DOI: 10.11817/j.ysxb.1004.0609.2020-39608

3D打印砂型铸造Al-7Si-0.4Mg合金的组织和力学性能

赖晓玉,朱德智,陈维平,詹泉泉,陈 龙

(华南理工大学 广东省金属新材料制备与成形重点实验室,广州 510640)

摘 要:利用ProCAST软件对不同壁厚(5~30 mm)阶梯件的充型和凝固过程进行模拟,结合模拟结果进行浇注实验,重点研究壁厚对3D打印砂型铸造Al-7Si-0.4Mg合金的微观组织和力学性能的影响。结果表明:随着壁厚减小,合金中α(Al)的二次枝晶臂间距、共晶硅尺寸以及含Fe相的尺寸均减小;而合金的致密度和拉伸力学性能显著升高。T6态下,合金的最高(壁厚5 mm)抗拉强度为279 MPa,断后伸长率为2.13%。随着壁厚减小,合金的凝固冷却速度增加,组织得到细化,致密度提高,合金的强度和伸长率提高。此外,3D打印砂型铸造的铝合金性能受到砂模粘结剂含量的制约,断后伸长率较低。

关键词:砂型3D打印;铸造铝合金;ProCAST模拟;组织;力学性能

文章编号:1004-0609(2020)-07-1512-11 中图分类号:TG146 文献标志码:A

传统砂型铸造采用模具造型,砂型组合后浇注得到产品[1]。模具制造成本高,耗时长,复杂曲面造型困难。随着现代工业的发展,产品复杂性在提高,对生产效率,个性化定制的需求在增长,砂型铸造行业面临新的挑战。增材制造技术应用在砂型铸造领域,为砂型铸造带来全新的技术活力。

砂型3D打印技术,通过选择性地将粘结剂喷射到铸造砂的粉末床上直接制造砂模和芯盒,然后浇注得到产品,实现快速铸造[2]。砂型3D打印无需开模,直接实现所需砂型的一体化制造成形,大大提高了生产效率,降低了制造风险度,特别适合于新品开发、实验试制、个性化定制及中小批量型生产。该技术可以快速制造高度几何复杂性的砂型模具[3],可以打印中空砂型[4]结构,可以多材料打印[5],这些是传统铸造技术无法实现的,从而成为了近几年的研究热点。李栋等[6]利用砂型3D打印技术生产了具有复杂内腔的气缸盖,将铸造周期缩短为传统有模砂型铸造的1/6,大幅度节约生产时间。詹泉泉等[7]研究了树脂加入量、固化剂加入量、固化温度和固化时间4个因素对3D打印砂型的强度和发气量的影响规律。WALKER等[8]设计并打印了可以定点放置蓝牙测温传感器的砂型模具,验证了砂型3D打印技术可以实现在砂模内部关键位置无线与有线地集成前所未有的监控水平。SAMA等[9]设计了三种类型的直浇道(传统直锥型、抛物线型以及锥形螺旋线型),利用Viridis3D RAM printer打印了硅砂模具并且浇注了17-4不锈钢,CT断层扫描显示,与传统直锥型相比,抛物线型与锥形螺旋线型分别使整体铸造缺陷减少了56%和99.5%。利用3D打印可成形任意复杂结构的技术优势来设计可内置蓝牙的砂型和曲线型浇道,这些是传统砂型铸造和金属型铸造难以实现的。尽管砂型3D打印技术展现了一系列的优点,但是目前关于该技术的研究仍然存在着一些问题,需要深入研究,如:目前主要研究点集中在砂型3D打印的成形性,如研究打印参数[10]、粘结剂含量[11-12]、固化参数[13]、砂子类型[14]和模具性能[15]等,而其铸造的产品性能(力学性能,物理性能,孔隙率等)如何以及如何提升性能鲜有文献报道;作为粘结剂的树脂在高温金属液浇注过程中发生分解,产生大量气体,金属极易产生铸造缺陷[16],如何解决这个问题急待研究;3DP砂模复杂性增加,需要更加精确的铸造模拟来指导生产[17]才能获得质量优异的铸件等。

砂型3D打印技术通常用于制造结构复杂,含内腔和弯管的零件,此类零件的壁厚往往跨度较大,厚薄不一。一般情况下,铸件的壁厚对其性能有着重要影响[18-21],再者,3D打印砂型采用印刷方式逐层堆积,舍弃手工砂铸的压实过程,由松散砂子直接成形具有一定力学强度的模具,根据文献[22 -24]的报道,砂型3D打印技术使用的砂子物性参数和粘结剂添加量与传统树脂自硬砂有区别,那么在此种新情况下,壁厚对合金性能会产生怎样新的影响,变化规律如何,目前还未有文献报道出来。基于此,本文首先基于ProCAST软件设计了一套合理的铝合金阶梯件(壁厚5~30 mm)浇注系统,排除工艺不合理带来的负面影响,然后铸造了Al-7Si-0.4Mg合金的阶梯件,再重点研究了壁厚对3D打印砂型铸造铝合金微观组织和力学性能的影响。

1 实验

1.1 实验材料制备

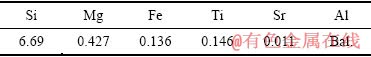

实验中的砂型模具和八字砂块由广东峰华卓立科技股份有限公司的砂型3D打印机PCM-800生产,工艺为标准生产工艺:原砂为湖北应城的高白砂,粘接剂为呋喃树脂,固化剂为磺酸类固化剂,粘结剂添加量为2.5%(质量分数),固化剂为粘结剂的30%,打印层厚为0.4 mm。铸件和模具结构示意图如图1所示。所有测试取样位置均从铸件阶梯面最底部开始取样,并且避开壁厚过渡区。实验所用原料为A356合金铝锭和Al-10Sr中间合金。在井氏坩埚电阻炉中进行熔炼,熔体经过精炼、氩气除气,扒渣后,于(720±5) ℃进行浇注,模具温度为室温,浇注时间控制在4~5 s。表1所列为本文中所用材料的具体成分。铸件热处理工艺:固溶540 ℃,4 h,淬火介质为水,温度60~70 ℃,时效180 ℃,8 h。固溶和时效均在空气热循环炉中进行。

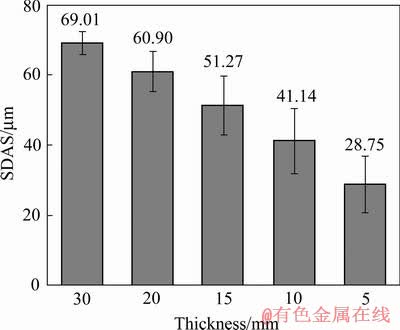

表1 本文中所用材料的化学成分(质量分数,%)

Table 1 Chemical composition of materials used in this article (mass fraction,%)

1.2 表征方法

采用Quanta 200型环境扫描电子显微镜和Nano SEM 430型场发射扫描电子显微镜观察铸件不同阶梯部位的微观组织、拉伸断口形貌及能谱分析。采用LeiCa/DMI 5000M型倒置金相显微镜观察合金的微观组织。采用直读光谱仪ARL4600测量本文制备的铝合金化学成分。室温拉伸性能测试(GB/T 228.1—2010)在MTS-100kN型万能材料试验机上完成,引伸计长度为25 mm,加载速率1 mm/min。实际密度与致密度采用阿基米德排水法测试,其中理论密度是将合金具体成分输入JMatPro 7.0中计算得到。二次枝晶臂间距(Secondary dendrite arm spacing, SDAS)采用截线法测量,测量时在放大100倍视场下选取至少10张金相照片,测量不少于50个数据,最后求平均值。共晶硅的形貌特征参数由Image Pro Plus 6.0测量,在放大2000倍视场下选取至少5张SEM照片,单张测量数据不少于50个,最后求平均值。

图1 铸件和模具结构示意图

Fig. 1 Schematic diagram of casting and mold structure

2 结果与分析

2.1 ProCAST模拟结果与分析

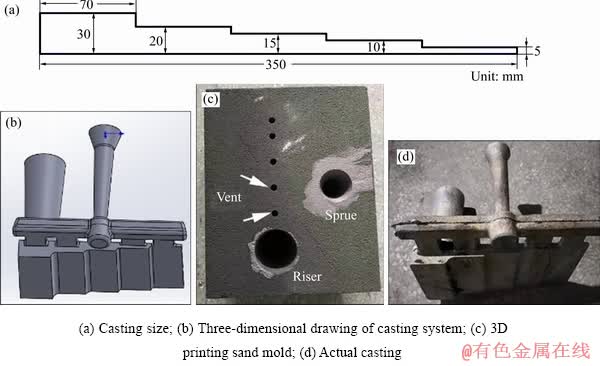

铝合金化学性质活泼,极易氧化和吸收气体,因此要求合金在浇注系统中流动平稳,不产生涡流、不发生喷溅。浇注系统设计不合理极易产生铸造缺陷[18-21],为了消除因为浇注系统等工艺因素不合理带来的负面影响,单一研究壁厚对合金性能的影响,在进行实际铸造之前,对阶梯件的浇注系统进行设计,并利用ProCAST软件进行铝合金的充型和凝固过程模拟,得到合理的浇注工艺参数。本文阶梯件浇注系统采用开放式底注浇注系统[18-21],浇口比(直浇道、横浇道、内浇道总截面积之比)为1:2:4,模拟参数:合金材料为Al-7Si-0.4Mg,砂型材料为呋喃树脂砂(CBFMS-M),浇注速度0.53 kg/s,浇注时间4 s,模具温度25 ℃,浇注温度720 ℃。图2所示为铸件充型过程示意图,可以看到,充型顺序是直浇道→横浇道→内浇道→铸件→冒口,金属液平稳上升。图3所示为铸件从薄到厚顺序凝固,缩孔缩松出现在浇道和冒口,本体铸件不出现。模拟结果显示浇注系统设计合理,可以用于实际铸造实验。

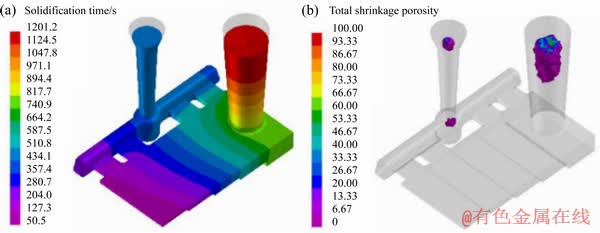

2.2 显微组织分析

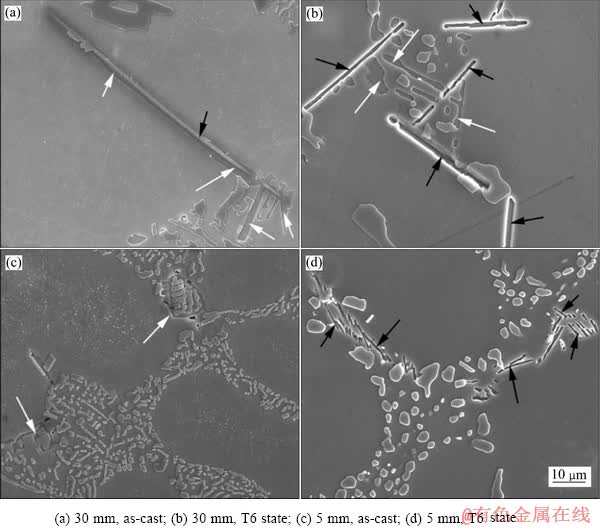

图4所示为阶梯件的微观组织。由图4(a)~(e)可以看出,合金的组织主要由α(Al)枝晶和(α(Al)+β-Si)共晶组成。金相照片显示α(Al)二次枝晶臂间距随着壁厚尺寸减小而不断细化,枝晶愈加发达,图4(e)中合金的SDAS最小,而且枝晶系最发达。图5所示为不同壁厚下合金的SDAS的统计数据,阶梯件壁厚越小,冷却速度越快,SDAS越小,当试样壁厚为30 mm时,SDAS为69.01 μm;试样壁厚5 mm时SDAS为28.75 μm,减少了58.3%。由图4(a1)~(e1)可以看到,壁厚30 mm和20 mm的合金组织中除了有纤维状的较细小共晶硅外,还存在一些粗大的块状共晶硅,形状不规则。这表明虽然合金中添加了Sr元素用于变质共晶 硅[20, 25-26],但是当冷却速度较慢时,共晶硅仍然会长成尺寸较大的不规则块状。而在壁厚10 mm和5 mm合金中的大部分共晶硅尺寸较小,形状接近圆形。

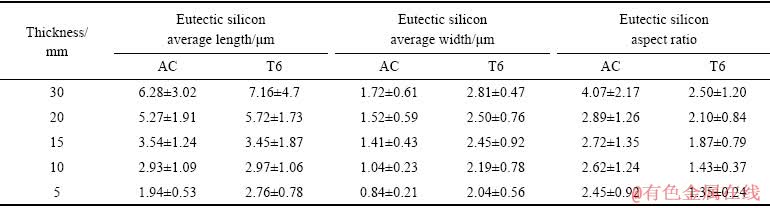

共晶硅颗粒的尺寸、形状和分布状态对合金的性能有重要影响,因此对其形貌特征参数进行统计,从表2可以看出铸态(As-cast, 简称AC)下共晶硅颗粒的平均长度、宽度及长径比随着壁厚尺寸减小而减小,当壁厚从30 mm减小到5 mm,共晶硅的长度从6.28 μm减小到1.94μm,减小了69.1%;宽度从1.72 μm减小到0.84μm,减小51.1%;长径比从4.07减小到2.45,减小39.8%。这表明合金的凝固冷却速度增加,有利于得到尺寸细小,更加圆整的共晶硅相。经过T6热处理后,共晶硅发生熔断,球化,长大,共晶硅的宽度明显变大,但是长径比变小,硅颗粒变得非常圆整,尤其是在壁厚为10mm和5 mm的合金中(见图4(d2)和(e2))。

图2 铸件充型顺序图

Fig. 2 Filling sequence diagram of casting

图3 铸件凝固时间与总收缩孔隙率

Fig. 3 Solidification time and total shrinkage porosity of casting

图4 阶梯件不同壁厚处的微观组织

Fig. 4 Microstructures of stepped parts with different thicknesses

图5 不同壁厚下合金的二次枝晶臂间距

Fig. 5 SDAS of alloys with different thicknesses

由图6可以看到,合金中的含Fe相主要有两种,经EDS分析,一种是π-Fe(Al8FeMg3Si6)[27-29](白色箭头所指),呈不规则形状;另一种是β-Fe(Al5FeSi)[27-29] (黑色箭头所指),呈针状。在铸态合金中,壁厚减小,形成的含Fe相尺寸会不断减小,与此同时,冷速增加,β-Fe的形成会受到抑制,如图6(b)所示,壁厚5 mm的合金中大部分含Fe相为π-Fe。从图6(a1)~(b1)的变化可知,T6热处理后,壁厚30 mm的合金中含Fe相尺寸仍然较大,而壁厚5 mm的合金中含Fe相尺寸变小了很多,且经EDS分析大部分为β-Fe。

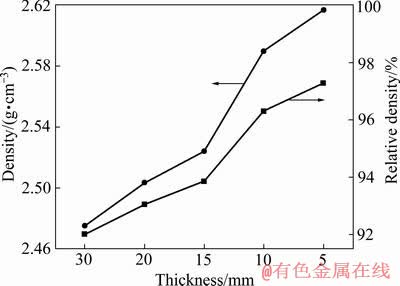

2.3 密度与致密度

对不同壁厚的合金进行密度测试,计算出其理论密度为2.69 g/cm3,实际密度和致密度测试结果如图7所示。从图7中可以看出,随着壁厚减小,合金的实际密度不断增大,在壁厚为5 mm时达到密度最大值2.62 g/cm3。密度的变化出现这种趋势是因为壁厚减小,合金冷却速度提高,组织得以细化致密,铸造缺陷(缩松、缩孔等)的数量和尺寸减小[30-31],所以合金的密度不断提高。另外,壁厚从30 mm减小到5 mm,致密度从92.01%升高到97.28%,提高了5.73%。合金致密度最高为97.28%,内部存在孔隙,这与3D打印砂型铸造过程中粘结剂发气量大有关[22, 32]。发气量过大导致气体无法及时排出,钻入铝液中形成孔洞,降低了合金的致密度。

图6 含Fe相的形貌和种类

Fig. 6 Morphologies and types of Fe-containing phases

表2 共晶硅的形貌特征参数

Table 2 Morphological characteristic parameters of eutectic silicon

图7 壁厚与密度和致密度的关系

Fig. 7 Relationship between wall thickness and density and density

2.4 合金的力学性能

图8所示为合金的力学性能随壁厚的变化关系。由图8(a)可以看到,随着壁厚减小,合金的铸态力学性能不断提高。铸态试样经过T6热处理之后,合金的屈服强度和抗拉强度大幅提升,断后伸长率下降。对于T6态试样,当壁厚从30 mm减小到5 mm,屈服强度从205.95 MPa增加到243.2 MPa,抗拉强度从209.1 MPa增加到279 MPa,断后伸长率从0.23%增加到2.13%,分别提高了18.1%、32.6%、830.4%,这主要是因为随着壁厚减小,合金SDAS减小,致密度提高,此外,共晶硅颗粒尺寸和含Fe相尺寸均减小,有利于T6过程中共晶硅颗粒熔断,球化以及含Fe金属间化合物的溶解,这也有利于合金力学性能的提高。壁厚30 mm和20 mm的合金几乎没有任何塑性,从15 mm减小到5 mm,合金的伸长率开始提高,最高(5 mm,其中SDAS为28.75 μm)的伸长率达到5.13%(铸态)和2.13%(T6态)。SNELLING[14]利用EXONETM的砂型3D打印技术铸造了直径25.4 mm的A356圆柱棒,其SDAS为45.28 μm,T6热处理后的抗拉强度为236.36 MPa。而本文制备的合金在SDAS为60.90 μm时,T6后抗拉强度就可以达到232 MPa,当SDAS为41.14 μm时,T6抗拉强度更是达到275 MPa,拥有比文献[14]更好的性能。此外,本文制备的A356铝合金铸态抗拉强度和伸长率还远高于SINGAMNENI等[33]利用ZCastTM的3D打印砂型铸造工艺制备的A356铝合金铸态抗拉强度和伸长率(132 MPa,0.8%)。

图8 合金的力学性能与壁厚的关系

Fig. 8 Relationship between mechanical properties of alloy and wall thickness

清华大学的陈瑞[27]研究了传统砂型铸造的Al-7Si-0.4Mg-T6合金在不同壁厚下的拉伸性能,当SDAS为70.1 μm时,合金抗拉强度为225 MPa,伸长率为0.6%;当SDAS为24.9 μm时,合金抗拉强度为278 MPa,伸长率为8.2%。孙少纯等[34]也制备了不同壁厚的传统砂铸A356铝合金,当SDAS为30 μm时,合金的抗拉强度为280 MPa,伸长率为7.9%。对比本文中合金的拉伸性能数据可以得出,无论SDAS较大或者较小,本文制备的合金抗拉强度都可以媲美工业化成熟的传统砂型铸造,但是当SDAS较小时,断后伸长率低于它们,展现出不一样的特点(具体分析详见后文)。

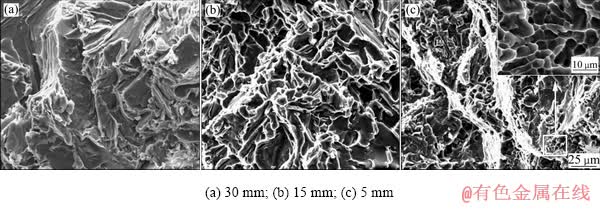

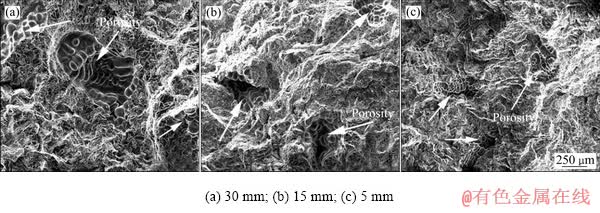

图9所示为阶梯件拉伸试样的断口形貌。从图9可以看到,在壁厚30 mm合金的拉伸断口中,存在大量的不规则解理面,呈现明显的脆性断裂特征[35]。这种特征与合金中粗大的共晶硅相和含Fe相密切相关,断裂优先起源于这些位置[27]。随着壁厚减小,合金断口上开始出现韧窝,解理区域减少。壁厚5 mm合金的断口表面主要是尺寸细小的韧窝和撕裂棱,呈现明显的韧性断裂特征[35],这表明,合金断裂前发生了大量的塑性变形,因此断后伸长率最高。从断口形貌的变化可知,随着壁厚减小,合金的断裂行为由脆性断裂向韧性断裂转变。T6处理之后,如图10所示,壁厚30 mm合金断口上仍然是许多解理台阶和少量的韧窝,随着壁厚减小,断口上解理区域减少,韧窝数量开始增加,深度加深,韧窝尺寸变得细小均匀。如图10(c),壁厚5 mm的合金断口上韧窝数量最多,深度最深,尺寸最细小,因此表现出最高的拉伸力学性能。

图9 铸态阶梯件拉伸试样的断口形貌

Fig. 9 Fracture morphologies of tensile specimen of stepped part (as-cast

图10 T6态阶梯件拉伸试样的断口形貌

Fig. 10 Fracture morphologies of tensile specimen of stepped part (T6 state)

图11 T6态阶梯件拉伸试样断口形貌低倍照片

Fig. 11 Fracture low magnification morphologies of stepped tensile specimen (T6 state)

图12 孔洞的形成原理

Fig. 12 Formation principle of holes

图11所示为合金的拉伸断口低倍图片。可以看到,断口表面分布有大气孔,无特定形状,内部是裸露的圆形凸起峰,它们的尺寸可达0.2~0.7 mm。随着壁厚减小,孔洞的尺寸和数量同时减少,这与2.3节中合金的致密度随壁厚减小而升高的规律一致。形成这些气孔缺陷的气体一部分来自于浇注前金属液本身,但是大部分气体来源于树脂砂模具发气[36]。孔洞的形成规律可以结合图12来解释:当高温铝液流经3DP阶梯模具型腔时,呋喃树脂和固化剂遇到高温发生分解,短时间内产生大量气体,如H2、O2、N2和CmHn[21, 37]等,一部分气体透过模具或者排气通道逸出,无法及时排出的气体滞留在砂型内,砂型内气体压力增大,气体(主要是H2[38-39])便钻入铝液中;合金凝固结晶时,氢原子在铝合金液中的溶解度急剧降 低[40],凝固界面前沿由于溶质再分配富集的大量氢原子大于其饱和浓度,就会析出气泡,最后形成气孔,阻碍合金继续凝固,于是在枝晶分叉间就形成了这些分散、不规则的大孔洞。壁厚越厚,合金冷速越慢,凝固时间越长,越有利于气泡析出和长大,形成的孔洞便越多、越大。当薄壁处已经凝固为固相(Solid),气体无法进一步侵入时,厚壁处仍然是未凝固状态(Melt),气体会继续侵入其中,所以厚壁处形成的孔洞会更多。

合金的伸长率对气孔缺陷非常敏感,断裂往往起源于孔洞,这些孔洞是文中制备的合金伸长率在SDAS较小时比传统砂型铸造低的主要原因。3DP砂模由散砂逐层印刷而成,无压实过程,为保证足够的机械强度用于铸造,当前阶段,其粘结剂含量(1%~4%)一般会比传统自硬树脂砂(0.8%~1.5%)高[32, 41-42]。较高粘结剂含量确保了砂模的强度,同时发气量也随之增加[43],气体缺陷增多,因此,合金的伸长率相较于传统砂型铸造出现了下降。但是从实用角度看,本文制备的3D打印砂型铸造Al-7Si-0.4Mg合金抗拉强度可以媲美已经工业化成熟的传统砂型铸造,对于汽车缸盖、缸体类对伸长率无高要求的铸件来说,3D打印砂型铸造可以满足其工业应用要求[44]。未来的研究方向可以放在降低粘结剂发气量,这对提高3D打印砂型铸造产品性能和加速其大规模工业化应用非常有价值。

3 结论

1) 利用3D打印砂型铸造的Al-7Si-0.4Mg合金,其中壁厚5 mm时合金的屈服强度、抗拉强度、断后伸长率可以达到234.4 MPa、279 MPa、2.13%。

2) 当壁厚从30 mm减小到5 mm,铸态合金中α(Al)枝晶的SDAS减小了58.3%,含Fe相尺寸减小且β-Fe形成受到抑制,共晶硅颗粒平均长度、宽度以及长径比分别减小了69.1%、51.2%、39.8%;合金的致密度随壁厚减小而升高,30 mm壁厚处仅为92.01%,5 mm壁厚处的致密度为97.28%,提高了5.73%;合金的屈服强度和抗拉强度随壁厚减小而大幅度提升,断后伸长率小幅度提升。因此,3D打印砂型铸造的Al-7Si-0.4Mg合金的力学性能与组织和致密度密切相关。

3) 本文制备的3D打印砂型铸造的Al-7Si-0.4Mg合金的抗拉强度可以媲美工业化成熟的传统砂型铸造,但受到3DP砂模粘结剂含量的制约,断后伸长率较低。

REFERENCES

[1] 郭少豪, 吕 振. 3D打印改变世界的新机遇新浪潮[M]. 北京: 清华大学出版社, 2013: 15-30.

GUO Shao-hao, L? Zhen. A new wave of new opportunities for 3D printing to change the world[M]. Beijing: Tsinghua University Press, 2013: 15-30.

[2] UPADHYAY M, SIVARUPAN T, EL MANSORI M. 3D printing for rapid sand casting-A review[J]. Journal of Manufacturing Processes, 2017, 29: 211-220.

[3] 金 枫. 基于粘结剂喷射的喷墨砂型三维打印技术新进展[J]. 机电工程技术, 2018, 47(9): 109-114.

JIN Feng. New development of 3D printing technology for inkjet sand mould based on binder jetting[J]. Electromechanical Engineering Technology, 2018, 47(9): 109-114.

[4] KANG Jin-wu, SHANGGUAN Hao-long, DENG Cheng-yang, HU Yong-yi, YI Ji-hao, WANG Xiang, ZHANG Xiao-chuan, HUANG Tao. Additive manufacturing-driven mold design for castings[J]. Additive Manufacturing, 2018, 22: 472-478.

[5] ROACH D J, HAMEL C M, DUNN C K, JOHNSON M V, XIAO Kuang, JERRY Q H. The m4 3D printer: A multi-material multi-method additive manufacturing platform for future 3D printed structures[J]. Additive Manufacturing, 2019, 29: 100819.

[6] 李 栋, 原晓雷, 孟庆文. 3D打印技术在高端铸件研发中的创新应用[J]. 工业技术创新, 2017, 4(4): 67-70.

LI Dong, YUAN Xiao-lei, MENG Qing-wen. 3D printing technology innovatively applied in R&D of professional casting[J]. Industrial Technology Innovation, 2017, 4(4): 67-70.

[7] 詹泉泉, 朱德智, 陈维平, 陈 龙, 温东宝. 响应面法优化3D打印呋喃树脂砂工艺条件[J]. 特种铸造及有色合金, 2019, 39(9): 981-983.

ZHAN Quan-quan, ZHU De-zhi, CHEN Wei-ping, CHEN long, WEN Dong-bao. Optimization of 3D printing furan resin sand process conditions by response surface methodology[J]. Special Casting & Nonferrous Alloys, 2019, 39(9): 981-983.

[8] WALKER J, HARRIS E, LYNAGH C, BECK A, LONARDO R, VUKSANOVICH B, THIEL J, ROGERS K, CONNER B, MACDONALD E. 3D printed smart molds for sand casting[J]. International Journal of Metalcasting, 2018, 12(4): 785-796.

[9] SAMA S R, WANG J, MANOGHARAN G. Non- conventional mold design for metal casting using 3D sand-printing[J]. Journal of Manufacturing Processes, 2018, 34: 765-775.

[10] VAEZI M, CHUA C K. Effects of layer thickness and binder saturation level parameters on 3D printing process[J]. The International Journal of Advanced Manufacturing Technology, 2011, 53(1/4): 275-284.

[11] KHANDELWAL H, RAVI B. Effect of molding parameters on chemically bonded sand mold properties[J]. Journal of Manufacturing Processes, 2016, 22: 127-133.

[12] XUE Liang, HU Chang-an, LI Xing-xing, LI Wang-ze, ZHANG Rui. Research on the influence of furan resin addition on the performance and accuracy of 3D printing sand mold[J]. Materials Science and Engineering A, 2018, 392(6): 062044.

[13] MITRA S, DE CASTRO A R, EL MANSORI M. The effect of ageing process on three-point bending strength and permeability of 3D printed sand molds[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97(1/4): 1241-1251.

[14] SNELLING D A, WILLIAMS C B, DRUSCHITZ A P. Mechanical and material properties of castings produced via 3D printed molds[J]. Additive Manufacturing, 2019, 27: 199-207.

[15] TOTH J, SVIDRO J T, DIOSZEGI A, STEVENSON D. Heat absorption capacity and binder degradation characteristics of 3D printed cores investigated by inverse Fourier thermal analysis[J]. International Journal of Metalcasting, 2016, 10(3): 306-314.

[16] WEN Shi-feng, SHEN Qi-shen, WEI Qing-song, YAN Chun-ze, ZHU Wei, SHI Yun-song, YANG Jing-song, SHI Yu-sheng. Material optimization and post-processing of sand moulds manufactured by the selective laser sintering of binder-coated Al2O3 sands[J]. Journal of Materials Processing Technology, 2015, 225: 93-102.

[17] NASTAC L. Modelling approach for quantitative prediction of macroshrinkage and microshrinkage in A356 sand mould castings[J]. International Journal of Cast Metals Research, 2012, 25(3): 144-154.

[18] 吕振林, 周勇欣, 徐春杰. 铸造工艺及应用[M]. 北京: 国防工业出版社, 2011.

Lü Zhen-lin, ZHOU Yong-xin, XU Chun-jie. Casting process and application[M]. Beijing: National Defense Industry Press, 2011: 123-180.

[19] 李魁盛, 侯福生. 铸造工艺学[M]. 北京: 中国水利水电出版社, 2005.

LI Kui-sheng, HOU Fu-sheng. Foundry technology[M]. Beijing: China Water Resources Press, 2005: 145-167.

[20] 李传栻. 铸造工程师手册[M]. 北京: 机械工业出版社, 2001: 334-385.

LI Chuan-shi. Foundry engineer manual[M]. Beijing: China Machine Press, 2001: 334-385.

[21] 吴殿杰, 章 舟. 呋喃树脂砂铸造生产及应用实例[M]. 北京: 化学工业出版社, 2012.

WU Dian-jie, ZHANG Zhou. Furan resin sand casting production and application examples[M]. Beijing: Chemical Industry Press, 2012: 120-146.

[22] 李 慧. 基于增材制造技术的无模铸型工艺优化[D]. 太原: 太原理工大学, 2016.

LI Hui. Optimization of pattern less casting manufacturing based on additive manufacturing technology[D]. Taiyuan: Taiyuan University of Technology, 2016.

[23] SNELLING D, LI Q, MEISEL N, WILLIANS C B, BATRA R C, DRUSCHITZ A P. Lightweight metal cellular structures fabricated via 3D printing of sand cast molds[J]. Advanced Engineering Materials, 2015, 17(7): 923-932.

[24] HAWALDAR N, ZHANG J. A comparative study of fabrication of sand casting mold using additive manufacturing and conventional process[J]. The International Journal of Advanced Manufacturing Technology, 2018, 97: 1037-1045.

[25] ZHANG Wei-da, MA Shi-xuan, WEI Zhen-hua, BAI Pei-kang. The relationship between residual amount of Sr and morphology of eutectic Si phase in A356 alloy[J]. Materials, 2019, 12(19): 3222.

[26] TIMELLI G, CALIARI D, RAKHMONOV J. Influence of process parameters and Sr addition on the microstructure and casting defects of LPDC A356 alloy for engine blocks[J]. Journal of Materials Science & Technology, 2016, 32(6): 515-523.

[27] 陈 瑞. 铝合金凝固-热处理全过程微观组织数值模拟及性能预测[D]. 北京: 清华大学, 2017.

CHEN Rui. Numerical simulation of microstructure and mechanical property of aluminum alloy during solidification and heat treatment processes[D]. Beijing: Tsinghua University, 2017.

[28] WANG Q G, DAVIDSON C J. Solidification and precipitation behaviour of Al-Si-Mg casting alloys[J]. Journal of Materials Science, 2001, 36(3): 739-750.

[29] 汪 黎. Fe对A356铸造铝合金性能的影响研究[D]. 重庆: 重庆大学, 2015.

WANG Li. Effect of Fe on the properties of A356 alloy[D]. Chongqing: Chongqing University, 2015.

[30] CESCHINI L, MORRI A, MORRI A, PIVETTI G. Predictive equations of the tensile properties based on alloy hardness and microstructure for an A356 gravity die cast cylinder head[J]. Materials and Design, 2011, 32(3): 1367-1375.

[31] CARRERA E, GONZALEZ J A, TAMANTES-SILVA J, COLAS R. Effect of the delay in time between cooling and aging in heat-treated cast aluminum alloys[J]. Metallurgical and Materials Transaction B, 2011, 42: 1023-1030.

[32] ZHAO Dong-hua, GUO Wei-zhong, ZHANG Bai-bing, GAO Feng. Research on key technique of line forming for 3D sand mould printing based on quantitative analysis of binder content[J]. Rapid Prototyping Journal, 2019, 25(1): 62-75.

[33] SINGAMNENI S, DIEGEL O, SINGH D, MCKENNA N. Rapid casting of light metals: An experimental investigation using taguchi methods[J]. International Journal of Metalcasting, 2011, 5(3): 25-36.

[34] SUN Shao-chun., YUAN Bo, LIU Man-ping. Effects of molding sands and wall thickness on microstructure and mechanical properties of Sr-modified A356 aluminum casting alloy[J]. Transactions of the Nonferrous Metals Society of China, 2012, 22(8): 1884-1890.

[35] 彭瑞东. 材料力学性能[M]. 北京: 机械工业出版社, 2018: 24-48.

PENG Rui-dong. Mechanical properties of materials[M]. Beijing: China Machine Press, 2018: 24-48.

[36] 陈 玲. 铝合金树脂砂铸造中侵入性气孔形成的研究[D]. 南京: 东南大学, 2016.

CHEN Ling. Study on the formation of intrusive pores in Al-Si castings made in sand mold[D]. Nanjing: Southeast University, 2016.

[37] 季文华. 呋喃树脂砂铸件常见缺陷及防止措施[J]. 现代铸铁, 2006, 5: 76-78.

JI Weng-hua. Common defects and preventive measures of furan resin sand castings[J]. Modern Cast Iron, 2006, 5: 76-78.

[38] 冯鹏发, 唐靖林. 铸造铝合金精炼技术现状及发展[J]. 热加工工艺, 2005, 1: 58-61.

FENG Peng-fa, TANG Jing-lin. Progress and prospect of refining technologies of aluminum casting alloys[J]. Hot Processing Technology, 2005, 1: 58-61.

[39] 铸造有色合金及其熔炼联合编写组. 铸造有色合金及其熔炼[M]. 北京: 国防工业出版社, 1980: 18-23.

Casting nonferrous alloy and its smelting joint writing group. Casting nonferrous alloy and its smelting[M]. Beijing: National Defense Industry Press, 1980: 18-23.

[40] 章四琪, 黄劲松. 有色金属熔炼与铸锭[M]. 北京: 化学工业出版社, 2006: 67-78.

ZHANG Si-qi, HUANG Jin-song. Smelting and ingot casting of non-ferrous metals[M]. Beijing: Chemical Industry Press, 2006: 67-78.

[41] WOODS K, GIESE S, TRIKHA S. Feasibility of US foundry supply chain consumables for three-dimensional sand printing[J]. International Journal of Metalcasting, 2019, 13(3): 500-503.

[42] 邢振国, 齐自新, 常连波, 李立新. 绿色铸造在呋喃树脂砂铸造中的应用[J]. 铸造技术, 2017, 38(1): 27-30.

XING Zhen-guo, QI Zi-xin, CHANG Lian-bo, LI Li-xin. Application of green casting idea in furan resin sand casting[J]. Foundry Technology, 2017, 38(1): 27-30.

[43] MITRA S, DE CASTRO A R, EL MANSORI M. On the rapid manufacturing process of functional 3D printed sand molds[J]. Journal of Manufacturing Processes, 2019, 42: 202-212.

[44] 徐伟业, 陈维平, 金 枫, 朱德智, 凌志成. 基于数值模拟和砂3D打印的机匣整体重力铸造工艺研究[J]. 铸造, 2019, 68(8): 905-910.

XU Wei-ye, CHEN Wei-ping, JIN Feng, ZHU De-zhi, LING Zhi-cheng. Study of cartridge receiver gravity casting process based on 3D printing sand mold and numerical simulation[J]. Foundry, 2019, 68(8): 905-910.

Microstructures and mechanical properties of 3D printing sand casting Al-7Si-0.4Mg alloy

LAI Xiao-yu, ZHU De-zhi, CHEN Wei-ping, ZHAN Quan-quan, CHEN Long

(Guangdong Provincial Key Laboratory for Processing and Forming of Advanced Merallic Materials, South China University of Technology, Guangzhou 510640, China)

Abstract: ProCAST software was used to simulate the filling and solidification process of step parts with different thicknesses (5-30 mm), and the casting experiment was carried out in combination with the simulation results, the effects of thickness on the microstructure and mechanical properties of 3D printing sand casting Al-7Si-0.4Mg alloy were studied. The results show that, as the wall thickness decreases, the secondary dendrite arm spacing, eutectic silicon size, and Fe-containing phase size of α(Al) in the alloy decrease, while the density and tensile mechanical properties of the alloy increase significantly. In the T6 state, the highest (thickness of 5 mm) tensile strength of the alloy is 279 MPa, and the elongation after break is 2.13%. According to the analysis, as the thickness decreases, the solidification cooling rate of the alloy increases, the microstructure is refined, the density is increased, and the strength and elongation of the alloy are improved. In addition, the properties of 3D printings and casting aluminum are limited by the sand mold binder content, and the elongation is low.

Key words: 3D sand printing; cast aluminum alloy; ProCAST simulation; microstructure; mechanical properties

Foundation item: Project(201804020071) supported by Guangzhou Basic Research, China; Project(2017B090911010) supported by Guangdong Science and Technology Plan Project-Major Special, China; Project (2018B090905002) supported by Guangdong Province Key Field Research and Development Program

Received date: 2019-09-25; Accepted date: 2020-01-12

Corresponding author: ZHU De-zhi; Tel: +86-20-87113267; E-mail: mezhudz@scut.edu.cn.

(编辑 龙怀中)

基金项目:广州市基础研究项目(201804020071);广东省科技计划项目-重大专项(2017B090911010);广东省重点领域研发计划资助项目(2018B090905002)

收稿日期:2019-09-25;修订日期:2020-01-12

通信作者:朱德智,副教授,博士;电话:020-87113267;E-mail:mezhudz@scut.edu.cn