文章编号: 1004-0609(2005)08-1272-06

湿化学法合成YAG纳米粉体及透明陶瓷

闻 雷1, 孙旭东2, 其 鲁1, 马伟民3

(1. 北京大学 化学与分子工程学院, 北京 100871;

2. 东北大学 材料与冶金学院, 沈阳 110004; 3. 沈阳大学 机械工程学院, 沈阳 110041)

摘 要: 分别以AlCl3和YCl3的混合溶液为母盐, 碳酸氢铵(AHC)或氨水(AW)为沉淀剂, 采用共沉淀法制备了YAG超微粉。 AHC法得到的沉淀物经900℃煅烧2h后, 全部转变为YAG相, 没有YAM和YAP等中间相生成。 1100℃煅烧2h后获得的YAG粉体分散性好, 一次颗粒尺寸为80nm, 具有良好的烧结活性, 使用0.5%(质量分数)的正硅酸乙酯(TEOS)作为烧结添加剂, 经过1700℃真空烧结5h后, 获得了YAG半透明陶瓷。 AW法煅烧过程中出现了YAP相, 得到的粉体团聚严重, 烧结体密度很低。

关键词: YAG; 透明陶瓷; 纳米粉; 湿化学法

中图分类号: TQ174. 75

文献标识码: A

Nanocrystalline YAG powders and translucent ceramics

by wet-chemical method

WEN Lei1, SUN Xu-dong2, QI Lu1, MA Wei-min3

(1. College of Chemistry and Molecular Engineering,Peking University, Beijing 100871, China;

2. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

3. School of Mechanical Engeering, Shenyang University, Shenyang 110004, China)

Abstract: By using the mixture of aluminum and yttrium chloride and ammonium hydrogen carbonate (AHC) or ammonia water (AW) as the reagent and precipitants, respectively, the nanocrystalline yttrium aluminum garnet(YAG) powder was synthesized by the co-precipitation method. The precursor obtained through the AHC method completely was transformed to YAG phase after calcining at 900℃ for 2h, and no intermediate YAM or YAP phase was detected during calcining. YAG powders obtained by calcining the carbonate precursor at 1100℃ are well dispersed, the primary particle diameter is about 80nm and the YAG powders have high sinterability. Translucent YAG ceramics were fabricated after vacuum sintering at 1700℃ for 5h using 0.5% tetraethyl orthosilicate(TEOS) as sintering aid addition. YAP phase is formed during calcing the hydroxide precursor by AW method. The resultant YAG powders are severely agglomerated and caused low density of the sintered body.

Key words: YAG; translucent ceramic; nanocrystalline powder; wet-chemical method

钇铝石榴石(yttrium aluminum garnet, YAG)具有优良的光学性能和稳定的化学性能, 作为结构材料和功能材料得到了广泛应用[1-3]。 YAG单晶体通常采用Czochralski法来生长, 但其过程十分复杂, 条件苛刻[4], 因此许多学者研究通过烧结方法获得YAG透明多晶体的方法, 以降低成本, 提高晶体的性能。 目前采用共沉淀法得到YAG纳米粉体, 再经过烧结制取YAG透明陶瓷的方法得到了广泛重视。 Li等[5]采用NH4Al(SO4)2·24H2O和Y(NO3)3·6H2O为原料, 以NH4HCO3为沉淀剂, 得到了YAG纳米粉体, 并在1700℃下烧结得到了YAG透明体。 Tokumatsu等[6]采用了以肼(联氨, (NH2)2·H2O)为沉淀剂的共沉淀制备了YAG粉体。 沉淀法需要对反应过程仔细加以控制, 才能得到性能优良的YAG纳米粉体, 为此本文作者开展了共沉淀法合成YAG粉体及透明陶瓷的研究, 并对沉淀物煅烧过程中的不同物相变化的原因进行了分析。

共沉淀法可以采用正向或反向滴定两种方式。 正向滴定是将沉淀剂滴入到盐溶液中, 反向滴定则与之相反, 其主要差别在于滴定过程中pH值变化趋势的不同[7]。 采用不同的沉淀剂和滴加次序时, 沉淀物具有不同的化学组成, 最终YAG粉体的烧结性能也有很大差别。

AlCl3和YCl3与NH3·H2O作用时, 由于Al3+和Y3+形成沉淀的初始pH值不相同, 在正向滴定过程中, 首先形成Al(OH)3沉淀, 然后形成Y2(OH)6-xClx·nH2O沉淀。 而在反向滴定过程中, 由于氨水溶液具有较高的pH值(12), 在盐溶液滴加的瞬间立即形成了沉淀, 两种离子被同时沉淀下来, 因而反向滴定的沉淀物具有更高的均匀程度[8]。

使用NH4HCO3作为沉淀剂时, 沉淀产物取决于加入方式和速度[8, 9]。 在慢速滴定时(滴速为2mL/min), 由于AHC溶液中具有较高的CO2-3浓度, Y3+与碳酸氢铵反应生成Y2(CO3)3·nH2O正盐[10, 11]。 而Al3+与碳酸氢铵在不同的反应条件下, 将得到碳酸铝铵(NH4AlO(OH)HCO3, AACH)或勃姆石(γ-AlOOH)两种不同的反应产物[12], 影响产物组成的关键是滴加方式和速度。 向AlCl3水溶液中滴加碳酸氢铵时, AlCl3发生水解而生成γ-AlOOH凝胶。 反之, 把AlCl3溶液滴入碳酸氢铵溶液中时, 只要AlCl3溶液的滴加速度较慢, Al3+ 周围便会存在大量的NH4HCO3, 此时, Al3+将与NH4HCO3作用生成NH4AlO(OH)HCO3。

不同滴定方式下的沉淀物具有不同的组成, 最终产物的烧结性能也将会有明显的差异。 文献[12]表明, NH4AlO(OH)HCO3的煅烧产物分散性较好, 能够得到活性较高的Al2O3粉体, 而通过煅烧Y2(CO3)3·nH2O也能够获得高活性的Y2O3粉体[14, 15]。 因此, AHC法沉淀物的理想组成为Y2(CO3)3·nH2O+ NH4AlO(OH)HCO3, 相应实验的反应条件为反向慢速滴加。

1 实验

1.1 样品的制备

实验原料为AlCl3·9H2O、 Y2O3粗粉(99.99%, 质量分数)、 NH4HCO3、 氨水(25%, 质量分数)、 HNO3(67%, 质量分数)。 将Y2O3溶解于盐酸中, 制成YCl3溶液。 AlCl3溶液中Al3+的浓度通过等离子发射光谱ICP测定。 仔细量取一定量的两种溶液, 以保证Y和Al的摩尔比为3∶5, 将两种溶液混合作为母盐溶液。 混合溶液中Al3+的浓度为0.15mol/L, 碳酸氢铵沉淀剂的浓度为1.5mol/L, 氨水浓度为1mol/L。

将母盐溶液滴入到NH4HCO3(AHC)或氨水(AW)溶液中, 滴定速度小于2mL/min, 在滴定同时不断搅拌, 滴定结束后时效1h。 然后, 用蒸馏水清洗4次, 除去反应副产物, 再用无水乙醇清洗2次以防止其在烘干过程中产生严重团聚。 沉淀物在烘箱中80℃干燥36h之后装入石英坩埚内, 在流动的O2气氛中, 于900~1100℃的不同温度下煅烧。 煅烧后的粉料加入0.5%(质量分数)的正硅酸乙酯(TEOS), 以高纯ZrO2球球磨24h, 球磨介质为无水乙醇。 球磨后的粉料在800℃的流动氧气气氛下煅烧2h, 以除去球磨过程中带入的有机杂质。 800℃煅烧后的粉料采用钢模双向压制成型, 压制压力为200MPa, 压制后的坯体直径为13mm, 厚度为3mm。 烧结采用VSF-7型真空炉, 真空度大于1mPa。

1.2 测试方法

采用日本理学D/MAX-RB型X射线衍射仪检测不同煅烧条件下的物相变化。 采用阿基米德法测定烧结后试样的密度。 采用PhilipsEM420型透射电子显微镜(TEM)观察沉淀物及其在不同煅烧条件下的粉体一次颗粒形貌。

2 结果与分析

2.1 沉淀物煅烧过程中的物相变化

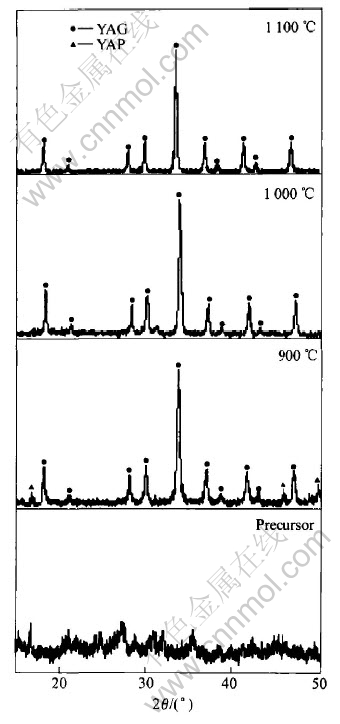

图1所示为AW法得到的沉淀物在煅烧过程中的物相变化。 由图1可见, 沉淀物为非晶态, 在900℃煅烧2h后, 产物中存在YAG和YAP相。 随着煅烧温度的提高, YAP相逐渐减少, 在1000℃煅烧2h后, 全部转化为YAG相, 反应过程中没有出现YAM相。

图1 AW法不同温度煅烧产物的X射线衍射谱

Fig.1 XRD patterns of precursor and calcined powders synthesized by AW method at different temperatures

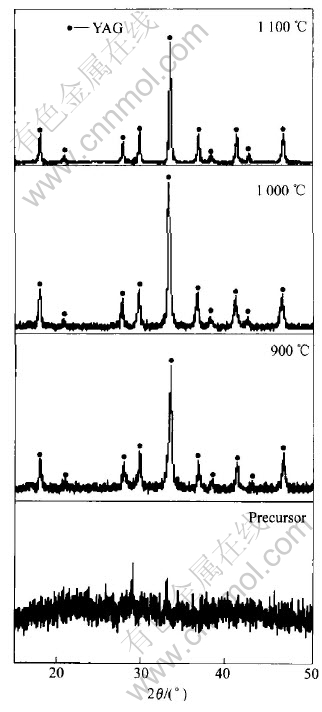

图2所示为AHC法得到的沉淀物在煅烧过程中的物相变化。 从图2可看出, 沉淀物为非晶态, 在900℃煅烧2h后, 全部转化为YAG相, 没有出现YAM和YAP等中间相。 共沉淀法中物相的变化与Li等的研究结果相符合。 可见, AHC法在较低的温度就能获得均匀单一的YAG纳米粉, 这是由于沉淀物的不同组成所致。

图2 AHC法不同温度煅烧产物X射线衍射谱

Fig.2 XRD patterns of precursor and calcined powders synthesized by AHC method at different temperatures

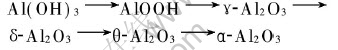

采用AW法和AHC法得到的沉淀物分别为Al(OH)3·0.3Y2(OH)6-xClx·nH2O和Y2(CO3)3·nH2O·NH4AlO(OH)HCO3, 而Al(OH)3和NH4AlO(OH)HCO3具有不同的分解温度。 根据Li[13]等的研究, 纯净Al(OH)3干凝胶在煅烧过程中需经历AlOOH, γ-Al2O3, δ-Al2O3, θ-Al2O3等中间相而最终转变为稳定晶型的α-Al2O3, 其相转变次序为

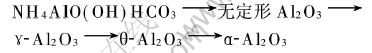

其中AlOOH的形成温度为440℃ , 转变为γ-Al2O3的温度为500℃, δ-Al2O3、 θ-Al2O3和α-Al2O3的开始形成温度分别为800、 900和1100℃。 经1200℃煅烧1h后, Al(OH)3可完全转变为稳定晶型的α-Al2O3。 而NH4AlO(OH)-HCO3煅烧时的物相转变温度却不同于Al(OH)3凝胶, 根据SUN等[12]的研究, NH4AlO(OH)-HCO3煅烧过程中的物相变化为

400℃左右时反应生成无定形Al2O3, θ-Al2O3的形成温度为800℃, 而α-Al2O3开始形成的温度为1050℃。 经过1100℃、 1h煅烧, NH4AlO-(OH)HCO3可完全转化为α-Al2O3, NH4AlO-(OH)HCO3转变为θ-Al2O3和α-Al2O3的温度均比Al(OH)3约低100℃。 因此, 煅烧YAG沉淀物时, Al(OH)3·0.3Y2(OH)6-xClx·nH2O 比Y2(CO3)3·nH2O·NH4AlO(OH)HCO3煅烧时的Al2O3相生成晚并且相对量要少, 所以最终的煅烧产物也就生成了一部分Al含量较少的YAP(YAl-O3)相, 然后少量的YAP再与Al2O3生成YAG(Y3Al5O12)相。

2.2 沉淀物及其YAG纳米粉的形貌

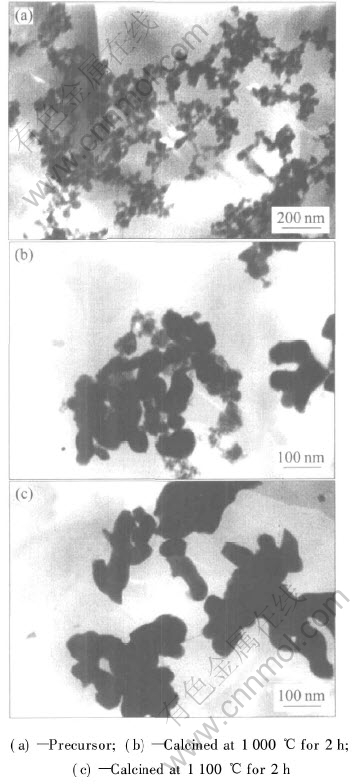

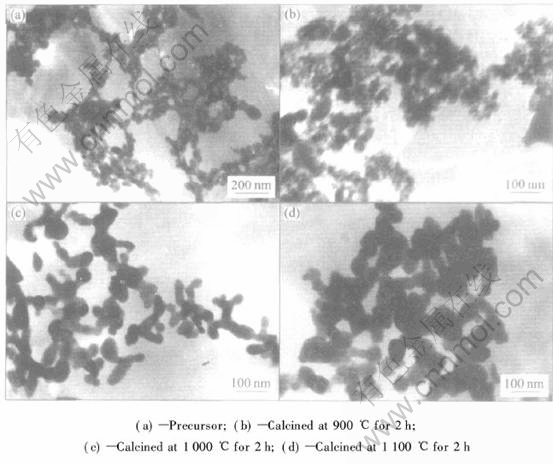

图3和4所示分别为采用两种沉淀剂得到的沉淀物及其煅烧产物的TEM像。 使用氨水作为沉淀剂时, 形成颗粒非常细小的沉淀物, 颗粒直径大约为20nm。 沉淀物在溶液中形成凝胶, 干燥后的凝胶非常坚硬, 形成大量的硬团聚体, 难以破碎。 煅烧后的产物团聚仍然十分严重, 粉体形貌很不规则, 1100℃煅烧后颗粒尺寸约为200~600nm。

图3 采用AW法滴定的沉淀物与煅烧产物的TEM像

Fig.3 TEM images of precursor and powders synthesized by AW method

图4 AHC法滴定时的沉淀物与煅烧产物的TEM像

Fig.4 TEM images of precursor and powders synthesized by AHC method at different temperatures

采用AHC法制备沉淀物的形态与AW法相似, 颗粒直径大约为40nm。 但沉淀物结构松散, 经过不同温度煅烧后, 产物依然保持松散的状态。 AHC法获得的YAG纳米粉分散较好, 粉体基本为球形, 1100℃煅烧后颗粒尺寸约为40~100nm。

2.3 YAG纳米粉的烧结

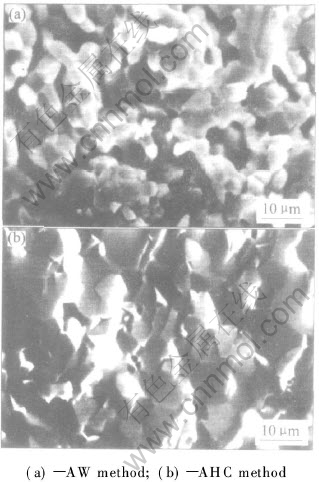

对两种方法得到的YAG纳米粉体进行了烧结性比较, 所用粉体均为1100℃煅烧沉淀物2h得到的YAG粉体。 烧结过程中加入0.5%正硅酸已酯(TEOS)作为烧结添加剂。 生坯的密度分别为49.08%(AW method)和47.57%(AHC method), 烧结后的相对密度分别为91.0%(AW method)和99.1% (AHC method)。 AW法滴定得到的粉体由于含有很多的团聚体, 得到的粉体烧结性很差。 图5所示为烧结体断口的SEM像。 由图5可看出, 采用AW法得到的烧结体内含有大量气孔, 没有完全致密。 同时也说明, 采用氨水为沉淀剂时, 难以得到具有良好烧结活性的YAG粉体。 而采用AHC法得到粉体的烧结体具有均匀的微观组织, 气孔很少。

图5 烧结体断口的SEM像

Fig.5 SEM images fracture surfaces of YAG ceramics synthesized

图6 YAG半透明陶瓷的实物照片

Fig.6 Appearance of mirror-polished translucent YAG ceramics

AHC法得到的YAG陶瓷已经呈现半透明状态, 图6所示为烧结体的实物照片。 由图6可以清楚地看到纸面上的字迹。

3 结论

1) 分别以AlCl3和YCl3的混合溶液为母盐, 碳酸氢铵(AHC法)和氨水(AW法)为沉淀剂, 采用共沉淀法制备了YAG纳米粉体。

2) AHC法得到的沉淀物经过900℃煅烧后, 全部转变为YAG相, 没有YAM和YAP等中间相生成, 煅烧得到的YAG纳米粉体分散性好。 AW法煅烧过程中出现了YAP相, 得到的粉体团聚严重。

3) AHC法得到的沉淀物经1100℃煅烧2h后获得的YAG粉体具有良好的烧结性能, 加入0.5% TEOS作为烧结添加剂, 经过1700℃真空烧结, 获得了YAG半透明陶瓷。

4) AW法得到的YAG粉体, 由于大量团聚体的存在, 导致烧结体的致密程度很低, 难以得到透明YAG陶瓷。

REFERENCES

[1] Li J G, Lee J H, Mori T. Crystal phase and sinterability of wet-chemically derived YAG powders[J]. J Ceram Soc Jpn, 2000, 108(5): 439-444.

[2] 王介强, 陶珍东, 郑少华, 等. 制备条件对固相反应法制取YAG多晶体透光性的影响[J]. 中国有色金属学报, 2003, 13(2): 432-436.

WANG Jie-qiang, TAO Zhen-dong, ZHENG Shao-hua, et al. Influence of fabrication conditions on transparency of YAG polycrystalline by solid-state reaction method[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 432-436.

[3] Mah T, Parthasarathy T A, Lee H D. Polycrystalline YAG; structural or functional[J]. Journal of Ceramic Processing Research, 2004, 5(4): 369-379.

[4] Yokoyama T. Single crystal for solid state laser material[J]. Bull Ceram Soc Jpn , 1988, 23(5): 461-63.

[5] Li J G, Ikegami T, Lee J H. Low-temperature fabrication of transparent yttrium aluminum garnet(YAG) ceramics without additives[J]. J Am Ceram Soc, 2000, 83(4): 961-963.

[6] Tachiwaki T, Yoshinaka M, Hirota K. Novel synthesis of Y3Al5O12(YAG) leading to transparent ceramics[J]. Solid State Communication, 2001, 119(10-11): 603-606.

[7] Voigt J A. An Integrated Study of Ceramic Processing of Yttria[M]. Ames: Department of Chemical and Engeering, Iowa State University, 1986.

[8] Li J G, Ikegami T, Lee J H. Co-precipitation synthesis and sintering of yttrium aluminum granet (YAG) powders: the effect of precipitant[J].J Euro Ceram Soc, 2000, 20(14-15): 2395-2405.

[9] Li J G, Ikegami T, Lee J H. A wet-chemical process yielding reactive magnesium aluminate spinel (MgAl2-O4) powder[J]. Ceramics International, 2001, 27(4): 481-489.

[10] Li J G, Ikegami T, Lee J H. Reactive yttrium aluminate garnet powder via coprecipitation using ammonium hydrogen carbonate as the precipitant[J]. Journal of Materials Research, 2000, 15(9): 1864-1867.

[11] Li J G, Ikegami T, Lee J H. Characterization of yttrium aluminate garnet precursors synthesized via precipitation using ammonium bicarbonate as the precipitant[J]. Journal of Materials Research, 2000, 15(11): 2375-2386.

[12] Sun X D, Li J G, Zhang F. Synthesis of nanocrystalline α -Al2O3 powders from nanometric ammonium aluminium carbonate hydroxide[J]. J Am Ceram Soc, 2003, 86(8): 1321-1325.

[13] Li J G, Sun X D. Synthesis and sintering behavior of a nanocrystalline alpha-alumina powder[J]. Acta Materialia, 2003, 48(12): 3103-3112.

[14] Saito N, Matsuda S, Ikegami T. Fabrication of transparent yttria ceramics at low temperature using carbonate-derived powder[J]. J Am Ceram Soc, 1998, 81(8): 2023-28.

[15] Huang Z G, Sun X D, Xiu Z M. Precipitation synthesis and sintering of yttria nanopowders[J]. Materials Letters, 2004, 58(15): 2137-2142.

基金项目: 国家自然科学基金资助项目(50172010)

收稿日期: 2005-01-07;

修订日期: 2005-04-26

作者简介: 闻 雷(1974-), 男, 博士.

通讯作者: 闻 雷, 博士; 电话: 010-62755290; E-mail: wenleicn1974@163.com

(编辑 李艳红)