文章编号:1004-0609(2010)S1-s0577-04

双重退火温度对高应力水平TC11合金组织性能的影响

韩 栋1,毛小南1,张鹏省 1,周义刚2

(1. 西北有色金属研究院 钛合金研究所,西安710016;

2. 西北工业大学 材料科学与工程学院,西安 710072)

摘 要:利用光学显微镜(OM)、扫描电镜(SEM)对合金微观组织进行分析,并结合室温力学性能测试研究了热处理温度对TC11锻件微观组织和力学性能的影响。结果表明:升高第一阶段的退火温度,等轴α数量减少,条状α增加,从而大幅度降低合金塑性;第二阶段时效温度的升高使得等轴α相转变为长条状,增加了初生α相颗粒间距,这有利于降低次生α相缺口敏感性,从而提高材料的塑性和韧性。通过合理的双重热处理温度控制,可得到强韧性最佳匹配的合金组态。

关键词:TC11钛合金;高应力水平锻件;双重退火;强韧性匹配

中图分类号:TG 146.2 文献标志码:A

Effect of double annealing temperature on microstructure and mechanical properties of TC11 alloy

HAN Dong1, MAO Xiao-nan1, ZHANG Peng-sheng1, ZHOU Yi-gang2

(1. Titanium Alloy Research Center, Northwest Institute for Nonferrous Metal Research, Xi’ an 710016, China;

2. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Through the detection of mechanical properties and microstructure analysis by optical microscope and SEM, the influence of variant heat treatment processing (two-stage annealing) on the mechanical properties and the microstructure of the TC11 titanium alloy large forgings was investigated. The results show that increasing the annealing temperature of the first stage is harmful to the alloy plasticity, due to reduced content of equiaxed α-phase and increased content of stripy α-phase. However, increasing secondary ageing temperature promotes the equiaxed α-phase transforming into stripy α-phase, resulting in good plasticity and toughness. The best alloy microstructure of plasticity and durability matching can be obtained by choosing double annealing temperature parameters simply and resonably.

Key words: TC11 alloy; forgings bearing high stress; double annealing; strengthening and toughening matching

我国航空航天器的快速发展对飞行器动力系统提出了更高的推重比要求。TC11钛合金主要用于制造飞行器压气机盘、叶片、环形件和紧固件等[1-3],现已推广应用于火箭发动机的转动部件,但要满足新型飞行器的设计要求就需要材料在满足高强度和塑性的同时兼具良好的损伤容限性能和疲劳性能。工业生产主要采用常规锻造方法成型,由此得到(α+β)转变组织,具有好的塑性和热稳定性,但热强和断裂韧性差[4-5],常规锻造后常采用热处理方法改善和提高其使用性能,但不能完全发挥钛合金的性能潜力。所以,有必要研究TC11的优化热处理工艺及强韧性匹配技术,以获得具有高强、高塑、高韧的组织,满足苛刻服役环境和高应力水平选材的要求。本文作者研究TC11热加工工艺,以提高转动部件抗环境恶劣性和工作稳定性,为新一代航天器推进装置的研制提供技术保障。

1 实验

1.1 实验材料

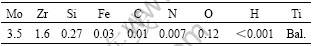

对TC11合金的成分进行优选后确定最佳的成分配料,经3次真空自耗电弧熔炼熔铸成d440 mm的铸锭,化学成分见表1。

表1 TC11的化学成分

Table 1 Chemical composition of TCll titanium alloy (mass fraction, %)

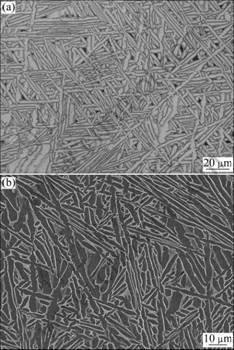

采用2 000 t锻造水压机在β相区进行变形量>80%开坯,在β区采取逐级降温的加热方式进行开坯锻造,充分破碎原始β晶粒和晶界α相。在两相区锻造过程中进行高温均匀化处理,最后在α+β相区反复镦拔,使晶粒充分破碎,终锻成d160 mm的棒材。此种优化锻造工艺只进行了少量的球化,获得了如图1所示由少量初生α相和细转变β组织构成的片状编织结构,这种组织预期可得到良好强韧性匹配。

图1 TC11棒材原始组织

Fig.1 Original microstructure of TC11 bars: (a) OM image; (b) SEM image

1.2 热处理工艺

终锻之后采用如下3种热处理制度进行实验: (Ⅰ) (950 ℃, 1 h, AC)+(540 ℃, 6 h, AC); (Ⅱ) (975 ℃, 1 h, AC)+(540 ℃, 6 h, AC); (Ⅲ) (950 ℃, 1 h, WC)+(510 ℃, 6 h, AC)。

将经过不同热处理的试样机械抛光后,选用V(HF):V(HNO3):V(H2O)为1:3:5的混合溶液对试样表面进行腐蚀。用Olympus PMG3型金相光学显微镜分析其显微组织,用HITACHIS-570型扫描电镜(SEM)分析表面形貌;力学性能在 CMT5105 型万能拉伸试验机上进行测试。

2 结果与讨论

2.1 不同热处理工艺对显微组织的影响

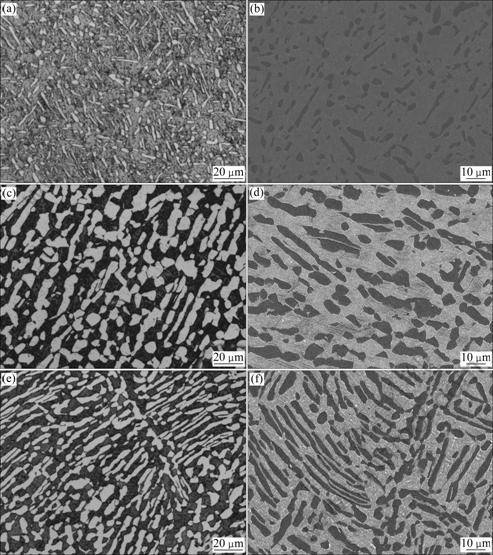

对经高温均匀化锻造得到的试样进行热处理。分别经3种热处理工艺得到的组织见图2,可见,与锻态组织(图1(b))相比变化很大,采用3种工艺处理后均能得到一定数量的等轴α和转变β组成的片状编织组织,且原始态的片层组织不同程度地发生了球化。其中工艺Ⅱ热处理球化最为明显,已经看不出锻态网篮组织的痕迹,工艺Ⅲ热处理球化率最低,组织仍表现为编织态,工艺Ⅰ热处理的球化率居中,既能看到明显的球化又保留了编织的痕迹。3种工艺处理后组织形貌差异主要表现在初生α相尺寸与含量上,其中工艺Ⅱ热处理得到的组织中初生等轴α相含量多于另两种工艺处理的,这是由于高温均匀化加固溶时效的热处理方式等同于经历了2 h的高温固溶,使得α相得到了比较充分的长大。

对经高温均匀化锻造得到的试样进行热处理。分别经3种热处理工艺得到的组织见图2,可见,与锻态组织(图1(b))相比变化很大,采用3种工艺处理后均能得到一定数量的等轴α和转变β组成的片状编织组织,且原始态的片层组织不同程度地发生了球化。其中工艺Ⅱ热处理球化最为明显,已经看不出锻态网篮组织的痕迹,工艺Ⅲ热处理球化率最低,组织仍表现为编织态,工艺Ⅰ热处理的球化率居中,既能看到明显的球化又保留了编织的痕迹。3种工艺处理后组织形貌差异主要表现在初生α相尺寸与含量上,其中工艺Ⅱ热处理得到的组织中初生等轴α相含量多于另两种工艺处理的,这是由于高温均匀化加固溶时效的热处理方式等同于经历了2 h的高温固溶,使得α相得到了比较充分的长大。

工艺Ⅱ热处理的第一阶段的退火温度高于工艺Ⅰ、Ⅲ的。由图2可见:退火温度的升高使得等轴α数量增加。由工艺Ⅰ和Ⅱ得到的显微组织可见:初生α相颗粒间距明显大于工艺Ⅲ所获得的,这是由于第二阶段时效温度的升高,使得等轴α相转变为长条状,从而增加了初生α相颗粒间距。

2.2 不同热处理工艺对力学性能的影响

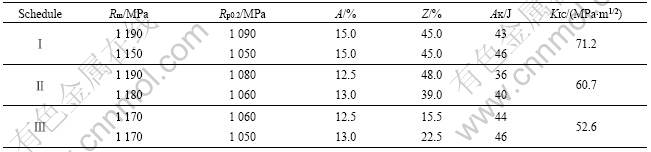

由表2可见,经过3种热处理工艺处理后的组织均获得了极佳的强度性能,尤其是工艺Ⅰ所得到的双态组织克服了等轴和网篮组织各自性能上的缺点,使材料兼具等轴组织高拉伸性能,网篮组织高持久强度和断裂韧性的优点,从而获得了良好的综合力学性能。

图2 不同热处理后TC11合金的显微组织

Fig.2 Microstructures of TC11 alloy after different heat-treatments: (a, b) Schedule Ⅰ; (c, d) Schedule Ⅱ; (e, f) Schedule Ⅲ

表2 TC11合金棒材经不同工艺热处理后的室温力学性能

Table 2 Mechanical properties at room temperature of TC11 bar after different heat-treatments

由采用工艺Ⅰ所获得的组织可见:β相基体中析出大量的网篮交织的片状α相,降低了等轴α间的平均自由程, 使滑移带间距减小,材料的塑性变形能力与位错滑移带间距成反比[6],所以滑移带间距减小,位错线分布均匀、细密,没有位错局部严重塞积,减小了应力集中,整个试样变形较均匀,推迟了孔洞的形核与发展[7],显示出较其他两种工艺处理更高的塑性。工艺Ⅱ在975 ℃高温下保温1 h,初生α聚集、合并、球化以提高塑性,α相的形态由等轴转变为针状或片状时,塑性降低,断裂韧性提高。工艺Ⅲ较之前两种工艺降低了第二阶段的退火温度,从而减小了片状α之间的间距,使得转变β基体中次生α相的缺口敏锐度增大,从而减低了塑性和韧性指标。

工艺Ⅱ处理后冲击韧性低原因是:等轴初生α相体积分数的降低使得裂纹扩展的路径曲折度减小,从而减小了断裂所需的能量。

采用工艺Ⅰ处理所获得的片状为主的组织中,由于片状α多而厚,而且不断改变方向,裂纹只能随着片状α位向的变化不断改变扩展方向,因而扩展路径曲折、分支多。因此,此工艺所得到的组织具有高的断裂韧性。裂纹总是沿着晶界扩展,在采用工艺Ⅱ处理得到的以等轴α为主的组织中,由于魏氏α集束领域小,裂纹易于穿过α魏集束或片状α,沿着主裂纹运动方向扩展,而且50%左右的等轴α晶粒(晶界)为裂纹以低能量的断裂方式提供了优先扩展的通道,所以扩展路径平直、分支少,造成断裂韧性相对较低。

3 结论

1) TC11钛合金经高-低-高加热锻造得到的组织为由少量初生α相和细转变β组织构成的片状编织结构,这种组织为锻后热处理提供了良好的基础,通过合理的双重热处理温度控制α相在晶界上优先形核,α相的形成速率、数量和形态分布主要取决于时效温度。

2) 升高第一阶段的退火温度,等轴α数量减少,条状α增加,从而大幅度降低合金塑性;第二阶段时效温度的升高使得等轴α相转变为长条状,这有利于降低次生α相缺口的敏感性,从而提高材料的塑性和韧性。通过合理的双重退火热处理温度控制,可得到片状α的宽长比最佳匹配的合金组态,使得退火态组织在满足高强塑性的同时将断裂韧性KIC提高至71.2 MPa·m1/2。

REFERENCES

[1] 郭鸿镇, 姚泽坤, 苏 华, 苏祖武, 施祥生, 赵步章, 孙雪征, 吴维干. TC11钛合金叶片组织和性能控制[J]. 航空学报, 1997, 18(2): 189-195.

GUO Hong-zhen, YAO Ze-kun, SU Hua, SU Zu-wu, SHI Xiang-sheng, SUN Xue-zheng, WU Wei-gan. Structure and property control of the TC11 alloy blade die forgings [J]. Acta Aeronautica Et Astronautica Sinica, 1997, 18(2): 189-195.

[2] 白晓环, 冯永琦, 王韦琪, 王永强, 徐祝萍. 飞机结构用TC11 钛合金异型锻件的组织与性能[J]. 钛工业进展, 2005, 22(5): 37-40.

BAI Xiao-huan, FENG Yong-qi, WANG Wei-qi, WANG Yong-qiang, XU Zhu-ping. Structure and performance of formed forgings of titanium alloy TC11 for aircraft structure [J]. Titanium Industy Progress, 2005, 22(5): 37-40.

[3] SHANG Shun-li, SHEN Jian-yun, WANG Xi-zhe. Transformation textures in an α+β titanium alloy thin sheet [J]. Materials Science and Engineering A, 2002, 326: 249-254.

[4] ZHOU Y G, ZENG W D, YU H Q. A new high-temperature deformation strengthening and toughening process for titanium alloy [J]. Materials Science and Engineering A, 1996, 221: 58- 62.

[5] SEMIATIN S L, SEETHARAMAN V, WEISS I. Flow behavior and globularization kinetics during hot working of Ti-6A1-4V with a colany alpha microstructure [J]. Materials Science and Engineering A, 1999, 263: 257-271.

[6] 周义刚, 曾卫东, 李晓芹, 俞汉清, 曹春晓. 钛合金高温形变强韧化机理[J]. 金属学报, 1999, 35(1): 45-48.

ZHOU Yi-gang, ZENG Wei-dong, LI Xiao-qin, YU Han-qing, CAO Chun-xiao. An investigation of high-temperature deformation strengthening and toughening mechanism of titanium alloy [J]. Acta Metallurgica Sinica, 1999, 35(1): 45-48.

[7] 崔喜平, 耿 林, 宋益标, 冯义成, 王庆伟. 高温变形与热处理对TC11钛合金组织和性能的影响[J]. 材料热处理学报, 2009, 30(2): 89-92.

CUI Xi-ping, GENG Lin, SONG Yi-biao, FENG Yi-cheng, WANG Qing-wei. Effect of hot plastic deformation and heat treatment on microstructure and properties of TC11 titanium alloy [J]. Transactions of Materials and Heat Treatment, 2009, 30(2): 89-92.

(编辑 杨 兵)

基金项目:国家科技支撑计划资助项目(2007BAE07B01);国家重点基础研究发展计划资助项目(2007CB613807)

通信作者:韩 栋; 电话:029-86231078; E-mail: hand227@163.com