文章编号:1004-0609(2015)-05-1163-05

热轧AlB2-Al原位复合材料的显微组织和力学性能

元琳琳,韩静涛,刘 靖

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:850 ℃下在真空熔炼炉中通过液态铝与无定形硼粉之间的化学反应,原位合成AlB2-Al复合材料。研究该铝基复合材料经过热轧和固溶处理后显微组织与力学性能的变化。分别利用扫描电镜(SEM)、光学电镜和X射线衍射仪(XRD)对合成复合材料的显微组织和物相组成进行分析,并采用室温下的拉伸实验确定AlB2-Al复合材料的力学性能。结果表明:由于在铝基体中生成了高纵横比的AlB2薄片,复合材料的硬度与抗拉强度明显高于纯铝基体的,但其塑性降低。经固溶处理后,AlB2-Al复合材料的伸长率可达26%以上。

关键词:AlB2-Al;原位复合材料;热轧;固溶处理;力学性能

中图分类号:TG 146 文献标志码:A

Microstructure and mechanical properties of hot-rolled AlB2-Al in-situ composite

YUAN Lin-lin, HAN Jing-tao, LIU Jing

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: In-situ AlB2-Al composite was synthesized by chemical reaction between liquid aluminum and amorphous boron powder at 850 ℃ in vacuum melting furnace. The changes of microstructure and mechanical properties of this aluminum matrix composite after hot-rolling and solution treatment were studied. Scanning electron microscopy (SEM), optical microscopy and X-ray diffraction (XRD) were used to investigate the morphology and phase composition of the composite. The mechanical properties of AlB2-Al composite were determined by the tensile test at room temperature. The results show that the AlB2 flakes with high aspect ratio form in Al matrix, therefore, the micro-hardness and tensile strength of the composite are significantly higher than those of pure aluminum, but the ductility of matrix is reduced. And the elongations of composites can reach more than 26% after solution treatment.

Key words: AlB2-Al; in-situ composite; hot-rolling; solution treatment; mechanical property

铝基复合材料因其具有高比模量,优异的耐磨性,低热膨胀系数,高温下稳定的性能以及较有竞争力的制造成本而被广泛应用于工业生产中。作为非结构和结构应用材料,其发展由航空航天和汽车产业推动[1]。连续纤维增强铝基复合材料在长度方向具有高强度和系数。然而,这种复合材料由于需要保护纤维表面,致使生产增强相工序多,经济性欠佳[2]。陶瓷相或金属颗粒的铝基复合材料由于具有高强度和耐磨性且易于加工,在军事、航空航天及机械等领域得到广泛应用[3]。原位铝基复合材料是通过混合体中组分之间的化学反应生成一种或多种高硬度和高熔点增强相。原位生成增强相细小且均匀分布于铝合金基体上, 达到强化基体的作用。此外,由于原位比非原位形成的增强相-基体界面更清洁,因此增强相与基体结合好[4-5]。原位合成增强相的尺寸和数量易于控制,且增强相与基体的兼容性良好[6]。这种方法为制备热力学稳定且强度破坏相含量低的复合材料提供了可能。一些原位增强相,如AlB2、Al2O3、TiB2、TiC等已在铝基复合材料的研发中被大量使用[7]。

具有较低密度和较高耐磨性的AlB2-Al复合材料是航空航天应用的替代材料之一,AlB2与周围的铝基体能够达到热力学平衡,因此,组成相之间没有发生减弱界面的化学反应。另外,弥散体可作为固体铝的形核位,强化界面,提高颗粒与基体间的载荷转换[8]。DEPPISCH等[2, 9]采用高温热处理伴随熔体浸渗法制备高纯度AlB2增强Al-Cu复合材料,并研究了保温时间、温度和冷却速率对AlB2单晶层片在铝中结晶与长大的影响。OMER等[10]通过在1400 ℃下将氧化硼直接添加到液态铝中制备出Al-B中间合金,并用Taguchi设计方法检验保温温度等工艺参数对硼溶解度和AlB2薄片结构尺寸分布的影响。SAKIP等[11]和FERIT等[12]还对载荷、滑动速率、滑动距离以及增强相比例对原位合成AlB2-Al复合材料的干滑磨损性能的影响进行研究。DUMITRU等[13]通过AA6060铝合金与KBF4间的铝热反应原位合成AA6060/AlB2金属基复合材料。DERAKHSHESH等[14]通过离心铸造制备了不同特性的Al-5%B和Al-2%Mg-2%B复合材料并研究了它们的显微组织和硬度。类似地,MELGAREJO等[15]用离心铸造制备了含AlB2颗粒增强的铝基功能梯度复合材料。然而,关于铝基增强颗粒复合材料轧制成型的报道非常有限[16-17],尤其是热轧成型[18]。

本文作者通过真空熔炼原位合成制备AlB2-Al增强复合材料,并对复合材料进行了热轧成型。为了进一步改善复合材料的性能,对热轧的复合材料进行了不同时间的固溶处理。研究了不同状态下复合材料的显微组织和力学性能,并与基体合金进行比较。

1 实验

将无定形硼粉(B摩尔分数约为19.9%)压制成块,与高纯铝锭(纯度为99.999%)一起放入真空熔炼炉中,抽真空到0.1 MPa并通入氩气作为保护气氛,升温到850 ℃保温10 min,这样可以尽量避免硼粉漂浮在合金表面,同时在炉内涡流搅拌作用下尽可能均匀混合。随后将溶液浇注到钢模,冷却到室温取出。铸锭在电阻加热炉中升温至500 ℃,保温约0.5 h后进行热轧,轧制温度为450~500 ℃,板料的厚度由初始的50 mm轧制到3 mm厚,每道压下量约为30%。当板料温度低于轧制温度时,板料需重新加热。将热轧后的板料在450 ℃下分别固溶2和4 h,最后在冷水中淬火。

试样经标准的金相检验技术处理,用混合酸(V(HF):V(HCl):V(HNO3)=1:5:5)进行腐蚀。使用光学显微镜(LEO-1450)和扫描电镜(ZEISS ULTRA 55)观察铸态、热轧及固溶处理后复合材料的显微组织,并结合X射线衍射仪(XRD)进行分析。采用公共图片分析软件Image Pro Plus进行定量图片分析,测量铸造后硼化物的体积分数。在室温下进行拉伸实验,以确定复合材料的力学性能,并与高纯铝进行比较。

2 结果与讨论

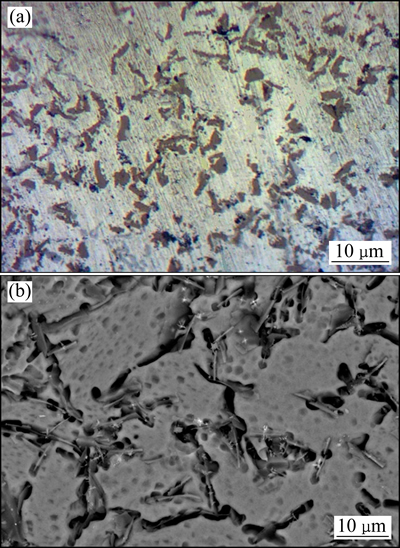

图1 铸态Al基复合材料侵蚀后的表面金相照片和横截面SEM像

Fig. 1 Surface optical micrograph (a) and section SEM image (b) of etched as-cast Al matrix composite

图2 铸态铝基复合材料的XRD谱

Fig. 2 XRD pattern of as-cast aluminum matrix composite

图1所示为AlB2-Al复合材料侵蚀后的铸态显微组织。铸锭表面的金相组织如图1(a)所示,可看到深色的长条状以及六边形颗粒均匀地分布在铝基体中,增强相与基体间界面清晰。图1(b)所示为铸锭横截面的SEM像,由图1(b)可知,在原位复合材料制备过程中,硼与铝合成高纵横比的片状硼化物。根据文献[19]可知,当增强相均匀分布在基体中时,含有高模量、高纵横比的层片或晶须增强相的复合材料要比含有相同模量的低纵横比颗粒增强相的复合材料强度高。同时,通过对图1(b)定量分析,铸态AlB2-Al原位复合材料的增强相体积分数约为10%。根据XRD分析结果(见图2)可以推断,在较高的冷却速率下形成了高纵横比的AlB2层片。结合AlB2的化学反应式和吉布斯自由能表达式(如式(1)和(2)所示)可知,在低于900 ℃时,AlB2是稳定相。

(1)

(1)

(2)

(2)

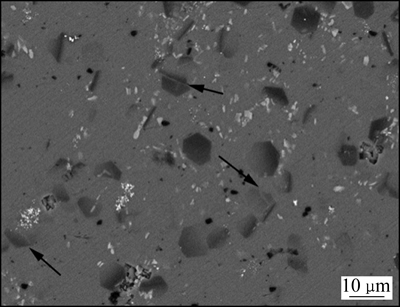

图3所示为AlB2-Al原位复合材料热轧后试样表面的显微组织。由于AlB2颗粒为脆硬相,刚度为448 GPa[2],在(001)晶面上的努氏显微硬度可达9.6 GPa[20]。因此经过热变形后,部分AlB2层片会发生破碎(如图3中箭头所指)。但增强相颗粒与基体之间仍保持良好的界面结合。

图3 热轧后铝基复合材料的SEM像

Fig. 3 SEM image of hot-rolled aluminum matrix composite

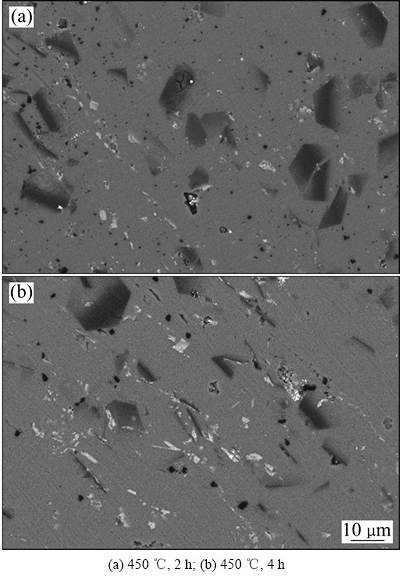

由于合适的热处理工艺可改善合金的显微组织和性能[21],因此将热轧后的AlB2-Al原位复合材料分别固溶处理2和4 h。图4所示为固溶处理后AlB2-Al复合材料的SEM像。由图4可知,具有六边形状的AlB2颗粒随着保温时间的增长,层片变宽,而横截面密度降低,这与DEPPISCH等[9]的研究结果类似。

图4 固溶处理后AlB2-Al复合材料的SEM像

Fig. 4 SEM image of AlB2-Al composites after different solution treatments

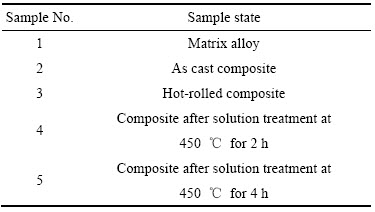

表1 不同状态AlB2-Al复合材料对应的样品

Table 1 Different states of AlB2-Al composite samples

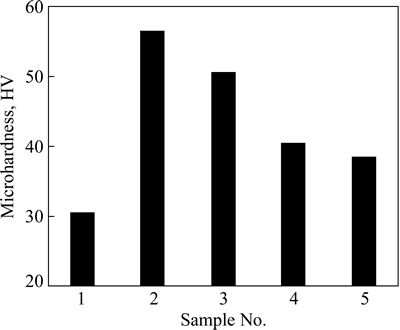

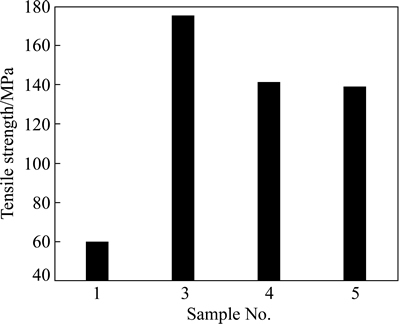

表1所示为不同状态AlB2-Al复合材料对应的样品编号。将不同状态下的AlB2-Al原位复合材料与纯铝基体的力学性能进行比较,结果如图5~7所示。与纯铝基体相比,原位合成高硬度的AlB2颗粒增强复合材料的硬度和抗拉强度显著提高。这是因为高纵横比的AlB2层片具有高强度(3500 MPa)[2]。在热轧变形初期,复合材料随形变量增大,位错急剧增加,应变能增大,产生加工硬化。增加的位错密度会导致强度变化。位错密度表达式如式(3)所示[22]:

(3)

(3)

式中:e为微观应变均方根;d为平均晶粒尺寸;b为柏氏矢量,b(Al)为0.286 nm[23]。

位错密度对强度的增强值可由式(4)表示[16]:

(4)

(4)

式中:α为常数,其值取为0.24;M为Taylor因子,其值取为2.75[23];G为剪切模量(26 GPa[22])。

但通过观察发现热轧后,铝基复合材料的显微硬度比铸态时的略有下降。这可能是因为当应变能增大到一定程度时,诱发动态回复产生,使应力得到松弛。但这种回复是在动态中进行的,因此,呈硬化还是软化的趋势取决于形变过程中回复和硬化的综合结果。由于铝基体的层错能较高,在形变过程中,位错易于通过交滑移运动使异号位错相互抵消,并且位错在运动过程中产生动态回复,软化速率大于硬化速率,从而出现了加工软化现象。经过450 ℃固溶热处理后,基体晶粒会产生粗化,试样硬度和抗拉强度逐渐降低。因为B在Al中的溶解度非常有限(659.7 ℃时仅为0.022%)[24],所以该温度下AlB2在基体中的溶解也十分缓慢,溶解量小,对基体的固溶强化不明显。

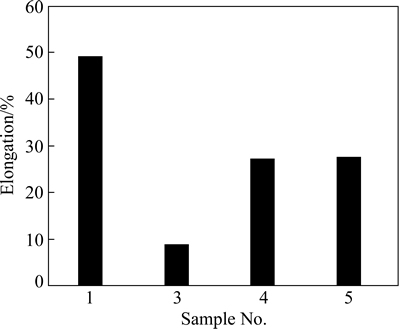

而各状态下试样的伸长率变化趋势则与抗拉强度的变化趋势相反,在热轧变形后伸长率最低,经固溶处理后试样伸长率可达26%以上,随着固溶时间增长,伸长率略有提高。

图5 不同状态下样品的硬度

Fig. 5 Microhardness of samples at various states

图6 不同状态下样品的伸长率

Fig. 6 Elongations of samples at various states

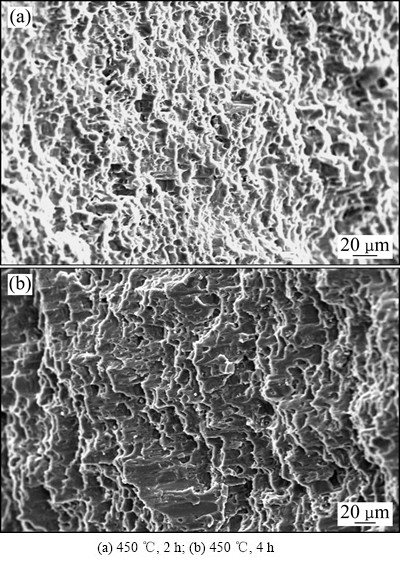

图8所示为不同固溶时间处理后试样的拉伸断口SEM像。由图8可以看出,AlB2-Al界面结合良好,没有层片分离。断口形貌为韧性断裂和脆性断裂的混合断裂。这是因为脆性断裂是片状AlB2的主要断裂模式,且裂纹通过层片沿底面传播[2]。固溶处理2 h后的样品断口韧窝分布较均匀,比固溶4 h的更细小和密集,因此抗拉强度略高。

图7 不同状态下试样的抗拉强度

Fig. 7 Tensile strength of samples at various states

图8 固溶处理后拉伸断口的SEM像

Fig. 8 Tensile fracture SEM images of composites after different solution treatments

3 结论

1) 在850 ℃真空熔炼无定形硼粉与高纯铝锭,原位合成出含10%(体积分数)高纵横比AlB2增强颗粒的铝基复合材料。

2) 原位合成的AlB2-Al复合材料硬度和抗拉强度明显高于基体合金的,但其塑性较低。经热轧变形和固溶处理后,复合材料的抗拉强度可达135 MPa,伸长率可达26%以上。

3) 铝基复合材料的拉伸断口表明AlB2-Al界面结合良好,断裂模式为由穿过AlB2层片的脆性断裂与基体韧性断裂组成的混合型断裂。

REFERENCES

[1] GHOMASHCHI M R, VIKHROV A. Squeeze casting: An overview[J]. Journal of Materials Processing Technology, 2000, 101(1/3): 1-9.

[2] DEPPISCH C, LIU G, SHANG J K, ECONOMY J. Processing and mechanical properties of A1B2 flake reinforced Al-alloy composites[J]. Materials Science and Engineering A, 1997, 225(1/2): 153-161.

[3] 马国俊, 丁雨田, 金培鹏, 刘国龙. 挤压比对粉末热挤压制备铝基复合材料组织和力学性能的影响[J]. 中国有色金属学报, 2013, 23(7): 1826-1831.

MA Guo-jun, Ding Yu-tian, JIN Pei-peng, LIU Guo-long. Influence of extrusion ratio on microstructure and mechanical properties of Al matrix composites by hot extrusion of powders[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1826-1831.

[4] CHEN Y Y, CHUNG D D L. In situ Al-TiB composite obtained by stir casting[J]. Journal of Materials Science, 1996, 31(2): 311-315.

[5] SAHOO P, KOCZAK K J. Elevated temperature response of in-situ TiC reinforced aluminium copper alloys[J]. Materials Science and Engineering A, 1990, 144(1): 25-30.

[6] KOCZAK M J, PREMKUMAR M K. Emerging Technologies for the in situ production of MMCs[J]. Journal of Materials, 1993, 45(1): 44-48.

[7] ZHU H G, AI Y L, MIN J, WU Q, WANG H Z. Dry sliding wear behavior of Al-based composites fabricated by exothermic dispersion reaction in an Al-ZrO2-C system[J]. Wear, 2010, 268(11/12): 1465-1471.

[8] SUAREZ O M. Mechanical properties of a novel aluminum matrix composite containing boron[J]. Journal of Mechanical Behavior of Materials, 2001, 12(4): 225-238.

[9] DEPPISCH C, LIU G, HALL A. The crystallization and growth of AlB2 single crystal flakes in aluminum[J]. Journal of Materials Research, 1998, 13(12): 3485-3498.

[10] OMER S, RAMAZAN K. A Taguchi optimisation for production of Al-B master alloys using boron oxide[J]. Journal of Alloys and Compounds, 2013, 580: 232-238.

[11] SAKIP K, FERIT F, RAMAZAN K, OMER S. Experimental optimization of dry sliding wear behavior of in situ AlB2/Al composite based on Taguchi’s method[J]. Materials and Design, 2012, 42: 124-130.

[12] FERIT F, SAKIP K, RAMAZAN K, OMER S. Investigation of unlubricated sliding wear behaviors of in-situ AlB2/Al metal matrix composite[J]. Advanced Composites Letters, 2011, 20(4): 109-116.

[13] DUMITRU D, PETRU M, MIHAI B, EMILIA U. Characterization of in-situ AA6060/AlB2 metal matrix composite[J]. Science Bulletin, 2011, 73(4): 161-170.

[14] DERAKHSHESH M R, SINA H, NAZEMI H. The comparison of the microstructure and hardness of Al-B and Al-Mg-B composites[J]. International Journal of Advanced Design and Manufacturing Technology, 2011, 4(4): 27-31.

[15] MELGAREJO Z H, SUAREZ O M, SRIDHARAN K. Wear resistance of a functionally-graded aluminum matrix composite[J]. Scripta Materialia, 2006, 55(1): 95-98.

[16] KRISHNA N N, SIVAPRASAD K, SUSILA P. Strengthening contributions in ultra-high strength cryorolled A1-4%Cu- 3%TiB2 in situ composite[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(3): 641-647.

[17] GOPI B, NAGA K, SIVAPRASAD K, VENKATESWARLU K. Effect of rolling temperature on microstructure and mechanical properties of cryorolled Al-Mg-Si alloy reinforced with 3wt% TiB2 in-situ composite[J]. Advanced Materials Research, 2012, 584: 556-560.

[18] Electric Power Research Institute. Handbook of neutron absorber materials for spent nuclear fuel transportation and storage applications 2006 edition[R]. American: EPRI, 2006.

[19] KAYIKCI R, SAVA  , KOKSAL S, DEMIR A. The effect of reinforcement ratio on the wear behavior of AlB2 flake reinforced metal matrix composites[J]. Acta Physica Polonica A, 2014, 125: 590-592.

, KOKSAL S, DEMIR A. The effect of reinforcement ratio on the wear behavior of AlB2 flake reinforced metal matrix composites[J]. Acta Physica Polonica A, 2014, 125: 590-592.

[20] DUSCHANEK H, ROGL P. The Al-B (aluminum-boron) system[J]. Journal of Phase Equilibria, 1994, 15(5): 543-552.

[21] 曹国剑, 王丽萍, 郭二军, 郭 瑞. 固溶处理对4004铝合金组织与力学性能的影响[J]. 金属热处理, 2013, 38(2): 95-98.

CAO Guo-jian, WANG Li-ping, GUO Er-jun, GUO Rui. Influence of solid solution treatment on microstructure and mechanical properties of 4004 aluminum alloy[J]. Heat Treatment of Metals, 2013, 38(2): 95-98.

[22] KORZNIKOV A V, SAFAROV I M, NAZAROV A A. High strength state in low carbon steel with submicron fibrous structure[J]. Materials Science and Engineering A, 1996, 206(1): 39-44.

[23] KRASILNIKOV N, LOJKOWSKI W, PAKIELA Z, VALIEV R. Tensile strength and ductility of ultra-fine-grained nickel processed by severe plastic deformation[J]. Materials Science and Engineering A, 2005, 397(1/2): 330-337.

[24] SIGWORTH G K. The grain refining of aluminum and phase relationships in the Al-Ti-B system[J]. Metallurgical and Materials Transactions A, 1984, 15(2): 277-282.

(编辑 王 超)

收稿日期:2014-09-05;修订日期:2014-11-07

通信作者:韩静涛,教授,博士;电话:010-62332572;E-mail:hanjt@ustb.edu.cn