DOI: 10.11817/j.ysxb.1004.0609.2020-36590

铜渣还原活化制备新型胶凝材料与矿山充填的应用

朱茂兰1,肖 妮2,谭良春1,衷水平2,吕旭龙2,迟晓鹏2

(1. 厦门理工学院 材料科学与工程学院,厦门 361024;

2. 福州大学 紫金矿业学院,福州 350108)

摘 要:以铜渣为研究对象,煤炭作为还原剂,石灰作为活化剂,对铜渣进行高温熔融还原回收铁和渣相重构活化,研究了不同温度、煤炭和石灰含量、还原渣粒度对铁的回收率和胶凝材料抗压强度的影响。结果表明:在铜火法冶炼产生的铜渣温度范围内,可以满足铜渣还原回收铁的要求。石灰和还原剂在还原渣的物相重构中起到了关键作用。另外,在温度为1400 ℃、石灰39 g、煤炭13 g条件下,铁的回收率达89.6%,以产生的还原渣制备胶凝材料的抗压强度28 d时达到9.7 MPa。并且还原渣与尾砂调配制备的新型胶凝材料,其28 d后的抗压强度均满足矿山充填的要求。

关键词:铜渣;还原活化;胶凝材料;抗压强度

文章编号:1004-0609(2020)-11-2736-10 中图分类号:TF111.15 文献标志码:A

铜渣是火法炼铜时冰铜吹炼和转炉吹炼产生的废渣[1]。铜渣中含有大量的有价金属,现有技术实现了铜的回收,但对于铁的回收仍然存在成本高,尾渣难处理的问题[2-3]。近年来,为了解决尾渣堆存问题,许多学者研究了尾渣制备新型胶凝材料应用于胶结填充过程中[4]。大多数矿山选用普通硅酸盐水泥作为胶结剂,高昂的充填成本给矿企带来巨大的经济压力[5-6]。但使用铜渣制备新型胶凝材料用于矿山充填不仅可降低矿山胶结充填料的成本,而且能节约大量普通硅酸盐水泥,并可减少废渣排放,保护环境[7]。但铜渣具有铁含量高、钙含量低、胶凝活性差等特点,无法直接进行利用[8]。因此,提高铜渣胶凝活性是其应用的关键所在。

虽然铜渣在混凝土和矿山充填的利用有一定成果,但仍有些不足,主要是铜渣的添加量较低,不能解决大量固废堆积的问题[9]。且铜渣内的有价金属未回收利用,造成资源浪费[10]。因此,论文以铜渣为研究对象,采用高温熔融还原回收铁和渣相重构活化的方法,利用熔融还原提铁过程来活化铜渣,产生的还原渣用于制备胶凝材料。本文研究了不同温度、煤炭、石灰含量和还原渣粒度对铁的回收率和胶凝材料抗压强度的影响,确定最佳渣相重构回收金属铁和还原渣制备胶凝材料的实验条件。依据新型凝胶材料的抗压强度,探索还原渣与尾砂用于矿山充填的合适比例。真正意义上实现“矿从山中来,渣回山中去”的循环经济理念。

1 实验

1.1 实验方案

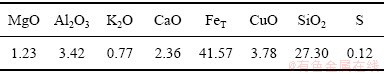

铜渣(来自福建省某企业)的主要成分如表1所示。从表1中可知,铜渣中总铁含量为41.57%,CaO含量为2.36%,SiO2含量为27.30%。与具有高活性水泥相比,铜渣具有“高铁低钙”的特点。

表1 铜渣的主要成分

Table 1 Copper slag chemical characterisation (mass fraction, %)

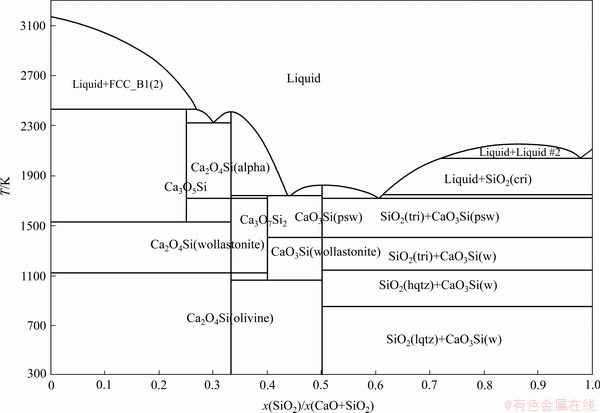

在胶凝材料中,胶凝活性物质主要为高钙硅酸盐,图1所示为CaO-SiO2二元相图。从图1中可知,当SiO2在二元相图中摩尔分数大于50%时,Ca和Si以CaSiO3和SiO2的形式存在;当SiO2在二元相图中摩尔分数等于50%时,Ca和Si以CaSiO3的形式存在;当SiO2在二元相图中摩尔分数小于50%时,Ca和Si以CaSiO3和Ca3Si2O7的形式存在。尽管随着钙含量增加会逐渐形成高钙硅酸盐,有利于提高还原渣的胶凝活性,但所需的反应温度也增大(最高达2100 ℃),远远高于实际熔炼渣的温度(1300~1400 ℃)。因此,考虑到尽可能的与实际生产相结合,利用原有铜渣熔体具有的热量完成还原回收铁和渣相重构活化,选择实验的温度为1300~1400 ℃。

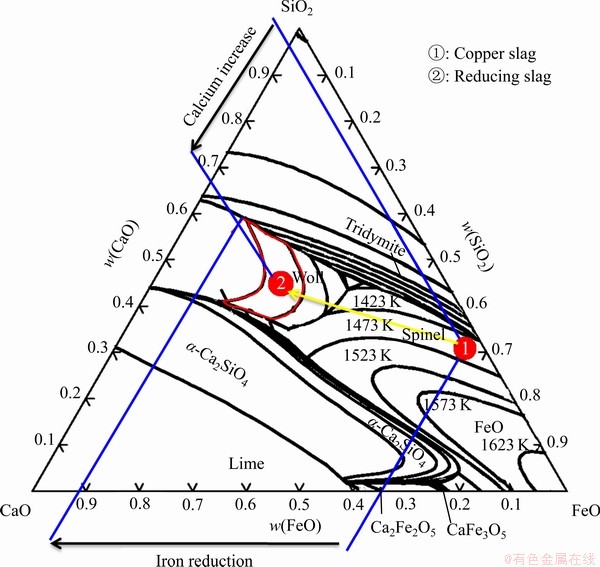

铜渣主要含有铁橄榄石、氧化钙等物质。在制备胶凝材料时,铜渣的胶凝活性低,具有“高铁低钙”的特点。因此,为了制备较好的新型胶凝材料用于矿山充填,需要回收铜渣中一部分铁和加入一部分CaO。CaO的加入一方面促进铁的还原,另一方面为铜渣提供Ca源,增加渣相的钙含量,形成具有活性的高钙硅酸盐。图2所示为CaO-SiO2-Fe2O3三元相图铜渣中FeO、SiO2、CaO含量分别为64.32%、32.84%、2.84%(质量分数)。标号1为铜渣的CaO-SiO2-Fe2O3三元成分组成。在1300~1400 ℃下,加入还原剂煤炭和活化剂石灰,经过还原析出一部分铁之后,产生的还原渣成分组成在图2红线内,标号2为还原渣的CaO-SiO2-Fe2O3三元成分组成。同时,为了实现还原渣具有胶凝活性物质的αCaO·SiO2用于制备新型胶凝材料,FeO的含量需要由64.32%下降到5%~25%之间,CaO需要由2.84%增加到20%~45%之间。在试验中每处理100 g铜渣(假设仅含有FeO、CaO、SiO2三种成分),大约需要7.80~11.77 g还原剂煤炭(C含量84%)和石灰18.65~45.83 g(CaO含量92%)。因此,实验条件每100 g铜渣选择煤炭8、9、10、11、12、13 g,石灰15、21、27、33、39、45 g。

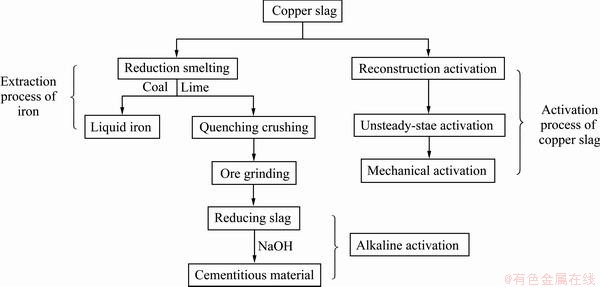

在制备胶凝材料时,铜渣的胶凝活性低,其中铁含量高和钙含量低是主要原因之一。为了提高铜渣的胶凝活性,借鉴现有学者的研究基础上,对铜渣通过以下方式进行活化。

1) 高温重构法。将调节材料加入到胶凝材料中,通过温度和冷却过程控制来增加胶凝矿物或高钙玻璃体含量,从而提高胶凝材料活性。LI等[11]以石灰、电炉钢渣等作为添加材料,在高温下对钢渣结构进行重构,结果表明与原钢渣相比重构钢渣活性提高。ZHANG等[12-13]研究了赤泥作为添加剂经过高温煅烧煤矸石来提高材料的活性,当赤泥添加量低于50%时,制作的水泥强度均高于硅酸盐水泥的强度。因此,实验选择煤炭作为还原剂和石灰作为添加剂,在还原回收铁的同时对铜渣进行高温重构活化。

图1 CaO-SiO2二元相图

Fig. 1 Phase diagram of CaO-SiO2

图2 CaO-SiO2-FeO三元相图

Fig. 2 CaO-SiO2-FeO ternary phase diagram

2) 机械力活化法。在强机械力的作用下,矿物晶体结构发生畸变,结晶度下降,晶格能迅速减小,水分子容易进入颗粒内部,从而加速水化反应进行[14]。CHEN等[15]研究了粉煤灰的机械活化在胶凝材料中的应用,结果表明机械活化可以改善粉煤灰的性能,其抗压强度35.3 MPa提高到56.9 MPa。实验在高温重构活化之后,熔体经过淬火破碎进入磨矿选铁,在磨矿的过程中对铜冶炼渣进行机械力活化。

3) 化学激发法。化学激发法主要是碱活化,碱活化是一种广泛发展的技术,在室温下固体铝硅酸盐前驱体和碱活化剂之间的化学反应,产生硬化产物[16]。SINGH等[17]以氢氧化钠和硅酸钠为碱激发剂,研究了粉煤灰、偏高岭土等矿物掺合料对碱活性铜渣性能的影响。试验结果表明,在碱活性铜渣水泥中加入矿物掺合料可改善其性能。因此,在还原渣制备胶凝材料时使用NaOH作为碱活化剂。

基于以上方法,本文采用高温还原回收铁和渣相重构活化的方法,利用熔融还原提铁过程进行高温重构活化,产生熔融的还原渣经过水淬进行非稳态活化,其次通过磨矿进行机械活化,最后用氢氧化钠作为碱性激发剂活化制备新型胶凝材料,其流程示意图如图3所示。

1.2 实验原理

在实验过程中主要发生的化学反应包括两个阶段,第一阶段,煤炭对铁元素的还原;第二阶段,石灰的加入形成新的渣相同时产生具有胶凝活性的高钙硅酸盐。

第一阶段:铁元素的还原。

Fe2SiO4+2C=2Fe+SiO2+2CO (g) (1)

Fe3O4+4C=3Fe+4CO (g) (2)

第二阶段:高钙硅酸盐的形成。

Fe2SiO4+2CaO+2C=2Fe+Ca2SiO4+2CO (g) (3)

SiO2+CaO=CaO·SiO2 (4)

2(CaO·SiO2)+CaO=3CaO·2SiO2 (5)

3CaO·2SiO2+CaO=2(2CaO·SiO2) (6)

图3 高温还原回收铁和渣相重构活化流程示意图

Fig. 3 Schematic diagram of high temperature reduction recovery of iron and slag phase reconstruction activation process of copper slag

1.3 实验步骤

实验中将100 g铜渣与不同含量的煤炭、石灰混合均匀,放入刚玉坩埚中,在高温电阻炉(型号BLMT-QD-16-36)中,以5 ℃/min的速度升温至实验温度,保温相同的时间2 h后,取出坩埚将铁水与还原渣分离,还原渣经过水淬处理,然后破碎、球磨(型号XQM-4)。根据铁水中含铁量与原铜渣中铁量计算铁的回收率。

还原渣用碱性激发剂进行新型胶凝材料制备,将还原渣、氢氧化钠、水玻璃(浓度50%)按照75%、5%、20%进行配比混合均匀,倒入圆柱形模具(高径比为1.2:1)后轻微振实,放入一段时间后脱模,将制备的胶凝材料在压力测试仪上进行抗压强度检测分析。

2 结果与讨论

2.1 温度对铜渣还原提铁和渣相活化重构的影响

为了研究温度对铜渣还原提铁活化造渣的影响,采用控制变量法,100 g铜渣放入煤炭13 g、石灰45 g,分别探究了温度为1300、1320、1340、1360、1380、1400 ℃时对铜渣还原提铁活化造渣的影响。

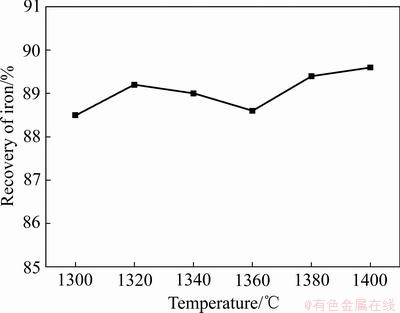

图4所示为不同温度下铁的回收率。从图4可知,温度在1300~1400 ℃内,铁的回收率在88.5%~89.6%之间变动,相差并不大。铁的回收率超过了85%,说明在1300~1400 ℃范围内,可以满足铜渣还原回收铁的要求。

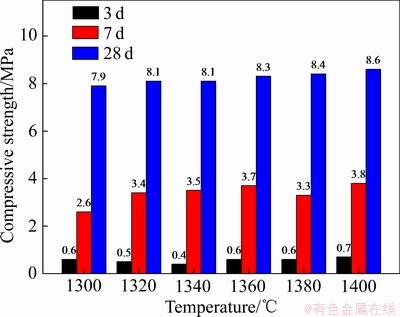

不同温度下铜渣经过还原提铁后,产生的还原渣用于制备新型的胶凝材料,并对其3、7、28 d的抗压强度进行测试,如图5所示。温度在1300~1400 ℃范围内,3、7、28 d的抗压强度分别在0.4~0.7、2.6~3.8、7.9~8.6 MPa范围内变化。其中3 d和7 d的抗压强度有一定的波动,整体来看有轻微增加的趋势,胶凝材料经28 d水化后的抗压强度随着温度的升高而逐渐增加。说明温度的升高有利于提高胶凝材料的抗压强度。虽然在熔融的铜渣加入了一部分煤炭还原铁可以提高铜渣的温度,但提供的能量非常有限。为了避免能量的消耗和成本增加,结合铜火法冶炼实际生产条件,在高温还原提铁和渣相重构时,其适宜的温度为1400 ℃。

图4 不同温度下铁的回收率

Fig. 4 Iron recovery at different temperatures

图5 不同温度下胶凝材料水化后的抗压强度

Fig. 5 Compressive strength of cementitious material at different temperatures

2.2 石灰对铜渣还原提铁和渣相活化重构的影响

本实验考察了100 g铜渣在1400 ℃、煤炭13 g条件下,15、21、27、33、39、45 g石灰对铜渣还原提铁和渣相活化重构的影响。

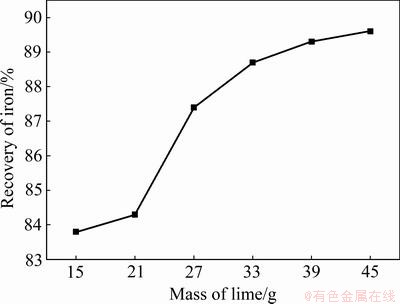

对比不同石灰条件下铁的回收率,其结果如图6所示。从图6中可知,随着石灰含量的不断增加,还原金属铁的回收率出现先增加后趋于稳定的趋势。当石灰含量由15 g增加到45 g时,铁的回收率从83.8%达到89.6%。在石灰含量增加的前期对铁还原的影响比较明显,后期越来越弱。可以发现,石灰含量的增加有利于铁的还原,这主要由于石灰的加入使铜渣中的铁硅渣转向为含有高硅酸盐的钙硅渣,打破原有橄榄石的状态,促进了煤炭与铁的还原。从结果可知,适宜的石灰量应该为33~45 g。

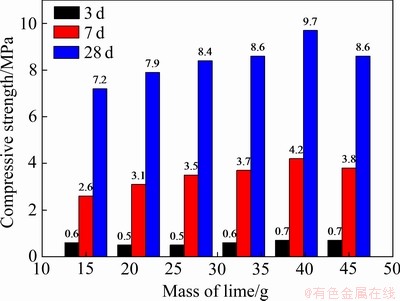

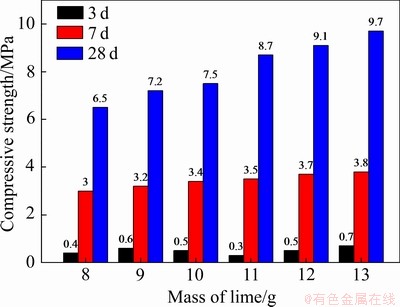

图7所示为不同石灰含量下胶凝材料水化后的抗压强度。从图7中可知,28 d后,随着石灰含量的增加,抗压强度出现先增加后降低的趋势。当石灰含量由15 g增加到39 g时,还原渣制备胶凝材料抗压强度由7.2 MPa增加到 9.7 MPa。当石灰含量由39 g增加到45 g时,还原渣制备胶凝材料抗压强度由9.7 MPa下降到 8.6 MPa。3 d后,胶凝材料抗压强度在0.5~0.7 MPa之间波动,并没有明显的规律。7 d后,胶凝此材料的抗压强度与3 d时胶凝此材料的抗压强度相比增加了较多,在2.6~4.2 MPa之间。随着石灰含量的增加7 d后的抗压强度与28 d呈现相同的趋势,说明在前期石灰含量的增加有利于提高胶凝材料的抗压强度,但石灰含量继续增加使还原渣中存在过量的CaO,CaO水化时易膨胀,造成还原渣的不稳定,使其抗压强度下降。因此,为了得到胶凝活性更好的还原渣,综合石灰含量对铁还原的影响,其适宜的石灰含量在为39 g。

图6 不同石灰量下还原金属铁的回收率

Fig. 6 Recovery of iron under different lime content

图7 不同石灰含量下胶凝材料水化后的抗压强度

Fig. 7 Compressive strength of cementitious material under different lime contents

2.3 煤炭对铜渣还原提铁和渣相活化重构的影响

在进行石灰对铜渣还原提铁和渣相活化重构的影响后,确定了石灰含量在39 g时,新型胶凝材料的抗压强度效果较好。但煤炭是铁的还原剂,也较为重要,因此本实验考察了100 g铜渣在1400 ℃、石灰39 g条件下,8、9、10、11、12、13 g煤炭对铜渣还原提铁和渣相活化重构的影响。

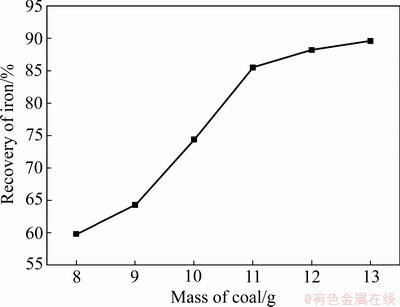

图8所示为不同煤炭含量下铁的回收率。从图8中可知,还原剂煤炭由8 g增加到13 g时,铁的回收率由59.8%增加到89.6%,铁的回收率随着煤炭的增加而增加。在煤炭量为8~11 g时,增加速度要比煤炭量为11~13 g时的快。煤炭含量的增加有利铁的还原,相比于石灰对铁还原的影响,煤炭对其影响比较大。

图8 不同煤炭含量下铁的回收率

Fig. 8 Recovery of iron at different coal contents

图9所示为不同煤炭含量下新型胶凝材料水化后的抗压强度。从图9中可知,随着还原剂煤炭含量的增加,新型胶凝材料水化3 d时的抗压强度在0.3~0.7 MPa范围内波动,此时,还原渣胶凝活性物质水化才刚刚开始,水化反应并不完全,还原渣中存在一定的水分,受各种因素干扰比较大,所以呈现出来的规律并不那么明显。新型胶凝材料水化7 d和28 d的抗压强度随着石灰的含量增加而增加,呈现出增长的趋势。还原剂煤炭的增加有利于提高新型胶凝材料的抗压强度,且对其抗压强度影响较为明显。根据煤炭对铜渣还原提铁和渣相活化重构的影响,在8~13 g探索的范围内,选择煤炭13 g较为适宜。

在铜渣的高温还原-渣相重构的过程中,温度大小、石灰含量、煤炭含量对铁的还原率和还原渣制备的新型胶凝材料抗压强度都有影响。在冶炼温度为1300~1400 ℃范围内,随着温度的升高,铁的还原率和抗压强度均增加。石灰含量的增加有利于铜渣中铁的还原,但是加入过多的石灰,CaO会存在还原渣中,水化产生Ca(OH)2,其晶体强度低稳定性差,从而会降低胶凝材料的抗压强度。煤炭含量的增加对铁的还原率和胶凝材料的抗压强度影响较为明显,对二者都起到促进作用,铜渣中的铁还原率越高,使还原渣中的铁含量越少,越有利于渣相重构产生胶凝活性物质。在100 g铜渣进行还原提铁和渣相活化石时,温度为1400 ℃、石灰39 g、煤炭13 g条件下,铁的回收率达89.6%,其产生的还原渣用于制备的胶凝材料抗压强度28 d达到9.7 MPa。

图9 不同煤炭含量下胶凝材料的抗压强度

Fig. 9 Compressive strength of cementitious material at different coal contents

2.4 还原渣粒度对胶凝材料抗压强度的影响

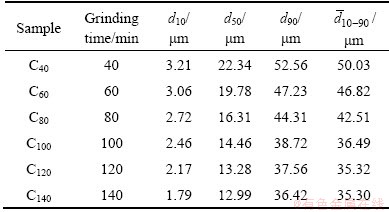

为了研究还原渣粒度对胶凝材料的影响,取6份在1400 ℃、石灰39 g、煤炭13 g条件下还原提铁后产生的还原渣,每份100 g,放入立式行星球磨机,分别研磨40、60、80、100、120、140 min,其粒度分布如表2所示(其中d10、d50和d90为颗粒含量为10%、50%和90%的粒径; 为颗粒含量为10%~90%的平均粒径)。

为颗粒含量为10%~90%的平均粒径)。

表2 不同研磨时间下还原渣的粒径分布

Table 2 Particle size distribution of reducing slag under different grinding time

从表2可以看出,随着研磨的时间增加,还原渣的d10、d50、d90、 粒径显著的减小。另外,从

粒径显著的减小。另外,从 还可以看出,随着研磨时间的增加粒径的大小逐渐趋向于稳定。

还可以看出,随着研磨时间的增加粒径的大小逐渐趋向于稳定。

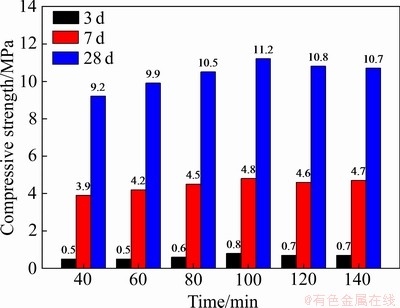

图10所示为不同还原渣粒度下胶凝材料的抗压强度。由表2和图10可知,随着研磨时间的延长,还原渣的粒径减小,其制备的胶凝材料在3 d、7 d、28 d的抗压强度呈现出先增大后减小,规律较为明显,尤其是在28 d时。出现这种现象的主要原因在于:随着还原渣粒径的减小,其比表面增大,有利于提高还原渣的胶凝活性;但还原渣粒径过小时,易发生团聚的现象,导致比表面积较小,降低了还原渣的胶凝活性。另外,在1400 ℃、石灰39 g、煤炭13 g条件下对比图7、9、10抗压强度可知,还原渣的粒径减小有利于促进新型胶凝材料的水化反应,但随着还原渣的粒径过小,这种促进会逐渐的减弱。综上所述,还原渣的粒径并不是越小越好。当研磨到100 min时,还原渣制备的胶凝材料活性最好,即28 d抗压强度达到11.2 MPa。

图10 不同还原渣粒度下胶凝材料的抗压强度

Fig. 10 Compressive strength of cementitious material with different particle sizes of reducing slag

2.5 还原渣制备新型胶凝材料的活性分析

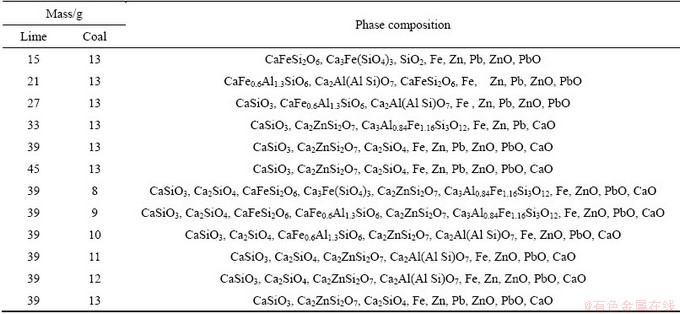

在1400 ℃条件下对不同石灰和煤炭含量制备的还原渣进行XRD物质组成进行检测分析,其结果如表3所示。

从XRD结果来看,随着石灰含量的增加,形成的还原渣中物质组成逐渐发生变化。当石灰含量由10 g增加到33 g时,还原渣主要以硅酸铁钙、硅酸铝钙、SiO2等形式存在。随着石灰含量的增加,硅酸铁钙逐渐消失。当石灰含量由33 g增加到45 g时,硅酸铝铁钙也逐渐的消失,形成CaSiO3、Ca2ZnSi2O7、Ca2SiO4等高钙硅酸盐。这表明随着石灰含量的增加,还原渣中物相从硅酸铁钙逐渐转变为CaSiO3和Ca2SiO4,这些物相皆具有胶凝活性物质。此外,在还原渣中出现的CaO,说明石灰中CaO没有完全参与硅酸钙的合成中。随着还原剂煤炭不断的增加,铁逐渐被还原,含铁硅酸盐在还原渣中也逐渐消失。当煤炭从8 g增加到10 g时,Ca3Fe(SiO4)3和CaFeSi2O6中的铁被还原,形成硅酸盐物质,出现Ca2Al(Al Si)O7。当煤炭含量从10 g增加到11 g时,CaFe0.6Al1.3SiO6中的铁被还原,晶相消失。当煤炭从11 g增加到13 g时,还原渣中除了铁被还原以外,还出现了Zn和Pb的还原。

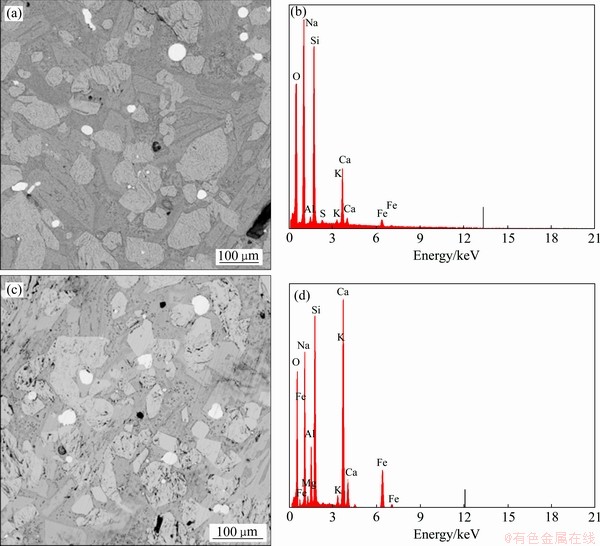

对还原渣制备的新型胶凝材料水化28d后进行SEM分析,其结果如图11所示。用能谱成分检测发现,胶凝材料中主要元素含Ca、Na、Si、O等元素,可以推测是具有胶凝性的水化硅酸盐物质。从形貌观察来看,还原渣在碱激发水化后呈现凝胶状,结构比较致密,看不到明显的裂缝,此时的胶凝材料抗压强度达到最大。

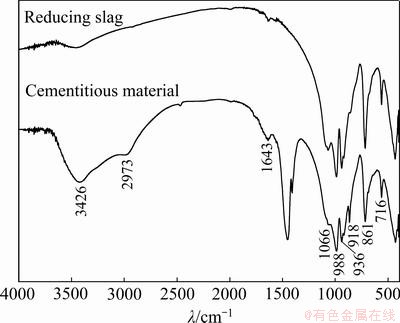

对还原渣制备的新型胶凝材料进行FTIR分析,结果如图12所示。图中波数为3425和1643 cm-1属于OH的吸收特征峰,波数1066、988、936、918、861、716 cm-1属于S—O—Si 非对称伸缩振动和O—Si—O对称伸缩振动引起吸收带,557 cm-1属于为Si—O弯曲振动引起的吸收带。对比还原渣及其胶凝材料的FTIR光谱图,Si—O—Si伸缩振动峰明显变宽,说明硅氧四面体结构对称性降低,反映了还原渣在碱激发条件下发生水化反应,使原来结晶良好的硅酸盐物质转变为结晶性差的水化硅酸盐。

表3 不同石灰和煤炭含量下还原渣的物相组成

Table 3 Phase composition of reducing slag with different lime content

图11 还原渣制备的胶凝材料微观形貌和能谱

Fig. 11 Micro morphologies and energy spectra of cementitious material prepared by reducing slag

图12 还原渣与制备的胶凝材料的FTIR对比

Fig. 12 FTIR curves comparison of reducing slag and prepared cementitious material

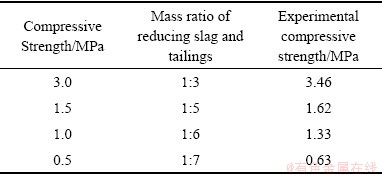

2.6 新型胶凝材料在矿山充填中应用

根据以上实验数据可知,当温度为1400 ℃、石灰39 g、煤炭13 g时,铁的回收率达89.6%,其产生的还原渣用于制备的新型胶凝材料抗压强度28 d达到9.7 MPa。与水泥相比新型胶凝材料的抗压强度低,但远超于矿山填充的要求,因此,可以将还原渣与尾砂调配制备适用于矿山填充的新型胶凝材料,其矿山填充抗压强度要求来自福建某矿山。

表4所列为福建某矿山填充要求与新型胶凝材料抗压强度。从表4中可知,对于矿山的4种不同要求,通过还原渣与尾砂配比均能达到。

表4 福建某矿山填充要求与新型胶凝材料28 d的抗压强度

Table 4 Requirements for filling of mine in Fujian Province and compressive strength of new cementing material at 28 d

3 结论

1) 在铜火法冶炼产生的铜渣1300~1400 ℃范围内,铁的回收率超过了85%,可以满足铜渣还原回收铁的要求。28 d胶凝材料水化后,抗压强度随着温度的升高而逐渐增加,结合冶炼实际生产条件,其适宜的温度为1400 ℃。

2) 活化剂石灰和还原剂煤炭是还原渣物相重构的关键因素。且随着随着二者含量的不断增加,不仅有利于还原金属铁的回收率,而且有利于提高新型胶凝材料的抗压强度。相比于石灰对铁还原的影响,煤炭对其影响比较大。还原剂煤炭的增加其抗压强度影响较为明显。

3) 随着还原渣的粒径减小,其制备的胶凝材料抗压强度呈现出先增大后减小。当研磨到100 min时,以还原渣制备的胶凝材料28 d的抗压强度达到11.2 MPa。虽然适宜的粒径可以增加胶凝材料的抗压强度,但会使生产成本增加。因此,对于还原渣的粒径需要综合考虑。

4) 在温度1400 ℃、石灰39 g、煤炭13 g条件下,铁的回收率达89.6%,其产生的还原渣制备的胶凝材料的抗压强度28 d时达到9.7 MPa。并用还原渣与尾砂调配制备适用于矿山填充的胶凝材料,其28 d后的抗压强度均满足矿山充填的要求。

REFERENCES

[1] 杨慧芬, 景丽丽, 党春阁. 铜渣中铁组分的直接还原与磁选回收[J]. 中国有色金属学报, 2011, 21(5): 229-234.

YANG Hui-fang, JING Li-li, DANG Chun-ge. Iron recovery from copper slag with lignite-based direct reduction followed by magnetic separation[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 229-234.

[2] 刘 纲, 朱 荣, 王昌安, 王振宙, 高 峰. 铜渣熔融氧化提铁的试验研究[J]. 中国有色冶金, 2009(1): 71-74.

LIU Gang, ZHU Rong, WANG Chang-an, WANG Zhen-zhou, WANG Zhen-zhou, GAO Feng. Experiment of molten oxidation iron extraction in copper slag[J]. China Nonferrous Metallurgy, 2009(1): 71-74.

[3] 王 琛, 田庆华, 王亲猛, 刘 栋, 郭学益. 铜渣有价金属综合回收研究进展[J]. 金属材料与冶金工程, 2014, 42(6): 50-56.

WANG Chen, TIAN Qing-hua, WANG Qin-meng, LI Dong, GUO Xue-yi. Research progress in comprehensive recovery of valuable metals from copper slag[J]. Metal Materials and Metallurgy Engineering, 2014, 42(6): 50-56.

[4] BEHNOOD A, GHAREHVERAN M M, ASL F G, AMERI M. Effects of copper slag and recycled concrete aggregate on the properties of CIR mixes with bitumen emulsion, rice husk ash, Portland cement and fly ash[J]. Construction and Building Materials, 2015, 96: 172-180.

[5] 曹洪杨, 付念新, 王慈公, 张 力, 夏风中, 隋智勇, 冯乃祥. 铜渣中铁组分的选择性析出与分离[J]. 矿产综合利用, 2009(2): 8-11.

CAO Hong-yang, FU Nian-xin, WANG Ci-gong, ZHANG Li, XIA Feng-zhong, SUI Zhi-yong, FENG Nai-xiang. Selective precipitation and separation of Fe components from copper smelting slags[J]. Multipurpose Utilization of Mineral Resource, 2009(2): 8-11.

[6] EDWIN R S, SCHEPPER M D, GRUYAERT E, BELIE N D. Effect of secondary copper slag as cementitious material in ultra-high performance mortar[J]. Construction and Building Materials, 2016, 119: 31-44.

[7] WANG Z C, WANG Z C, XIA H C, WANG H F. Analysis of hydration mechanism and microstructure of composite cementitious materials for filling mining[J]. Journal of Wuhan University of Technology (Mater Sci Ed), 2017, 32(4): 910-913.

[8] YANG X, GAO Q, YANG Z, TIAN L P. Activator proportion for a new filling cementitious material of full tailings in Jinchuan mine[J]. Electronic Journal of Geotechnical Engineering, 2015, 20(8): 2097-2106.

[9] 杜海云, 马倩敏, 郭荣鑫, 颜 峰, 林志伟, 何科成, 黄丽萍. 铜渣-水泥复合胶凝材料力学性能研究[J]. 硅酸盐通报, 2017, 36(5): 1634-1645.

DU Hai-yun, MA Qian-min, GUO Rong-xin, YAN Feng, LIN Zhi-wei, HE Ke-cheng, HUANG Li-ping. Mechanical properties of Portland cement-copper slag compound cementitious material[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(5): 1634-1645.

[10] MURARI K, SIDDIQUE R, JAIN K K. Use of waste copper slag, a sustainable material[J]. Journal of Material Cycles and Waste Management, 2015, 17(1): 13-26.

[11] LI J X, YU Q J, WEI J X, ZHANG T S. Structural characteristics and hydration kinetics of modified steel slag[J]. Cement and Concrete Research, 2011, 41(3): 324-329.

[12] ZHANG N, LIU XM, SUN HH, LI L T. Evaluation of blends bauxite-calcination-method red mud with other industrial wastes as a cementitious material: Properties and hydration characteristics[J]. Journal of Hazardous Materials, 2011, 185(1): 329-335.

[13] ZHANG N, LIU X M, SUN H H, LI L T. Pozzolanic behavior of compound-activated red mud-coal gangue mixture[J]. Cement and Concrete Research, 2011, 41(3): 270-278.

[14] SANJAY K, KUMAR R, BANDOPADHYAY A. Mechanical activation of granulated blast furnace slag and its effect on the properties and structure of Portland slag cement[J]. Cement and Concrete Composites, 2008, 30(8): 679-685.

[15] CHEN Z, LU S, TANG M, DING J, BUEKENS A, YANG J, QIU Q, YAN J. Mechanical activation of fly ash from MSWI for utilization in cementitious materials[J]. Waste Management, 2019, 88(1): 182-190.

[16] BERNAL S A, GUTIERREZ R M, RODRIGUEZodríguez E D. Alkali-activated materials: Cementing a sustainable future[J]. Ingeniería y Competitividad, 2013, 15(2): 211-223.

[17] SINGH J, SINGH S P. Development of alkali-activated cementitious material using copper slag[J]. Construction and Building Materials, 2019, 211(30): 73-79.

Preparation of new cementitious material by reduction and activation of copper slag and its application in mine filling

ZHU Mao-lan1, XIAO Ni2, TANG Liang-chun1, ZHONG Shui-ping2, Lü Xu-long2, CHI Xiao-peng2

(1.School of materials science and engineering, Xiamen Institute of Technology, Xiamen 361024, China;

2. College of Zijin Mining, Fuzhou University, Fuzhou 350108, China)

Abstract: Copper slag was used as the research object, coal was used as reducing agent, lime was used as activator, and iron was recovered by high temperature smelting reduction, and slag phase reconstruction activation were carried out. The effects of different reduction temperature, reducing agent coal and activator lime on the cementitious strength of reducing slag were studied. The results show that, within the temperature range of copper slag produced by copper pyrometallurgy, it can meet the requirements of iron recovery. Lime and reducing agent play key roles in the phase reconstruction of reducing slag. In addition, under the conditions of 1400 ℃, lime 39 g and coal 13 g, the recovery rate of iron reaches 89.6%, and the compressive strength of the cementitious material produced by the reduction slag used for preparation reaches 9.7 MPa in 28 d. Moreover, the compressive strength of the new cementitious material prepared by mixing reducing slag and tailings after 28 d meets the requirements of mine filling.

Key words: copper slag; reconstruction activation; cementitious material; compressive strength

Foundation item: Project(51704153) supported by the National Natural Science Foundation of China

Received date: 2020-06-30; Accepted date: 2020-09-30

Corresponding author: ZHONG Shui-ping; Tel: +86-15280385768; E-mail: zspcsu@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51704153)

收稿日期:2020-06-30;修订日期:2020-09-30

通信作者:衷水平,教授级高级工程师,博士;电话:15280385768;E-mail:zspcsu@163.com