文章编号: 1004-0609(2005)03-0334-04

中间退火前后冷轧变形量对3003铝合金

阴极箔比电容的影响

通讯作者: 张新明, 教授; 电话: 0731-8830265; E-mail: xmzhang@mail.cus.edu.cn

张新明, 蹇 雄

(中南大学 材料科学与工程学院, 长沙 410083)

摘 要: 采用扫描电镜及能谱仪, 透射电镜和比电容检测等方法研究了中间退火前后冷轧变形量对3003铝合金阴极箔第二相分布及比电容的影响。 结果表明: 随着最终冷变形程度的增加, 位错密度增大, 从而比电容值显著提高; 最终冷轧变形量为90%时, 比电容达到最大值, 继续增加冷轧变形量, 比电容值反而下降; 但对于最终冷轧变形量95%的箔材, 由于中间退火前冷轧变形量较低, 使得退火过程中析出的弥散第二相数目减少, 最终导致成品箔中的腐蚀位置减少, 比电容降低。

关键词: 3003铝合金; 比电容; 变形; 位错密度; 第二相; 冷轧

中图分类号: TG335; TG146.2 文献标识码: A

Effects of cold deformation before and after

intermediate annealing on specific capacitance of

cathode foils of 3003 aluminum alloy

ZHANG Xin-ming, JIAN Xiong

(School of Materials Science and Engineering,

Central South University, Changsha 410083, China)

Abstract: By means of SEM(EDX), TEM and specific capacitance testing, the effects of cold rolling reduction before and after mediate annealing on the distribution of the second phases and the specific capacitance of cathode foil of 3003 aluminum alloy were investigated, respectively, The results show that the quantity of the fine second phase particles increases with the cold rolling reduction before the annealing treatment. The more the fine second phase particles, the higher the specific capacitance. The dislocation density which increases with the final cold rolling reduction can effectively enhance the specific capacitance, but there is a maximum specific capacitance at 90% reduction. So, both the dislocation density after the final cold rolling and the quantity of the second phases precipitated during the mediate annealing affect the final specific capacitance of the cathode foils of 3003 aluminum alloy obviously.

Key words: 3003 aluminum alloy; specific capacitance; strain; dislocation density; second phase; cold rolling

3003铝合金是一种重要的电容器用阴极材料[1-7], 工业生产中都是以铝箔产品形式供货, 其高比电容量一直是材料科学工程者追求的目标。 对于3003铝合金阴极硬态箔而言, 位错是腐蚀扩孔的有效通道, 利用箔中高能量的位错缺陷及第二相析出物与基体的电极电位差, 将其腐蚀可形成具有大量小空洞的海绵体结构, 以增大其比表面积, 从而提高箔材比电容[8, 9]。 van Alphen等[8]研究的重点在于探讨材料的织构、 晶粒尺寸、 析出物的分布与尺寸、 合金成分等对铝电解电容器阴极箔比电容的影响; Li等[10]、 Chen等[11]、 Dutta等[12]、 Pamiere等[13]研究了变形材料在退火过程中第二相的析出行为。 但这些工作都没有研究位错密度与第二相的综合作用对材料比电容(α)的影响。 目前国内外还有一些研究则集中于3003铝合金铸锭在加热和均匀化过程中Al6(Mn, Fe)相和α-Al(Mn, Fe)Si相之间的转化规律[14-16], 以及在转化过程中Si元素和Mn元素的作用[17]。 本文作者通过能谱分析确定了3003铝合金阴极箔中第二相的组成, 将位错密度对第二相析出行为的影响规律结合到3003铝合金阴极箔比电容的研究之中, 研究了中间退火前的冷轧变形程度和最终冷轧变形程度与第二相和位错密度的关系, 探讨了中间退火前后冷轧变形量对3003铝合金阴极箔比电容的影响规律。

1 实验

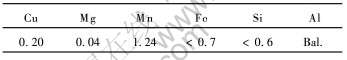

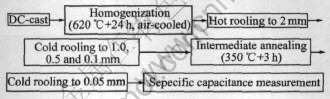

本实验所用的3003合金阴极箔的化学成分如表1所示。 箔材的制备流程如图1所示。 设定中间退火前的箔材厚度分别为1.0、 0.5、 0.1mm, 以保证铝箔最终的冷轧变形量相应分别为95%, 90%, 50%。 样品电解抛光后观察金相组织, 抛光液为10mL HCl4+90mL C2H5OH; 时间为50~60s, 电压为18V。 将抛好的试样用酒精和清水洗净, 吹干后在KYKY-2800扫描电镜上观察箔材表面的第二相的分布, 应用EDX对第二相的成分进行分析。 比电容测试选择JCC公司的方法, 测试液为1L纯水中溶入已二酸铵100g, ρ<sub>30℃=15Ω·cm, pH=6.8~7.0, 液温为(30±5)℃。

表1 3003铝合金的成分

Table 1 Chemical composition of studied 3003 aluminum alloy (mass fraction, %)

图1 0.05mm箔材的制备流程图

Fig.1 Procedure of cathode foils with thickness of 0.05mm

透射电镜实验在Hitachi-800型电镜下进行, 样品先用机械方法减薄至厚度为0.1mm的薄片, 在MIT-II型双喷电解仪上用HNO3和CH3OH(体积比为3∶7)溶液双喷减薄, 采用液氮冷却, 双喷温度为-25℃, 电压为10~20V, 电流为80~100mA。

2 结果和分析

2.1 位错密度和0.05mm阴极箔的比电容

变形材料的晶胞大小δ[11] 为

δ=0.35+0.17/ε(1)

式中 ε为真应变。 材料的位错密度ρ可由式(2)获得[11]:

δ=cδρ-0.5(2)

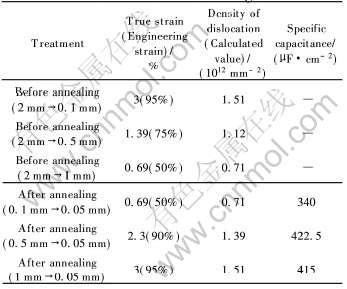

式中 cδ为常数, 约等于5。 由式(1)和(2)可以计算出位错密度的大小。 从2mm厚的3003铝合金热轧板到最终的0.05mm箔共经过两次冷轧变形, 变形前后的真应变、 位错密度和0.05mm腐蚀箔的比电容结果列于表2。

表2 中间退火前后铝箔的真应变、 位错密度和比电容

Table 2 True strain, dislocation density and specific capacitance of cathode foils before and after mediate annealing

由表2可见, 退火前应变小的样品, 退火后应变大; 但退火后铝箔的比电容量随着最终冷轧变形量的增加先增加, 然后降低, 90%时出现最大值。

中间退火处理前后随着冷轧变形量的增加, 位错密度增大, 但增加的趋势随着变形量的增大而变缓。 由于本实验所用3003铝合金阴极箔第二相和位错之间作用机制为奥罗万绕过机制[11]。 根据位错理论, 迫使位错线弯曲到曲率半径为r时所需的切应力为

τ=Gb/(2r)(3)

此时, 由于r=λ/2, 所以位错线弯曲到该状态所需的切应力为:

τ=Gb/λ(4)

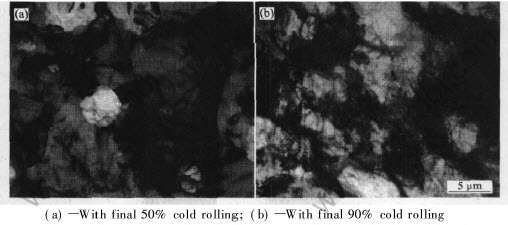

式中 G为切变弹性模量, b为柏氏矢量, λ为粒子间距的一半。 只有当外力大于Gb/λ这一临界值时, 位错才能绕过粒子, 陆续形成位错环。 位错环产生的应力场作用就等于增加了粒子的有效尺寸, 减小了粒子间的距离。 随着变形量的增加, λ减小, 所需外力τ快速增加, 位错运动更加困难。 当达到一定的变形程度后, 第二相的钉扎作用愈益明显, 位错运动变得更加困难, 这将直接影响位错密度, 使其趋势减缓。 图2所示为最终冷轧变形量为50%和90%的0.05mm箔材的位错组态。

由图2可见, 最终冷轧变形量由50%增加到90%时, 位错密度明显增加。 由表2还可以看出, 随着中间退火后最终冷变形量的增加, 比电容先增加。 最终冷轧变形量达到90%后, 比电容开始减小, 这说明最终冷变形所得到的位错密度不是影响比电容量的唯一因素, 中间退火过程析出的第二相也影响铝箔的最终比电容量。

2.2 扫描电镜及能谱实验结果

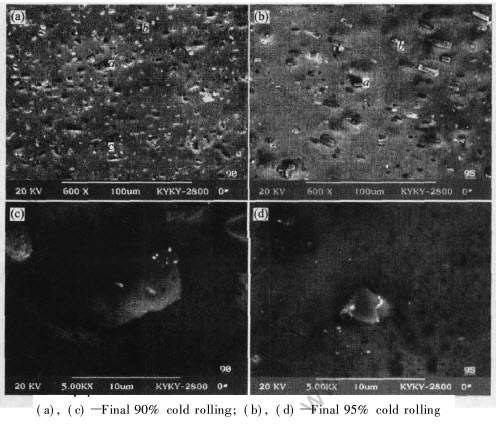

图3所示为0.05mm箔材中的第二相分布。 由 图3可见, 在最终冷轧变形量为90%的箔材中的第二相明显比在最终冷轧变形量为95%的箔材中的第二相多, 而且分布更弥散。 这种差别可能是由于中间退火前样品经历了比较大的冷轧变形。 按照Chen等[11]的实验结果可知,位错密度显著影响第二相的析出动力学, 高的位错密度有利于增强元素的扩散能力, 从而有利于沉淀相的形核和长大。 从表2可以看出, 退火前相应两个样品的位错密度分别为0.71×1012和1.12×1012/mm2, 因此形成了中间退火后的第二相数目上的差别。

图2 0.05mm阴极箔材中的位错组态TEM像

Fig.2 TEM images of dislocation configuration of cathode foils with thickness of 0.05mm

图3 0.05mm箔材中的第二相分布

Fig.3 Secondary phase distributions of cathode foils with thickness of 0.05mm

由图3还可看出, 箔材中的第二相主要呈棒状(图3(a))或者方块状(图3(b)),由能谱分析和文献[10-16]可知这些第二相可能是长条状的β-(Mn,Fe)Al6相和近方形(或球形)的α-Al(Mn,Fe)Si相。 这些相中随着铁和硅元素的溶入, 加大了与基体之间的电极电位差, 有利于腐蚀的进行。

3 结论

1) 最终冷轧变形量的增加, 导致位错密度快速增加, 但是达到一定的变形程度以后(约90%), 位错密度的增速减缓; 位错密度的增加导致了比电容的上升。

2) 退火前的冷变形量(或位错密度)影响比电容量。 随着冷轧变形量的提高, 第二相周围和晶界处位错密度高, 促使沉淀相的弥散析出, 增加了腐蚀位置, 进而提高箔材的比电容。

3) 为了获得高的比电容量需考虑位错密度和第二相的综合作用, 中间退火前的冷轧应有利于第二相的弥散析出; 退火后的冷轧应有利于位错密度的提高。

REFERENCES

[1]Aluminium S. Aluminum Alloy Foil for Cathode of Electrolytic Capacitor [P]. JP88106A-KoKai, Japan, 1988.

[2]Aluminium S. Aluminum Alloy Foil for Cathode of Electrolytic Capacitor [P]. JP88153811A-KoKai, Japan, 1988.

[3]Mitsubishi Aluminum Co. Ltd. Aluminum Alloy Containing Manganese, Iron and Copper for Use as Cathode in Electrolytic Capacitor [P]. JP51097519, 1975.

[4]Mitsubishi Light Metal Industries. Aluminum Alloy Foil Cathode for Electrolytic Capacitor [P]. JAJ81127759-KoKai, 1980.

[5]Sumitomo Light Metals. Manufacturing Aluminum Foil for Electrolytic Capacitor Cathode [P]. JP88137505A-KoKai, 1988.

[6]Sumitomo Light Metals. Aluminum Foil for Used as Electrolytic Capacitor Cathode [P]. JP88137504A-KoKai, 1988.

[7]Aluminium S. Aluminum Alloy Foil for Electrolytic Capacitor Cathode [P]. JAJ54135347, 1978.

[8]van Alphen L, Nauwen P, Slakhorst J. The relationship between the composition, the structure parameters and the etchability of alloyed Al-cathode foil for electrolytic capacitors [J]. Z Metallkde, 1979, 70(3):158-167.

[9]高亢之. 电解电容器用铝箔概述[J]. 轻合金加工技术, 2000, 28(11): 9-15.

GAO Kang-zhi. The survey of aluminium foil for electrolytic capacitor[J]. Process Technology of Light Alloy, 2001, 28(11): 9-15.

[10]Li J, Saimoto S. The role of solute segregation and precipitation at dislocations to enhance continuous recrystallization [J]. Mater Sci Eng A, 1997, A234-236: 1011-1014.

[11]Chen S P, Kuijpers N C W, Van der Zwang S. Effect of microsegregation and dislocations on the nucleation kinetics of precipitation in aluminium alloy AA3003 [J], Mater Sci Eng A, 2003, A341: 296-306.

[12]Dutta B, Palmiere E J, Sellers C M. Modelling the kinetics of strain induced precipitation in Nb microalloyed steels [J]. Acta Mater, 2001, 49: 785-794.

[13]Palmiere E J, Garcia C I, DeArdo A J. Influence of niobium supersaturation in austenite on the static recrystallization behavior of low carbon microalloyed steels[J]. Metall Mater Trans A, 1994, A25: 277-287.

[14]Li Y J, Arnberg L. Evolution of eutectic intermetallic particles in DC-cast AA3003 alloy during heating and homogenization [J]. Mater Sci Eng A , 2003, A347: 130-135.

[15]Tibballs J E, Horst J A, Simensen C J. Precipitation of α-Al(Fe,Mn)Si from the melt [J]. Journal of Materials Science, 2001, 36: 937-941.

[16]Bahadur A. Intermetallic phases in Al-Mn alloys [J]. Journal of Materials Science, 1988, 23; 48-54.

[17]Alexander D T L, Greer A L. Solid-state intermetallic phase transformations in 3XXX aluminium alloys[J]. Acta Materialia, 2002, 50: 2571-2583.

(编辑何学锋)

基金项目: 国家自然科学重点基金资助项目(50230310); 国家自然科学青年基金资助项目(50301016)

收稿日期: 2004-09-21; 修订日期: 2004-12-03

作者简介: 张新明(1946-), 男, 教授, 博士.