文章编号:1004-0609(2010)06-1220-06

掺杂TEOS的YAG透明陶瓷相转变、烧结及微观组织

吕光哲1, 2,孙旭东1

(1. 东北大学 材料与冶金学院 材料各向异性与织构教育部重点实验室,沈阳 110004;

2. 辽宁科技学院 冶金系,本溪 117004)

摘 要:分别添加0.3%~3.0%(质量分数)的正硅酸乙酯(TEOS)为烧结助剂,利用液相烧结合成钇铝石榴石(Y3Al5O12,YAG)透明陶瓷。结果表明:液相生成是一种动态过程,最低形成温度约为1 400 ℃。烧结体相对密度随着烧结温度的升高而明显增大,且烧结助剂对致密化过程的促进作用与其含量有关。当w(TEOS)≤0.5%时,TEOS能够更明显地促进烧结,TEOS含量对真空烧结后烧结体内残留硅酸盐相的数量、分布和显微结构产生很大的影响。当w(TEOS)≤0.5%时,Y2Si2O7与Al2O3?SiO2(MUL)固溶于YAG晶粒内,晶界处没有残留第二相;当w(TEOS)为2%和3%时,过量的Y2Si2O7与MUL在晶界析出而成为散射源,严重损害陶瓷的光学性能。

关键词:YAG透明陶瓷;液相烧结;液相含量;Y2Si2O7;3Al2O3·2SiO2

中图分类号:TQ174, 75 文献标志码:A

Phase transformation, sintering and microstructures of transparent YAG ceramics doping TEOS

L? Guang-zhe1, 2, SUN Xu-dong1

(1. Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education,Northeastern University, Shenyang 110004, China;

2. Metallurgy Department, Liaoning Institute of Science and Technology, Benxi 117004, China)

Abstract: The transparent YAG ceramics were prepared by liquid phase sintering (LPS) with 0.3%~3.0%TEOS (mass fraction) as sintering additive. The results indicate that the formation of the liquid phase is a continous course, and the initial formation temperature for the liquid phase is about 1400 ℃. The relative density of sintered bodies increases with increasing sintering temperature. The different enhanced densification is a result of the different additive content. The sintering process is obviously improved in the doping sample with w(TEOS)≤0.5%. The content of TEOS has a strong inflence on the quantity and distribution of the remaining metasilicate phases and the microstructure of the vacuum-sintered bodies. When w(TEOS)≤0.5%, Y2Si2O7 and Al2O3?SiO2 (MUL) phases exist in YAG grains and the second phase at the grain boundary is not observed. When w(TEOS) are 2% and 3%, surplus Y2Si2O7 and MUL appear at the grain boundary and become the scattering source to damage the optical performance strongly.

Key words: transparent YAG ceramics; liquid phase sintering; liquid phase content; Y2Si2O7;3Al2O3·2SiO2(MUL)

YAG(Y3Al5O12,钇铝石榴石)晶体因其具有良好的可见光和红外光透过率,是一种优良的固体激光材 料[1-5],引起了人们的广泛关注。YAG单晶体通常采用Czochralski法制备,但生长周期长,条件苛刻。因此,利用烧结方法研制低成本的且有接近YAG单晶体光学性能的多晶体透明陶瓷具有重要的意义。

YAG透明陶瓷通常采用固相烧结法制备。固相反应法[6-12]使用高纯度的Y2O3和Al2O3粉体为原料,与湿化学法合成YAG多晶体[13-14]相比,具有成本低、易于控制配比等优势。为获得具有高透光率的透明陶瓷,添加烧结助剂是比较常用的方法,例如在Al2O3中加入MgO[15]、在MgAl2O4中加入CaO[16]、在AlN中加入CaF2[17]等。有些烧结助剂在高温烧结时形成晶间液相,加快了物质的扩散与传输速率,从而促进了透明陶瓷的致密化。与固相烧结相比,液相烧结可使材料在较低温度获得致密的烧结体,有利于提高材料的光学性能。YAG透明陶瓷的制备通常添加正硅酸乙酯(TEOS),TEOS在与原料湿法混合过程中可水解生成SiO2,促进YAG的烧结致密化过程。虽然TEOS已是公认的YAG透明陶瓷有效的烧结助剂,但其烧结机理还缺乏系统的研究。本文作者系统研究TEOS在YAG透明陶瓷烧结过程中的作用,分析液相形成的温度、过程、生成量对烧结体致密化、残留硅酸盐相的数量和分布及陶瓷显微结构的影响。

1 实验

采用的高纯Y2O3(99.99 %)和Al2O3(99.99 %)超细原始粉料均购自广东惠州瑞尔化学科技有限公司,粉体平均粒径分别为70和200 nm。称量上述两种原料,以保证Y与Al的摩尔比符合化学式Y3Al5O12。在原料中分别添加0.3%、0.5%、2%、3%的正硅酸乙酯(Tetraethyl orthosilicate, TEOS)作为烧结助剂(分别相当于0.001 4%、0.002 3%、0.009 3%、0.014%(摩尔分数)的SiO2),以无水乙醇为球磨介质,混合粉料球磨10 h并于60 ℃烘干,然后在空气气氛于1 300 ℃煅烧4 h。煅烧后的粉体采用钢模双向压制成型,压制压力为200 MPa,压制后的坯体直径为16 mm,厚度为2.5 mm。烧结采用VSF-7型真空炉,于1 300~1 700 ℃真空烧结15 h,真空度大于1×10-3 Pa。

利用排水法测量烧结体的相对密度。采用日本理学(Rigaku)D/MAX–RB型X射线衍射仪(XRD),利用CuKa辐射Ni滤波分析原料粉体及其在不同煅烧温度下的物相组成。扫描速度为8(?)/min,2θ角扫描范围为10?~60?。采用日本岛津SSX-550型扫描电子显微镜(SEM)结合能量散射型X射线光谱仪(EDX)分析晶界的微观结构、元素成分分布。样品热蚀条件为1 500 ℃,2 h,空气气氛。

2 结果与讨论

2.1 烧结液相的产生及含量变化

图1所示为Al2O3和Y2O3混合粉体在1 000~1 700 ℃煅烧后的物相。由图1可以看出,经1 000 ℃煅烧后,YAM(Y4Al2O9)相首先出现,同时仍残留有未反应的Al2O3和Y2O3;当煅烧温度达到1 300 ℃时,YAG(Y3Al5O12)相为粉体的主要成分,但仍残留有YAP(YAlO3)和YAM;经1 500 ℃ 煅烧后,得到纯YAG相。

图1 不同温度煅烧后粉体的XRD谱

Fig.1 XRD patterns of raw powders calcined at different temperatures

FABRICHNAYA等[18]的研究表明,YAG-SiO2氧化物间通过固相反应可以生成Y2Si2O7、莫来石(3Al2O3·2SiO2,MUL)硅酸盐相。现选取SiO2的摩尔分数为80%和20%的成分点为例,详细说明液相生成过程。

1) SiO2的摩尔分数为80%(简记为条件Ⅰ):

当温度达到约1 230 ℃时,体系由MUL+ Y2Si2O7(β)+SiO2(TR)三相组成。随着温度的升高,体系中将发生如下反应[18]:

当温度达到1 347 ℃时,发生晶型转变:

转变完成后体系组成为MUL+Y2Si2O7(γ)+ SiO2(TR)。

当温度达到1 380 ℃时,发生四相转变:

转变完成后,体系由新生成的液相和剩余的MUL 和SiO2组成,即LIQ+MUL+ SiO2(TR)

当温度达到约1 420 ℃时,发生三相转变:

转变完成后,体系组成为LIQ+ SiO2(TR)

当温度达到约1 480 ℃时,发生晶型转变:

转变完成后体系仍由LIQ+SiO2(CR)组成。

2) SiO2摩尔分数为20%(简记为条件Ⅱ):

当温度达到约1 230 ℃时,体系由YAG+Al2O3+ Y2Si2O7(β)三相组成。随着温度的提高,体系中将发生如下反应[18]:

当温度达到约1 347 ℃时,发生晶型转变:

转变完成后体系组成为YAG+Al2O3+Y2Si2O7(γ)。

温度达到1 452 ℃时,发生四相平衡转变:

转变完成后,体系由新生成的液相和剩余的Al2O3和YAG组成,即LIQ+YAG+Al2O3。

当温度达到约1 690 ℃时,发生三相平衡转变:

转变完成后,体系组成为LIQ+YAG。

TEOS水解后生成的SiO2位于烧结体的晶界。在升温过程中,在相界面的SiO2一侧,可发生类似于条件Ⅰ的化学反应,当烧结温度达到1 380 ℃左右时,按照反应式(2)生成液相;在相界面的YAG一侧,SiO2含量少,类似于条件Ⅱ的情况。在1 452 ℃时,按照反应式(6)的化学反应生成液相。以上分析表明,对于添加SiO2的YAG陶瓷,液相可以在较低烧结温度下(约1 400 ℃)开始生成,液相含量随烧结温度的升高而不断增多。

图2所示为添加不同含量TEOS样品的XRD谱。所有样品均在真空条件下,1 700 ℃烧结5 h。由图2可知,不含添加剂的样品中所有的衍射峰高都对应单相YAG,而对于含有添加剂的样品,无论含量多少,真空烧结后都可以观察到Y2Si2O7和MUL的衍射峰。这说明添加了TEOS的样品在烧结和随后冷却过程中确实形成了Y2Si2O7和MUL相。由相图可见,本实验成分下室温的相组成应为YAG+Al2O3+ Y2Si2O7,这说明MUL形成后比较稳定。

图2 真空烧结后样品的XRD谱

Fig.2 XRD patterns of vacuum-sintered samples

2.2 液相烧结过程分析

图3所示为液相烧结样品相对密度与烧结温度和烧结助剂含量的关系。由图4(a)可以看出,液相烧结初期(1 400~1 500 ℃),烧结体相对密度随烧结温度的升高而明显增大,例如,0.5%的样品相对密度由1 400 ℃时的79.3%增加到1 500 ℃时的94.9%。根据以上对YAG-SiO2准二元系相图的分析,液相可以在较低烧结温度下(约1 400 ℃)开始生成,液相含量随烧结温度的升高而不断增多,有利于颗粒在毛细管力驱使下形成密排,因此烧结体致密化程度明显得到提高。液相烧结中后期(1 500~1 700 ℃),由于气孔已基本消失,颗粒间距很小,液相填充孔隙变得更加困难,因此液相的存在对YAG陶瓷致密化过程的影响与液相烧结初期相比有所减弱。

图3 液相烧结样品的相对密度与烧结温度和烧结助剂含量的关系

Fig.3 Relationships between relative density of samples by LPS and sintering temperature and additive content

图4 密度与烧结温度关系的烧结方程回归线

Fig.4 Regression line of density on sintering temperature

通常认为,在液相烧结的颗粒重排、溶解-沉淀和后期聚合3个过程中,颗粒重排阶段经历的时间很短,因此烧结初期的样品很难获得完全致密[19]。重排过程结束后,样品的相对密度主要通过溶解-沉淀作用得到提高。研究表明,液相含量越高,液相烧结样品的致密速度也越快[20-21]。因此,在添加剂含量较低时(w(TEOS)≤0.5%),样品相对密度随液相含量的提高而明显增大(见图3(b))。更多的添加剂(如w(TEOS)为2%和3%)虽然可以增加少量的晶间液相,但对于颗粒的重排致密化和溶解-沉淀过程来说贡献非常有限,与w(TEOS)≤0.5%时相比,并不能更显著地促进液相烧结(见图3(b))。

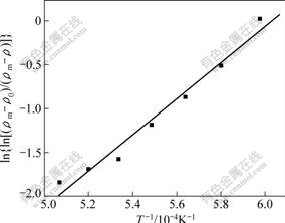

根据综合烧结作用理论[19],密度与温度倒数之间有如下关系:

式中:ρm、ρ和ρ0分别为材料的理论密度(YAG,4.55 g/cm3)、烧结体在某烧结温度下的烧结密度和生坯密度(2.10 g/cm3)。对添加0.5%TEOS的YAG样品不同温度烧结后的实验数据进行回归处理,可得到表征密度和烧结温度关系的烧结回归方程:

烧结方程的回归直线和实验值如图4 所示。从图4可看出,实验值与回归直线计算值基本吻合。这说明YAG陶瓷的液相烧结过程是扩散、流动和物理化学反应综合作用的过程[19]。

2.3 TEOS添加量对烧结体内残留硅酸盐相的数量和分布的影响

样品经过液相烧结,相对密度已达到99%,残留液相位于晶界处。由于Si4+的半径(0.041 nm)稍小于Al3+的半径(0.055 nm),二者差远小于15%。当SiO2含量较低时(≤0.5%),Si4+可替代部分YAG晶体四面体格位中的Al3+[22], 由于两种元素原子价和晶体结构类型的差异,这种置换是有限的。当SiO2含量较高时(为2%和3%),Si4+含量超过了固溶极限,最终Y2Si2O7和MUL以第二相的形式存在于晶界处。由此可知,TEOS含量是决定烧结体晶粒和晶界处残留硅酸盐相数量及分布的关键因素。这一结果同样可以通过对晶粒和晶界处进行SEM检测得到证实。

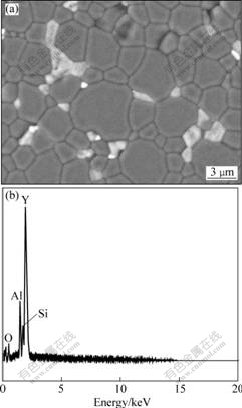

图5所示为真空烧结后样品的显微组织。图6所示为添加2%TEOS的YAG陶瓷的SEM像和晶界处的EDX谱。由图5可看出,添加0.3%和0.5%的样品中,晶界处没有明显的第二相。但是,在添加剂含量为2%时(见图6(a)),样品中可以清晰看到沿晶界分布的第二相。由EDX分析结果可知,晶界位置的第二相为富钇相(见图6(b))。图7所示为添加不同含量烧结助剂的样品烧结后的实物照片。从图7可以看出,当添加剂含量为0.5%时,样品完全透明(见图7(b));当添加剂含量小于或大于0.5% 时,试样呈半透明状态(见图7(a)和(c))。

图5 添加不同量TEOS真空烧结后样品SEM像

Fig.5 SEM images of vacuum-sintered samples with different amounts of TEOS additive: (a) 0.3%; (b) 0.5%

图6 添加2%TEOSYAG陶瓷SEM像和晶界处的EDX谱

Fig.6 SEM image (a) and EDX spectrum (b) of grain boundary phase of YAG ceramics with 2%TEOS

图7 添加不同含量烧结助剂YAG陶瓷真空烧结后的照片

Fig.7 Photos of vacuum-sintered samples with different additive contents: (a) 0.3%; (b) 0.5%; (c) 2%

烧结后期由于晶界上的气孔已经很少,气孔对晶界的定扎作用大大降低,同时较高的烧结温度造成晶界以较快的速度迁移,因此,少量残留气孔可能被捕获而进入晶体内部,导致致密化过程大大减慢。烧结过程中液相的存在可以使固-固界面转变为固-液界面,界面能的降低导致晶界迁移速率的降低,从而减少气孔被捕获的几率(见图6(a)和(b))。在添加剂含量为2%的样品中,由于添加过量的TEOS会造成以Y2Si2O7为主要成分的硅酸盐第二相富集于晶界(见图7(a))。对于含量为0.5%的样品,由于可以产生适量的液相,既保证烧结的顺利完成,使烧结体获得较高的相对密度,又利于硅酸盐相通过扩散进入晶粒内,从而有效避免由于晶界处第二相的存在引发光的散射, 保证陶瓷具有良好的透明度(见图7(b))。

3 结论

1) 添加正硅酸乙酯(TEOS)为烧结助剂的YAG陶瓷,在烧结和随后冷却过程中形成了Y2Si2O7和MUL相,其烧结过程是物质扩散、流动和物理化学反应综合作用的结果。TEOS的存在明显促进了材料的致密化。当添加剂含量不大于0.5%时,样品的相对密度随液相数量的提高而快速增大;但当含量大于0.5% 时,液相数量的提高并不能进一步促进材料的烧结。

2) TEOS含量对真空烧结后烧结体残留气孔和硅酸盐相的数量和分布产生很大的影响。当含量为0.5%时,既保证液相烧结的顺利完成,样品中无残留气孔存在,又利于硅酸盐相通过扩散进入晶粒内,从而有效避免由于晶界处第二相的存在引发对光的散射;当液相含量小于0.5%时,烧结体不能达到完全致密,残留气孔位于晶粒内部和晶界处;当液相含量远大于0.5%时,由于过量的Y2Si2O7在晶界析出,损害陶瓷的光学性能。

REFERENCES

[1] PRADHAN A K, ZHANG Kai, LOUTTS G B. Synthesis of neodymium-doped yttrium aluminum garnet (YAG) nanocrystalline powders leading to transparent ceramics[J]. Mater Res Bull, 2004, 39: 1291-1298.

[2] RAMANATHAN S, ROY S K, BHAT Y J. Transparent YAG from powder prepared by homogeneous precipitation reaction—Al(NO3)3 +Y(NO3)3+(NH4)2SO4+CO(NH2)2[J]. Mater Sci Lett, 2001, 20: 2119-2121.

[3] LI Xia, LI Qiang, WANG Ji-yang, YANG Shun-liang, LIU Hong. Synthesis of Nd3+ doped nano-crystalline yttrium aluminum garnet (YAG) powders leading to transparent ceramic[J]. Opti Mater, 2007, 29: 528-531.

[4] XIA Guo-dong, ZHOU Sheng-ming, ZHANG Jun-ji, WANG Su-mei, XU Jun. Solution combustion synthesis, structure and luminescence of Y3Al5O12: Tb3+ phosphors[J]. Journal of Alloys and Compounds, 2006, 421: 294-297.

[5] LI Ji-guang, IKEGAMI T, LEE J H. Low temperature fabrication of transparent yttrium aluminum garnet (YAG) ceramics without additives[J]. J Am Ceram Soc, 2000, 83 (4): 961-963.

[6] IKESUE A., FRUSTA I, KAMATA K. Fabrication of polycrystalline, transparent YAG ceramics by a solid-state reaction method[J]. J Am Ceram Soc, 1995, 78 (1): 225-228.

[7] IKESUE A, KINSHITA T, KAMATA K, YOSHIDA K. Fabrication and optical properties of high-performance polycrystalline Nd-YAG ceramics for solid-state lasers[J]. J Am Ceram Soc, 1995, 78(4): 1033-1040.

[8] IKESUE A, YOSHID A K. Influence of pore volume on laser performance of Nd: YAG ceramics[J]. J Mater Sci, 1999, 34: 1189-1195.

[9] WEN Lei, SUN Xu-dong, XIU Zhi-meng, CHEN Shao-wei, TSAI C T. Synthesis of nanocrystalline yttria powder and fabrication of transparent YAG ceramics[J]. J Euro Ceram Soc, 2004, 24: 2681-2688.

[10] IKESUE A, AUNG Y L, YODA T, NAKAYAMA S, KAMIMURA T. Fabrication and laser performance of polycrystal and single crystal Nd:YAG by advanced ceramic processing[J]. Opti Mater, 2007, 29: 1289-1294.

[11] IKESUE A, YOSHIDA K, YAMAMOTO T, YAMAGA I. Optical scattering in polycrystalline Nd: YAG laser[J]. J Am Ceram Soc, 1997, 80(6): 1517-1522.

[12] RABINOVITCH Y, TETARD D, FAUCHER M D, PHAM-THI M. Transparent polycrystalline neodymium doped YAG: synthesis parameters, laser efficiency[J]. Opti Mater, 2003, 24: 345-351.

[13] RABINOVITCH Y, BOGICEVIC C, KAROLAK F, TETARD D, DAMMAK H. Freeze-dried nanometric neodymium-doped YAG powders for transparent ceramics[J]. Journal of materials processing technology, 2008, 199: 314-320.

[14] CHEN Zhi-hui, LI Jiang-tao, XU Jiu-jun, HU Zhang-gui. Fabrication of YAG transparent ceramics by two-step sintering[J]. Ceram Int, 2008, 34(7): 1709-1712.

[15] COBLE R L. preparation of transparent ceramic Al2O3[J]. Am Ceram Soc Bull, 1959, 38(10): 507-510.

[16] BRATTON R J. Translucent sintered MgAl2O4[J]. J Am Ceram Soc, 1974, 57(2): 283-285.

[17] XIONG Yan, FU Zheng-yi, WANG Hao. Effect of grain boundary phase on transmittance of translucent AlN ceramics[J]. Journal of the Chinese Ceramic Society, 2006, 34(1): 1-4.

[18] FABRICHNAYA O, SEIFERT H J, WEILAND R, LUDWIG T, ALDINGER F, NAVROTSKY A. Phase equilibria and thermodynamics in the Y2O3-Al2O3-SiO2 system[J]. Z Metallkd, 2001, 92: 1083-1097.

[19] 黄培云. 粉末冶金基础[M]. 第2版. 北京: 冶金工业出版社, 1997: 310-311.

HUANG Pei-yun. The theory of powder metallurgy[M]. 2nd ed. Beijing: Metallurgical Industry Press, 1997: 310-311.

[20] KWON O H, MESSING G L. Kinetic analysis of solution-precipitation during liquid-phase sintering of alumina[J]. J Am Ceram Soc, 1990, 73(2): 275-281.

[21] WRAY P J. The geometry of two-phase aggregates in which the shape of the second phase is determined by its dihedral angle[J]. Acta Metall, 1976, 24 (2): 125-135.

[22] MAO Hua-hai, SELLEBY M, FABRICHNAYA O. Thermodynamic reassessment of the Y2O3-Al2O3-SiO2 system and its subsystems[J]. Calphad, 2008, 32(2): 399-412.

__________________________________

基金项目:国家杰出青年基金资助项目(50425413);国家自然科学基金重大资助项目(50990303)

收稿日期:2008-07-18;修订日期:2010-04-26

通信作者:孙旭东,教授,博士;E-mail: xdsun@mail.neu.edu.cn

(编辑 李艳红)