文章编号:1004-0609(2014)03-0615-09

电磁-超声能场对3003铝合金铸轧组织和性能的影响

乐 鹏,毛大恒,李建平,赵苏琨,扶宗礼

(中南大学 机电工程学院 高性能复杂制造国家重点实验室,长沙 410083)

摘 要:通过在铸轧区的关键部位引入电磁-超声能场,实现对3003铝合金的普通对称铸轧、非对称铸轧和非对称电磁-超声铸轧。用该方法分别制备了上述3种铸轧带坯,并将普通对称铸轧带坯与非对称电磁-超声铸轧带坯加工成厚度为0.25 mm的成品薄带。通过金相显微观察、扫描电镜观察和动静万能试验机测试分析了3种3003铝合金铸轧板的组织和性能。结果表明:与对称铸轧相比,非对称铸轧有效地抑制了宏观偏析,并使铸轧速度提高了33.3%;施加电磁-超声复合能场后,铸轧带坯晶粒显著细化,力学性能明显提高;电磁-超声成品薄带的抗拉强度、屈服强度和伸长率分别比普通成品薄带的提高了32.93%、38.91%和6.25%。

关键词:3003铝合金;电磁超声复合能场;冷轧退火;力学性能;析出相

中图分类号:TG113 文献标志码:A

Effect of electromagnetic-ultrasonic energy-field on structure and properties of roll-casting 3003 aluminum alloy strips

YUE Peng, MAO Da-heng, LI Jian-ping, ZHAO Su-kun, FU Zong-li

(State Key Laboratory of High Performance Complex Manufacturing,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Three kinds of plates (asymmetric and sunken aluminum plates, asymmetric and sunken plates under the electromagnetic-ultrasonic compound field and symmetric ones) were manufactured by introducing electromagnetic- ultrasonic field at the key parts of the roll-casting area. Then, asymmetric and sunken plates under the electromagnetic-ultrasonic compound field and symmetric ones were processed into 0.25 mm-thick end aluminum strip. The microstructures and properties were investigated by optical microscopy, scanning electron microscopy and static/dynamic universal testing machine. The results show that the speed of the asymmetric rolling is improved by 33.3% and the macro-segregation is diminished. By applying compound energy field, the grains are significantly refined and the mechanical properties are improved. Compared with those of the general roll-casting strips, the ultimate tensile strength, yield strength and elongation of compound energy field aluminum of roll-casting strips are improved by 32.93%, 38.91% and 6.25%, respectively.

Key words: 3003 aluminum alloy; electromagnetic-ultrasonic compound energy field; cold rolling annealing; mechanical properties; precipitate

连续铸轧制备的3003铝合金具有能耗低、流程短、加工成本低等优点,然而其发展却受到多方面的制约:常规铸轧生产的铝带坯枝晶网胞较发达,组织不均匀,晶粒较粗大,并且易产生中间偏析,导致铝带坯的力学性能下降,与通过传统铸锭热轧工艺制备的3003铝合金相比存在一定的差距,工业上一般采用添加变质剂的方法获得细晶组织,但存在成分偏析等问题[1];连续铸轧速度低,单机生产量小,无法满足国内与国际市场的需求。

为了提高铸轧速度,丁培道等[2]和YUN等[3]利用减薄铸轧带坯尺寸的方法来提高铸轧速度,但该方法对铸轧板的质量影响较大;HAGA等[4]采用立式双辊连铸技术有效地提高了铸轧速度,并拓宽了合金品种范围,但由于工艺条件十分严格,过程控制困难,该技术也不易推广。为了进一步节能降耗,同时提高铸轧带坯质量,VIVES[5]将电磁场引入连铸生产中,研究了电磁场对铸坯微观组织的影响,但缺乏对电磁场铸坯后续加工的研究;赵啸林等[6]和毛大恒等[7]研究了电磁场对金属凝固的作用机理,并研发了铝及铝合金电磁连续铸轧新技术;RAMIREZ等[8]研究了高密度超声波处理对镁合金晶粒细化作用和机理,认为超声波能打碎柱状晶,细化晶粒,使组织更加均匀;李建平等[9]将电磁场与超声能场结合并应用于铸轧,研究了复合能场对镁合金带坯组织和性能的影响。目前,有关电磁-超声复合能场对3003铝合金铸轧板组织和性能影响方面的研究未见报道。本文作者通过将电磁-超声复合能场引入铝合金带坯双辊铸轧的铸轧区,实现了多能场铸轧,验证了该方法的可行性,探讨了电磁-超声复合能场改善铝合金带坯以及其成品板材组织和性能的作用机理;此外,采用非对称下沉式新型铸轧工艺,研究了其作用机理和实施效果。

1 实验

1.1 实验设备和材料

1) 水平式双辊铸轧机组:d400 mm×500 mm、速度0~15 m/min、可铸轧厚度2~10 mm。

2) 熔化炉:电阻加热炉、容量300 kg。

3) 铸嘴:宽200 mm、型腔高13 mm、铸嘴材质为Al2O3+硅酸铝纤维+石棉烧结制品。

4) 超声波发生器:频率(20±0.5) kHz、功率2000 W、可调。

5) 电磁感应系统:变频电源、频率可变范围为0~50 Hz,电流可变范围为0~12 A,感应线圈(三相,每相580匝)。

6) 精炼除气装置:瓶装高纯氩气以及保护装置、覆盖剂、精炼剂。

7) 辅助设备:冷水系统、液压系统、剪切机、卷取机等。

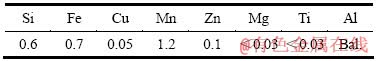

在上述设备上分别实施普通对称铸轧、非对称下沉式铸轧和非对称下沉式电磁-超声铸轧。制备3种宽度为200 mm、厚度为6.0 mm的3003铝合金带坯,标记为1号、2号和3号样品。3003合金的化学组成如表1所列。

表1 3003铝合金的化学组成

Table 1 Chemical composition of 3003 aluminum alloy (mass fraction/%)

1.2 实验方法

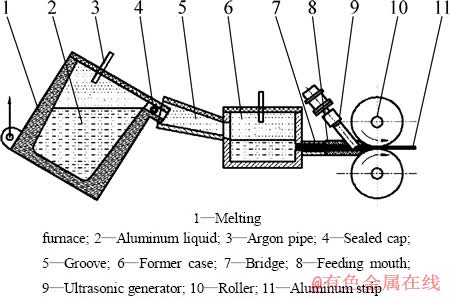

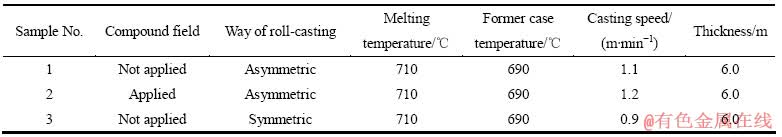

按表1所示成分配制3003铝合金,在电阻加热炉中进行融化,加入打渣剂熔炼,并加热至720~725 ℃进行保温。同时,将铸嘴和过桥分别放置于150 ℃左右和400 ℃左右的炉子内烘烤保温,除去水分。实验开始前加入精炼剂,通入氩气精炼并进行扒渣,升温至730 ℃静置30 min。实验开始时,将铸轧机辊缝调为6.0 mm,非对称铸轧的铸轧区长度为60 mm,对称铸轧的铸轧区长度为45 mm,熔体经流槽进入前箱,前箱温度保持在680~690 ℃之间,在合适的液面高度下保持稳定。经过多次降速,铝熔体持续与通有冷却水的棍套接触,制备了厚度为6.0 mm、宽度为200 mm的3003合金带坯。进行复合能场铸轧时超声波发生器安装在铸轧机的凝固前沿,功率为200 W;电磁场使用频率f=(13±1) Hz,电流I=10 A。铸轧过程示意图如图1所示,具体工艺参数见表2。

分别取本次实验的3种铸轧铝板截取试样,经镶样、粗磨、细磨、电解抛光和浸蚀后,在Leica DMI 5000M金相显微镜下进行观察。

图1 铸轧过程示意图

Fig. 1 Schematic diagram of roll-casting process

表2 铸轧实验参数

Table 2 Parameter of roll-casting experiment

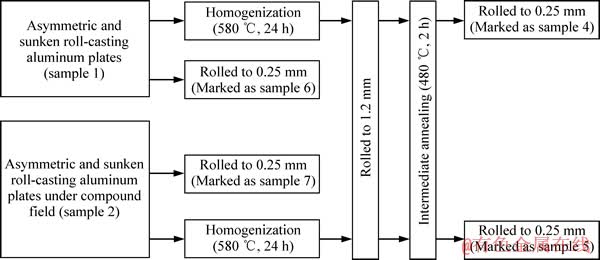

图2 0.25 mm厚薄带样品的制备流程图

Fig. 2 Flowchart of manufacturing of aluminum strip samples with thickness of 0.25 mm

取上述实验得到的初轧带坯试样1和2按照制罐料流程[10-11]加工为成品薄带试样4~7,工艺路线如图2所示。分别取非对称普通铸轧、非对称电磁-超声和普通对称式3种粗轧板(试样编号为1~3)和4种成品薄带(试样编号为4~7)在WPL-300动静万能实验机上沿铸轧方向(Roll-casting direction,RD)、45°方向、90°方向(Transverse direction,TD)进行拉伸测试。拉伸速率分别为2和1 mm/min,记录3种铸轧状态和4种成品状态下的铝带坯的σb、σ0.2和δ,每个测定值取3个试样拉伸结果的平均值。

最后,在JSM-6490LV扫描电镜下观察各状态下铝带坯的SEM像和析出相情况,并在能谱仪上对其指定区域进行DES成分分析。

2 结果与讨论

2.1 宏观组织观察

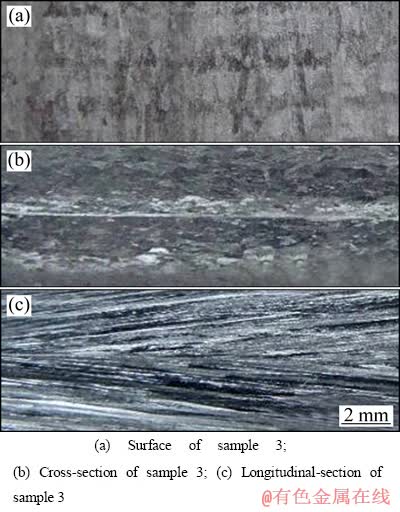

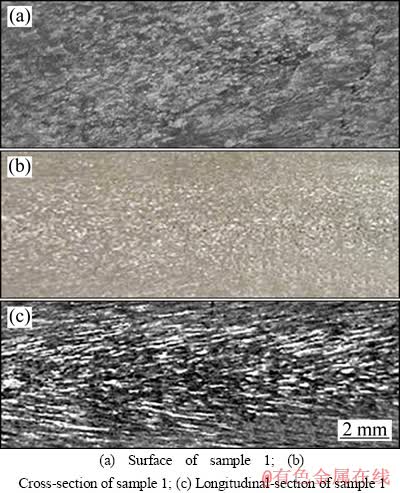

图3和4所示分别为对称铸轧和非对称铸轧带坯低倍金相组织。宏观组织观察表明:普通对称铸轧带坯中间偏析较严重,图3(b)中间分层明显,图3(c)中纵断面上、下两侧均呈明显的柱状晶并与中心界面成一定角度,以“人”字形有规则地排布;而非对称下沉式铸轧能够使铝带坯中间偏析层消失,如图4所示,并且组织更加致密。

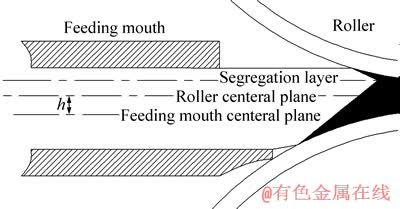

其次,由表2的实验参数可知:非对称下沉式铸轧速度达到1.2 m/min以上,远大于常规对称式铸轧的速度0.9 m/min,有效地提高了生产效率。图5所示为非对称铸轧机理图。由图5可知,当铸嘴中心面下沉至与轧辊中心面相距h的位置时,相应的铸轧区长度从45 mm增大到65 mm,下表面熔体和辊面的接触时间比上表面与辊面的接触时间长,则上、下表面熔体冷却强度不同,结晶条件也发生变化,其结果是使偏析层上移。当这种变化接近于极限状态时,偏析层消失,使带坯组织更加均匀;由于非对称下沉式铸轧的铝熔体接触面积比普通对称式的大,散热快,因此,提高了铸轧速度。

图3 对称铸轧铝板的宏观金相组织

Fig. 3 Macro-metallographs of symmetric roll-casting aluminum alloy plates

图4 非对称铸轧铝板的宏观金相组织

Fig. 4 Macro-metallographs of asymmetric roll-casting aluminum alloy plates

图5 非对称铸轧机理图

Fig. 5 Schematic diagram showing mechanism of asymmetric roll-casting

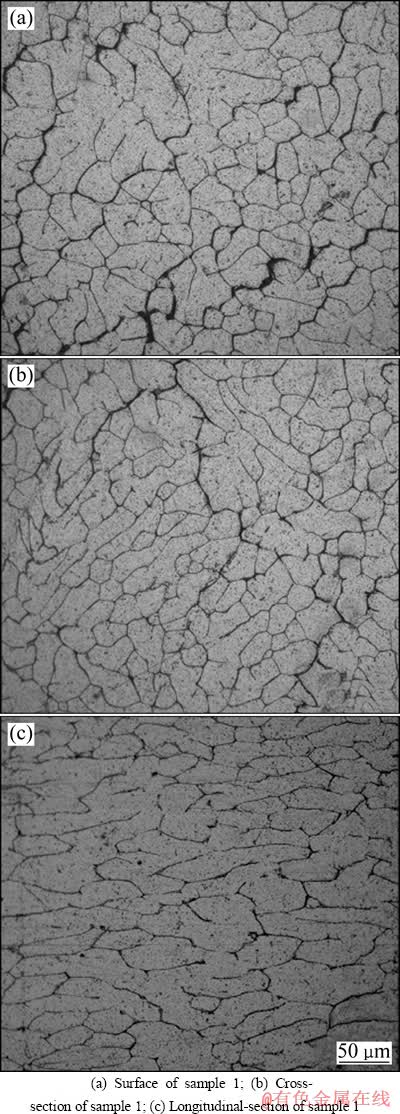

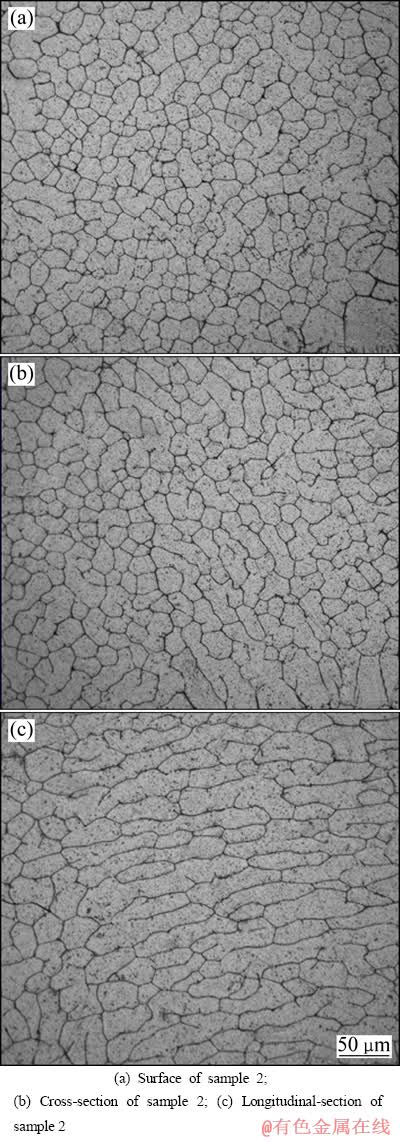

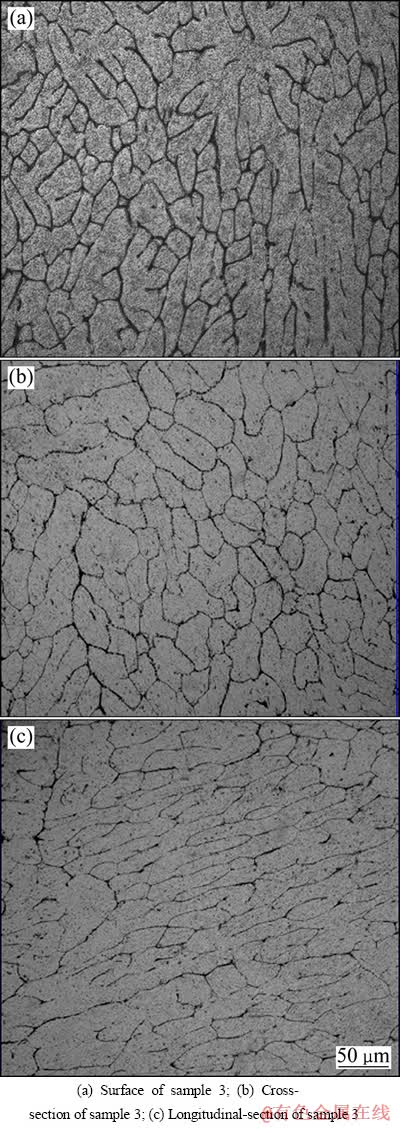

2.2 金相组织观察

由于铸轧是铸造与轧制在同一时间内完成,所以组织中含有“铸”与“轧”两个过程,带坯内有铸造、变形和再结晶3种组织,且致密度较低,晶界较宽。图6所示为普通对称铸轧铝板的微观金相组织;图7所示为施加复合能场铸轧带坯的金相组织;图8所示为未添加变质剂的非对称铸轧带坯的金相组织。由图8可见,非对称普通铸轧板带的晶粒较粗大,枝晶网胞发达,二次枝晶间距为15~20 μm,晶粒平均尺寸(直径)为40~50 μm,部分晶粒直径达到200 μm。通过将图6与图8对比可知,采取非对称工艺对铝带坯组织影响不大。将图7与图8对比可知,各截面经过电磁-超声波处理后的铸轧铝带坯大部分枝晶网胞被击碎,转化为更加细小的等轴晶粒,且分布较为均匀,晶粒平均尺寸(直径)在20~30 μm之间。

图6 普通对称铸轧铝板的微观金相组织

Fig. 6 Micro-metallographs of symmetric roll-casting aluminum alloy plates

图7 非对称下沉式电磁-超声铸轧铝板的微观金相组织

Fig. 7 Micro-metallographs of asymmetric and sunken roll-casting aluminum alloy plates under electromagnetic- ultrasonic compound energy field

超声波在熔体内传播的过程中,形成声流效应,发生超声空化作用[12]。此外,电磁场也起到强烈的搅拌作用,剪切枝晶并改善枝晶偏析。本研究中,在铸轧关键部位同时添加电磁和超声两种能场,使搅拌作用得到加强,组织中发达的枝晶组织被打碎,部分枝晶剥落成为新的晶核,从而提高了形核率;此外,复合能场使铝熔体凝固温度升高且凝固时间缩短,凝固方式由逐层凝固变为体积凝固,抑制了柱状晶的生成。在复合能场的作用下,熔体被均匀搅拌,晶粒更细小均匀。

图8 非对称下沉式铸轧铝板的微观金相组织

Fig. 8 Micro-metallographs of symmetric roll-casting aluminum alloy plates

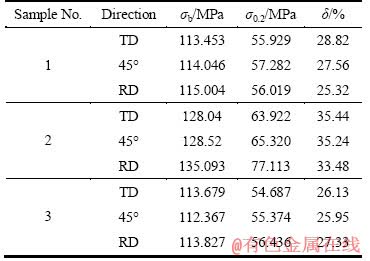

2.3 力学性能

表3所列为3种铸轧铝合金带坯的力学性能。从表3中可以看出,非对称普通铸轧带坯试样1的σb、σ0.2和δ的平均值分别为114.168 MPa、56.41 MPa和27.23%,施加电磁-超声能场后,试样2的3项力学性能分别提高到了130.551 MPa、68.785 MPa和34.72%,增幅分别为14.3%、21.94%和27.5%,其中3个不同方向上的伸长率的最大差值从试样1的3.5%减小到试样2的1.96%,说明施加复合能场后带坯的各向异性有所减小;而对比试样3和试样1的力学性能发现,它们并无显著差别。由此可见,非对称铸轧相比对称式铸轧并不能显著改善力学性能,而施加复合能场可显著地提高原始铸轧铝合金带坯的力学性能。

表3 铸轧合金板的拉伸性能

Table 3 Tensile properties of roll-casting aluminum alloy plates

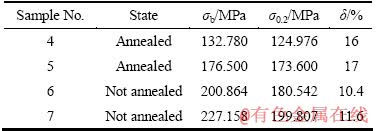

表4所列为4种成品薄带沿轧制方向的力学性能。表4表明:对于只经过冷轧的成品薄带,施加复合能场的试样7的σb、σ0.2和δ比未施加复合能场的试样6的分别提高了13.09%、10.67%和11.54%;而在均匀化处理和中间退火状态下,施加复合能场的试样5的σb和σ0.2较未施加复合能场的试样4的也分别提高了32.93%和38.91%,但伸长率的变化不大。无论对于直接冷轧组(试样6和7)或是经过均匀化和中间退火组(试样4和5),施加复合能场后,试样都表现出更加优良的力学性能。

表4 铸轧铝合金成品薄带沿轧制方向的拉伸性能

Table 4 Tensile properties of roll-casting aluminum alloy strips along RD

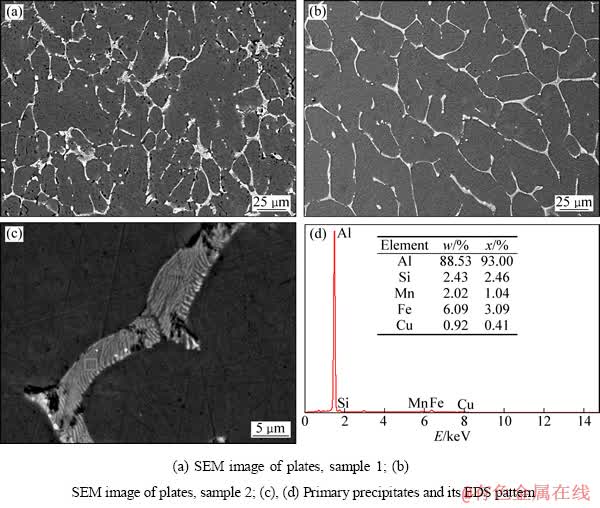

2.4 扫描电镜分析

通过对比普通铸轧带坯试样1和电磁-超声铸轧带坯试样2的SEM像(见图9)可以发现:两种带坯的析出相沿晶界析出,普通铸轧板材析出相主要聚集在晶界上,呈网络状分布,第二相较粗大;而施加复合能场后的析出相较少,且更加弥散,第二相较为细小。这是由于经复合能场处理后合金元素在基体相中的固溶度增加。对析出相进行EDS分析(见图9(d))可知,两种铸轧带坯中粗大的块状析出相主要为(Fe, Mn)Al6。

图9 3003铝合金铸轧板试样表面析出相的SEM像及EDS分析

Fig. 9 Precipitate morphologies and EDS pattern of 3003 aluminum roll-casting plates

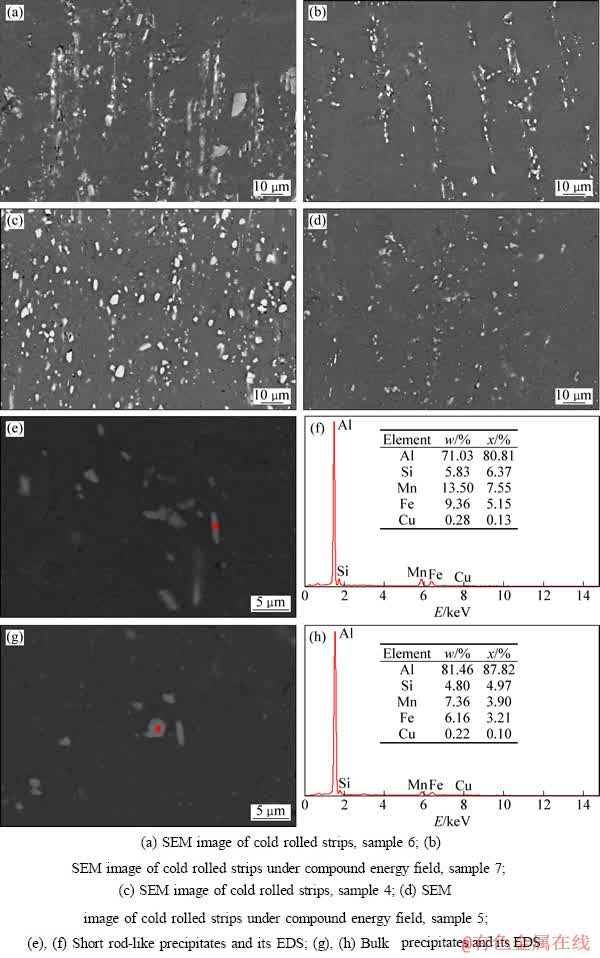

图10所示为两种铸轧带坯成品薄带试样4~7的SEM像。对比图10(a)、(b)与(c)、(d)可知,经热处理后的析出相不再沿轧制方向排列,这是由于高温均匀化过程中的析出相经过长大,对位错和亚晶界的钉扎力减小, 晶界发生移动[13-14]。对4种成品薄带进行EDS分析, 根据所得析出相各元素含量可知:图10(e)所示圆短棒状析出相是Al(Fe, Mn) Si相;图10(g)所示的块状相含有Al、Mn、Si和Fe 4种元素,该相为(Fe, Mn)Al6相。进一步对比施加电磁-超声的成品薄带试样5、7和未施加电磁-超声的成品薄带试样4、6的SEM像发现:普通成品薄带中析出相大小不均匀且块状大颗粒较多,而电磁-超声带坯制备的成品薄带析出相细小且分布较为均匀,这是由于电磁-超声的搅拌作用使得析出相充分弥散;其次,经复合能场处理后大量析出相粒子作为强化相弥散到基体中,使得普通成品薄带的析出相数量明显较多;最后,虽然两种成品薄带析出相种类相似,但是在组成比例上略有不同,施加电磁-超声处理的试样,析出相基本转化为Al(Fe, Mn)Si相,在数目上明显多于(Fe, Mn)Al6相,这是由于复合能场促进(Fe, Mn)Al6相向Al(Fe, Mn)Si相转变。Al(Fe, Mn)Si相对于(Fe, Mn)Al6相具有更高的强度,可以更好地防止深冲时擦伤的发生,从而有利于改善材料的加工性能[15]。

图10 成品铝薄带试样表面析出相的SEM像及其EDS谱

Fig. 10 Precipitate morphologies and EDS patterns of 3003 aluminum strips

3 结论

1) 所采用的非对称下沉式铸轧的铸轧速度可达1.2 m/min,与普通对称方式铸轧相比,铸轧速度可提高33.3%,并且铸轧带坯的中间偏析得到有效消除。

2) 普通铸轧带坯原始晶粒粗大且不均匀,而复合能场铸轧带坯原始晶粒为均匀细小的等轴晶;随着冷轧变形量的增加,两种铸轧板晶粒逐渐被压扁和拉长,最终获得明显的链状排列的纤维组织,其中复合能场铸轧板的组织更加细小。

3) 引入电磁-超声复合能场后3003铝合金铸轧带坯的组织和性能均得到明显改善,其抗拉强度、屈服强度和伸长率比普通铝带坯的分别提高了14.3%、21.94%和27.5%,其后续加工的成品薄带相应的力学性能比普通成品薄带也分别提高了32.93%、38.91%和6.25%。

4) 4种成品薄带的析出相主要为块状(Fe, Mn)Al6相和圆短棒状Al( Fe, Mn) Si相,经电磁-超声处理后薄带的析出相相对弥散均匀,数量较少,并且其圆短棒状析出相较普通薄带量大。

REFERENCES

[1] 侯 波, 李永春, 李建荣. 铝合金连续铸轧和连铸连轧技术[M]. 北京: 冶金工业出版社, 2010: 206-207.

HOU Bo, LI Yong-chun, LI Jian-rong. Aluminum alloy roll-casting and continuous casting and rolling technology[M]. Beijing: Metallurgical Industry Press, 2010: 206-207.

[2] 丁培道, 蒋 斌, 杨春楣, 方 亮. 薄带连铸技术的发展现状与思考[J]. 中国有色金属学报, 2004, 14(1): 192-196.

DING Pei-dao, JIANG Bin, YANG Chun-mei, FANG Liang. Development and thought of thin-strip continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 192-196.

[3] YUN M, LOKYER S, HUNT J D. Twin roll casting of aluminum alloys[J]. Materials Science and Engineering A, 2000, 280(1): 116-123.

[4] HAGA T, NISHIYAMA T, SUZUKI S. Strip casting of A5182 alloy using a melt drag twin-roll caster[J]. Journal of Materials Processing Technology, 2003, 133: 103-107.

[5] VIVES C. Effects of electromagnetic vibrations on the microstructure of continuously cast aluminum alloys[J]. Materials Science and Engineering A, 1993, 173(1/2): 169-172.

[6] 赵啸林, 毛大恒, 陈欠根. 将电磁场引入连续铸轧的新技术探讨[J]. 中国有色金属学报, 1995, 5(4): 145-149.

ZHAO Xiao-lin, MAO Da-heng, CHEN Qian-gen. Discussion of the introduction of the electromagnetic field to continuous roll casting technology[J]. The Chinese Journal of Nonferrous Metals, 1995, 5(4): 145-149.

[7] 毛大恒, 肖立隆, 丁道廉. 电磁场对铸轧板织构和力学性能的影响[J]. 中南大学学报: 自然科学版, 1998, 29(6): 573-576.

MAO Da-heng, XIAO Li-long, DING Dao-lian. Effect of electromagnetic field on texture and mechanical properties of casting and rolling plate[J]. Journal of Central South University of Technology: Natural Science, 1998, 29(6): 573-576.

[8] RAMIREZ A, MA Q, DAVIS B. Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloys[J]. Scripta Materialia, 2008, 9: 19-22.

[9] 李建平, 胡建冰, 毛大恒, 赵冠中. 超声波辅助铸轧AZ31镁合金板材的实验研究[J]. 华中科技大学学报: 自然科学版, 2010, 38(12): 126-132.

LI Jian-ping, HU Jian-bing, MAO Da-heng, ZHAO Guan-zhong. Experiment research on ultrasound cast-rolling AZ31 alloy strip[J]. Journal of Huazhong University of Science and Technology: Natural Science Edition, 2010, 38(12): 126-132.

[10] 张新明, 吴文祥, 蹇 雄, 周卓平. 退火过程中AA3003铝合金的析出行为[J]. 中国有色金属学报, 2005, 15(5): 666-679.

ZHANG Xin-ming, WU Wen-xiang, JIAN Xiong, ZHOU Zhuo-ping. Precipitation behavior of AA3003 aluminum alloy during annealing[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 666-679.

[11] 张新明, 蹇 雄. 中间退火前后冷轧变形量对3003铝合金阴极箔比电容的影响[J]. 中国有色金属学报, 2005, 15(3): 334-337.

ZHANG Xin-ming, JIAN Xiong. Effects of cold deformation before and after intermediate annealing on specific capacitance of cathode foils of 3003 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 334-337.

[12] MAO Da-heng, ZHANG Yun-fang, NIE Zhao-hui, LIU Qiao-hong, ZHONG Jue. Effects of ultrasonic treatment on structure of roll casting aluminum strip[J]. Journal of Central South University of Technology, 2007, 14(3): 363-369.

[13] ALEXANDER D T L, GREER A L. Solid-state intermetallic phase transformations in 3xxx aluminum alloys[J]. Acta Materialia, 2002, 50(10): 2571-2583.

[14] CHEN S P, KUIJPERS N C W, ZWAAG S. Effect of microsegregation and dislocations on the nucleation kinetics of precipitation in aluminum alloy AA3003[J]. Materials Science and Engineering A, 2003, 341(1/2): 296-306.

[15] 张永皞, 张志清, 林 林. 3xxx系罐身铝合金第二相及其对加工过程的影响研究进展[J]. 材料导报, 2012, 26(7): 101-108.

ZHANG Yong-hao, ZHANG Zhi-qing, LIN Lin. Research progress of second phases in 3xxx can body aluminium alloys and their effects on manufacturing[J]. Material Review, 2012, 26(7): 101-108.

(编辑 陈卫萍)

基金项目:国家重大专项资助项目(2010ZX04017–013)

收稿日期:2013-04-01;修订日期:2013-09-04

通信作者:毛大恒,教授;电话:13017297034;E-mail:276913655@qq.com