文章编号:1004-0609(2016)-01-0037-13

粉末特性对镍基粉末冶金高温合金组织及热变形行为的影响

何国爱1, 2,丁晗晖1, 2,刘琛仄1, 2,刘 锋1, 2,黄 岚1, 2,江 亮1, 2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中南大学 粉末冶金研究院,长沙 410083)

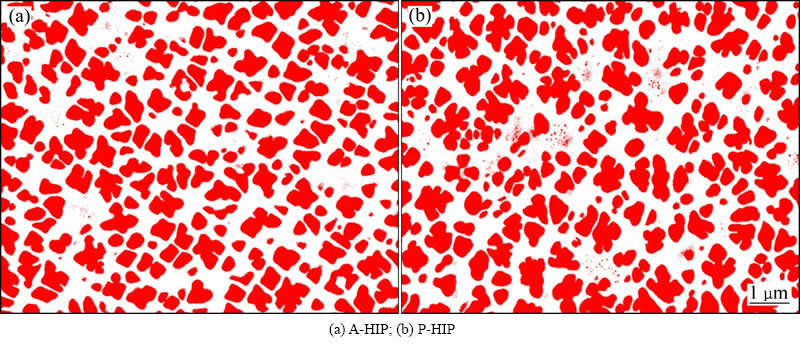

摘 要:分别采用氩气雾化(Argon atomization, AA)和等离子旋转电极(Plasma rotating electrode process,PREP)两种方法制备具有不同特性的镍基高温合金粉末,然后在相同条件下对两种粉末进行热等静压制备成块体材料(A-HIP及P-HIP)。分别对粉末和块体材料进行显微组织分析和形貌表征,并对热等静压材料在温度为1000~1100 ℃下、应变速率为0.01~1.0 s-1下进行热压缩实验,利用采集的应力、应变参数,通过迭代和线性回归的方法计算热激活能并构建本构方程,并利用所建立的本构方程预测合金在不同应变下的应力。结果表明:PREP粉末表面洁净度、球形度和粒径均匀度要比AA粉末的好,其表面氧含量也相对较低,仅为0.0079%,而AA粉末中氧含量为0.0139%(质量分数);相比P-HIP,A-HIP中分布着较多的原始颗粒边界和孔洞,原始颗粒边界的主要组成是大尺寸的γ′相和碳氧化物颗粒;A-HIP的平均晶粒尺寸为8.59 μm, P-HIP的平均晶粒尺寸为12.54 μm;A-HIP的强化相γ′的体积分数(43.91%)与P-HIP的强化相γ′体积分数(43.65%)基本相等。两种材料的激活能分别为1012.9 kJ/mol和757.1 kJ/mol,并采用双曲正弦Arrhenius模型构建不同应变下的本构方程并预测不同变形条件下的真应力,其与实验值间的绝对误差分别为6.46%和4.87%。A-HIP在压缩过程出现宏观裂纹,原始颗粒边界是压缩裂纹产生主要因素之一,且裂纹沿原始颗粒边界进行扩展。

关键词:镍基粉末冶金高温合金;氩气雾化制粉; 旋转电极制粉;热等静压;热模拟;热变形激活能;本构方程

中图分类号:TG304 文献标志码:A

粉末冶金镍基高温合金由于其优异的综合性能,包括在高温复杂环境下优越的抗腐蚀和抗氧化性能、疲劳性能和力学性能等,使得其被广泛用于制备喷气式发动机的核心部件,如航空发动机高性能涡轮盘[1]。随着科技的发展,对发动机涡轮盘用材料要求越来越高,许多研究表明在镍基高温合金中,随着钴含量在一定范围内的增加,能提高合金中相的稳定性、降低γ′的固溶温度以及减小由于冷却过程所致的残余应力[2-3],有研究报道了高钴镍基高温合金已被用于服役温度高达725 ℃,这比传统的典型镍基高温合金U720Li的高出了50 ℃[4],本实验中研究对象为自主设计的一种高钴镍基粉末冶金高温合金。

粉末的制备方法对其形貌、组织和粒度分布等粉末特性有着重要的作用,粉末特性直接影响粉末经过热固结成型和热加工后的块体材料的组织特征,从而影响材料的服役性能。目前制备镍基高温合金的粉末的主要方法有两种,等离子旋转电极法(PREP)和氩气雾化法(AA)[5],欧美等先进工业国家主要采用AA粉制备航空发动机粉末盘,而俄罗斯主要采用PREP粉制备粉末盘[6]。PREP最显著的优点就是污染小,合格粉末收得率高、物理性能好,而雾化制粉的细粉收得率较高,但粉末粘结和空心粉末较AA粉多,二者制备粉末的工艺相对都比较成熟,各有优缺点[7]。许多学者对两种不同制粉方法进行了广泛研究,袁华等[8]报道了利用AA制粉的方式制备了高温合金粉末,讨论了粉末的组织、形貌等关系,研究表明,AA高温合金粉末以球形为主,具有较高的细粉收得率,小于100 μm的粉末达到90%以上。粉末氧含量较低,且随着粉末粒度的变小,氧含量有所增加,粉末中含有极少量的空心粉,随着粉末粒度的减小,粉末中空

心粉的数量不断减少,粉末表面也由枝晶组织逐渐过度为胞状晶组织,夹杂主要为非金属氧化物夹杂,含量较少。另有学者[9-10]对PREP制粉方法进行了研究,指出PREP制粉方法所得的粉末表面洁净、球形度好、粘结粉少、夹杂少,且所得粉末含氧量和陶瓷含量比原始坯料合金低。综上所述,PREP和AA两种粉末制备工艺对高温合金粉末特性的影响规律研究较为系统,但是,两种粉末制备工艺对高温合金的热变形行为的影响机制方面的研究还尚未见报道。

热变形过程中的表面裂纹一直是材料工作者在研究材料热变形过程中的重点研究内容,裂纹的产生会严重损害合金的性能,对最终产品的成型具有不可逆转的影响。合金的本征特性、加工历史及其变形参数是影响塑性的主要原因,然而对于变形过程中的开裂行为及其成因,一直都没有统一的定论。

基于此,本文作者采用上述两种不同制粉方法制备一种自主设计的新型镍基高温合金,对比其粉末形貌、粒度分布、平均粒径及含氧量等粉末特性,并分析研究了不同粉末所制备的材料的形貌、强化相的体积分数等,利用热模拟的方法分析二者热激活能及热变形行为,并建立本构方程以描述和预测加工参数与加工应力之间的关系,并对开裂行为进行了分析。通过研究不同制备方法下的粉末特性及对应合金的组织特征和热变形行为,为后续选择合理的制粉方法及热机械加工工艺参数提供科学依据。

1 实验

本实验中研究对象分别是采用旋转电极制备的粉末(简称P粉,P-powder)和氩气雾化方法制备的粉末(简称A粉,A-powder)。其名义成分(质量分数, %)如下:Cr+Mo+W:21.0;Al+Ti:7.0;Co:26.0;Nb+Zr:1.0;及少量的C、B、Hf,其余量为Ni。制备的粉末经包套、除气、封焊,然后热等静压实现致密化,得到两种不同的热等静压材料(简称A粉和P粉热等静压材料,A-HIP和P-HIP),并采用光学显微镜(LEICA-DM4000M)、场发射扫描电镜(Quanta 650)及牛津(Oxford)电子背散射衍射分析了粉末形貌和热等静压块体材料的显微组织和晶粒尺寸。金相组织分析采用了Kalling’s 腐蚀剂(100 mL HCl, 100 mL ethanol, and 5 g CuCl2),而γ′腐蚀剂为HNO3、acetic acid、H2O和HF的体积比为3:3:3:1。采用氮氧氢分析仪(TCH- 600)测定粉末的氧含量以及激光衍射粒度分析仪(MASTERSIZER)统计粉末的粒度及分布。利用线切割加工热压缩所需要的毛坯材料,再经过表面处理等方式制得最终热压缩需要的试样,尺寸为直径6 mm,高度9 mm。热模拟实验在Gleeble-3180gajf型试验机上进行,加热速率为5 ℃/s,保温时间2 min以减小样品的温度梯度,实验的温度如下:1000~1100 ℃,间隔25 ℃,应变速率为0.01、0.1及1.0 s-1,真应变为0.7。利用采集的应力应变数据计算材料的热变形激活能,并构建Arrhenius双曲正弦型本构方程。

2 结果与讨论

2.1 粉末的粒度和表面形貌

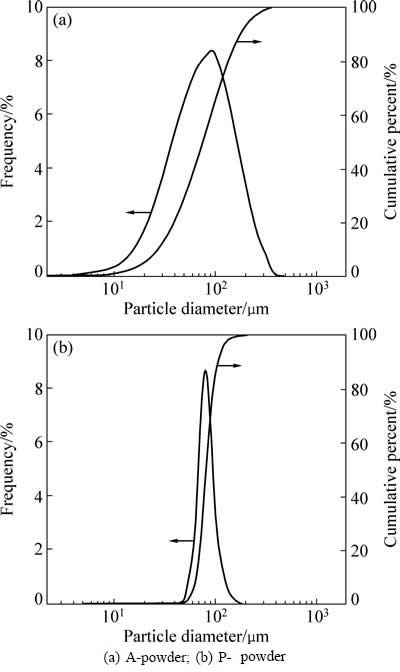

两种粉末的粒度分布曲线如图1所示,其粒径统计结果如表1所列。由图1(a)可以看出,利用AA法制备的粉末粒度分布较宽,跨度大(从几十微米到200多微米),细粉比例也比较多,但均匀度比较差;而采用PREP制备的粉末的粒度分布比较集中,95%的粉末分布集中在50~150 μm之间,均匀度较好。

图1 粉末的粒度分布

Fig. 1 Particle distributions of powder

表1 粉末粒度的检测结果

Table 1 Test results of powder particle size

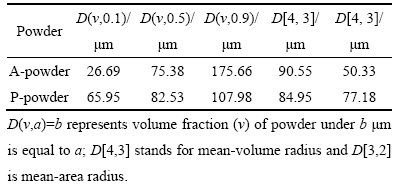

图2所示为粉末的显微形貌。对比图2(a)和2(c)中可以看出,P粉的球形度要比A粉的球形度好,这是由于在PREP方法制备粉末过程中,液态金属受到等离心力作用,金属流凝固成粉末过程中受到的力差异小;而利用AA方法制备粉末时,液态金属受到高速氩气流的冲击,其冲击力大小受到气流速度、喷嘴与液流的距离、角度等因素的影响,金属流在各方向上受到的力存在不小差异,导致金属流在凝固成粉末过程中受到的冲击效果不一致,雾化后的粉末尺寸也不一致。除此以外,A粉表面有很多粘结颗粒和包覆层,如图2(b)所示,这是由金属液凝固顺序不同所致,后凝固的金属粉末粘结在先凝固的金属颗粒表面。

粉末表面的含氧量测试结果为,A粉的氧含量为0.0139%(质量分数),而P粉的氧含量为0.0079%,氧含量的差别主要是由于AA方法受设备真空度和氩气纯度的影响。研究表明[11-12],原始粉末的氧含量具有遗传特征,即原始粉末的氧含量越高,对应的热等静压态材料中氧含量就越高。实验检测的结果显示,A-HIP中的氧含量为0.0145%(质量分数),而P-HIP的氧含量为0.0083%。

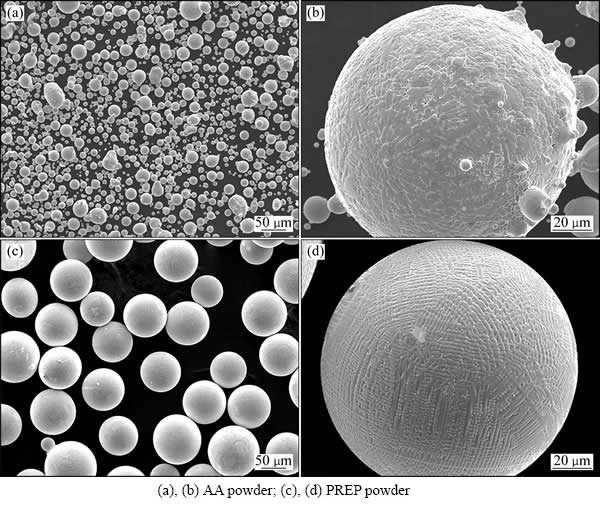

2.2 热等静压态材料显微组织

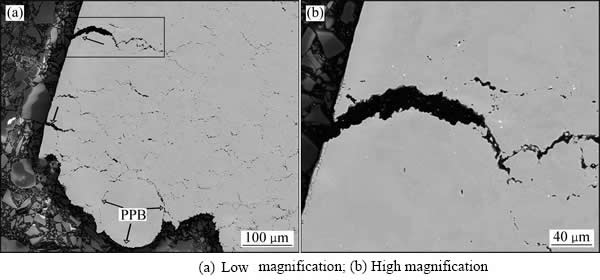

图3(a)和3(b)所示分别为A-HIP和P-HIP组织的SEM像。从图3(a)可以看出,A-HIP存在着许多原始颗粒边界和孔洞,而P-HIP相对来说原始颗粒边界和孔洞较少。这是由于采用氩气雾化方式制备的粉末中含有的气体含量较多,在热等静压过程中,气体受热膨胀挥发留下了许多孔洞[9]。此外,前人的工作[13-15]表明,原始颗粒边界的组成主要组成之一是氧化物。如前所述,A粉的氧含量比P粉的氧含量高,且氧含量具有遗传特性,所以在热等静压过程中粉末中的氧更容易在粉末边界处与扩散出来的金属元素结合成氧化物,从而形成原始颗粒边界(Prior particle boundary, PPB)。PPB的存在阻碍了粉末颗粒间的扩散和结合,成为潜在裂纹源,降低了合金的塑性和力学性能,同时阻碍变形和晶粒生长,不利于合金组织的控制[16-17]。

图2 粉末的微观形貌

Fig. 2 Morphologies of powder

图3 热等静压态材料的SEM像

Fig. 3 SEM images of as-HIPed alloy

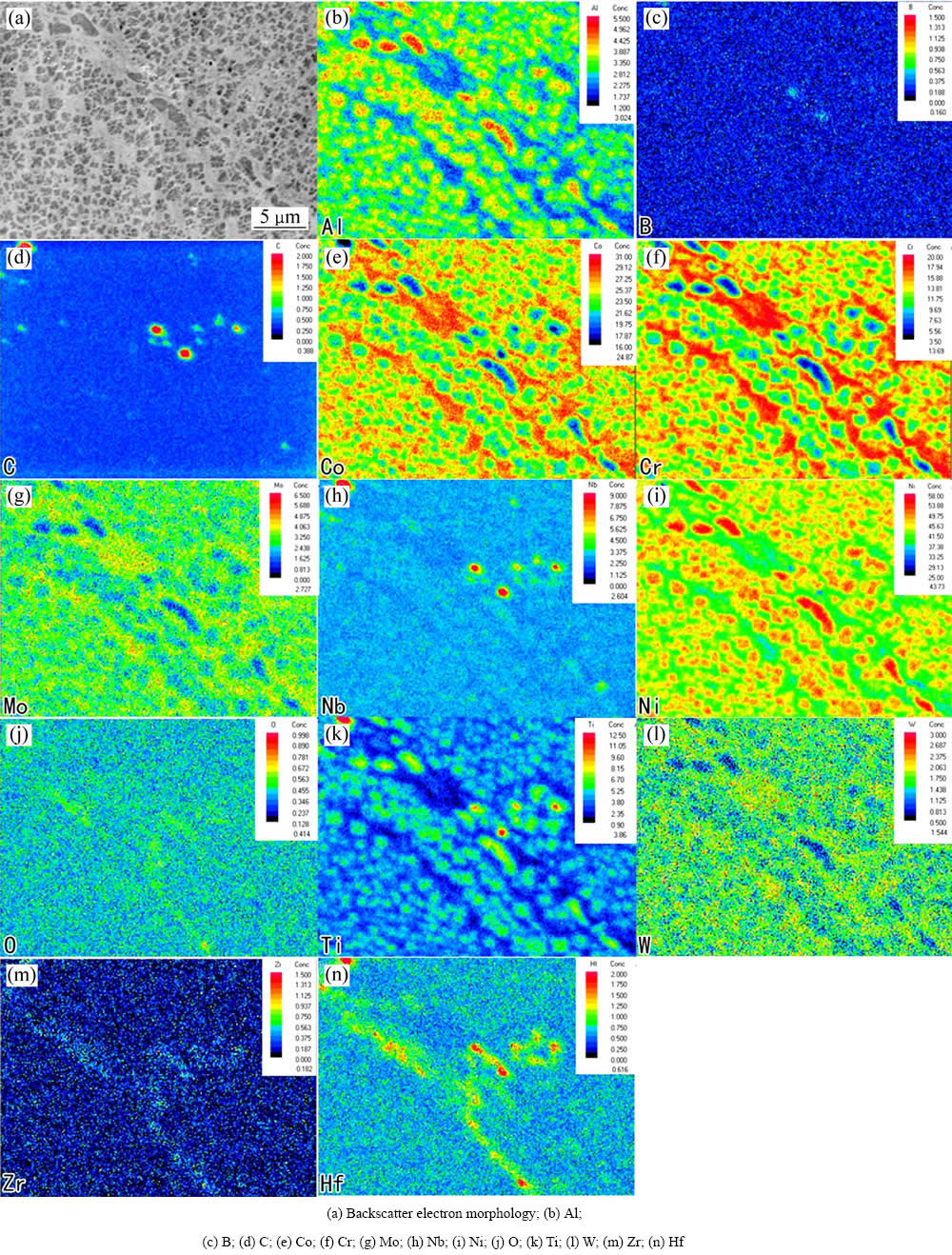

2.3 热等静压态材料原始颗粒边界组成

图4所示为热等静压态原始颗粒边界处EPMA的采集照片。从图4可以看出,W、Mo、Cr和Co元素主要分布于基体内,Nb元素在PPB上有富集现象明显;Zr和B在PPB上有轻微富集;且观察到明显的O元素富集现象;C、B、Nb、Hf的富集位置相同,为(B, Nb, Hf, Ti)C;O、Hf 、Zr的富集位置相同,为(Hf, Zr)O。可以推断,合金的原始颗粒边界析出相主要为大尺寸的γ′相和碳氧化物颗粒。具体的相结构需要进一步的实验分析。

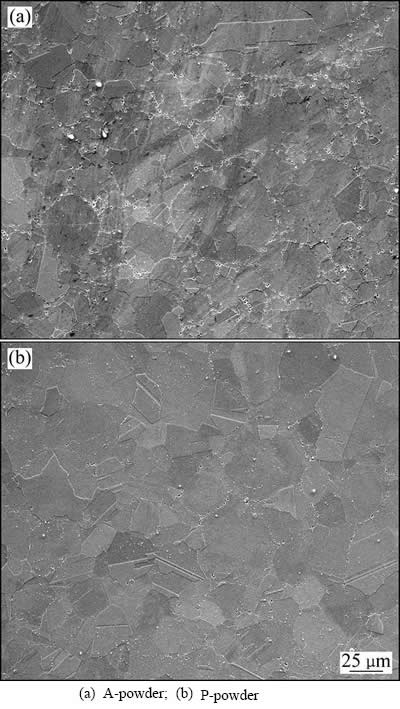

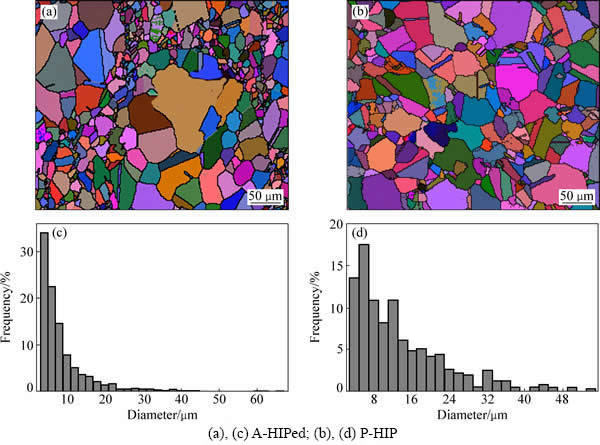

2.4 热等静压态材料晶粒尺寸

图5所示为A-HIP和P-HIP的电子背散射衍射(Electron backscatter diffraction,EBSD)电子像及其晶粒统计分布图。晶粒统计选取了材料内5个不同部位的晶粒进行了统计,并取其平均值。图5(a)所示为A-HIP的晶粒取向图。从图5(a)可以看出,A-HIP的晶粒分布较广,小晶粒所占的比例较多,平均晶粒尺寸为8.59 μm,其统计数字显示晶粒尺寸在20 μm以下的晶粒所占的比例在80%以上,而10 μm以下的比例高达70%以上,同时也存在晶粒尺寸较大(>50 μm)的晶粒,甚至在60 μm以上。图5(b)所示为P-HIP的晶粒取向图。可以看出,P-HIP的晶粒分布相对而言比较集中和均匀,平均晶粒尺寸为12.54 μm,大部分集中在30 μm以下,也有小部分在30~50 μm之间。这是由于,采用AA方法制备粉末时候,由于粉末在凝固过程中速度较快,细粉的比例也相对较多,对应的晶粒尺寸也较小,如前所述(见表1)。粉末经热等静压制备成块体材料后,其晶粒尺寸在一定程度上由粉末态的晶粒尺寸决定,所以A-HIP的晶粒相对P-HIP的晶粒细小些。此外,由于在A粉制备过程中金属流的冷却速率差异较大,导致粉末粒度分布相对P粉而言更广一些。

2.5 热等静压态材料γ′相分布及体积分数

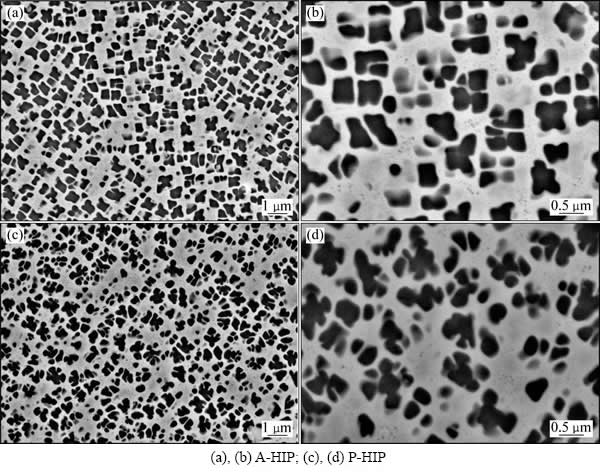

图6所示为A-HIP和P-HIP的SEM像。图6(a)和(b)所示分别为低倍和高倍下A-HIP的SEM像。而图6 (c)和(d)所示分别为低倍和高倍下的P-HIP。图中被腐蚀掉的部分为γ′相。对比图6(b)和(d)可以明显看出,A-HIP中γ′相的形貌与P-HIP中的有所区别,A-HIP中的γ′形状多为方块状或“田”字形的形貌,而P-HIP的γ′的形状多为细小的近似球形状。这在前人的工作中[18-20]也有类似的发现。采用图像处理软件Image Pro plus进行统计分析,可以计算出A-HIP中的γ′相的体积分数为43.91%,而P-HIP中的γ′的体积分数约为43.65%,二者基本相当,其计算的示意图如7所示,其中红色区域代表被腐蚀掉的γ′相,白色区域为基体γ相。

2.6 材料压缩过程的本构关系及应力预测

应变速率和应变温度及材料变形过程中的流变应力之间存在着密切的关系,但不是简单的线性关系,并且高温热塑性变形中变形速率受热激活能控制,因此采用双曲正弦型Arrhenius方程[21]构建本研究中合金的本构关系模型,此模型适用于任何应力水平,其表达式为

(1)

(1)

式中: 为应变速率(s-1);Q为变形激活能(J/mol),与材料有关;σ为流变应力(MPa);n为应力指数;T为热力学温度(K);R为摩尔气体常数(8.314 J/(mol·K));A和α为与材料有关的常数。根据α与应力σ之间的关系:

为应变速率(s-1);Q为变形激活能(J/mol),与材料有关;σ为流变应力(MPa);n为应力指数;T为热力学温度(K);R为摩尔气体常数(8.314 J/(mol·K));A和α为与材料有关的常数。根据α与应力σ之间的关系:

当ασ≤0.8时,

(2)

(2)

当ασ≥1.2时,

(3)

(3)

总结如下:

当ασ为任意值时,

当ασ≤0.8时,

当ασ≥1.2时,

当温度不变时,Q、R、T 和 A 均为常数,对式(2)和(3)两边取对数可确定n和β值:

(4)

(4)

(5)

(5)

通过变形可得出:

图4 热等静压材料原始颗粒边界处SEM像及元素分布

Fig. 4 SEM image and element map scanning distributions of PPB for as-HIPed alloy

图5 电子背散射衍射晶粒取向图及晶粒统计结果

Fig. 5 OIM images ((a), (b)) by EBSD and results of distribution ((c), (d)) of grain size

图6 合金的SEM像

Fig. 6 SEM images of alloy

(6)

(6)

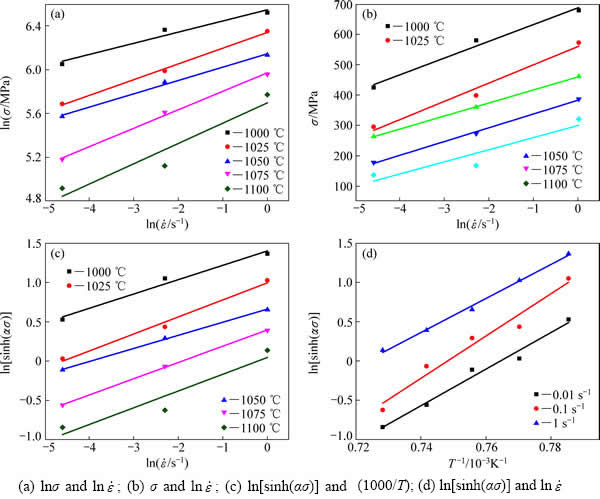

取不同条件下的峰值应力为流变应力,绘出σ-ln 和lnσ-ln

和lnσ-ln 的关系曲线,并通过线性回归进行拟合,计算出材料常数

的关系曲线,并通过线性回归进行拟合,计算出材料常数 ,如图8(a)和(b)所示 (以A粉材料为例)。

,如图8(a)和(b)所示 (以A粉材料为例)。

假设热变形激活能Q在一定温度范围内与T无关,对式(1)两边分别取对数,整理得:

(7)

(7)

在一定温度条件下,对上式求微分可得到激活能表达式如式(8)所示:

(8)

(8)

本实验中取峰值应力进行激活能的计算,作出ln[sinh(ασ)]-ln 和ln[sinh(ασ)]-T-1关系曲线,分别如图8(c)和(d)所示(以A粉材料为例)。取两个图中曲线斜率的平均值,代入式(8)计算可得变形激活能Q。

和ln[sinh(ασ)]-T-1关系曲线,分别如图8(c)和(d)所示(以A粉材料为例)。取两个图中曲线斜率的平均值,代入式(8)计算可得变形激活能Q。

图7 合金γ′相体积分数计算示意图

Fig. 7 Sketchs of calculating volume fraction of γ′ phase

图8 A粉热等静压材料中应力、应变速率、温度间的关系

Fig. 8 Relationships among stress, strain rate and temperature for A-HIP

已有研究表明[22],材料在高温塑性变形时应变速率受热激活过程控制,应变速率与温度之间的关系可用Z 参数表示:

(9)

(9)

Z参数的物理意义是温度补偿的应变速率因子,对其两边取对数可得:

(10)

(10)

根据式(9)与(10),由双曲正弦函数的定义可以得出真应力和Z参数之间的表达式如下:

(11)

(11)

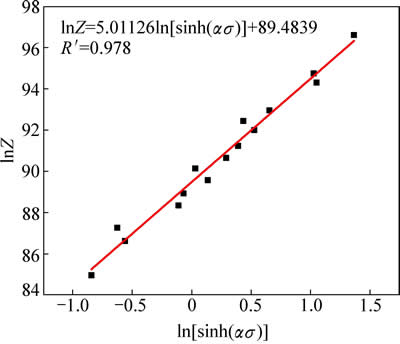

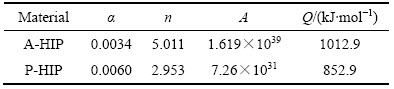

根据式(10)对 lnZ-ln[sinh(ασ)]数据进行线性回归,如图 9 (以A-HIP为例)所示,可算出材料常数A和应力指数n的值。从图9可以看出,拟合曲线具有很好的线性关系(相关系数R′=0.978),说明由此所建立的本构方程在变形过程是有效的,计算结果如表2所列。

根据上述的计算方法,最终分别算出两种材料的常数和热激活能,结果如表1所列。

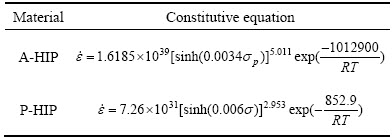

将表1中各数值代入式(1),得到A粉和P粉所制备的热等静压材料的本构方程如表3所列。

图9 A粉热等静压材料中lnZ与ln[sinh(ασ)] 的关系

Fig. 9 Relationship between lnZ and ln[sinh(ασ)] for A-HIP

表2 本构关系式中各参数计算结果

Table 2 Calculation results of parameters among constitutive equation

表3 材料的本构方程表达式

Table 3 Constitutive equations of these two alloys

仿照上述的方法,在应变0.05~0.693范围内每隔0.05选取一个值,求出不同应变下本构方程的材料常数(Q,A,α和n),然后将材料常数和真应变进行五次多项式拟合,获得α、Q、n和lnA值与应变量之间的函数关系式:

A-HIP的本构关系式如下所示,

(12)

(12)

(13)

(13)

(14)

(14)

(15)

(15)

P-HIP的本构关系式如下所示,

(16)

(16)

(17)

(17)

(18)

(18)

(19)

(19)

从表2的热激活能计算结果可以看出,采用A粉制备的材料,其热变形激活能比采用P制备的材料要高,这是由于在材料变形过程中,改善材料的缺陷会消耗一部分能量,使得所消耗的能量会增高,激活能升高[23]。A粉热等静压材料由于其制粉方式、运输过程和设备等原因,使得其氧含量较高,在热等静压过程中易于形成原始颗粒边界,使得在变形过程消耗的能量较P粉热等静压材料的高。此外,由于A粉的表面洁净度和球形度都较P粉的差以及A粉内部含有的气体在热等静压过程容易挥发形成热致性孔洞,如图3所示,在变形过程也需要消耗一部分额外的能量[24]。再者,A-HIP的平均晶粒尺寸相比P-HIP的小,且分布相对不均匀,其强化相γ′的体积分数(43.91%)较P-HIP(43.65%)的高,这也会使得变形过程的激活能有所上升,从而出现上述结果。

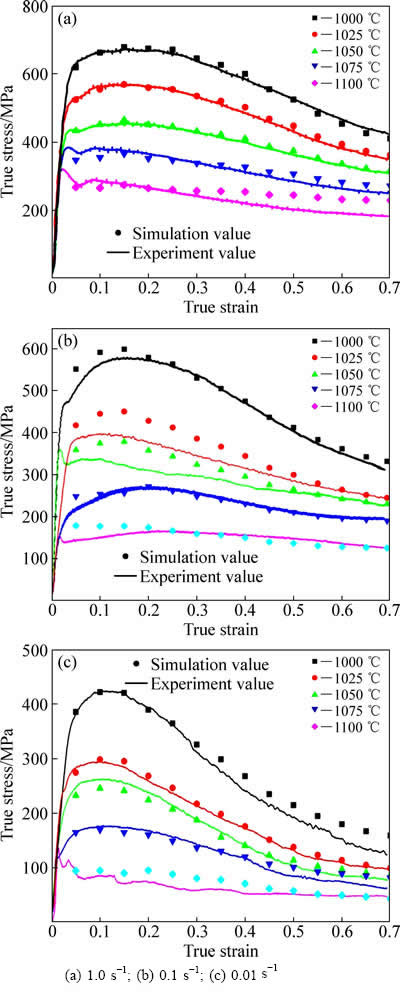

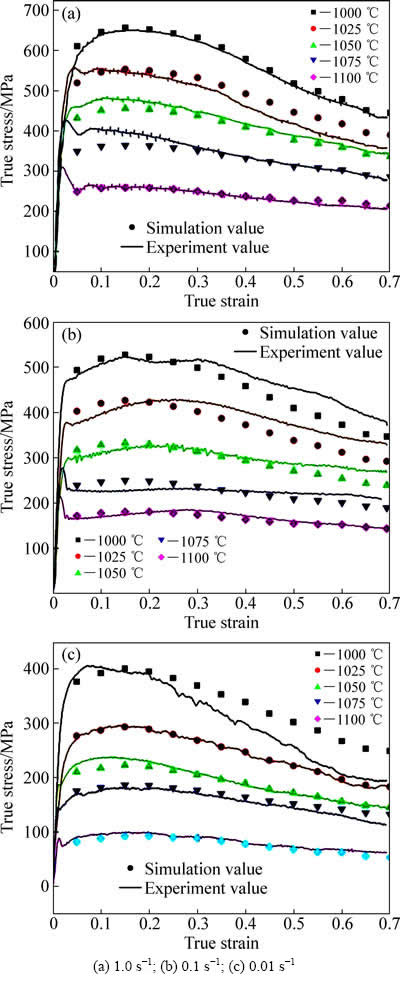

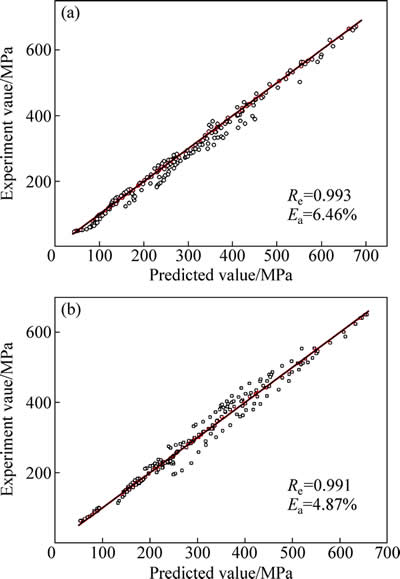

将上述得到的本构方程用于预测不同变形条件和应变的下的真应力值,其结果如图10和图11所示。

图10 A粉热等静压合金实验与模拟所得的真应力-真应变曲线

Fig. 10 True stress-true strain curves obtained by experiment and simulation for the A-HIP

图11 P粉热等静压合金实验与模拟所得的真应力-真应变曲线

Fig. 11 True stress-true strain curves obtained by experiment and simulation for P-HIP

可以看出,总体上预测值与实验值能够较好的符合。

为了验证本构方程的准确性,引入标准统计参数即相关系数(Re)和平均相对误差绝对值(Er)来对其进行评价:

(20)

(20)

图12 实验数据和预测数值统计误差

Fig. 12 Correlations between experimental and predicted flow stress

(21)

(21)

式中:Xi为利用所得的本构方程预测的真应力值;而Yi为实验所测的真应力值;N表示参与统计的实验数据的个数。结果表明,对于A-HIP的预测应力值与实验值之间的平均误差为6.46%;而P-HIP的预测应力值与实验值之间的平均误差为4.87%,说明本实验中所建立的本构方程能较好地预测合金在变形过程的流变应力,能为研究合金的热变形行为提供参考。

2.7 热压缩过程的裂纹

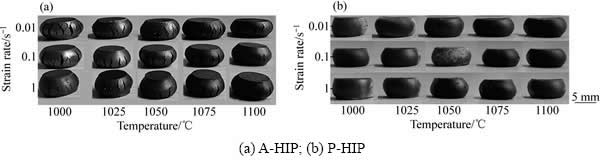

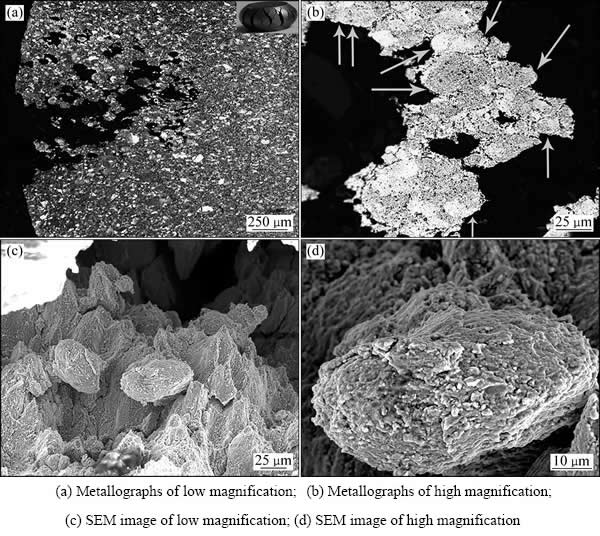

A-HIP及P-HIP的压缩外观如图13所示。由图13可以看出,A-HIP经热压缩后,表明出现了许多宏观裂纹,而P-HIP的外观并没有出现宏观裂纹。图14所示为变形条件为1000 ℃、1.0 s-1下的裂纹微观形貌。其中图14(a)和(b)所示为金相显微形貌;图14(c)和(d)所示为扫描电镜显微形貌。从图14可以看出,压缩裂纹大部分起源于鼓形最大处(最大外径处,见图14(a)右上角所示),然后沿着原始颗粒边界逐渐的扩展,如图14(b)可以看到清晰的粉末边界(见箭头所指);这是由于裂纹沿着边界扩展时使得颗粒边界显露出来。而从图14(c)可以清晰看出,断口处分布着明显的粉末颗粒,这进一步证实裂纹的扩展是沿着粉末边界进行扩展的,A-HIP中的原始颗粒边界是导致裂纹产生和扩展的主要因素。图14(d)所示为断后单颗粉末颗粒的微观形貌,可以看出粉末的直径约为50 μm,这进一步佐证了上述结论。图15所示为垂直于裂纹扩展方向的扫描电镜背散射电子像图。从图15可以更加清楚地看出,裂纹的起源在试样的边缘或者靠近边缘的原始颗粒边界处(见图15(a)中箭头所示)。然后随着变形的进行,裂纹不断地向试样的中心扩展,并伴随着新的裂纹的产生,直到实验终止。

3 结论

1) A粉的氧含量为0.0139%,而P粉的氧含量为0.0079%;A粉的粒度分布较P粉的广,粉末平均粒度相对较小,A粉的表面洁净度和球形度要较P粉的差,A粉表面粘结颗粒较多,A-HIP内部显微组织含有较多原始颗粒边界及孔洞,合金的原始颗粒边界析出相主要为大尺寸的γ′相和碳氧化物颗粒。

2) A-HIP和P-HIP的氧含量分别为0.0145%和

图13 材料热压缩的宏观形貌

Fig. 13 Macrostructures of hot compression for alloy

图14 热压缩裂纹的微观形貌

Fig. 14 Hot compression cracking morphologies of alloy deformed at 1000 ℃ and 1.0 s-1

图15 热压缩裂纹扩展方向的SEM像

Fig. 15 SEM images showing direction of hot compression cracking propagation deformed at 1075 ℃ and 0.01 s-1

0.0083%;二者平均晶粒尺寸分别为8.59 μm和12.54 μm;A-HIP与P-HIP强化相γ′的体积分数(43.91%)和(43.65%)高。

3) A-HIP的变形激活能比P-HIP的高,A-HIP的热激活能为1012.9 kJ/mol,而P-HIP的为852.9 kJ/mol。

4) 建立了两种合金在不同应变下的本构方程,并对比了本构方程所预测的应力值与实验所得的应力值之间的误差。其相关系数和误差分别为0.993(A-HIP)和0.991(P-HIP),6.46%以及4.87%,表明所建立的本构方程能较准确预测不同变形量时的流变应力值。

5) A-HIP在压缩过程出现了宏观裂纹,原始颗粒边界是压缩裂纹产生主要因素之一,且裂纹沿原始颗粒边界进行扩展。

REFERENCES

[1] ALNIAK M O, BEDIR F. Modelling of deformation and microstructural changes in P/M rene 95 under isothermal forging conditions[J]. Material Science and Engineering A, 2006, 429: 295-303.

[2] HESLOP J. Wrought nickel-chromium heat-resisting alloys containing cobalt[J]. Cobalt, 1964, 24: 128-134.

[3] TIEN J, HOWSON T, CHEN G, XIE X. Cobalt availability and superalloys[J]. Journal of Metals, 1980, 32: 12-20.

[4] YUAN Y, GU Y F, OSADA T, ZHONG Z H, YOKOKAWA T, HARADA H. A new method to strengthen turbine disc superalloys at service temperatures[J]. Scripta Materialia, 2012, 66: 884-889.

[5] 韩志宇, 曾 光, 梁书锦, 陈小林, 张 鹏, 张平祥. 镍基高温合金粉末制备技术的发展现状[J]. 中国材料进展, 2014, 12(33): 748-755.

HAN Zhi-yu, ZENG Guang, LIANG Shu-jin, CHEN Xiao-lin, ZHANG Peng, ZHANG Ping-xiang. Development in powder production technology of Ni-based superalloy[J]. Materials China, 2014, 12(33): 748-755.

[6] 张义文, 扬士仲, 李 力. 我国粉末高温合金的研究现状[J]. 材料导报, 2002, 5: 1-4.

ZHANG Yi-wen, YANG Shi-zhong, LI Li. Current status of research on PM superalloy in china[J]. Materials Review, 2002, 5: 1-4.

[7] 陈仕奇, 黄伯云. 金属粉末气体雾化制备技术的研究现状与进展[J]. 粉末冶金材料科学与工程, 2003, 3: 201-208.

CHEN Shi-qi, HUANG Bai-yun. The status and development of gas atomization for production of metal powders[J]. Powder Metallurgy Technology, 2003, 3: 201-208.

[8] 袁 华, 李 周, 许文勇. 氩气雾化制备高温合金粉末的研究[J]. 粉末冶金工业, 2010, 4(20): 1-5.

YUAN Hua, LI Zhou, XU Wen-yong. The study of argon atomized superalloy powders[J]. Power Metallurgy Industry, 2010, 4(20): 1-5.

[9] 张 莹, 李世魁, 陈生大. 用等离子旋转电极法制取镍基高温合金粉末[J]. 粉末冶金工业, 1998, 6(8): 17-22.

ZHANG Ying, LI Shi-kui, CHEN Sheng-da. Production of nickel-based superalloy powder by the plasma rotation electrode process[J]. Powder Metallurgy Industry, 1998, 6(8): 17-22.

[10] 国为民, 陈生大, 万国岩. 用不同方法制取的镍基高温合金粉末性能[J]. 航空制造工程, 1998, 2: 22-24.

GUO Wei-min, CHEN Da-sheng, WAN Guo-yan. Powder properties of PM nickel base superalloys fabricated by different methods[J]. Aeronautical and Manufacturing Engineering, 1998, 2: 22-24.

[11] 刘 娜, 李 周, 张国庆, 袁 华, 许文勇, 张 勇. 氩气雾化镍基高温合金粉末的氧化特性研究[J]. 稀有金属, 2011, 4(35): 481-485.

LI Na, LI Zhou, ZHANG Cuo-qing, YUAN Huan, XU Wen-Yong, ZHANG Yong. Oxidation characteristics of nickel-based superalloy powders prepared by argon gas atomization[J]. Chinese Journal of Rare Metals, 2011, 4(35): 481-485.

[12] 高正江, 张国庆, 李 周, 袁 华, 许文勇, 刘 娜. 粉末粒度和氧含量对HIP态FGH96合金组织的影响[J]. 稀有金属,2012, 4(36): 665-670.

GAO Zheng-jiang, ZHANG Guo-qing, LI Zhou, YUAN Hua, XU Wen-yong, LIU Na. Effect of size distribution and oxygen content of powder on microstructure of HIPed superalloy FGH96[J]. Chinese Journal of Rare Metals, 2012, 4(36): 665-670.

[13] 马文斌, 刘国权, 胡本芙. 镍基粉末高温合金FGH96中原始粉末颗粒边界的形成机理[J]. 金属学报, 2013, 10(49): 1248-1254.

MA Wen-bin, LIU Guo-quan, HU Ben-fu. Formation of previous particle boundary of nickel base PM superalloy FGH96[J]. Acta Metallurgical Sonica, 2013, 10(49): 1248-1254.

[14] 赵军普, 陶 宇, 袁守谦, 贾 建, 韩寿波. 粉末冶金高温合金中的原始颗粒边界(PPB)问题[J]. 粉末冶金工业, 2010, 4(20): 43-49.

ZHAO Jun-pu, TAO Yu, YUAN Shou-qian, JIA Jian, HAN Shou-bo. The problem of prior particle boundary in PM superalloys[J]. Powder Metallurgy Industry, 2010, 4(20): 43-49.

[15] 刘明东, 张 莹, 刘培英, 张义文. FGH95粉末高温合金原始颗粒边界及其对性能的影响[J]. 粉末冶金工业, 2006, 16(3): 1-5.

LIU Ming-dong, ZHANG Ying, LIU Pei-ying, ZHANG Yi-wen. Study on the PPB effect of PM superalloy FGH95[J]. Powder Metallurgy Industry, 2006, 16(3): 1-5.

[16] SILVA J M, CLAUDIO R A, SOUSAE B A. Characterization of powder metallurgy (PM) nickel base superalloys for aeronautical applications[J]. Materials Science Forum, 2006, 495: 514-516.

[17] CAROL M, GOLLELS F, ASHOK K K. Prior particle boundary precipitation in Ni-base superalloys[J]. International Journal of Powder Metallurgy, 1989, 25(4): 301-303.

[18] 贾 健, 陶 宇, 张义文, 张 莹. 热等静压温度对新型粉末冶金高温合金显微组织的影响[J]. 航空材料学报, 2008, 28: 20-23.

JIA Jian, TAO Yu, ZHANG Yi-wen, ZHANG Ying. Effects of HIP temperature on microstructures of a new P/M superalloy[J]. Journal of Aeronautical Materials, 2008, 28: 20-23.

[19] QIU C, WU X, MEO J, ANDERWS P, VOICE W. Influence of heat treatment on microstructure and tensile behavior of a hot isostatically pressed nickel-based superalloy[J]. Journal of Alloys and Compounds, 2013, 578: 454-464.

[20] PAYTON E, PHILLIPS P, MILLS M. Semi-automated characterization of the phase in Ni-based superalloys via high-resolution backscatter imaging[J]. Materials Science and engineering A, 2010, 527: 2684-2692.

[21] SELLARS C M, MCTEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgical, 1966, 14(9): 1136-1138.

[22] CHAKRAVARTTY J K, DEY G K, BANERJEE S, PRASAD Y V R K. Characterization of hot deformation behavior of Zr-2.5Nb-0.5Cu using processing maps[J]. Journal of Nuclear Materials, 1995, 218: 247-255.

[23] 谢兴华, 姚泽坤, 宁永权, 郭鸿镇, 陶 宇, 张义文. FGH4096粉末高温合金的热变形行为[J]. 稀有金属材料与工程, 2012, 1(41): 82-86.

XIE Xing-hua, YAO Ze-kun, NING Yong-quan, GUO Hong-zhen, TAO Yu, ZHANG Yi-wen. Investigation on hot deformation behavior of P/M superalloy FGH4096[J]. Rare Metal Materials and Engineering, 2012, 1(41): 82-86.

[24] XU W, ZHANG L W, GU S D, ZHANG J L. Hot compressive deformation behavior and microstructure evolution of HIPed FGH96 superalloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 66-71.

Effects of powder characteristics on microstructure and deformation activation energy of nickel based superalloy

HE Guo-ai1, 2, DING Han-hui1, 2, LIU Chen-ze1, 2, LIU Feng1, 2, LAN Huang1, 2, JIANG Liang1, 2

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Research Institute of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: A new Nickel based superalloy powder was fabricated by methods of argon atomization (AA) and plasma rotating electrode process (PREP), followed by hot isostatic pressing (HIP) under the same conditions. Microstructure analyzing of both as-powder and as-HIPed was carried out. The hot compression tests of two different materials were conducted using a thermal simulator under the deformation conditions at temperature range from 1000 to 1100 ℃ and strain rates range of 0.01-1.0 s-1. The deformation activity energy and constitutive equations were established to predict the true stress at different strains under deformation conditions. The results show that the surface cleanliness and homogeneity of the powder prepared by PREP are much better than those prepared by AA. The oxygen content of argon atomization powder is 0.0139% (mass fraction), while the oxygen content of PREP powder is 0.0079%. The prior particle boundary in as-HIPed fabricated by AA is more severe than that by PREP, which consists of γ′ phase with large size, carbides and oxidizes. The average grain size of A-HIP is determined as 8.59 μm, while that of the P-HIP is 12.54 μm. The volume fractions of γ′ phase of A-HIP and P-HIP are 43.92% and 43.65%, respectively. The deformation activation energies are calculated as 1012.9 kJ/mol (for AA) and 852.9 kJ/mol (for PREP), respectively. In addition, the constitutive equations for two alloys are also developed to predict the true stress at different deformation conditions with the absolute error of 6.46% and 4.87%. The PPB is one of the main reasons that leads to the occurrence of cracking, which propagates along the PPB.

Key words: nickel base powder metallurgy superalloy; argon atomization; plasma rotating electrode process; hot isostatic pressing; hot simulation; activation energy; constitutive equation

Foundation item: Project (2012AA03A514) supported by the National High-tech Research and Development Programm of China; Projects (51401242, 51301209) supported by the National Natural Science Foundation of China; Project (2015zzts031) supported by the Doctoral-Independent Exploration and Innovation of Central South University, China; Project supported by the Oustanding Graduate Project of Advanced Nonferrous Metal Structural Material and Manufacturing Collaborative Innovation Center, China.

Received date:2015-03-20;Accepted date:2015-10-25

Corresponding author: LIU Feng; Tel: +86-18670324887; E-mail: liufeng@csu.edu.cn

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2012AA03A514);国家自然科学基金资助项目(51401242,51301209);研究生自主探索项目资助项目(2015zzts031);有色金属先进结构材料与制造协同创新中心研究生拔尖创新人才培养课题资助

收稿日期:2015-03-20;修订日期:2015-10-25

通信作者:刘 锋,副教授,博士;电话:18607324887;E-mail:liufeng@csu.edu.cn