文章编号:1004-0609(2013)S1-s0452-04

双重退火对BTi-6431S合金板材组织与性能的影响

张文婧1,宋晓云1,惠松骁1,王永玲1,王小翔2,王韦琪2

(1. 北京有色金属研究总院 有色金属材料制备与加工国家重点实验室,北京 100088;

2. 宝钛集团有限公司,宝鸡 721014)

摘 要:采用光学显微镜、室温和高温拉伸实验研究热处理对BTi-6431S合金板材微观组织和力学性能的影响。结果表明:升高第一阶段的退火温度,块状初生α相粗化,趋于等轴状,体积分数逐渐降低。β相和次生α相的体积分数增加。室温强度和塑性变化不大。高温强度随第一级退火温度的升高而逐渐上升,塑性下降。在相同第一阶段退火温度下,第二阶段退火温度的升高使得初生α相含量急剧增加,趋于板条状,β转变组织含量降低,室温和高温拉伸性能同时下降。通过合理的控制双重退火的温度,可使BTi-6431S合金具有良好的高温强度和室温塑性的匹配。

关键词:BTi-6431S合金板材;双重退火;退火温度;显微组织;力学性能

中图分类号:TG146.2 文献标志码:A

Effect of double annealing on microstructure and mechanical properties of BTi-6431S plate

ZHANG Wen-jing1, SONG Xiao-yun1, HUI Song-xiao1, YE Wen-jun1, WANG Yong-ling1, WANG Xiao-xiang2, WANG Wei-qi2

(1. State Key Laboratory of Nonferrous Metals and Processes, General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. Baoti Group Co., Ltd., Baoji 721014, China)

Abstract: The influence of variant heat treatment processing (double annealing) on the microstructure and mechanical properties of the BTi-6431S plate were investigated by optical microscope and tensile tests at room and elevated temperatures. The results show that, with the first stage annealing temperature increasing, the shape of primary α phase (αp) becomes coarse, changes into equiaxial, and its volume fraction decreases gradually, while the volume fractions of β-matrix (βt) and secondary α phase increase. The room temperature strength and ductility have not obvious variation, but the high temperature strength increases and the ductility decreases. However, after the first annealing at the same temperature, increasing secondary aging temperature promotes αp transforming into lath-shape, meanwhile reducing the volume fraction of βt, resulting in the mechanical properties decreasing. The best alloy microstructure with good high temperature strength and room temperature plasticity can be obtained by choosing double annealing temperature parameter reasonably.

Key words: BTi-6431S plate; double annealing; annealing temperature; microstructure; mechanical properties

BTi-6431S合金是我国最新研制出的一种新型短时高温钛合金,它在BT25[1]的基础上同时加入一定量的Nb和W高熔点β稳定元素,并将Mo元素的质量分数调整到3%左右,最终获得的名义成分为Ti-6.5Al-3Sn-3Zr-3Mo-3Nb-1W-0.2Si(质量分数,%)。该合金具有良好的室温强度、加工塑性和焊接性能,并且在高温下显示出更高的瞬时强度以及大载荷持久和蠕变的良好匹配,可用于650~700 ℃下短时应用的航空航天结构件[2-4]。在加工工艺确定的基础上,热处理可以有效地改善钛合金的力学性能,因此,有必要研究BTi-6431S合金的优化热处理工艺以获得高强、高塑的组织,满足苛刻的服役环境要求。张文婧等[4]研究了单重退火对合金组织与性能的影响,结果表明合金在相变点以下(10~30)℃退火后,获得的双态组织具有良好的室温与高温性能的匹配。本文作者在前期研究工作的基础上,对BTi-6431S合金采用双重退火处理,研究其对显微组织和力学性能的影响,并确定最佳的双重退火制度。

1 实验

实验用BTi-6431S合金薄板由宝钛集团有限公司提供,为了得到大尺寸的3 mm厚薄板,保证合金的加工工艺性能,适当地降低了合金中β稳定元素质量分数,化学成分见表1。

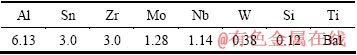

表1 BTi-6431S薄板化学成分

Table 1 Chemical composition of BTi-6431S plate (mass fraction, %)

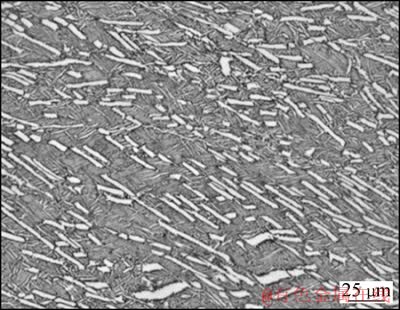

经两相区温度轧制后的合金原始组织如图1所示,其由块状和板条状的初生α相和片层状的β转变组织(βt)组成。采用淬火金相法测得该合金的相变点为990~1 000 ℃。对板材采用如下4种热处理制度进行实验:

(Ⅰ) (960 ℃,1 h),AC+(600 ℃,2 h),AC;

(Ⅱ) (960 ℃,1 h),AC+(750 ℃,2 h),AC;

(Ⅲ) (980 ℃,1 h),AC+(600 ℃,2 h),AC;

(Ⅳ) (980 ℃,1 h),AC+(750 ℃,2 h),AC。

将热处理后的板材线切割成标距为50 mm的标准拉伸试样,在AG-250 KNIS Ms型万能拉伸实验机上进行室温拉伸,拉伸速度为3 mm/min;并在Instron-5582型高温拉伸试验机上进行高温拉伸,拉伸速度为4 mm/min。

将经过不同热处理后的金相样品电解抛光,采用V(HF):V(HNO3):V(H2O)=1:3:7的混合液对试样表面进行腐蚀,并利用Axiovert 200 MAT型Zeiss光学显微镜观察分析合金的显微组织。

图1 原始组织

Fig. 1 Optical microstructure of original material

2 结果与讨论

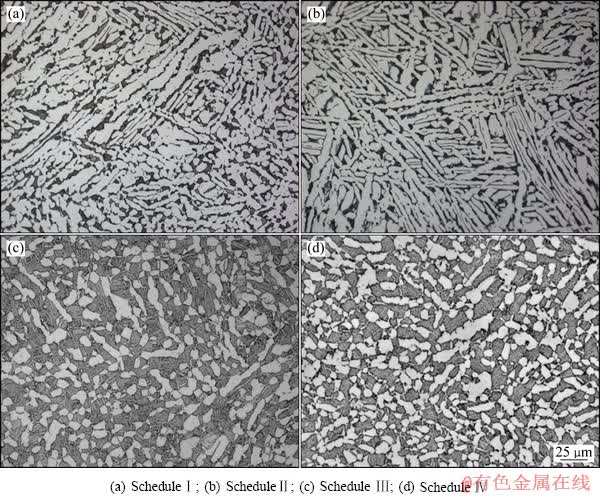

样品分别经4种工艺处理后得到的组织如图2所示。热处理后的组织与原始态相比发生明显变化,合金中各相发生了不同程度的球化。其中工艺Ⅲ热处理后的样品球化最显著,工艺Ⅱ的球化率最低。4种工艺处理后组织形貌差异主要表现在初生α相尺寸与含量上,对比工艺Ⅰ和Ⅲ发现:提高第一级退火温度促进板条状初生α相向β相的转变,形状逐渐趋于等轴状。对比工艺Ⅲ和Ⅳ发现,提高第二级退火温度,初生α相的体积分数增加,尺寸增大,β转变组织中的片状次生α相的厚度增加,数量增多。这是因为第二级退火温度升高促进了残余β相的分解,β相在α/β界面处生成了次生α相,次生α相通过界面迁移并长大[5],与初生α汇集在一起难以区分,最终导致等轴初生α相的体积分数大幅度上升,温度的升高同时也增大了β转变组织中的片状次生α相厚度。

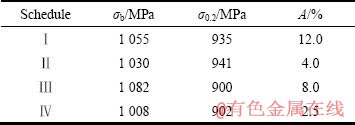

表2 BTi-6431S合金经不同工艺热处理后的室温拉伸性能

Table 2 Tensile properties of BTi-6431S plate after different heat-treatment at room temperature

图2 不同条件下热处理后BTi-6431S合金金相组织

Fig. 2 Microstructures of BTi-6431S alloy after different heat-treatments

表2所列为合金经不同工艺处理后的室温拉伸性能。由表2可见:经过4种工艺热处理后,样品的抗拉强度σb均在1 000 MPa以上,屈服强度σ0.2在900 MPa以上,室温塑性差异较大。

分别对比工艺Ⅰ和Ⅱ,Ⅲ和Ⅳ处理后的性能发现,提高第二级退火温度,合金的室温塑性显著降低。这主要由两方面原因引起:首先,第二级退火温度升高加剧了bcc结构的残余β相向hcp结构的次生α相转变,而β相变形能力高于α相,β相含量的减少降低了合金室温塑性[6];其次,合金经750 ℃退火后,与经600 ℃退火后的组织相比,初生α相的尺寸增大,部分等轴状的组织逐渐向板条状的组织发生转变。等轴状的组织具有良好的变形协调性,而板条状的组织在拉伸变形时要求相邻晶粒之间相互协调,增加了塑性变形的阻力[7],最终导致室温塑性的急剧下降。

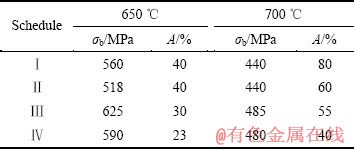

表3所列为BTi-6431S合金板材不同热处理制度下的高温拉伸性能。对比经工艺Ⅰ和Ⅲ以及Ⅱ和Ⅳ处理后的样品高温拉伸结果发现:提高第一级退火温度,有利于提高合金的高温强度。这主要是随第一次退火温度的升高,初生α相向β相转变的速度加快,空冷后残余的β相增加,在第二级退火过程中发生分解,生成大量的片状次生α相,高温强化效果明显。并且随着第一级退火温度的升高,初生α相体积分数减少,引起初生α相中的Al元素含量增加,提高了固溶强化作用,使合金的高温强度上升。

表3 BTi-6431S合金板材经不同工艺热处理后的高温拉伸性能

Table 3 Tensile properties of BTi-6431S plate after different heat-treatment

对比制度Ⅰ和Ⅱ以及Ⅲ和Ⅳ处理后的高温拉伸结果发现:随第二级退火温度的升高,等轴状的初生α相向板条状长大,β转变组织的体积分数减少,降低了合金的高温强度。

由图2可知:随退火温度的升高,合金中各相的尺寸均发生明显长大,粗大的组织不利于合金塑性变形,导致BTi-6431S合金的高温塑性随各阶段退火温度的升高而降低,并且第一级退火温度的升高对塑性降低的影响效果更明显。

通过对比发现,合金经工艺Ⅲ处理后,其在650 ℃下的σb可达到600 MPa以上,与常见的高温钛合金Ti-1100[8]和BT36[9]在600 ℃下的σb相当(Ti-1100的σb约为630 MPa,BT36的σb约为640 MPa)[10]。

3 结论

1) BTi-6431S合金双重退火时,升高第一阶段的退火温度,增加了合金中β转变组织和次生α相的体积分数,同时也提高了初生α相中Al元素的含量,两者的共同作用使得合金的高温强度有所上升。

2) BTi-6431S合金双重退火时,第二阶段退火温度的升高减少了β转变组织的体积分数,引起高温强度下降。

3) BTi-6431S合金通过合理提高第一级退火温度,降低第二级退火温度,可以获得良好的室温塑性和高温强度的匹配。该合金最佳的双重退火制度为(980 ℃,1 h),AC+(600 ℃,2 h),AC。

REFERENCE

[1] 袁少冲, 毛小南, 张鹏省, 于兰兰, 洪 权. 热强钛合金BT25组织与性能[J]. 钛工业进展, 2006, 23(3): 19-22.

YUAN Shao-chong, MAO Xiao-nan, ZHANG Peng-xing, YU Lan-lan, HONG Quan. Microstructure and property of heat strong titanium alloy BT25[J]. Titanium Industry Progress, 2006, 23(3): 19-22.

[2] 杨 伟, 王 俭, 王红武, 董振建, 王小翔, 王韦琪. 热加工工艺对BTi-6431S钛合金厚板与组织的影响[J]. 中国有色金属学报, 2010, 20(S1): s104-s106.

YANG Wei, WANG Jian, WANG Hong-wu, DONG Zhen-jian, WANG Xiao-xiang, WANG Wei-qi. Effect of hot working process on microstructure and properties of BTi-6431S titanium alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s104-s106.

[3] 王小翔, 王韦琪, 马红海. 700 ℃时高温高强BTi-6431S合金的组织与力学性能[J]. 中国有色金属学报, 2010, 20(S1): s792-s795.

WANG Xiao-xiang, WANG Wei-qi, MA Hong-hai. Microstructure and mechanical properties of high temperature and high strength BTi-6431S alloy at 700 ℃[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s792-s795.

[4] 张文婧, 宋晓云, 惠松骁, 叶文君, 王永玲, 王小翔, 王韦琪. 单重退火对BTi-6431S合金组织和力学性能的影响[J]. 中国有色金属学报, 2013, 23(6): 1530-1535.

ZHANG Wen-jing, SONG Xiao-yun, HUI Song-xiao, YE Wen-jun, WANG Yong-ling, WANG Xiao-xiang, WANG Wei-qi. Effect of single annealing on microstructure and mechanical properties of BTi-6431S titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1530-1535.

[5] 王志辉, 夏长清, 彭小敏, 陈志宏, 李学雄. 热处理工艺对Ti62421s 高温钛合金组织与力学性能的影响[J]. 中国有色金属学报, 2010, 20(10): 2298-2306.

WANG Zhi-hui, XIA Chang-qing, PENG Xiao-min, CHEN Zhi-hong, LI Xue-xiong. Effect of heat treatment on microstructure and mechanical properties of Ti62421s high temperature titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 2298-2306.

[6] 莱茵斯 C, 皮特尔斯 M. 钛与钛合金[M]. 北京: 化学工业出版社, 2005: 3-7.

LEYENS C, PETERS M. Titanium and titanium alloys[M]. Beijing: Chemical Industry Press, 2005: 3-7.

[7] 杨 义, 黄爱军, 徐 峰, 李阁平. BT18y钛合金等轴组织与全片层组织的室温拉伸塑性[J]. 中国有色金属学报, 2005, 15(5): 768-774.

YANG Yi, HUANG Ai-jun, XU Feng, LI Ge-ping. Room-temperature tensile plasticity of BT18y titanium alloy with equiaxed structure and fully lamellar structure[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 768-774.

[8] MADSEN A, GHONEM H. Effects of aging on the tensile and fatigue behavior of the near-α Ti-1100 at room temperature and 593 ℃[J]. Materials Science and Engineering A, 1994, 177: 63-73.

[9] 郝孟一, 蔡建明, 杜 娟. 热处理对BT36高温钛合金组织及性能的影响[J]. 航空材料学报, 2003, 23(2): 14-17.

HAO Meng-yi, CAI Jian-ming, DU Juan. The effect of heat treatment on microstructure and properties of BT36 high temperature alloy[J]. Journal of Aeronautical Material, 2003, 23(2): 14-17.

[10] 许国栋, 王凤娥. 高温钛合金的发展和应用[J]. 稀有金属, 2008, 32(6): 774-780.

XU Guo-dong, WANG Feng-e. Development and application on high-temperature Ti-based alloys[J]. Rare Metal, 2008, 32(6): 774-780.

(编辑 陈灿华)

基金项目:有研总院创新基金资助项目(23056)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:宋晓云,工程师,博士;电话:010-82241162;E-mail:songxiaoyun82@126.com