文章编号:1004-0609(2015)10-2666-06

镁合金壳体内部缺陷的精确超声定量方法

杨 岳1,戴万林1,李雄兵1,倪培君2,乔日东2

(1.中南大学 CAD/CAM研究所,长沙 410075;

2.中国兵器科学研究院 宁波分院,宁波 315103)

摘 要:利用基尔霍夫近似法建立镁合金壳体内部缺陷的超声测量模型,并利用该测量模型对缺陷回波幅值进行数值计算,获得缺陷波/底波幅值比曲线。在此基础上,建立基于幅值比曲线的缺陷检测理论模型,并对缺陷进行定量检测分析。采用搭建的超声检测实验系统,对含有人工缺陷的镁合金壳体进行缺陷检测试验。结果表明:相比于传统距离增益尺寸曲线定量方法,本实验方法在缺陷定量检测精度和有效检测深度范围上均有较大提高,从而为提升镁合金壳体内部缺陷的定量检测水平提供新的方法和技术途径。

关键词:镁合金壳体;缺陷定量;超声测量模型;距离增益尺寸

中图分类号:TG115.28 文献标志码:A

Ultrasonic method for accurately sizing flaws in magnesium alloy shell

YANG Yue1, DAI Wan-lin1, LI Xiong-bing1, NI Pei-jun2, QIAO Ri-dong2

(1. Computer Aided Design and Computer Aided Manufacture Institute, Central South University,

Changsha 410075, China;

2. Ningbo Branch, Ordnance Science Institute of China, Ningbo 315103, China)

Abstract: The model of ultrasonic measurement for defects in magnesium alloy shell was established by using Kirchhoff approximation, and then the numerical calculation on the echo amplitude of defects was conducted by the measurement model, and the defect wave/bottom wave amplitude ratio curve was drawn. On this basis, the defects quantitative evaluation model was presented according to the amplitude ratio curve for defects quantitative evaluation. The magnesium alloy shell containing artificial defects was analyzed by using the ultrasonic quantitative evaluation model. The result shows that, compared with the traditional distance gain size (DGS) curve of quantitative methods, the effective range and accuracy of defects quantitative evaluation are improved by this method. This method provides a new and effective tool to improve the performance of quantitative evaluation on the defects in magnesium alloy shells.

Key words: magnesium alloy shell; flaw-sizing; ultrasonic measurement model; distance gain size

镁合金是迄今在工程应用中最轻的结构材料,具有高的比强度和比刚度,且尺寸稳定性高、阻尼减震性能好、机械加工方便,并具有优良的耐蚀性能[1-3]。因此,镁合金被广泛应用在航空航天、国防军工、交通运输等领域,加速镁合金技术的开发和应用已经成为必然趋势[4-6]。但由于原材料、挤压和锻造工艺等原因,在制造过程中难免产生夹杂、孔洞等缺陷,进而直接影响材料的强度及性能[7]。因此,有效的无损检测方法对保证其安全可靠性至关重要,而超声波检测技术是应用最为普通的一种技术手段。但当前相关的超声方法研究主要集中在入射面规则壳体的缺陷检测,对于具有变曲率、变壁厚特征的组合几何体,如本研究的镁合金壳体,超声波在曲面上的聚焦、散射特性相比平面壳体的显著增强[8-9],且壳体的壁厚差异也将产生不同的声压衰减[10],缺陷的检出与定量难度较高。并且缺陷类型、材料的声学性能及探头参数等多方面因素都可能影响其缺陷的定量精度[11-12]。

对于镁合金壳体内部缺陷的超声无损检测,当前普遍采用当量计算法,利用距离增益尺寸(DGS)曲线判断缺陷的大小[13]。该方法适用于探头三倍近场外的缺陷有效评价,但当缺陷位于三倍近场内时,评价结果则存在很大误差。而采用挤压、轧制、锻造和冲压等塑性成形方法加工的镁合金壳体的近表面容易出现夹杂、孔洞等缺陷,因此,在镁合金壳体的超声检测过程中,有必要研究一种普遍适用的缺陷精确定量检测方法。

本文作者针对镁合金壳体内部缺陷检测的特点,通过引入超声测量模型[14-15],建立适用于镁合金壳体的缺陷响应理论模型,结合探头接收回波的有效面积、缺陷大小等影响因素,对探头接收到的缺陷回波和底面回波幅值进行预测,利用缺陷波与底面波的幅值比曲线进行缺陷的定量检测,以有效解决镁合金壳体检测过程中缺陷定量困难的问题。

1 缺陷评价方法

1.1 超声测量模型

采用接触超声法检测镁合金壳体内部缺陷时,探头布置在镁合金壳体表面,通过液态耦合剂传递声能。综合考虑超声检测系统的输入电压、脉冲电阻抗和探头电阻抗等因素影响,建立脉冲激励系统函数 ,并通过探头的多元高斯声场分布得到声弹性传播函数

,并通过探头的多元高斯声场分布得到声弹性传播函数 ,最终镁合金壳体底面的反射回波频域响应

,最终镁合金壳体底面的反射回波频域响应 为[14]

为[14]

(1)

(1)

式中: 可采用多元高斯声束模型进行计算[16],其表达式为

可采用多元高斯声束模型进行计算[16],其表达式为

(2)

(2)

式中: 为底面回波的质点振速;

为底面回波的质点振速; 为探头初始质点振速;ys为探头表面质点位置;

为探头初始质点振速;ys为探头表面质点位置; 为对探头表面的积分区域。

为对探头表面的积分区域。

当超声探头频率、晶片直径及壳体尺寸、材质的超声波声速等参数确定后即可实现该函数的计算。在镁合金壳体超声检测系统中,根据系统已知参数直接模拟得到系统函数[14],进行底面回波的数值计算。

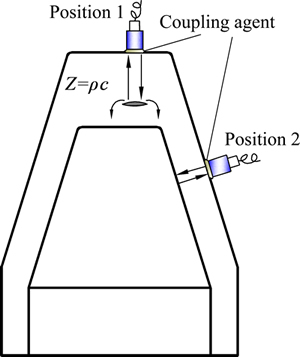

当检测过程中遇到缺陷时,如探头位于图1中的位置时,若依然通过计算声弹性传播函数实现缺陷回波响应的预测,则该过程相当复杂,而应用缺陷散射理论,通过求取缺陷的远场散射幅值方法可以较好地解决此问题[17-18]。采用缺陷散射理论,使用单探头采用脉冲回波法对镁合金壳体缺陷反射回波进行预测时,探头接收缺陷回波特性的方程为

(3)

(3)

式中: 为探头辐射阻抗;

为探头辐射阻抗; 和c分别为镁合金的密度和镁合金中的声速;

和c分别为镁合金的密度和镁合金中的声速; 为壳体介质中波数;

为壳体介质中波数; 为在缺陷表面处用多元高斯声束计算的质点振速值;

为在缺陷表面处用多元高斯声束计算的质点振速值; 为缺陷的远场散射回波幅值;

为缺陷的远场散射回波幅值; 为镁合金壳体缺陷反射回波的频域响应;i为虚数单位;x为探头表面质点的位置;S(x)为对探头表面的积分区域。

为镁合金壳体缺陷反射回波的频域响应;i为虚数单位;x为探头表面质点的位置;S(x)为对探头表面的积分区域。

将面状缺陷体作平底孔状近似,可以采用基尔霍夫近似方法计算由入射纵波引起的远场散射幅值[18],得到

(4)

(4)

式中:d为缺陷直径。可见,确定缺陷的参数后采用式(3)即可分析探头接收壳体缺陷反射信号在频域上的响应特性。

图1 镁合金壳体超声检测示意图

Fig. 1 Schematic diagram of ultrasonic detection to variable curvature and wall thickness magnesium alloy shells

1.2 缺陷定量评价模型

在频域上模拟得到缺陷及底面反射回波响应后,通过逆傅里叶变换获得缺陷及底面反射时域信号 和

和 ,进而得到信号时域幅值,其将用于镁合金壳体缺陷的定量检测方法中[19-20]。当镁合金壳体外侧面曲率为K且厚度为H时,设超声检测系统接收的底面回波幅值为

,进而得到信号时域幅值,其将用于镁合金壳体缺陷的定量检测方法中[19-20]。当镁合金壳体外侧面曲率为K且厚度为H时,设超声检测系统接收的底面回波幅值为 ;而当同一位置存在着深度为h、直径为d的缺陷时,记壳体缺陷的反射回波幅值为

;而当同一位置存在着深度为h、直径为d的缺陷时,记壳体缺陷的反射回波幅值为 ,则缺陷波/底波幅值比曲线计算公式为

,则缺陷波/底波幅值比曲线计算公式为

,0<h<H (5)

,0<h<H (5)

式中:K和H只与检测部位有关。

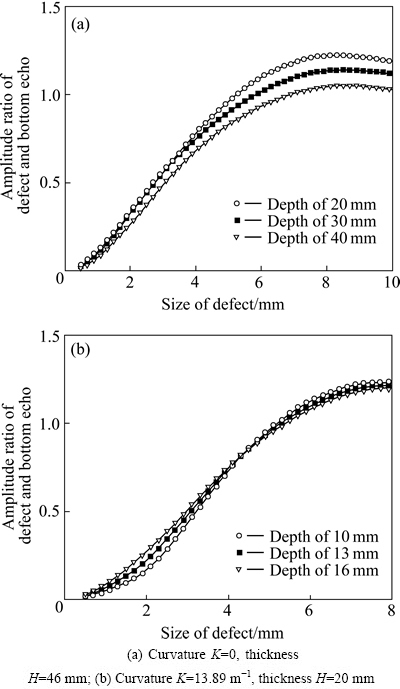

为绘制该幅值比曲线,首先当K和H一定时,计算得到底面反射回波幅值vb,然后在缺陷深度h确定的情况下,改变缺陷尺寸d获得不同尺寸下缺陷的反射回波幅值 ,便可计算和绘制该深度下缺陷波/底波幅值比曲线,其中横轴为缺陷尺寸,纵轴为幅值比;改变缺陷的深度h重复以上过程,可得到不同深度下缺陷波/底波幅值比曲线图,则用若干条曲线代表不同缺陷深度。

,便可计算和绘制该深度下缺陷波/底波幅值比曲线,其中横轴为缺陷尺寸,纵轴为幅值比;改变缺陷的深度h重复以上过程,可得到不同深度下缺陷波/底波幅值比曲线图,则用若干条曲线代表不同缺陷深度。

根据上述幅值比曲线进行镁合金壳体缺陷的定量反演:首先检测得到壳体底面反射回波幅值 ,然后在检测到缺陷时在缺陷位置邻域进行逐步搜索,获得最大反射回波幅值

,然后在检测到缺陷时在缺陷位置邻域进行逐步搜索,获得最大反射回波幅值 ,并根据缺陷波出现的时间计算得到缺陷深度

,并根据缺陷波出现的时间计算得到缺陷深度 ,于是根据缺陷波与底面缺陷波幅值比确定检测得到的缺陷尺寸

,于是根据缺陷波与底面缺陷波幅值比确定检测得到的缺陷尺寸 为

为

(6)

(6)

此时绘制一条与缺陷波和底面或当量缺陷波的比值相同的水平线,找到该水平线与该深度下的幅值比曲线的交点,交点所对应的横坐标值即为检测得到的缺陷尺寸。

2 结果与分析

2.1 实验方案及结果

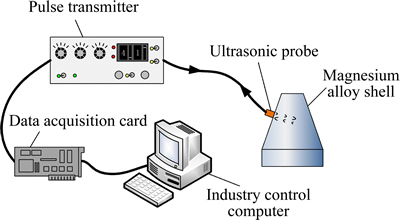

图2所示为镁合体壳体超声检测系统示意图。图2中,构建的变壁厚变曲率镁合金壳体超声检测实验系统主要由脉冲发射/接收器、线缆、超声探头、数据采集卡及被检测镁合金壳体试件等组成,在该系统中选择Olympus生产的接触式探头(V106-RM型)以及脉冲发射接收器(5072PR型),美国Signatec公司生产的PX12500A型数据采集卡,耦合剂为煤油。由脉冲驱动超声探头辐射声束,声束遇到缺陷或底面将产生反射或散射,并被探头接收,通过数据采集卡采集探头接收声压,最终在工控机显示并分析超声信号。

图2 镁合金壳体超声检测系统示意图

Fig. 2 Schematic diagram of magnesium alloy shell ultrasonic detection system

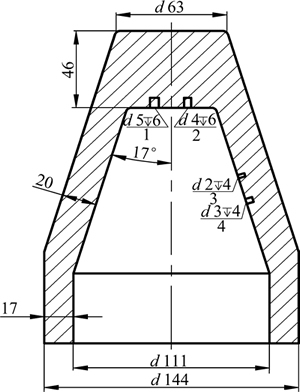

选取图3所示镁合金壳体作为具体实验对象。超声探头的直径12.7 mm,三倍近场长度为46.0 mm;镁合金壳体顶部厚度为46.2 mm,镁合金密度为1.8 g/cm3,经实际测量镁合金中声速为4988.9 m/s。

图3 镁合金壳体缺陷分布示意图

Fig. 3 Defects distribution diagram of magnesium alloy shell (Unit: mm)

图3中镁合金壳体上分布着4个平底孔缺陷:缺陷1和2位于壳体内部顶端,直径分别为5和4 mm,深度均为6 mm;缺陷3和4位于壳体的侧壁,直径分别为2、3 mm,深度均为4 mm。

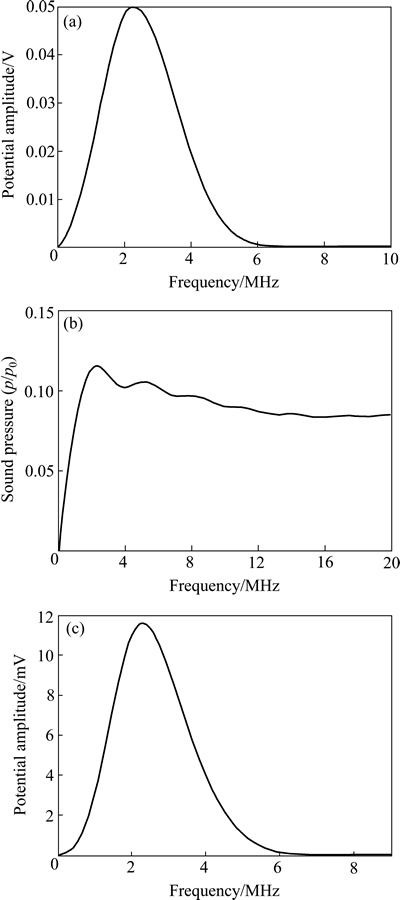

利用超声测量模型建立的系统函数 ,采用多元高斯声束模型计算声弹性传波函数

,采用多元高斯声束模型计算声弹性传波函数 ,并绘制底面反射回波频域响应曲线

,并绘制底面反射回波频域响应曲线 ,如图4所示。

,如图4所示。

分别绘制图3中所示镁合金壳体顶端和侧壁位置的缺陷波/底面波的幅值比曲线,其结果如图5所示。

图4 s(ω)、ta(ω)和Vb(ω)曲线

Fig. 4 s(ω)(a), ta(ω)(b) and Vb(ω)(c) curves

2.2 实验结果分析与验证

图5 幅值比曲线图

Fig. 5 Amplitude ratio curves

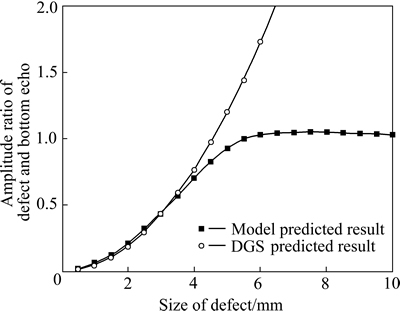

图6 不同尺寸缺陷波/底波幅值比曲线

Fig. 6 Amplitude ratio curves of different size defect wave/bottom waves

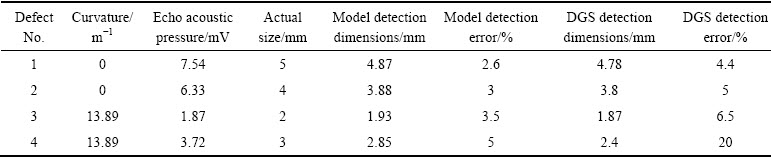

表1 图3中镁合金壳体缺陷的检测结果对比

Table 1 Comparison of detection results on magnesium alloy shell defects in Fig. 3

为验证以上所讨论的镁合金壳体缺陷定量检测方法的有效性,将本文方法与文献[21]和[22]提出的传统DGS曲线计算公式的计算结果进行比较,对比分析两方法曲线随缺陷尺寸的变化规律。图6所示为两种方法在40 mm深度处不同尺寸的缺陷波/底波幅值比曲线。从图6中可以看出,在缺陷较小的情况下,两个结果相对吻合;但当缺陷尺寸超过5 mm以后,DGS曲线值持续迅速增大,而本文方法的曲线变化缓慢。实际上,当缺陷尺寸超过该深度探头声束的直径15 mm时,声波已全部被反射回,导致探头接收信号趋于稳定,此段曲线值将不再增加,故DGS曲线的值显然已与实际不相符。对比结果显示:本方法的预测范围和精度均远优于传统DGS曲线方法的。

通过对比分析可知,采用超声测量模型检测镁合金壳体缺陷尺寸时,在缺陷尺寸的预测精度和有效预测深度上相比于DGS理论的均有很大的提高,将其应用于镁合金壳体缺陷的定量检测会使镁合金壳体缺陷尺寸评价结果更加可信。

接下来通过制作人工缺陷比较两者的实际性能。设计如图3所示的镁合金壳体检测试块,不同尺寸不同深度的缺陷在不同部位均有分布。采用镁合金壳体超声检测试验系统对试块进行检测,曲率为0的内顶面位置底面回波声压为98.65 mV;曲率为13.89 m-1的内侧面位置底面回波声压为74.83 mV。统计缺陷曲率和回波声压,利用建立的缺陷定量模型计算缺陷尺寸和检测误差,并与DGS曲线检测的结果进行对比,其结果如表1所列,并将其用于对镁合金壳体缺陷的定量检测。

由表1可见,在三倍近场内外的缺陷,本研究方法的缺陷预测结果均与实际缺陷大小相吻合,检测误差控制在5%以内;采用DGS曲线预测探头三倍近场外的小缺陷时结果相对较好,但检测误差随着缺陷尺寸的增加而增大,而对于探头三倍近场内的缺陷尺寸判断误差则普遍偏大。对比结果表明,采用本研究的超声测量模型对镁合金壳体缺陷进行定量分析更精确。

3 结论

1) 提出一种基于超声测量模型的镁合金壳体缺陷定量检测方法,该方法利用超声测量模型预测缺陷波及底面波幅值,绘制镁合金壳体缺陷波/底波幅值比曲线,实现对镁合金壳体内部缺陷定量分析。理论分析研究和壳体缺陷的实验检测结果均验证了该方法对镁合金壳体缺陷定量检测的有效性。

2) 相比较于DGS曲线的缺陷检测方法,本研究方法对缺陷检测的范围和精度均有较大的提高,尤其是采用超声测量模型方法对探头三倍近场镁合金壳体缺陷的定量评价时,将无需通过实验进行该区域内幅值比曲线的绘制,在保证较高的缺陷检测精度的同时,也较大地提高了检测效率。

3) 本研究假设缺陷为镁合金变形工艺中最常见的缺陷类型,即面状缺陷且与探头声束垂直。但在超声测量模型中未考虑晶粒尺寸对超声信号的影响,下一步工作将针对该方面展开研究。

REFERENCES

[1] 任国成, 赵国群, 徐淑波, 王桂青. AZ31镁合金等通道转角挤压变形均匀性有限元分析[J]. 中国有色金属学报, 2011, 21(4): 848-855.

REN Guo-cheng, ZHAO Guo-qun, XU Shu-bo, WANG Gui-qing. Finite element analysis of homogeneous deformation of AZ31 magnesium during equal channel angular pressing process[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 848-855.

[2] 李新凯, 张治民, 赵亚丽. 变形镁合金的研究现状及前景[J]. 热加工工艺, 2011, 40(24): 54-55.

LI Xin-kai, ZHANG Zhi-min, ZHAO Ya-li. Research and future development of wrought magnesium alloy[J]. Material & Heat Treatment, 2011, 40(24): 54-55.

[3] PRZONDZIONO J, HADASIK E, WALKE W, SZALA J. Resistance to electrochemical corrosion of extruded magnesium alloy AZ31[J]. Solid State Phenomena, 2015, 227: 35-38.

[4] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[5] 席俊杰, 刘 杰. 高性能稀土镁合金的研究及其应用[J]. 热加工工艺, 2014, 43(10): 6-10.

XI Jun-jie, LIU Jie. Research and application of high performance rare earth magnesium alloy[J]. Material & Heat Treatment, 2014, 43(10): 6-10.

[6] 杨 合, 李落星, 王渠东, 郭良刚. 轻合金成形领域科学技术发展研究[J]. 机械工程学报, 2010, 46(12): 31-42.

YANG He, LI Luo-xing, WANG Qu-dong, GUO Liang-gang. Research on the development of advanced forming for lightweight alloy materials area[J]. Journal of Mechanical Engineering, 2010, 46(12): 31-42.

[7] 梁佳佳, 李雄兵, 倪培君, 吕 铎. 镁合金壳体的超声相控阵检测方法[J]. 兵器材料科学与工程, 2014, 37(4): 108-111.

LIANG Jia-jia, LI Xiong-bing, NI Pei-jun,  Duo. An ultrasonic phased array testing method for magnesium alloy case[J]. Ordnance Material Science and Engineering, 2014, 37(4): 108-111.

Duo. An ultrasonic phased array testing method for magnesium alloy case[J]. Ordnance Material Science and Engineering, 2014, 37(4): 108-111.

[8] LEE J R, TAKATSUBO J, TOYAMA N, KANG D H. Health monitoring of complex curved structures using an ultrasonic wave field propagation imaging system[J]. Measurement Science and Technology, 2007, 18 (12): 3816-3825.

[9] 胡宏伟, 彭凌兴, 周正干, 李雄兵, 孙广开. 曲面构件水浸超声检测缺陷定量研究[J]. 航空学报, 2014, 35(11): 3166-3173.

HU Hong-wei, PENG Ling-xing, ZHOU Zheng-gan, LI Xiong-bing, SUN Guang-kai. Quantitative research on defect of curved components with immersion ultrasonic testing[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(11): 3166-3173.

[10] 张 杨, 周晓军, 杨辰龙, 李雄兵, 郑慧峰. 变厚度曲面构件超声检测灵敏度补偿[J]. 浙江大学学报(工学版), 2013, 47(1): 116-121.

ZHANG Yang, ZHOU Xiao-jun, YANG Chen-long, LI Xiong-bing, ZHENG Hui-feng. Sensitivity compensation method in ultrasonic inspection curved components with variable thickness[J]. Journal of Zhejiang University (Engineering Science), 2013, 47(1): 116-121.

[11] SCHMERR L W, SONG S J, SEDOV A. Ultrasonic flaw sizing inverse problems[J]. Inverse Problems, 2002, 18(6): 1775-1793.

[12] 聂 勇, 李晓梅, 许远欢. 核设备不锈钢堆焊层下裂纹超声波检测技术[J]. 无损检测, 2011, 33(7): 25-28.

NIE Yong, LI Xiao-mei, XU Yuan-huan. Ultrasonic examination research of cracks under stainless steel cladding for nuclear components[J]. Nondestructive Testing, 2011, 33(7): 25-28.

[13] 周路生, 张晓源, 吴明明, 顾 清. AVG曲线的应用[J]. 无损检测, 2010, 32(3): 225-226, 229.

ZHOU Lu-sheng, ZHANG Xiao-yuan, WU Ming-ming, GU Qing. The application of AVG curve[J]. Nondestructive Testing, 2010, 32(3): 225-226, 229.

[14] SCHMERR L W, SONG S J. Ultrasonic nondestructive evaluation systems-models and measurement[M]. America: Springer, 2007.

[15] KIM H J, SONG S J, KIM Y H. Quantitative approaches to flaw sizing based-on ultrasonic testing model[C]// Review of Progress in Quantitative Nondestractive Evaluation. New York: AIP Conference Proceedings, 2003: 703-710.

[16] DARMON M, CALMON P, BELE B. An integrated model to simulate the scattering of ultrasounds by inclusions in steels[J]. Ultrasonics, 2004, 42(1/9): 237-241.

[17] JEONG H, SCHMERR L W. Ultrasonic transducer fields modeled with a modular multi-Gaussian beam and application to a contact angle beam testing[J]. Research in Nondestructive Evaluation, 2008, 19(2): 87-103.

[18] KIM H J, SONG S J, SCHMERR L W. Modeling ultrasonic pulse-echo signals from a flat-bottom hole in immersion testing using a multi-Gaussian beam[J]. Journal of Nondestructive Evaluation, 2004, 23(1): 11-19.

[19] 李雄兵, 杨 岳, 胡宏伟, 倪培君, 阳 程. 面向超声检测的曲面自动测量[J]. 中南大学学报(自然科学版), 2010, 41(1): 194-200.

LI Xiong-bing, YANG Yue, HU Hong-wei, NI Pei-jun, YANG Cheng. Complex surface automatic measurement for ultrasonic inspection[J]. Journal of Central South University (Science and Technology), 2010, 41(1): 194-200.

[20] 李雄兵. 曲面工件自动超声检测中若干关键问题的研究[D]. 杭州: 浙江大学, 2008.

LI Xiong-bing. Study on key problems of automated ultrasonic inspection for complex surface parts[D]. Hangzhou: Zhejiang University, 2008.

[21] 侯文科. 纵波探伤实用AVG曲线的计算、制作和使用[J]. 无损检测, 1998(1): 44-46.

HOU Wen-ke. Calculation, production and use of practical AVG curve in L-wave testing[J]. Nondestructive Testing, 1998(1): 44-46.

[22] 赵友杉, 苑家琪, 刘 畅. 通用AVG曲线误差的研究[J]. 无损探伤, 2009, 33(2): 22-25.

ZHAO You-shan, YUAN Jia-qi, LIU Chang. Research on the error of general AVG curve[J]. Nondestructive Test, 2009, 33(2): 22-25.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(61271356, 51205031);湖南省自然科学基金资助项目(2015JJ2168,14JJ2002);中国博士后科学基金资助项目(2014M562126);国家高技术研究发展计划资助(2012AA03A514)

收稿日期:2015-02-09;修订日期:2015-04-22

通信作者:李雄兵,副教授,博士;电话:0731-82655135; E-mail: lixb213@mail.csu.edu.cn