation indicate that with the increased nitrogen pressures, droplet-free coatings are possible to form on the reverse side of sample of small pieces [17]. This means that plasma filters have not to be applied. Additionally, the deposition rates on the front and reverse sides of the substrate with respect to the cathode, are comparable, and low surface roughness and high nanohardness on the reverse side of the substrate are observed. In the case of ZrN coatings deposited in the range of nitrogen pressure from 0.2 to 6.65 Pa, it was found that deposition rates on the front and back sides of the substrates are similar if their diameters are less than 40 mm, and the ZrN coating obtained on the back side of the substrate shows better mechanical properties than that deposited on the front side [8].

OVCHARENKO et al [9] investigated the CrN coatings deposited at nitrogen pressure of 3.0 Pa and substrate bias voltage from -70 to -300 V. They found that the roughness of the coatings obtained on both sides of the substrates in the applied voltage range from -70 to -300 V decreases by more than 60%. The density of the coatings deposited on the front side of the substrate is lower compared with that of the coatings deposited on the back side of the substrate. The hardness of the coatings deposited on the front and back sides of the substrate is comparable, and decreases with increasing substrate bias voltage.

The aim of other investigations was evaluation of the difference in deposition rates, statistics of macroparticles on the surface, roughness, chemical compositions of the coatings deposited on samples placed in the same as above arrangement during the deposition of Cr-N coatings at substrate bias voltage of -70 V and nitrogen pressures of 0.5, 1.8 and 3.0 Pa [20]. The chemical compositions are about 65 at.% Cr and 35 at.% N, and 68 at.% Cr and 32 at.% N of the coatings deposited at nitrogen pressure of 0.5 Pa on the front and back sides of the substrate, respectively. Nitrogen concentration increases and chromium concentration decreases to be near stoichiometric when nitrogen pressure increases from 0.5 to 1.8 Pa. Above this pressure the composition of the coatings is almost unchanged [20].

The problematic aspects of coating deposition in a stationary system, especially in terms of substrates of different shapes and sizes, and their position in the working chamber with respect to the arc source are extremely interesting. Till now however, they have not met with comprehensive research. The current work focused on determining the conditions for the formation of different chromium nitride phases under the influence of nitrogen pressure variations. The purpose of these studies as a continuation of our previous investigations shown in Ref. [20] is also evaluating the difference in the structural and mechanical properties, as hardness, adhesion wear resistance of the coatings obtained on the front and back sides of the substrates.

2 Experimental

2.1 Coating deposition

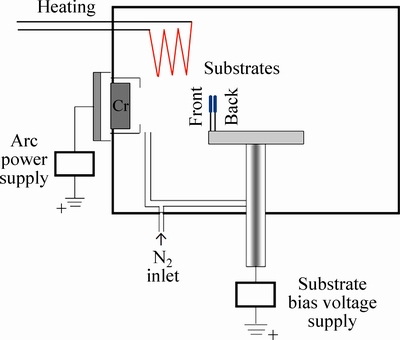

TINA 900M system with cathodic evaporation deposition method equipped in arc sources having 100 mm in dimension was used to synthesize CrN coatings on HS6-5-2 steel substrates with 32 mm in diameter and 3 mm in thickness. The chromium target purity is 99.99%. The chemical composition of the substrates is as follows (wt.%): C (0.36-0.42), Mn (Max. 1.0), Si (Max. 1.0), P (Max. 0.04), S (Max. 0.03), Cr (12.5-14.5), Ni (Max. 0.6) and Fe balanced. The samples were ground with a sand paper of mesh up to 2500 grit and then finished in an oscillating polisher using an alundum slurry with a grain size of 0.3 μm to obtain a substrate roughness Ra of about 0.02 μm. Then, they were chemically degreased and ultrasonically cleaned in hot alkaline bath for 10 min, rinsed with distilled water and dried in warm air. After that, the substrates were placed at the distance of 16 cm from the arc source in vacuum chamber. Two substrates were applied to evaluating the properties of the coatings deposited on the front and back sides of the samples, at a fixed position with respect to the arc source, as shown in Fig. 1. It is only the draft of deposition system. The substrates were centrally located with the respect to the cathode. The diameter of substrates (32 mm) is much smaller than that of the source.

Fig. 1 Schematic diagram of CrN coating deposition system on front and back sides of substrate

The chamber was evacuated to a base pressure of 1 mPa. Then, the second step of substrate cleaning, ion etching using argon and chromium ions at argon pressure of 0.5 Pa under 70 V of negative substrate bias voltage for 10 min was performed. Due to the temperature increase above steel substrates tempering temperature the application of higher bias voltage was not possible. Argon ions were generated using an electrical arc in a shielded cathode and they were accelerated towards etched substrate (anode). Argon and chromium ions stroke against the samples surface to remove the residual contamination-mainly oxides. The thin (~0.1 μm) chromium layer was deposited onto the substrate to improve the adhesion before coating deposition [12]. A deposition process was performed on the substrates heated to a temperature of 300 °C, at substrate bias voltage of -70 V with arc current of 80 A. Two sets of samples with fixed substrate bias voltage of -70 V and three nitrogen pressures of 0.5, 1.8 and 3.0 Pa on the front and back sides of substrate were prepared.

2.2 Coating evaluation

The coating phase composition was evaluated by X-ray diffractometer (DRON 04-7). Cu Kα radiation source and nickel-selectively absorbing filter were applied. All spectra were recorded under the same conditions. The results were interpreted using the JCPDS database. The Rietveld method [21,22] was used to determine the phase composition of the coatings and their textures. The Williamson-Hall method was used to calculate the crystalline size and microstrain level. In order to account for instrumental peak broadening, Si powder with a grain size of about 30 μm was used as a reference.

The thickness of the coatings was evaluated using the crater grinding method (Calotest). The hardness of the coatings was investigated using Fisherscope  HM2000 system. Due to high surface roughness, typical for its deposition technique, the method described by ROMERO et al [23] was applied. Using the fine alumina powder (1 μm) as a medium, the coatings were polished to reduce the roughness to 0.04-0.05 μm. After this operation, the statistic of measurements was highly improved. The average hardness value was computed at least 20 measurements.

HM2000 system. Due to high surface roughness, typical for its deposition technique, the method described by ROMERO et al [23] was applied. Using the fine alumina powder (1 μm) as a medium, the coatings were polished to reduce the roughness to 0.04-0.05 μm. After this operation, the statistic of measurements was highly improved. The average hardness value was computed at least 20 measurements.

Adhesion and other mechanical failure modes were performed by a scratch test (Revetest Scratch-CSEM). A diamond type C Rockwell indenter with the radius of 200 μm was applied. Each sample was made at least 3 parallel scratches (10 mm in length) by a moving indenter with a speed of 10 mm/min. The load increased linearly from 0 to 100 N. The critical load

Scratch-CSEM). A diamond type C Rockwell indenter with the radius of 200 μm was applied. Each sample was made at least 3 parallel scratches (10 mm in length) by a moving indenter with a speed of 10 mm/min. The load increased linearly from 0 to 100 N. The critical load  was the load at which the coating failures appeared and was determined on the basis of the acoustic emission registered during the test and microscope observations. The critical load

was the load at which the coating failures appeared and was determined on the basis of the acoustic emission registered during the test and microscope observations. The critical load  occurred when total delamination of the coating was observed. Additionally, the adhesion was determined using the Daimler-Benz test [24]. A six-grade scale indicates good adhesion (HF1–HF4) with small cracking or delamination of the coating in the surrounding of the crater, whereas HF5 and HF6 represent a poor adhesion with a large coating delamination around the indented zone.

occurred when total delamination of the coating was observed. Additionally, the adhesion was determined using the Daimler-Benz test [24]. A six-grade scale indicates good adhesion (HF1–HF4) with small cracking or delamination of the coating in the surrounding of the crater, whereas HF5 and HF6 represent a poor adhesion with a large coating delamination around the indented zone.

The friction coefficient was determined using the ball-on-disk device under the following conditions: counterbody of Al2O3 ball (a hardness of 15 GPa, a diameter of 10 mm and Ra of ~0.03 μm), load of 20 N, sliding speed about 0.2 m/s, sliding distance of 1000 m (14000 revolutions). Measurements were carried out without lubrication (dry sliding) at an ambient temperature in an atmosphere with a humidity being around 50%.

The surface roughness and profiles of wear tracks were measured with a T 8000 Hommel–Werke roughness tester profilometer. The wear rate was calculated from the volume of the material removed during the friction test divided by the product of the length of the friction distance and load [25]. Calculations were made for 5 samples.

3 Results and discussion

3.1 General characterization of deposited samples

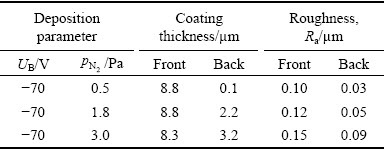

It has been found that the thickness of the coatings (Table 1) obtained on the front side of the substrate is almost uniform. The thickness of the coatings obtained on the back side of the substrate depends on the technological conditions and grows with increasing nitrogen pressure. There is no difference in the thickness of the coating on the sample measured by ball-cratering method (Calotest) or in its chemical composition. The thickness of the coating is connected with deposition rate and deposition time. The change in thickness for constant deposition time is related with deposition rate. The latter changes with substrate bias voltage [8,9,17], type of gas [20] and gas pressure [8,17,20]. According to KHOROSHIKH et al [17], the rate of particle generation at the discharge cathode decreases with the increasing nitrogen pressure. However, an increase in deposition rate can be observed under high nitrogen pressure on the front and back sides of the substrates. As a result of large number of collisions of the metal particles with nitrogen, the spatial distribution of the particles changes, leading to an increase in the concentration of particles in the region of the sample location. During the collisions, there is probably a reduction in their energy, and consequently, a reduction in the resputtering phenomenon. Therefore, the deposition rate will increase. There is also another effect of the collisions. The movement of the particles is more chaotic, which increases the deposition rate on the back side of the substrate.

Table 1 Thickness and roughness (Ra) of CrN coatings deposited on front and back sides of substrates dependent on technological conditions

The surface roughness of CrN coatings also depends on the nitrogen pressure in the working chamber during deposition process. Nitrogen pressure has an immense effect on the surface roughness of the growing film. An increase in the roughness of the coatings obtained in both substrate positions with increasing nitrogen pressure was observed.

It is known that many coating properties such as roughness, adhesion and wear rate should be considered for coatings of similar thicknesses. Unfortunately, due to different deposition rates dependent on nitrogen pressure the thickness for coatings deposited on the back side of the substrate varies. For example, at nitrogen pressure of 0.5 Pa the thickness ratio of on the front side to back side is 88:1. This means that deposition time ought to be at least 88 times longer to obtain coatings with similar thickness. Very long deposition time with coatings and substrates heated to about 300 °C may change the structure of the coating, e.g. grain growth, which may result in reduced hardness. Simultaneously, the increase in deposition time affects the increase of surface roughness [26]. Particle migration process activated by temperature can also occur. Particles overcome the energy barrier of the site and jump to their vacant neighboring site, thus reducing porosity [27]. Low deposition rate and very long deposition time can favor dense structure forming with other mechanical properties. Based on it the coatings deposited at the same time were evaluated.

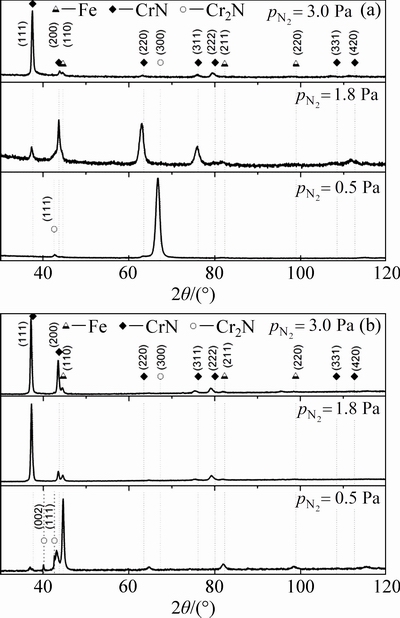

3.2 XRD pattern

X-ray diffraction was used to determine the chromium nitride phases in coatings obtained. Although the diffraction pattern of the Cr-N phases is well described in the literature, in the case of coatings containing a mixture of cubic and hexagonal phases of CrN obtained on a steel substrate, the unequivocal identification of the resulting phases is straitened.

The diffraction patterns of Cr-N coatings deposited on the front and back sides of the substrate under varying nitrogen pressure conditions are shown in Fig. 2. The presence of iron (probably from steel substrate), CrN cubic and Cr2N hexagonal phases is confirmed.

Fig. 2 X-ray diffraction patterns of Cr-N coatings deposited at front (a) and back (b) sides of substrates at different nitrogen pressures

Cr-N coating obtained on the front of the substrate under a nitrogen pressure of 0.5 Pa at a substrate bias voltage UB=-70 V (Fig. 2(a)) is characterized by hexagonal structure (Cr2N) with lattice parameters of a=0.4859 nm and c=0.4309 nm. These values differ from the standard data a=0.48113 nm and c=0.44841 nm (JCPDS 35-0803). The shift of the diffraction lines to lower diffraction angles, as well as the lattice microstrain of about 3.6×10-3 (about 0.36%), may be caused by the stresses generated in the coating during deposition. The concentration of Cr2N phase was evaluated by Rietveld method, about 94%. This coating is characterized by strong texture. The highest intensity of diffraction lines was recorded not for (111) plane but for (300) plane. An increase in nitrogen pressure favors the formation of a cubic CrN phase. The crystal lattice parameter grows from 0.4156 nm (1.8 Pa) to 0.4171 nm (3.0 Pa). These values are higher than standard data (0.4140 nm, ICDD 11-0065). The differences are related to the strong texturing of coatings, about 65%. For the coating obtained at nitrogen pressure of 1.8 Pa, the (220) plane dominates, and for the coating obtained at higher pressure (3 Pa), (111) plane dominates.

Cr-N coating deposited on the back side of the substrate (Fig. 2(b)) under nitrogen pressure of 0.5 Pa is also characterized by hexagonal structure of chromium nitride and lattice parameters different from standard data and amounted to a=0.4816 nm and c=0.4504 nm. (111) and (002) planes dominate in this coating. The most intense (300) plane for coating deposited on the front side of the substrate was not observed. The increase in nitrogen pressure to 1.8 Pa changes the phase composition of the coating. The typical diffraction lines for cubic phase of chromium nitride appear: (111), (200) and (222) positioned at 2θ values about 37.6°, 43.6° and 80.0°, respectively. For coatings deposited at nitrogen pressure of 3.0 Pa, a diffraction line from the plane (311) was also recorded. It should be noted that the diffraction lines from the coatings obtained at nitrogen pressures of 1.8 and 3.0 Pa are characterized by varying intensity. The coating obtained at the highest nitrogen pressure of 3.0 Pa shows lattice microstrain about 0.25%, similar to the coating deposited on the front substrate.

The crystallite sizes increase with the increase of nitrogen pressure in deposition process. For coatings deposited at  =1.8 Pa on the front and back sides of the substrate they are about 40 and 60 nm, respectively. For coatings deposited at the highest nitrogen pressure of 3.0 Pa, the crystallite size increases by about 15%.

=1.8 Pa on the front and back sides of the substrate they are about 40 and 60 nm, respectively. For coatings deposited at the highest nitrogen pressure of 3.0 Pa, the crystallite size increases by about 15%.

It should be noted that the positions of diffraction lines of iron (ICDD 06-0696) and chromium (ICDD 06-0694) are very close due to the strong similarity of the crystalline structure: both cubic Im3m (229) and the lattice parameters respectively 0.28839 and 0.28664 nm. Cathodic arc evaporation deposition method is characterized by the presence of a large number of macroparticles composed mainly of pure metal, here chromium, which occurs both on the surface of the coating and its cross-section [28]. Additionally, because the macroparticles occupy relatively large surface area [20] the overlapping of diffraction lines from substrate (iron) and chromium (macroparticles) cannot be excluded.

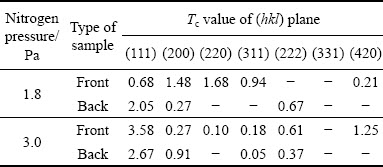

The values of the texture coefficients Tc for the planes are proportional to the number of crystallite that are oriented with the corresponding crystallographic plane parallel to the sample surface. The texture coefficient Tc(hkl) was calculated using Eq. (1) [29] and the diffraction patterns of the coatings shown in Fig. 2:

(1)

(1)

where I(hkl) is the diffraction line intensity from the (hkl) plane for the textured sample, Io(hkl) is the respective intensity corresponding to the bulk CrN data from JCPDS file No. 11-0065, and n is the number of diffraction lines analyzed.

Table 2 Texture coefficients Tc(hkl) for CrN coatings deposited at nitrogen pressures of 1.8 and 3.0 Pa

The texture coefficient Tc(hkl) measures the relative degree of preferred orientation among crystal planes. It was calculated for all registered planes, as shown in Table 2. The value of the coefficient is proportional to the number of preferentially oriented (hkl) planes. Tc(hkl) close to unity indicates a randomly distributed powder sample, and Tc(hkl)>1 indicates preferential orientation. High preferred orientation is attributed to many grains in this orientation.

It should also be pointed out that the coating deposited on the front side of the substrate was significantly greater in thickness compared to the coatings obtained on the back side of the substrate, as shown in Table 1. In spite of this, the intensity of the recorded diffraction lines is higher in the latter case, which may indicate the presence of greater number of crystallites in the coating.

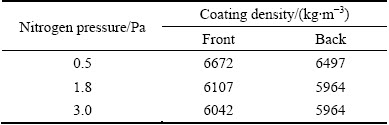

Using Rietveld method, the densities of the coatings were calculated and shown Table 3. The results show the lower density of the coatings deposited on the back side of the substrates compared to the front side. The next finding is connected with nitrogen pressure relationship during deposition. The higher the nitrogen pressure is, the lower the coating density is.

Table 3 Densities of CrN coatings deposited at different nitrogen pressures on front and back sides of substrates

The density of the hexagonal Cr2N phase is about 6.54 g/cm3 [12,14]. Cubic CrN phase is characterized by lower density values of 6.17-6.3 g/cm3 [12,14,30,31]. However, there are also reports about CrN coating density lower than 6 g/cm3 [30]. Significantly lower CrN density was reported by CUNHA et al [32]. They found that coating density depends on the substrate temperature, substrate bias voltage, and magnetron power. Their CrN coatings were generally loosely packed with mean density of 55%-85% bulk density.

The coating deposited at nitrogen pressure of 0.5 Pa shows that Cr2N structure and its density ought to be higher than coatings deposited at nitrogen pressures of 1.8 and 3.0 Pa.

The decrease of coating density is probably connected with a decrease of the mean free path in the deposition chamber. High temperature of the substrate as well as high substrate bias voltage should favor the formation of a dense coating [9]. However, the energy dissipation of particles and ions by collisions reduces the density of coatings. Observed density reduction of CrN coatings with the increase of nitrogen pressure results from the increasing number of collision of particles, ions and Cr atoms with nitrogen, which makes them lose energy in this process. The nucleation of such particles is poor, the micro-holes and pores form, which leads to low density of coatings [30].

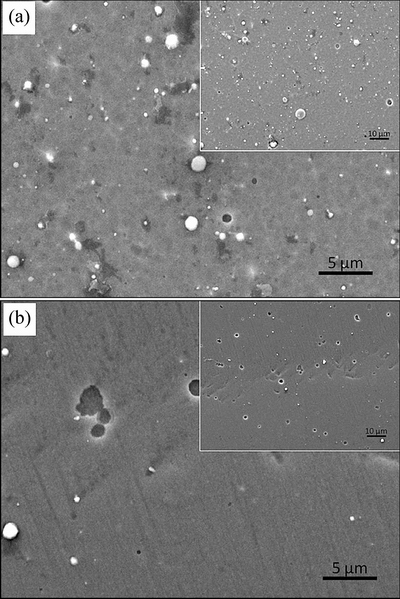

3.3 Morphology

The differences in morphology of CrN coatings obtained at nitrogen pressure of 1.8 Pa on the front and back sides of the substrate are shown in Figs. 3(a) and (b), respectively. The greater amount, especially small particles on the surface of the coating deposited on the front side of the substrate (Fig. 3(a)) compared to back side (Fig. 3(b)) is clearly visible. With the increase in nitrogen pressure, the amount of macroparticles on the coating surface grows. It is probably the reason for the increase in surface roughness (Table 1). These macro defects of the coatings can be identified as drops of cathode material. The number of surface defects decreases with the increase in the bias voltage of the substrate [20]. This is because most of the drops placed in plasma get negative potential and are repelled by the sample surface to which the negative potential is applied. The tested samples were deposited at relatively small substrate bias voltage of -70 V. Macroparticles could also be deposited after reflection from structural elements of the vacuum chamber.

Fig. 3 SEM images of surface morphology of CrN coatings deposited on front (a) and back (b) sides of samples at nitrogen pressure of 1.8 Pa

In the coatings deposited on the back side of the substrate (Fig. 3(b)), large number of craters are apparent. In some of them small particles are positioned. Two possible interpretations of their formation can be presented. Firstly, the creation of craters can be associated with surface shadowing by large and poorly joined coating particles during deposition. The second one was presented by KHOROSHIKH et al [8]. They pointed out that some of the particles moving from the cathode to the condensation surface, can be heated to the temperature at which thermionic emission occurs and they acquire a positive potential. This leads to an increase in the flux of plasma electrons to the particle and, as a result, a sharp increase in its temperature, even to 5000-7000 K. The effect of heating droplets can be expected for materials combining a relatively small electron work function φ and a high melting point. Such materials include chromium with melting point of 2180 K and φ=4.5 eV. These positively charged droplets of high energy due to thermal and mechanical effects lead to the formation of the rounded craters.

The formation of craters is probably related to the energy and the ion flux. LIN et al [33] compared CrN coatings deposited by DC magnetron sputtering, middle frequency pulsed DC magnetron sputtering, and modulated pulse power magnetron sputtering. They found that the CrN coatings formed using modulated pulse power magnetron sputtering characterized by low ion energy and high ion flux exhibited dense microstructure, fine grain size and smooth surface with high hardness, improved adhesion and wear resistance. The increase in nitrogen pressure, due to scattering, reduces the free path and ion energy. Additionally, the ion flux increases. Because of the low ion kinetic energy the mobility of the adatoms on the substrate is low. These conditions will probably lead to the porous micro- structure development [34].

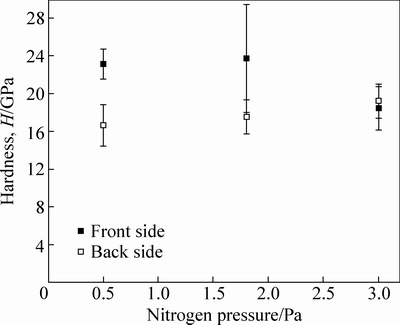

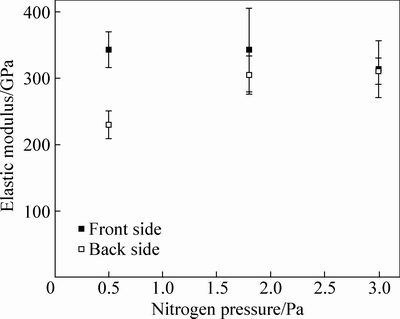

3.4 Hardness and elastic modulus

Values of mechanical characteristics such as hardness (H) and elastic modulus (E), were determined using microhardness testing for the coatings. Generally, the hardness of coatings deposited on the front side of the substrate decreases with the increase of nitrogen pressure, as shown Fig. 4, and ranges from 24 to 18 GPa. The hardness of coatings on back side of the substrate increases with increasing nitrogen pressure and is between 17 and 19 GPa. Due to the hardness measurement uncertainty, about 2 GPa, it can be concluded that hardness of such coatings is similar although the increasing trend of nitrogen pressure is apparent. The lower hardness on the back side of the substrates can be connected with lower coating density [9].

Fig. 4 Hardness of coatings deposited on front and back sides of substrate at different nitrogen pressures

In general, the hardness of hexagonal phase of chromium nitride is higher than that of the cubic phase [14,33,35]. GRECZYNSKI et al [36] did not confirm this trend. They found that hardness for stoichiometric Cr2N and CrN is essentially the same, about 26 GPa. Due to their prominent covalent bonding, the hexagonal transition metal nitrides such as Cr2N, Ta2N, V2N and Nb2N would exhibit significantly higher hardness values than CrN, TaN, VN and NbN cubic ones [37]. This means that hardness of the coatings deposited on both sides of substrate at 0.5 Pa should be higher than that of coatings deposited at higher nitrogen pressures. With coating deposited on the back side of the substrate at nitrogen pressure of 0.5 Pa it seems obvious. The coating thickness is very small, about 100 nm and the indentation depth ought to not exceed 10 nm. Probably the effect of the soft substrate is here registered.

The difference in hardness of the coatings deposited on the front side of the substrate can be more explained as follows. XRD results indicate that microstrain in this coating (3.6×10-3) is lower than that in coating deposited at 1.8 Pa of nitrogen pressure (5.6×10-3). For coating deposited at nitrogen pressure of 3.0 Pa the microstrain is the lowest, 2.5×10-3. Significantly lower microstrain is observed in coatings deposited on back side of the substrates. It ranges from 2.5×10-3 ( =3.0 Pa) to 3.0×10-3 (

=3.0 Pa) to 3.0×10-3 ( =1.8 Pa). Additionally, the increase in nitrogen pressure leads to the increase in the number of ions bombarding the surface of the coating. This can lead to an increase in compressive stresses in the coating and as a result, an increase in the hardness. The values of hardness are similar to coatings deposited under the same technological conditions, but in planetary rotation system [38].

=1.8 Pa). Additionally, the increase in nitrogen pressure leads to the increase in the number of ions bombarding the surface of the coating. This can lead to an increase in compressive stresses in the coating and as a result, an increase in the hardness. The values of hardness are similar to coatings deposited under the same technological conditions, but in planetary rotation system [38].

The hardness change of stoichiometric CrN phase can be connected with crystallite size. MAYRHOFER et al [39] indicated that hardness for stoichiometric CrN was not related to the smallest crystallite size. Based on Hall-Petch relationship, one can state that the hardness decreases for the crystallite dimensions other than 10-20 nm. For sputtered CrN films with stoichiometric composition the crystallite size was estimated to be 12 nm. The coatings investigated here are characterized by higher crystallite size. The coatings deposited on the front side of the substrates have lower crystallite size compared to the coatings deposited on the opposite side probably due to the hardness of the latter coatings is lower.

CUNHA et al [32] found that the hardness and elastic modulus of the coatings decreased with increasing density and crystallite size. LE et al [40] studied the effect of nitrogen pressure on mechanical and structural properties of CrAlBN thin films. They stated that hardness and crystalline size of the films decreased and crystalline size increased with the increase of the nitrogen pressure. This softening of the coatings can be connected with the particle and ion stream from cathode scattered during collisions with gas atoms as well as reflections and sputtering from the chamber walls. Hence, the density of coatings becomes lower with the increase in nitrogen pressure. This process also takes place on the back side of the substrate, where there is no direct impact of ions on the substrate. Therefore, its impact energy is lower, which results in a loose coating structure with more pores.

Fig. 5 Elastic modulus of coatings deposited on front and back sides of substrate at different nitrogen pressures

The changes of elastic modulus (Fig. 5) of the coatings are the same as changes of hardness. The values of elastic modulus for coatings deposited in stationary system (344 GPa) are higher than those of coatings deposited in planetary rotation system, 285 GPa [38].

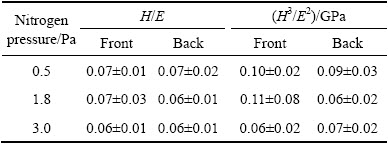

Hardness is one of the indicators of wear resistance. However, it seems that the elastic strain to failure related to the ratio of hardness (H) and elastic modulus (E) is a more suitable parameter for predicting the wear resistance [41]. It is regarded as a responsible parameter of elastic surface behavior in contact with external forces. High H/E is usually beneficial to wear resistance due to higher elastic strain to fracture. The high H/E ratio should indicate a good toughness, but in many cases it is associated with brittleness. The H3/E2 ratio allows the ranging of the coatings against the plastic deformation resistance. The calculated values of H/E and H3/E2 ratios in terms of nitrogen pressure during deposition and substrate position related to arc source are summarized in Table 4.

Table 4 Elastic strain to failure (H/E) and resistance to plastic deformation (H3/E2) ratios calculated for coatings deposited on front and back sides of substrate at different nitrogen pressures

The values of H/E in coatings deposited on the front and back sides of the substrates are similar, 0.06-0.07. It is smaller than 0.1 which defines the “nonplastic zone” (below) and “plastic zone” (above) [42]. It indicates the elastic properties of the coatings although it does not have to prejudge good anti-wear properties. Similar H/E values were presented in other researches [28,38,43]. LIN et al [33] found that H/E ratio is constant, about 0.08, and independent of coating thickness.

Due to relatively high elastic modulus of the coatings the H3/E2 ratio is small and ranges from 0.06 to 0.11 GPa. The values are rather small and indicate that coatings may exhibit rather low wear resistance, especially when using heavy loads.

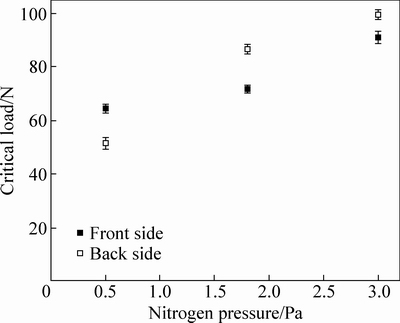

3.5 Adhesion

The critical load (Lc) of Cr-N coatings gradually increases with the increase of nitrogen pressure during deposition. The coating deposited at nitrogen pressure of 0.5 Pa exhibits the smallest Lc of 50-65 N dependent on substrate position during deposition, as shown in Fig. 6. The higher the nitrogen pressure is, the higher the critical load is, even to be 90-100 N at nitrogen pressure of 3.0 Pa.

Fig. 6 Critical load  of coatings deposited on front and back sides of substrate at different nitrogen pressures

of coatings deposited on front and back sides of substrate at different nitrogen pressures

The coatings deposited on the back side of the substrate show higher critical loads  except the coating deposited at nitrogen pressure of 0.5 Pa. The thickness of the latter coating is about 0.1 μm and cannot be compared to other thicker coatings. The deposition rate in the case of the coatings deposited on the back side of the substrate is significantly lower. This means that the number of defects in the coatings is also lower compared with “front” coatings. The coatings deposited on the back side of the substrates are characterized by a small number or even lack of the macroparticles on the surface. So, they are more homogenous than coatings deposited on the front side. The absence of the macroparticles on the surface is also connected with their absence in the coating. There are no defects to initiate cracking under load. The coatings show higher adhesion strength.

except the coating deposited at nitrogen pressure of 0.5 Pa. The thickness of the latter coating is about 0.1 μm and cannot be compared to other thicker coatings. The deposition rate in the case of the coatings deposited on the back side of the substrate is significantly lower. This means that the number of defects in the coatings is also lower compared with “front” coatings. The coatings deposited on the back side of the substrates are characterized by a small number or even lack of the macroparticles on the surface. So, they are more homogenous than coatings deposited on the front side. The absence of the macroparticles on the surface is also connected with their absence in the coating. There are no defects to initiate cracking under load. The coatings show higher adhesion strength.

Critical load Lc depends on many factors: the adhesive strength between the coating and the substrate, the thickness of the coating, the friction coefficient between the coating and the scratch stylus and its possible wear during test [4], the hardness of the coating and the substrate, the surface roughness, the size and hardness of the particles in contact with stylus [44]. This means that interpretation of the results is difficult. For example, the coatings deposited on harder substrates present higher critical loads [45]. For this reason, all tested coatings were deposited on HS6-5-2 steel substrates with similar hardness of 7.5-7.8 GPa (HRC 62-63). But due to technological conditions it is not always possible to deposit coatings with similar number of macroparticles on the surface (roughness) or coefficient of friction. This means that the inference of coating properties is only approximate.

As critical load  is the minimum load at which a failure or cracking of the coating occurs. The critical load

is the minimum load at which a failure or cracking of the coating occurs. The critical load  occurs when total delamination of the coating is observed. Simultaneously, critical force

occurs when total delamination of the coating is observed. Simultaneously, critical force  can be considered as resistance to crack initiation. Due to protecting character of the coatings the possible highest

can be considered as resistance to crack initiation. Due to protecting character of the coatings the possible highest  is required, because it is more difficult to initiate cracking of the coating. ZHANG et al [46] found that both possible high

is required, because it is more difficult to initiate cracking of the coating. ZHANG et al [46] found that both possible high  and difference

and difference  -

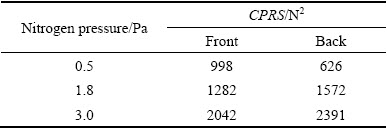

- are required for high toughness of the coating. The new parameter termed CPRS (crack propagation resistance of scratch) to quickly qualitative indication of the film toughness was defined as

are required for high toughness of the coating. The new parameter termed CPRS (crack propagation resistance of scratch) to quickly qualitative indication of the film toughness was defined as  -

- Based on the equation the CPRS was calculated, as shown in Table 5.

Based on the equation the CPRS was calculated, as shown in Table 5.

It was found that the highest toughness occurs for coatings deposited at nitrogen pressure of 3.0 Pa. This means that these coatings should present better wear resistant properties than others.

Table 5 CPRS parameter for CrN coatings deposited on front and back sides of substrates

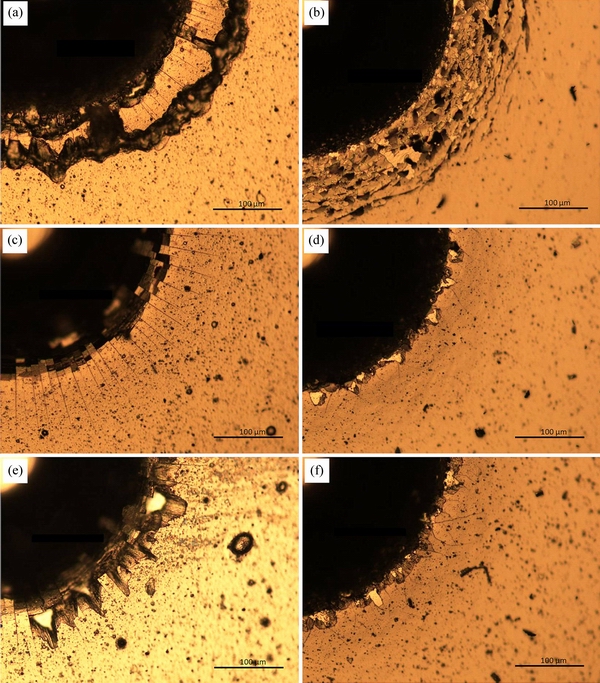

Fig. 7 Failure modes of Cr-N coatings deposited on front (a, c, e) and back (b, d, f) sides of substrates at nitrogen pressures of 0.5 Pa (a, b), 1.8 Pa (c, d) and 3.0 Pa (e, f)

The Daimler-Benz (DB) test showed (Fig. 7) all failure modes: the circumferential (Fig. 7(a)), the radial (Figs. 7(a, c, e)) and the lateral (Figs. 7(d, f)) cracks and small spallings around indentation (Figs. 7(b, c, d, e)). The coatings characterized by high hardness (highly brittle nature) and good adhesion possess only radial cracks around the indentation. Total delamination of the coating around the indentation is typical for hard coatings with poor adhesion. The thinnest hard coatings with good adhesion show a few radial cracks with/without small detachment of the coating. Due to the type of coating damage, the coatings were classified as HF1 and HF2, i.e. the coatings with the highest adhesion as shown in Fig. 6. The individual case is the coating deposited on back side of the substrate at nitrogen pressure of 0.5 Pa, Fig. 7(b). Very thin coating, about 0.1 μm, cannot appropriately react on high normal load during DB test. The cracking and flaking of the coating without radial cracks are observed.

3.6 Wear

The tribological properties of the coatings were tested using a CSM ball-on-disk system with Al2O3 counter body without lubrication at ambient temperature. During friction test the wear debris from the sliding pair were not removed. They can constitute in friction process so-called “third body” and in consequence lead to the increase in coefficient of friction. The mean coefficient of friction for coatings deposited at the lowest nitrogen pressure is high, about 0.68±0.3, typical for Cr2N coatings. The coatings deposited at higher nitrogen pressure are characterized by lower coefficient of friction ranging from about 0.52 to about 0.57 dependent on nitrogen pressure and side of substrate covered by coating. Similar values of coefficient of friction for Cr2N ranging from 0.65 to 0.8 were presented in Refs. [13,47]. Cubic CrN coatings are characterized by little lower values of friction coefficient ranging from 0.4 to 0.8 [13,47]. It probably depends on coating formation and test conditions: the nature of the counter body, load, sliding speed, etc.

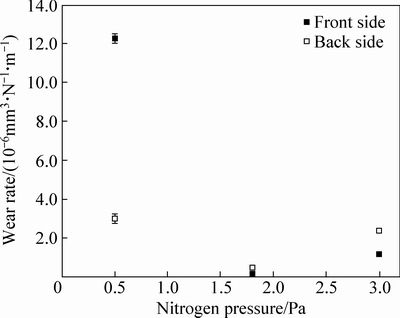

Fig. 8 Wear rates of coatings deposited on front and back sides of substrate at different nitrogen pressures

Based on the wear profiles in tracks produced in the friction test the wear rates were calculated, as shown in Fig. 8. The highest values of wear rates were for coatings deposited at nitrogen pressure of 0.5 Pa. The coatings with hexagonal structure Cr2N are characterized also by the highest coefficient of friction. This effect was described previously [47]. The coatings deposited at higher nitrogen pressures (1.8 and 3.0 Pa) present similar wear rate, ranging from 1.8×10-7 to 2.4×10-6 mm3/(N·m), despite deposition conditions.

Many authors consider hardness to be the main parameter determining good tribological properties of the coatings; however, some of them indicate that a high hardness does not correspond to a good wear resistance or elastic modulus [13,41].

Lower wear rate for coatings deposited on the front side of the substrate correlates with higher H/E and H3/E2 ratios. The other explanation can be connected with coatings density. Coatings deposited on the front of the substrates have higher density compared to the coatings deposited on the back side, see Table 3.

Due to increasing crystalline size, the critical fracture stress of grain boundary is decreased. The decrease of H3/E2 ratio corresponds to the increase of nitrogen pressure. It is known that the H3/E2 ratio is proportional to the resistance of the films to plastic deformation.

4 Conclusions

(1) The structural, mechanical and tribological properties of Cr-N coatings formed at different nitrogen pressures on front and back sides of the substrate were investigated in this work.

(2) The thickness of the coating deposited on the front side of the substrate is higher than that of the coating deposited on the back side of the substrate. The coating roughness Ra increases with the increase of nitrogen pressure. The surface roughness of the coatings deposited on the back side of the substrate is significantly lower. The number of surface defects in coatings deposited on the front side of the substrate is higher than that on the back side.

(3) Dependent on nitrogen pressure, hexagonal Cr2N and cubic CrN can be formed. The change of the lattice parameter in coatings deposited at nitrogen pressures of 1.8 and 3.0 Pa is probably due to changes in the nitrogen content in the resulting layer. All tested coatings are strongly textured.

(4) Hardness and elastic modulus of the coatings deposited on the front side of the substrate are higher compared with those of the coatings deposited on the back side; however, the H/E ratios are similar for all coatings. The coatings with higher concentration of nitrogen show higher critical load  Relatively low value of

Relatively low value of  for the coating deposited at nitrogen pressure of 0.5 Pa (about 60 N) is suitable for the resulting Cr2N hexagonal phase. The lowest wear rate presents for the coatings deposited at nitrogen pressure of 1.8 Pa. It is about 1.8×10-7 mm3/(N·m) on the front side of the substrate and 5.0×10-7 mm3/(N·m) on the back side. Above results are confirmed by the highest H/E and H3/E2 ratios.

for the coating deposited at nitrogen pressure of 0.5 Pa (about 60 N) is suitable for the resulting Cr2N hexagonal phase. The lowest wear rate presents for the coatings deposited at nitrogen pressure of 1.8 Pa. It is about 1.8×10-7 mm3/(N·m) on the front side of the substrate and 5.0×10-7 mm3/(N·m) on the back side. Above results are confirmed by the highest H/E and H3/E2 ratios.

References

[1] KUSIAK A, BATTAGLIA J L, MARCHAL R. Influence of CrN coating in wood machining from heat flux estimation in the tool [J]. International Journal of Thermal Science, 2005, 44: 289-301.

[2] KOPAC J, SOKOLIC M, DOLINEK S. Tribology of coated tools in conventional and HSC machining [J]. Journal of Materials Processing Technology, 2001, 118: 377-384.

[3] WAN S, PU J, LI D, ZHANG G, ZHANG B, TIEU A K. Tribological performance of CrN and CrN/GLC coated components for automotive engine applications [J]. Journal of Alloys and Compounds, 2017, 695: 433-442.

[4] YAO S H, SU Y L. The tribological potential of CrN and Cr(CN) deposited by multi-arc PVD process [J]. Wear, 1997, 212: 85-94.

[5] WARCHOLINSKI B, GILEWICZ A, RATAJSKI J, KUKLINSKI Z, ROCHOWICZ J. An analysis of macroparticle-related defects in the CrCN and CrN coatings in dependence on the substrate bias voltage [J]. Vacuum, 2012, 86: 1235-1239.

[6] WAN X S, ZHAO S S, YANG Y, GONG J, SUN C. Effects of nitrogen pressure and pulse bias voltage on the properties of Cr-N coatings deposited by arc ion plating [J]. Surface and Coatings Technology, 2010, 204: 1800-1810.

[7] AKSENOV I I, BELOUS V A. Vacuum-arc equipment for ion-plasma deposition of coatings [J]. Problems of Atomic Science and Technology, 2000, 3(5): 156-158.

[8] KHOROSHIKH V M, LEONOV S A, BELOUS V A, VASILENKO R L, KOLODIY I V, KUPRIN A S, TIKHONOVSKIY V A, TOLMACHEVA G N. Structure and mechanical properties of ZrN coatings formed by deposition of vacuum arc plasma fluxes [J]. Physical Surface Engineering, 2014, 12: 45-56. (in Russian)

[9] OVCHARENKO V D, KUPRIN A S, TOLMACHOVA G N, KOLODIY I V, GILEWICZ A, LUPICKA O, ROCHOWICZ J, WARCHOLINSKI B. Deposition of chromium nitride coatings using vacuum arc plasma in increased negative substrate bias voltage [J]. Vacuum, 2015, 117: 27-34.

[10] WANG Q M, KWON S H, KIM K H. Formation of nanocrystalline microstructure in arc ion plated CrN films [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S): s73-s77.

[11] SHAN L, ZHANG Y R, WANG Y X, LI J L, JIANG X, CHEN J M. Corrosion and wear behaviors of PVD CrN and CrSiN coatings in seawater [J]. Transactions of Nonferrous Metals Society of China, 2016, 26: 175-184.

[12] REBHOLZ C, ZIEGELE H, LEYLAND A, MATTHEW A. Structure. mechanical and tribological properties of nitrogen-containing chromium coatings prepared by reactive magnetron sputtering [J]. Surface and Coatings Technology, 1999, 115: 222-229.

[13] ZHANG Z G, RAPAUD O, BONASSO N, MERCS D, DONG C, CODDET C. Control of microstructures and properties of dc magnetron sputtering deposited chromium nitride films [J]. Vacuum 2008, 82: 501-509.

[14] BERTRAND G, SAVALL C, MEUNIER C. Properties of reactively RF magnetron-sputtered chromium nitride coatings [J]. Surface and Coatings Technology, 1997, 96: 323-329.

[15] MARTIN P M. Handbook of deposition technologies for films and coatings: Science, applications and technology [M]. Oxford: Elsevier Inc, 2010.

[16] FUENTES G G, RODRIGUEZ R, AVELAR-BATISTA J C, HOUSDEN J, MONTAL′A F, CARRERAS L J, CRISTOBAL A B, DAMBORENEA J J, TATE T J. Recent advances in the chromium nitride PVD process for forming and machining surface protection [J]. J Mater Proc Technology, 2005, 167: 415-421.

[17] KHOROSHIKH V M, LEONOV S A, BELOUS V A. Features of the process of vacuum-arc produced Ti-plasma flux deposition under gas pressure of 1 to 10 Pa [J]. Surface and Coatings Technology, 2015, 167: 167-173.

[18] BUJAK J, WALKOWICZ W, KUSINSKI J. Influence of the nitrogen pressure on the structure and properties of (Ti, Al)N coatings deposited by cathodic vacuum arc PVD process [J]. Surface and Coatings Technology, 2004, 180-181: 150-157.

[19] KUPRIN A S, KOLODIY I V, OVCHARENKO V D, TOLMACHOVA G N, GILEWICZ A, LUPICKA O, WARCHOLINSKI B. Effect of carbon on the properties of CrN coatings formed by cathodic arc evaporation in stationary system [J]. Problems of Atomic Science and Technology, 2016, 104: 72-75.

[20] OVCHARENKO V D, KUPRIN A S, TOLMACHOVA G N, GILEWICZ A, LUPICKA O, ROCHOWICZ J, WARCHOLINSKI B. Deposition of chromium nitride coatings from vacuum arc plasma in increased nitrogen pressure [J]. Problems of Atomic Science and Technology, 2014, 94: 204-207.

[21] RIETVELD H M. A profile refinement method for nuclear and magnetic structures [J]. Journal of Applied Crystallography, 1969, 2: 65-71.

[22] YOUNG R A. The Rietveld method [M]. Oxford: Oxford University Press, 1993.

[23] ROMERO J, GOMEZ M A, ESTEVE J, MONTALA F, CARRERAS L, GRIFOL M, LOUSA A. CrAlN coatings deposited by cathodic arc evaporation at different substrate bias [J]. Thin Solid Films, 2006, 515: 113-117.

[24] VIDAKIS N, ANTONIADIS A, BILALIS N. The VDI 3198 indentation test evaluation of a reliable qualitative control for layered compounds [J]. Journal of Materials Processing Technology, 2003, 143-144: 481-485.

[25] ARCHARD J F. Contact and rubbing of flat surfaces [J]. Journal of Applied Physics, 1953, 24: 981-988.

[26] OHJI T, SINGH M. Advanced Processing and Manufacturing Technologies for Structural and multifunctional materials [M]. New Jersey: John Wiley & Sons Inc, 2009.

[27] HU G, ORKOULAS G, CHRISTOFIDES P D. Regulation of film thickness, surface roughness and porosity in thin film growth using deposition rate [J]. Chemical Engineering Science, 2009, 64: 3903-3913.

[28] ALMER J, ODEN M, H KANSSON G. Microstructure, stress and mechanical properties of arc-evaporated Cr-C-N coatings [J]. Thin Solid Films, 2001, 385: 190-197.

KANSSON G. Microstructure, stress and mechanical properties of arc-evaporated Cr-C-N coatings [J]. Thin Solid Films, 2001, 385: 190-197.

[29] BARRET C S, MASSALSKI. T B. Structure of metals [M]. Oxford: Pergamon Press, 1980.

[30] XU J, UMEHARA H, KOJIMA I. Effect of deposition parameters on composition, structures, density and topography of CrN films deposited by R.F. magnetron sputtering [J]. Applied Surface Science, 2002, 201: 208-218.

[31] HOY R, SLOOF W G, JANSSEN G C A M. Hard dense CrNx coatings on three dimensional objects [J]. Surface and Coatings Technology, 2004, 179: 215-222.

[32] CUNHA L, ANDRITSCHKY M, PISCHOW K, WANG Z. Microstructure of CrN coatings produced by PVD techniques [J]. Thin Solid Films, 1999, 355-356: 465-471.

[33] LIN J, SPROUL W D, MOORE J J, LEE S, MYERS S. High rate deposition of thick CrN and Cr2N coatings using modulated pulse power (MPP) magnetron sputtering [J]. Surface and Coatings Technology, 2011, 205: 3226-3234.

[34] LIN J, MOORE J J, SPROUL W D, MISHRA B, WU Z, WANG J. The structure and properties of chromium nitride coatings deposited using dc, pulsed dc and modulated pulse power magnetron sputtering [J]. Surface and Coatings Technology, 2010, 204: 2230-2239.

[35] HONES P, SANJINES R, LEVY F. Characterization of sputter-deposited chromium nitride thin films for hard coatings [J]. Surface and Coatings Technology, 1997, 94-95: 398-402.

[36] GRECZYNSKI G, LU J, TENGSTRAND O, PETROV I, GREENE J E, HULTMAN L. Nitrogen-doped, bcc-Cr films: Combining ceramic hardness with metallic toughness and conductivity [J]. Scripta Materialia, 2016, 122: 40-44.

[37] SANJINES R, BENKAHOUL M, SANDU C, SCHMID P, LEVY F. Electronic states and physical properties of hexagonal β-Nb2N and δ′-NbN nitrides [J]. Thin Solid Films, 2006, 494: 190-195.

[38] WARCHOLINSKI B, GILEWICZ A. Effect of substrate bias voltage on the properties of CrCN and CrN coatings deposited by cathodic arc evaporation [J]. Vacuum, 2013, 90: 145-150.

[39] MAYRHOFER P H, MITTERER C, HULTMAN L, CLEMENS H. Microstructural design of hard coatings [J]. Progress in Materials Science, 2006, 51: 1032-1114.

[40] LE V V, NGUYEN T T, KIM S K. The influence of nitrogen pressure and substrate temperature on the structure and mechanical properties of CrAlBN thin films [J]. Thin Solid Films, 2013, 548: 377-384.

[41] LEYLAND A, MATTHEWS A. On the significance of the H/E ratio in wear control: nanocomposite coating approach to optimized tribological behaviour [J]. Wear, 2000, 246: 1-11.

[42] POSTOLNYI B O, BERESNEV V M, ABADIAS G, BONDAR O V, REBOUTA L, ARAUJO J P, POGREBNJAK A D. Multilayer design of CrN/MoN protective coatings for enhanced hardness and toughness [J]. Journal of Alloys and Compounds, 2017, 725: 1188-1198.

[43] QI Z, WU Z, ZHANG D, WEI B, WANG J, WANG Z. Effect of sputtering power on the chemical composition, microstructure and mechanical properties of CrNx hard coatings deposited by reactive magnetron sputtering [J]. Vacuum, 2017, 145: 136-143.

[44] HOLMBERG K, MATTHEWS A, RONKAINEN H. Coatings tribology—Contact mechanisms and surface design [J]. Triboloy International, 1998, 31: 107-120.

[45] VALLETI K, REJIN C, JOSHI S V. Factors influencing properties of CrN thin films grown by cylindrical cathodic arc physical vapor deposition on HSS substrates [J]. Materials Science and Engineering: A, 2012, 545: 155-161.

[46] ZHANG S, SUN D, FU Y, DU H. Effect of sputtering target power on microstructure and mechanical properties of nanocomposite nc-TiN/a-SiN thin films [J]. Thin Solid Films, 2004, 447-448: 462-467.

[47] WARCHOLINSKI B, GILEWICZ A, RATAJSKI J. Cr2N/CrN multilayer coatings for wood machining tools [J]. Tribology International, 2011, 44: 1076-1082.

B. WARCHOLINSKI1, A. GILEWICZ1, A. S. KUPRIN2, I. V. KOLODIY2

1. Faculty of Technology and Education, Koszalin University of Technology, Koszalin 75-620, Poland;

2. National Science Center, Kharkov Institute of Physics and Technology, Kharkov, Ukraine

摘 要:采用静态阴极电弧蒸发法,在基体面向等离子体源的正表面和其背面沉积CrN涂层。研究氮气压力对涂层的结构、相组成、力学性能和摩擦学性能的影响。分别用扫描电镜、接触轮廓仪和X射线衍射仪对涂层的形貌和结构进行表征,采用纳米压痕法对其力学性能进行研究,并采用球盘式摩擦计对涂层的摩擦磨损性能进行研究。结果表明,涂层沉积过程中氮气压力的增加将导致相变的发生,其顺序为Cr2N → Cr2N + CrN → CrN。与沉积在基体背面的涂层相比,沉积在基体正面的涂层的粗糙度更高,这主要是正面涂层中大颗粒的数量较多造成的。基体正面涂层的硬度和弹性模量也较高。研究还发现,涂层的附着力与磨损率呈反比关系。

关键词:氮化铬;电弧蒸发;相成分;粗糙度;硬度;磨损

(Edited by Wei-ping CHEN)

Corresponding author: B. WARCHOLINSKI; E-mail: bogdan.warcholinski@tu.koszalin.pl

DOI: 10.1016/S1003-6326(19)64990-3