DOI:10.19476/j.ysxb.1004.0609.2017.08.05

激光3D打印80Ni20Cr合金的显微组织及力学性能

谭树杰1,李多生1,Qinghua QIN2,刘红兵3,廖小军1,蒋 磊1

(1. 南昌航空大学 材料科学与工程学院,南昌 330063;

2. 澳大利亚国立大学 工程与计算机技术学院,堪培拉 2601;

3. 上海飞机制造有限公司 航空制造技术研究所,上海 201324)

摘 要:研究激光3D打印80Ni20Cr合金的层-层正交和层-层同向两种不同层激光加工路径打印的合金样件微结构和力学性能。结果表明:合金样件具有细小的等轴晶组织和柱状晶组织,柱状晶粒沿着激光加工路径生长。合金样件成分为Cr溶质溶于Ni溶剂的固溶体,打印样件密度与理论密度接近。层-层正交工艺打印合金样件的孔隙率要低于层-层同向工艺打印合金样件的,微观硬度和拉伸性能也要优于采用层-层同向工艺打印合金样件的,其抗拉强度可达410 MPa,硬度可达406 HV0.2。

关键词:3D打印;80Ni20Cr合金;微结构;力学性能;孔隙率

文章编号:1004-0609(2017)-08-1572-08 中图分类号:TG146 文献标志码:A

3D打印又称增材制造(Additive manufacturing, AM),ASTM F2792-12a标准中定义AM为一种与传统削减制造方法截然不同的,根据3D模型数据逐层连接材料来制造物体的工艺流程[1]。3D打印是一种绿色环保、安全节能、用户友好型的制造技术,它有着材料利用率高和加工时不受几何形状限制的优点,相比于传统加工技术,3D打印技术的用料只有原来的1/3到1/2,单件制造速度快3~4倍,特别适用于小批量、多品种、结构复杂、原材料价值高的结构件制造[2-5]。激光3D打印技术是使用激光作为输入热源的3D打印技术,目前激光3D打印技术发展迅速,在航空航天、医疗、船舶、汽车等领域有重要的应用前景[6-9]。姜华等[10]研究激光熔化沉积(Laser melting deposition, LMD) DZ408镍基高温合金的显微组织和力学性能,发现激光熔化沉积的板状DZ408合金具有微细定向生长的柱状晶组织,并具有优异的室温拉伸力学性能。张强等[11]研究沉积态激光3D打印Ti-5Al-2Sn-2Zr-4Mo-4Cr合金样的力学性能,发现试样表现出很强的各向异性。目前,国内外学者主要从激光功率、激光扫描速度、激光能量密度和送粉速度等不同角度研究了激光3D打印合金件宏观形貌、微观结构以及力学性能,并通过有限元分析软件模拟打印过程中温度场变化,揭示打印过程中合金件的成形机理[12-17];而有关激光加工路径对打印合金件的微结构以及力学性能的影响的研究较少。在激光3D打印过程中,随着激光加工路径的改变,金属凝固过程的温度梯度将发生改变,这会引起打印件微结构以及力学性能的变化。

镍基高温合金具有良好的耐磨、耐蚀和耐热性能,主要用于航空航天、船舶以及核反应堆制造领域[18]。有研究者发现,在80Ni20Cr合金中添加Ti和Al可以提高其抗蠕变性能,并于1941年研制出镍基高温合金Nimonic80(Ni-20Cr-2.5Ti-1.3Al)。镍基高温合金传统加工一般需要经过铸造、锻造及机加3个过程,加工过程中面临着加工设备昂贵、加工周期长、材料利用率低、难以制造形状复杂的零件等问题,而激光3D打印技术凭着自身的优点,可以较好地解决上述问题。SONG等[19]采用选区激光熔化(Selective laser melting, SLM) 技术打印80Ni20Cr合金样,样件致密,抗拉强度和硬度可达365 MPa、315 HV。本研究原材料为80Ni20Cr合金粉末,使用LMD这种激光3D打印技术,采用不同层向的激光加工路径打印80Ni20Cr合金样件,着重研究不同层向激光加工路径对合金力学性能的影响。

1 实验

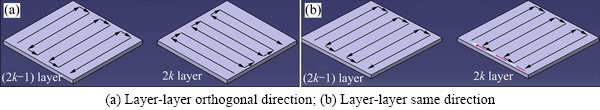

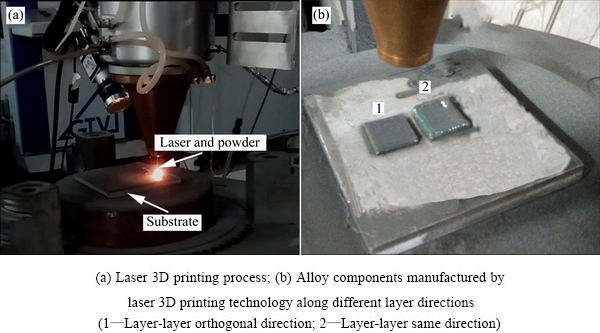

本研究原材料采用纯度为99.95%、平均粒径50 μm的Ni粉与纯度为99.95%、平均粒径50 μm的Cr粉,基板采用普通不锈钢基板。两种粉末放入球磨罐中球磨3 h,Ni粉与Cr粉质量比为80:20,球磨转速180 r/min。激光3D打印采用TH-2000F光纤激光机器人加工系统,该系统主要包括:1) 光纤激光器YLS-2000;2) KUKA机器人;3) 5轴联动数控成形机;4) GTV双筒送粉器。加工工艺参数如表1所列,不同层向激光加工路径如图1所示,打印过程及合金样件如图2所示。

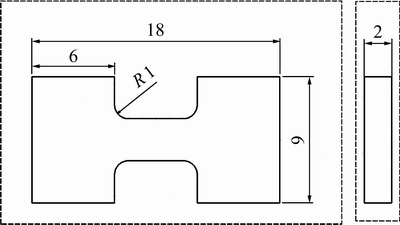

本研究采用阿基米德排水法测试样1和2的密度,试样经过石蜡密封后放入水中测量。采用Quanta200 FEG场发射扫描电镜(FE-SEM)观察合金样件的微结构和断口形貌,采用D8型X射线衍射仪对样件进行衍射分析,采用维氏硬度测试仪和万能试验机测量样件的微观硬度和拉伸性能。测量密度时,先对试样进行表面清洁,再使用精度为0.1mg的分析天平称量,并计算密度和孔隙率。扫描电镜观察样件从试样1的表面和侧面分别切取,镶嵌后打磨抛光,采用王水腐蚀,腐蚀时间为30 s;XRD测试样从试样1上切取,经打磨抛光后放入衍射仪中测试分析。维氏硬度测量时,分别从试样1和2上切取一小块样品,表面打磨抛光后进行测试实验,测量样品上表面的硬度,测试压力为1.96 N,保压时间10 s,每个样品测量3次,取其平均值作为测试结果。拉伸样件尺寸如图3所示,拉伸试样分别从试样1和2中切割得到,切割方向为沿着激光扫描方向,拉伸试验在室温下进行,拉伸速度为0.01 mm/s, 样件被拉断后,使用场发射扫描电镜观察断口的微观形貌。

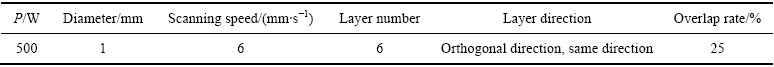

表1 激光3D打印工艺参数

Table 1 Parameters in laser 3D printing process

图1 不同层激光加工路径

Fig. 1 Laser printing directions of different layers

图2 激光3D打印过程及合金样件

Fig. 2 Laser 3D printing technology and alloy components

图3 拉伸试样尺寸

Fig. 3 Tensile specimen size (Unit: mm)

2 结果与讨论

2.1 密度和微结构

2.1.1 密度

对不同层向激光3D打印的80Ni20Cr合金样件密度进行了分析发现,激光3D打印的80Ni20Cr合金的密度与理论密度接近,致密度较好。计算出层-层正交打印的合金样件孔隙率为2.3%,层-层同向打印的合金样件孔隙率为4.7%。因此,采用层-层正交打印的合金样件密度要大于层-层同向打印的合金样件,孔隙较少,具有更好的致密性。

2.1.2 显微组织

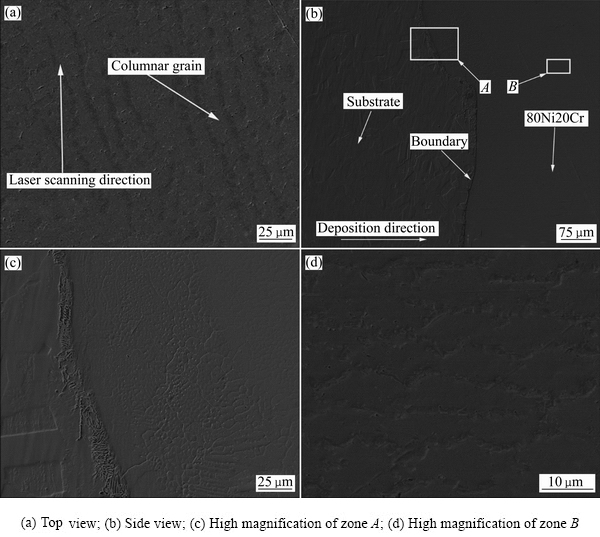

图4所示为层-层正交激光3D打印80Ni20Cr合金样件的FE-SEM像。从图4中可以看出,合金样件中主要分布着柱状晶粒。图4(a)所示为合金试样上表面的FE-SEM像。从图4(a)中可以看出,合金样件表面的柱状晶粒主要沿着激光扫描路径方向分布。图 4(b)所示为80Ni20Cr合金的侧面FE-SEM像,图4(c)和(d)所示分别为图4(b)中A区域和B区域的高倍照片。从图4(b)~(d)中可以看出,样件底部有细小的片状晶粒,随着沉积高度的增加,晶粒由底部的片状逐步转变为柱状。激光3D打印过程是一个快速加热和快速冷却的过程,在金属粉末进入熔池时,熔池中的高温金属液快速冷却,产生足够大的过冷度,瞬时形成大量晶核,而且这些晶核没有充分的时间长大,最终形成大量细小的晶粒。由于面心立方晶系晶体在与{100}面垂直的 方向长大速度最快,在激光3D打印过程中,那些

方向长大速度最快,在激光3D打印过程中,那些 方向与最大热流方向接近的晶粒择优生长,形成柱状晶[19-20]。在本研究中,层-层同向激光打印80Ni20Cr合金样的微观组织与层-层正交激光3D打印80Ni20Cr合金样的组织相近。

方向与最大热流方向接近的晶粒择优生长,形成柱状晶[19-20]。在本研究中,层-层同向激光打印80Ni20Cr合金样的微观组织与层-层正交激光3D打印80Ni20Cr合金样的组织相近。

图4 层-层正交打印80Ni20Cr合金FE-SEM像

Fig. 4 FE-SEM images of 80Ni20Cr alloy component produced by laser 3D printing with layer-layer orthogonal direction

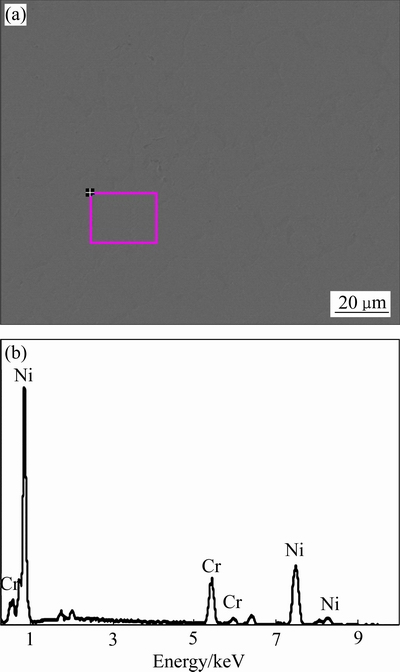

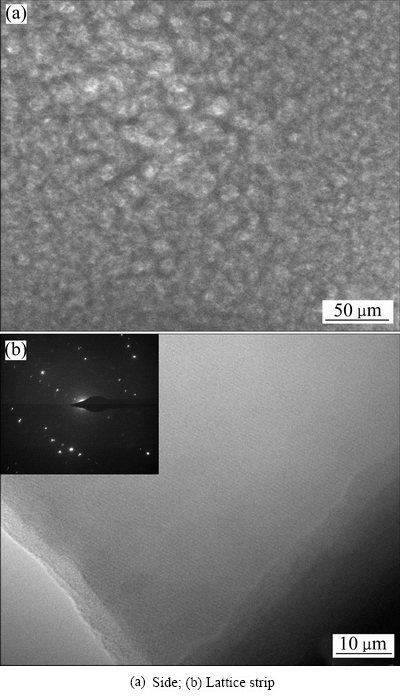

图5所示为层-层正交激光3D打印80Ni20Cr合金样的SEM像及EDS谱,表2所示为图5中长方形区域的EDS元素分析。结合图5及表2可以发现,激光3D打印80Ni20Cr合金中Ni与Cr质量比接近80:20,与设计值保持一致。

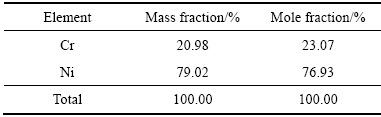

图6所示为80Ni20Cr合金样件侧面不同区域TEM像及衍射花样,测试试样从试样1侧面切取。从图6(a)中可以看出,晶粒内部生长良好,没有明显的缺陷;从图6(b)可看出,80Ni20Cr合金样中微晶的晶格,条纹方向一致,晶粒内部生长有序;电子衍射花样为点阵花样,点阵排列有序,经计算及与卡片对比可知该衍射花样为面心立方晶体的衍射花样,光点位置略有偏移,原因可能是由于Cr原子固溶进入Ni晶胞导致了晶格畸变。

图5 层-层正交激光3D打印80Ni20Cr合金FE-SEM像和EDS谱

Fig. 5 FE-SEM image(a) and EDS spectrum(b) of 80Ni20Cr alloy component produced by laser 3D Printing with layer-layer orthogonal direction

表2 EDS点分析元素含量

Table 2 Element content of EDS point scan

图6 试样1侧面不同区域TEM像

Fig. 6 TEM images of different regions at side of sample 1

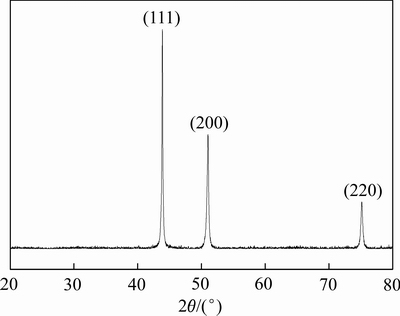

2.1.3 XRD衍射分析

图7所示为试样1的XRD谱。由图7可看出,衍射中特征峰明显,没有杂质峰出现。由图7可见,XRD谱中(111)、(200)、(220)对应着面心立方晶体Ni,因此,推断合金样件的成分为溶质Cr溶于溶剂Ni的固溶体。同标准卡片对比发现80Ni20Cr合金样件谱线与Ni标准卡片谱线相似,并且发现合金样件谱线向左偏移,其原因可能是由于Ni原子半径与Cr原子半径不同造成晶格畸变,以及在激光3D打印过程中因熔池快速冷却产生的残余热应力所导致,这与透射电镜观察结果一致。

图7 层-层正交3D打印80Ni20Cr合金样件XRD谱

Fig. 7 XRD pattern of 80Ni20Cr alloy component produced by laser 3D printing with layer-layer orthogonal direction

2.2 力学性能

2.2.1 微观硬度

对不同层向激光3D打印的80Ni20Cr合金样件硬度分析发现,层-层正交打印的80Ni20Cr合金样件硬度为406 HV0.2,层-层同向打印的合金样件硬度为 359 HV0.2。采用层-层正交打印的80Ni20Cr样件的硬度要比采用层-层同向打印的80Ni20Cr样件高出13%。层-层正交中导致两者硬度不同的原因可能为在激光3D打印过程中,沿着激光加工路径的过冷度较大,晶粒沿着激光加工路径方向长大;层-层正交打印的80Ni20Cr合金,相邻层的激光加工路径相互正交,合金样件相邻层的晶粒沿着相互正交的方向生长,这使得不同层中的晶粒方向偏差较大;层-层同向打印的80Ni20Cr合金,相邻层激光加工路径没有发生改变,不同层的晶粒生长方向没有很大的变化。两者相比,采用层-层正交打印的80Ni20Cr合金在不同层上存在着大量取向不同的晶粒,这些晶粒生长相互交错,抑制了晶粒进一步生长,晶粒分布均匀,使得样件微结构更加致密,抵抗变形的能力更强。而采用层-层同向打印的80Ni20Cr合金样件,不同层晶粒取向相同,晶粒容易长大,这使得内部晶粒不均匀,抵抗变形的能力差,所以层-层正交打印样件的硬度要大于层-层同向打印样件。

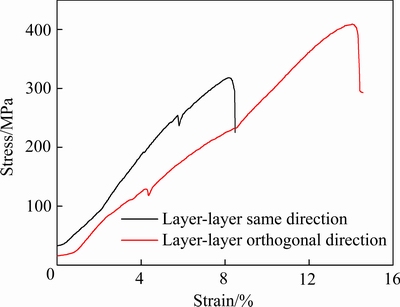

2.2.2 拉伸性能及断口微观形貌

图8所示为层-层正交和层-层同向打印的80Ni20Cr合金样件的应力-应变曲线。从图8中可以看出,层-层正交打印的80Ni20Cr合金样件抗拉强度为410 MPa,层-层同向打印的80Ni20Cr合金样件的抗拉强度为320 MPa,采用层-层正交打印的80Ni20Cr合金样件的抗拉强度要比采用层-层同向打印的样件高28%。层-层正交打印的80Ni20Cr合金的抗拉强度与经过固溶处理后的80Ni20Cr锻件相比仍有一定差距,锻件的抗拉强度在600~800 MPa。但与SONG等[19]使用SLM技术打印的80Ni20Cr合金相比,抗拉强度提高了10%。

图8 80Ni20Cr合金样件应力-应变曲线

Fig. 8 Stress-strain curves of 80Ni20Cr alloy component

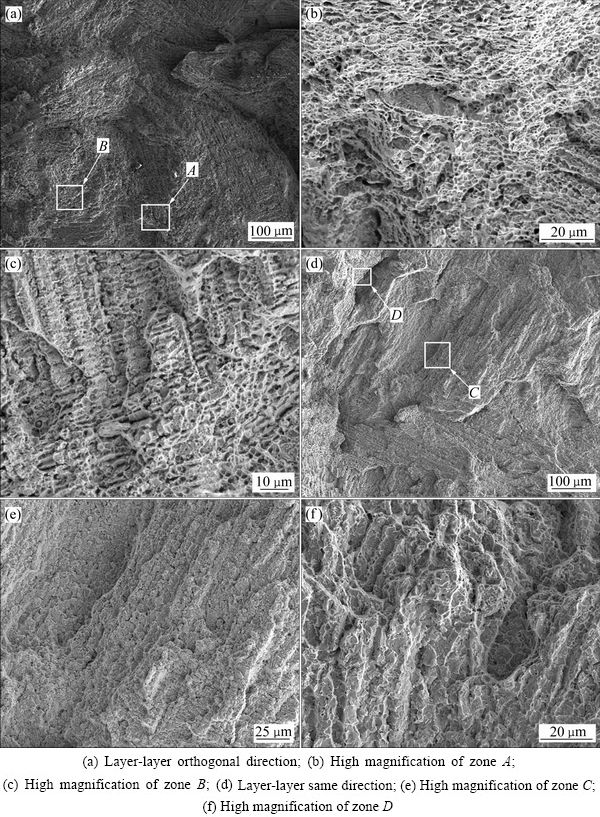

图9所示为合金样件断口的FE-SEM像,图9(a)所示为层-层正交打印的80Ni20Cr合金样件断口微观形貌断口形貌,图9(b)、(c)所示为图9(a)图中A、B两区域的高倍照片;图9(d)所示为层-层同向打印的80Ni20Cr合金样件断口微观形貌,图9(e)、(f)所示为图9(d)图中C、D两区域的高倍照片。从图9(a)和(d)中可以发现,合金断口表面有着柱状晶粒的存在,这些晶粒方向垂直于拉伸正应力方向,这表明了柱状晶粒在生长过程中沿着与拉伸正应力垂直的方向即激光加工路径方向生长,与显微组织分析中的结果一致。从图9(b)和(c)中可以看出,试样1断口存在大量的韧窝、河流状形貌和枝晶状形貌,其中以韧窝的数量较多;试样1的断裂主要为穿晶断裂和沿晶断裂。从图9(e)、(f)中可以发现,试样2断口以河流状形貌为主,伴随着较少的韧窝,表现为沿晶断裂为主要断裂方式,同时伴随着少量的穿晶断裂,因此,层-层正交打印样件的抗拉强度要大于层-层同向打印样件,其结果与图8应力-应变曲线较吻合。出现这种现象的原因可能是层-层正交与层-层同向激光3D打印80Ni20Cr合金样件具有不同的微结构特征,从而呈现不同的力学性能。在拉伸过程中,采用正交工艺制备的80Ni20Cr合金中可能存在着大量的交错的晶粒,随着正应力的加大,与正应力方向垂直的晶界先被撕裂,具体表现为图9(c)中的河床状形貌和枝晶状形貌,此处为沿晶断裂;而与正应力方向平行的晶粒则需要被拉断,具体表现为图9(b)中的韧窝形貌,此处为穿晶断裂。而采用层-层同向工艺制备的80Ni20Cr合金,因其晶粒取向大都相同,交错的晶粒较少,所以,晶粒在拉伸过程中逐渐转动到与正应力方向垂直,随后晶界断裂,发生沿晶断裂。

图9 不同层向激光3D打印80Ni20Cr合金样件拉伸断口FE-SEM像

Fig. 9 FE-SEM images of tensile fracture surfaces of 80Ni20Cr alloy components manufactured by laser 3D printing with different layer directions

3 结论

1) 激光3D打印的80Ni20Cr合金密度与理论密度接近,孔隙率为2.3%~4.7%,层-层正交3D打印样件孔隙率小于层-层同向打印样件,具有较好的微结构特征。

2) 在激光3D打印过程中,晶粒沿着 方向择优生长,打印的80Ni20Cr合金样件中主要的晶粒为柱状晶粒。

方向择优生长,打印的80Ni20Cr合金样件中主要的晶粒为柱状晶粒。

3) 层-层正交打印的80Ni20Cr合金样件的硬度和抗拉强度要优于使用层-层同向打印的合金样件,其抗拉强度可达410 MPa,硬度可达406 HV0.2;层-层正交打印的80Ni20Cr合金样件拉伸断裂表现为穿晶断裂和沿晶断裂,而层-层同向打印的80Ni20Cr合金表现为沿晶断裂为主,伴随着少量的穿晶断裂。

REFERENCES

[1] ASTM F2792-12a. Standard terminology for additive manufacturing technologies[S]. 2012.

[2] ANDREW J P. Lasers in additive manufacturing[J]. Optics & Laser Technology, Part A, 2016, 78: 25-32.

[3] POORAN C J, RYAN R D, CHAD E D, WILLIAM H P, RONALD D O, LONNIE J L, CRAIG A B. Direct digital additive manufacturing technologies: Path towards hybrid integration[C]// Future of Instrumentation International Workshop. Gatlinburg: IEEE, 2012: 1-4.

[4] 杨恩泉. 3D打印技术对航空制造业发展的影响[J]. 航空科学技术, 2013(1): 13-17.

YANG En-quan. The influence of 3D printing to the development of aviation manufacturing[J]. Aeronautical Science & Technology, 2013(1): 13-17.

[5] 田宗军, 顾冬冬, 沈理达, 谢德巧, 王东生. 激光增材制造技术在航空航天领域的应用与发展[J]. 航空制造技术, 2015(11): 38-42.

TIAN Zong-jun, GU Dong-dong, SHEN Li-da, XIE De-qiao, WANG Dong-sheng. Application and development of laser additive manufacturing technology in aeronautics and astronautics[J]. Aeronautical Manufacturing Technology, 2015(11): 38-42.

[6] SUGAVANESWARAN M, ARUMAIKKANNU G. Modelling for randomly oriented multi material additive manufacturing component and its fabrication[J]. Materials & Design, 2014, 54: 779-785.

[7] 王华明. 高性能大型金属构件激光增材制造: 若干材料基础问题[J]. 航空学报, 2014, 35(10): 2690-2698.

WANG Hua-ming. Materials’ fundamental issues of laser additive manufacturing for high-performance large metallic components[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(10): 2690-2698 .

[8] 林 鑫, 黄卫东. 应用于航空领域的金属高性能增材制造技术[J]. 中国材料进展, 2015, 34(9): 684-688, 658.

LIN Xin, HUANG Wei-dong. High performance metal additive manufacturing technology applied in aviation field[J]. Materials China, 2015, 34(9): 684-688, 658.

[9] 苏海军, 尉凯晨, 郭 伟, 马菱薇, 于瑞龙, 张 冰, 张 军, 刘 林, 傅恒志. 激光快速成形技术新进展及其在高性能材料加工中的应用[J]. 中国有色金属学报, 2013, 23(6): 1567-1574.

SU Hai-jun, WEI Kai-chen, GUO Wei, MA Ling-wei, YU Rui-long, ZHANG Bing, ZHANG Jun, LIU Lin, FU Heng-zhi. New development of laser rapid forming and its application in high performance materials processing[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1567-1574.

[10] 姜 华, 汤海波, 方艳丽, 王华明. 激光熔化沉积DZ408镍基高温合金微细柱晶显微组织及性能[J]. 中国激光, 2012, 39(2): 78-84.

JIANG Hua, TANG Hai-bo, FANG Yan-li, WANG Hua-ming. Microstructure and mechanical properties of rapid solidified ultra-fine columnar grain Ni-base superalloy DZ408 by laser melting deposition manufacturing[J]. Chinese Journal of Lasers, 2012, 39(2): 78-84.

[11] ZHANG Qiang, CHEN Jing, TAN Hua, LIN Xin, HUANG Wei-dong. Microstructure evolution and mechanical properties of laser additive manufactured Ti-5Al-2Sn-2Zr-4Mo-4Cr alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(8): 2058-2066.

[12] 杨海欧. Rene95合金激光立体成形显微组织与力学性能研究[D]. 西安: 西北工业大学, 2002.

YANG Hai-ou. The microstructure and mechanical characters of rene95 laser solid forming[D]. Xi’an: Northwestern Polytechnical University, 2012.

[13] 张剑峰, 沈以赴, 赵剑峰, 黄因慧, 余承业. Ni基金属粉末激光快速制造的研究[J]. 航空学报, 2002, 23(3): 221-225.

ZHANG Jian-feng, SHEN Yi-fu, ZHAO Jian-feng, HUANG Yin-hui, YU Cheng-ye. Study on laser sintering of Ni-based alloy powders[J]. Acta Aeronautica et Astronautica Sinica, 2002, 23(3): 221-225.

[14] ZHANG Qun-li, YAO Jian-hua, JYOTI M. Laser direct metal deposition technology and microstructure and composition segregation of Inconel 718 superalloy[J]. Journal of Iron and Steel Research International, 2011, 18(4): 73-78.

[15] ROBERTS I A, WANG C J, ESTERLEIN R, MYNORS D J. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing[J]. International Journal of Machine Tools & Manufacture, 2009, 49: 916-923.

[16] LI Ya-li, GU Dong-dong. Thermal behavior during selective laser melting of commercially pure titanium powder: Numerical simulation and experimental study[J]. Additive Manufacturing, 2014, 1/4: 99-109.

[17] JOHN R, LEILA L, JAFAR R, MAGDA S. Temperature distribution and melt geometry in laser and electron-beam melting processes–A comparison among common materials[J]. Additive Manufacturing, 2015, 8: 1-11.

[18] 韩 栋, 张永强, 雷文光, 毛小南. 镍基合金板带加工技术及应用发展现状[J]. 材料导报, 2015(5): 83-87.

HAN Dong, ZHANG Yong-qiang, LEI Wen-guang, MAO Xiao-nan. Development of manufacturing technology and application for nickel alloys sheets and strips[J]. Materials Review, 2015(5): 83-87.

[19] SONG B, DONG Shu-juan, CODDET P, LIAO Han-lin, CODDET C. Fabrication of NiCr alloy parts by selective laser melting: Columnar microstructure and anisotropic mechanical behavior[J]. Materials and Design, 2014, 53: 1-7.

[20] 张亚玮, 张述泉, 王华明. 激光熔化沉积定向快速凝固高温合金组织及性能[J]. 稀有金属材料与工程, 2008, 37(1): 169-172.

ZHANG Ya-wei, ZHANG Shu-quan, WANG Hua-ming. Microstructure and mechanical properties of directional rapidly solidified Ni-base superalloy Rene95 by laser melting deposition manufacturing[J]. Rare metal materials and engineering, 2008, 37(1): 169-172.

Microstructure and mechanical properties of 80Ni20Cr alloy manufactured by laser 3D printing technology

TAN Shu-jie1, LI Duo-sheng1, QIN Qinghua2, LIU Hong-bing3, LIAO Xiao-jun1, JIANG Lei1

(1. School of Materials Science and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. College of Engineering and Computer Science, Australian National University, Canberra 2601, Australia;

3. Aeronautical Manufacturing Technology Research Institute, Shanghai Aircraft Manufacturing Co., Shanghai 201324, China)

Abstract: 80Ni20Cr alloy was manufactured by laser 3D printing technology using two different laser 3D printing routes, namely, layer-layer orthogonal and layer-layer with the same direction, and the microstructure and mechanical properties of 80Ni20Cr alloy were also studied. The results show that the microstructures of alloy components present small lamellar grains and columnar grains, and the columnar grains grow along the path of laser 3D printing route. The composition of the alloy components is Ni-Cr solid solution based Ni solvent. Moreover, the density of 80Ni20Cr alloy manufactured by laser 3D printing is close to the theoretical density of alloy. The porosity of 80Ni20Cr alloy fabricated by laser 3D printing technology using layer-layer orthogonal route is lower than that of layer-layer with the same direction, meanwhile, the average micro-hardness and tensile properties of 80Ni20Cr alloy components using layer-layer orthogonal route are also higher than that of using layer-layer with the same direction, and the tensile strength of alloy reaches up to 410 MPa, the hardness of alloy reaches up to 406 HV0.2.

Key words: 3D printing; 80Ni20Cr alloy; microstructure; mechanical properties; porosity

Foundation item: Projects(11372100, 51562027) supported by the National Natural Science Foundation of China; Project(YC2015-S311) supported by Jiangxi Province Graduate Innovation Fund, China

Received date: 2016-06-28; Accepted date: 2017-02-27

Corresponding author: LI Duo-sheng; Tel: +86-791-83953320; E-mail: ldsnuaa@nuaa.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(11372100, 51562027);江西省研究生创新基金资助项目(YC2015-S311)

收稿日期:2016-06-28;修订日期:2017-02-27

通信作者:李多生,副教授,博士;电话:0791-83953320;E-mail: ldsnuaa@nuaa.edu.cn