文章编号:1004-0609(2009)05-0800-08

各向异性对镁合金板材渐进成形的影响及微观组织演变

张青来1,肖富贵1,郭海玲1,高霖2,A.B. Bondarev3,韩伟东4

(1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 南京航空航天大学 机电工程学院,南京 210016;

3. Industrial Center, MATEKS Ltd, Moscow 121596,Russia;

4. 宝鸡市博信金属材料有限公司,宝鸡 721013)

摘 要:利用数控实验机床(CNC)、热拉伸实验机和金相显微镜,研究了AZ31B镁合金薄板在加热时渐进加工成形和显微组织变化规律。结果表明:镁合金薄板在加热条件下可以实现单点渐进成形,极限角随着温度的增加而增加,200 ℃时的成形极限角为60?;各向异性对板料的渐进成形影响较大,且250 ℃时合金各向异性最小;渐进成形包括加工硬化、静态再结晶和动态再结晶的复杂过程;板材的微观组织由粗大和细小晶粒组成,这取决于板料的成形温度和成形时间;板料质量是影响镁合金渐进成形质量的主要因素之一。

关键词:镁合金;渐进成形;加热;各向异性

中图分类号:TG 146.2;TG 386 文献标识码:A

Effect of anisotropy on incremental forming of magnesium alloy sheet and its microstructure evolution

ZHANG Qing-lai1, XIAO Fu-gui1, GUO Hai-ling1, GAO Lin2, A.B. Bondarev3, HAN Wei-dong4

(1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China;

3. Industrial Center, MATEKS Ltd, Moscow 121596, Russia;

4. Baoji Boxin Metal Materials Ltd, Baoji 721013, China)

Abstract: The formability and microstructure evolution rules of AZ31B magnesium alloy thin sheet in the incremental forming at elevated temperature were investigated on CNC machine by hot tensile test machine and metallographic microscopy. The results show that, at elevated temperatures, the AZ31B magnesium alloy thin sheet can be formed by single-point incremental forming, the forming limit angle increases with increasing temperature, reaches 60? at 200 ℃. Anisotropy has a great impact on the sheet metal incremental forming and it reaches the minimum value at 250 ℃. Incremental forming is a complex process including work-hardening, static recrystallization and dynamic recrystallization. The microstructures of the sheet are composed of coarse and fine grains, which depend on the sheet metal forming temperature and time. The quality of magnesium alloy sheet is one of the main factors that affect the quality of the incremental forming.

Key words: magnesium alloy; incremental forming; heating; anisotropy

镁合金是具有良好前景的轻型结构材料,已被广泛应用于航空、电子和汽车等工业领域。由于镁具有密排六方晶格结构,其室温塑性差,难以塑性加工,因此,其在特定组织结构、变形温度和速度条件下的塑性加工受到国内外广泛关注。国内外学者对镁合金薄板热拉深成形[1-6]、超塑性成形[7-8]和气胀成形[9]作了较深入地研究。金属板料无模成形很早就有人探索,近十年来由于市场需求的多样化,加之机械和控制技术的进步, 促使金属板料无模成形有了新发展,这种成形方法类似于传统成形工艺中的“胀形”,又与通常的液压胀形及凸模整体胀形不同,属于累积胀形,即无模渐进成形[10-13]。板料无模分层成形无需一一对应的模具,零件的形状和结构也不受约束,极大地缩短了新产品开发周期和降低了成本,解决难成形板料零件小批量、多品种、回弹大和难成形的问题,都有着重要的意义。

迄今为止,国际上对数控渐进成形技术还处于探索阶段,理论方面的研究还不够成熟,有待继续完善。渐进成形用金属材料主要集中在纯铝、纯铜和08钢。最近,一些研究者[14-16]开展了AZ31镁合金板料渐进成形的研究工作。板料渐进成形不仅取决于金属材料的力学性能,而且还受金属材料晶体结构的影响。应用无模热渐进成形技术开发复杂形状的镁合金壳形件产品,对完善镁合金塑性加工技术具有重大理论和实际应用价值。

本文作者针对AZ31B镁合金板料,研究各向异性对板料热渐进成形的影响,并分析渐进成形中存在的问题以及微观组织的变化规律,为今后金属板料热渐进成形技术的开发打下基础。

1 实验

为了研究板料各向异性对单点渐进成形的成形性能影响,本实验选两种不同方式制备的AZ31B镁合金板料,即挤压+交叉轧制板料和连铸连轧板料,其厚度均为0.8 mm板料,化学成分(质量分数)如下:3% Al,0.95% Zn,0.28% Mn,0.022% Si,0.012% Fe,其余为Mg。

热拉伸实验采用RG型微机控制万能实验机。加热采用三段式加热,温度误差为±1 ℃。设备工作方式为:控温仪输入温度参数,经数模转换器转换后对加热炉加热,在炉温度达到设定值后,使得炉温恒定,在150~300 ℃下以1.0×10-3 s-1的应变速率对试样进行塑性变形,拉伸所得位移和受力曲线经计算机处理后输出,此数据作为该合金的热拉伸性能,并计算不同温度下合金的加工硬化系数。

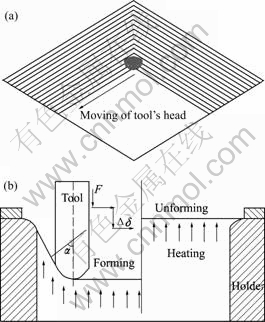

实验用设备是基于UG的数控渐进成形机床NH-SK1060。利用上下压边圈固定被加工板料,在配有CAD/CAM软件的数控机床上控制成形工具头运动轨迹(见图1(a))来实现板料的连续局部塑性成形。在数控装置下,通过事先被加热的板料与成形工具之间的单点运动促使三维轮廓得以成形,成形工具沿着模型的内表面成形,板料的边缘固定不动,成形工具由边缘向心部逐渐成形,直至成形完成。成形过程如图1(b)所示,图中α是成形后零件局部表面法线方向与成形工具轴向的夹角,即成形角;变形区厚度变化符合余弦定律,即t = t0cosα;F为压头对板料所施加的力;?δ为压头的道次压下量。在实验过程中,实验参数选择如下:压头直径12 mm,压下量0.1~0.5 mm,进给速度600~2 000 mm/min,成形温度为25 ℃(室温)~250 ℃。

用LEICA MEF4M光学显微镜观察镁合金显微组织。用型号为Hitachi S-125的扫描电镜观察合金断口形貌。

图1 AZ31B板料渐进成形示意图

Fig.1 Schematic diagram of AZ31B metal incremental forming: (a) Moving trajectory of tool’s head; (b) Process of incremental forming

2 实验结果

影响镁合金板料渐进成形的主要因素是被加工板料的温度、成形后零件局部法线方向与成形工具轴向夹角α、工具头进给量?δ和进给速度。实验中镁合金板料渐进成形参数:工具头进给量?δ为0.2 mm,工具头的进给速度v为2 m/min,成形温度范围为50~ 250 ℃,确定极限成形角α主要取决于成形温度。本实验中分别对50、100、150和200 ℃这4个温度下进行单点渐进成形研究。

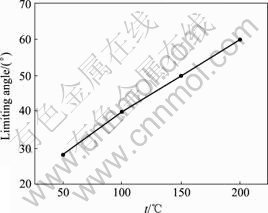

图2所示为板料成形极限角与成形温度之间关系。由图2可以看出,当温度为50 ℃时,AZ31B板材断裂时的成形极限角为27?;当温度为100 ℃时,成形极限角是40?;当成形温度提高到200 ℃时,极限角可达到60。因此,对镁合金板料热渐进加工成形来说,成形温度是镁合金板渐进成形非常重要影响因素之一,且随着成形温度的提高,成形极限角明显增加。

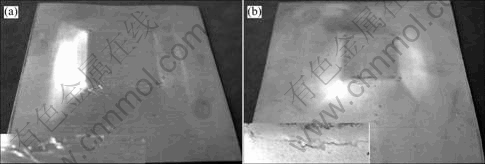

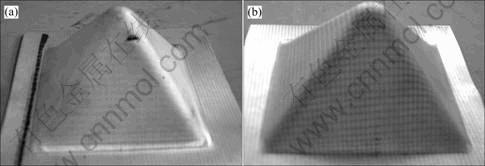

图3和4所示分别为50和100 ℃下AZ31B薄板单点渐进成形的方形锥体样品照片。结果表明,板材加工方式对镁合金板料渐进成形有重要的影响,如连铸连轧板料渐进成形累积量达到成形极限角时,此时裂纹后破裂均发生在轧制方向上,而垂直于轧制方向上未出现任何裂纹迹象,板料表现了明显的各向异性(见图3(a)和图4(a));而挤压+交叉轧制板料的裂纹发生在某一部位,未出现单向轧制板料各向异性的情况,横、纵向塑性变形比较均匀,因材料本身缺陷的原因使板料失稳而局部破裂(见图3(b)和图4(b))。在某 种程度上,成形温度决定了镁合金板料渐进成形成功与否。

图2 板料极限角与成形温度间的关系

Fig.2 Relationship between limiting angle and forming temperature for alloy sheet

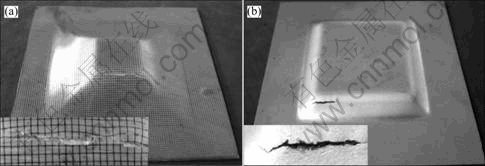

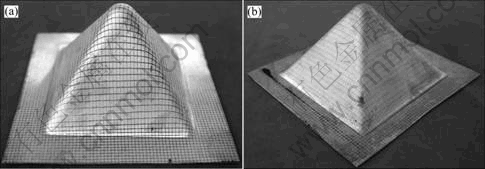

图5和6所示分别为150和200 ℃下AZ31B板料定角渐进加工的方形锥体样品照片。从图5可以看出,在温度为100 ℃时,对连铸连轧板料来说,沿轧制方向上局部仍有破裂现象;而对于挤压+交叉轧制板料,渐进成形方形锥体件没有任何缺陷。当温度进一步提高到200 ℃时,成形角提高到58?,证明在高温下渐进加工时,成形角比极限角小2~3?,符合室温板料渐进加工规律。对于两种加工方式制备的板料渐进成形完整的方形锥体件。这可能是由于具有密排六方体结构的镁合金的棱柱面和棱锥面在此温度左右被部分激活的缘故,使合金的塑性和各向异性得到明显改善。因此,AZ31B镁合金板料在一定温度下可实现渐进成形,成形温度是改善合金各向异性的重要因素,也是难以加工的金属材料渐进成形是否成功的关键因素之一。

图3 50 ℃时方形锥体样品的照片

Fig.3 Photos of samples of square cone at 50 ℃: (a) Longitudinal rolling; (b) Cross rolling

图4 100 ℃时方形锥体样品的照片

Fig.4 Photos of samples of square cone at 100 ℃: (a) Longitudinal rolling; (b) Cross rolling

图5 150 ℃成形角50?时方形锥体样品的照片

Fig.5 Photos of samples of square cone at 150 ℃ and forming angle of 50?: (a) Longitudinal rolling; (b) Cross rolling

图6 200 ℃成形角58?时方形锥体样品的照片

Fig.6 Photos of samples of square cone at 200 ℃ and forming angle of 58?: (a) Longitudinal rolling; (b) Cross rolling

3 分析与讨论

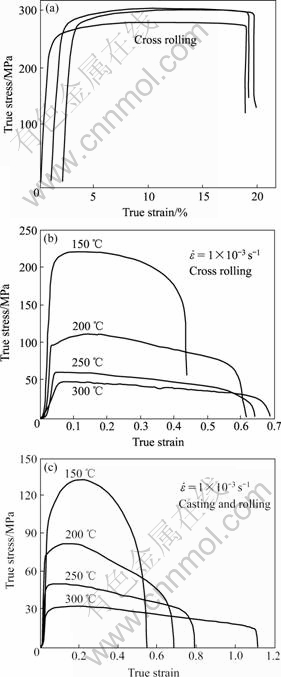

3.1 AZ31B镁合金板料拉伸时的应力—应变曲线

图7所示为AZ31B镁合金板料拉伸时的流动应 力—应变曲线。从图7(a)可知,室温拉伸初期,应 力—应变曲线突然上升,应力达到一定值后,曲线继续缓慢增加,板料发生塑性变形,没有经历蠕变阶段;当试样发生断裂时,流变曲线呈直线下降趋势,没有出现应力峰值、软化及流变阶段。

图7(b)和(c)所示为AZ31B镁合金板料热拉伸时的应力—应变曲线。由图7(b)和(c)可知,在流变应力未达到峰值应力前的变形初期,随着变形的进行,材料内部位错密度增加,使材料硬化;另一方面由于位错的滑移使正负位错抵消,材料位错密度降低而被软化。由于滑移引起的位错不足以抵消位错密度增加引起的硬化,因此,流变应力逐渐增大。随着变形量的增加,材料内部的空位浓度也提高,位错的攀移在该阶段的后期也开始产生作用,参与软化过程,从而使材料的软化程度增大。当流变应力达到峰值应力后,在位错密度较高区域达到动态再结晶的临界位错密度,并形成再结晶晶核,随着这些再结晶晶核的长大,再结晶晶界区域的位错密度降低很大,使材料的流变应力下降。

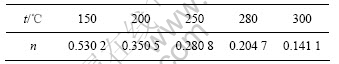

由此可知,AZ31B镁合金板料热拉伸时应力—应变曲线不同于室温拉伸时的应力—应变曲线。特别是极限流变应力的区别较大,且随温度的升高,其流变应力峰值大为降低。对交叉轧制板料来说,室温时的最大应力值约为300 MPa;而在应变速率为1×10-3 s-1, 150 ℃时其峰值流变应力约为220 MPa;随温度进一步升高到250 ℃时,峰值流变应力降低到60 MPa左右。与交叉轧制板料相比,连铸连轧板料在相同温度上的峰值流变应力比较小,即交叉轧制提高了板料塑性加工能力,从而增大了板料断裂时所需的变形抗力值。这说明随温度的升高,不同加工方式制备的镁合金板料流变应力差值越来越小,即在250 ℃时材料的峰值流变应力均为60 MPa左右,未表现出明显的各向异性。同时随温度的增加,合金的加工硬化系数也逐渐降低,结果列于表1。由表1可知,AZ31B镁合金板料更适合在温度为250 ℃时的渐进成形,板料制备方式对其热渐进成形过程有一定的影响,交叉轧制镁合金板料更适合于点接触渐进成形。

图7 AZ31B镁合金薄板的流动应力曲线

Fig.7 Flow stress curves of AZ31B Mg alloy sheet: (a) Room temperature tensile; (b), (c) Heat tensile

表1  s-1拉伸状态下的加工硬化系数

s-1拉伸状态下的加工硬化系数

Table 1 Work-hardening coefficient of stretch at  10-3 s-1

10-3 s-1

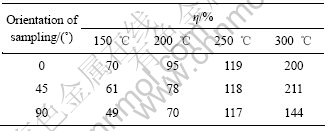

表2所列为AZ31B镁合金连铸连轧板料沿不同方向上热拉伸(应变速率为1×10-3 s-1)时的伸长率。从表2可以看出,沿轧制方向上的伸长率高于垂直于轧制方向(横向)上的伸长率,随温度的提高,各方向上的伸长率更加接近,如250 ℃时的伸长率几乎为118%,说明此时材料各向异性最小,但随温度的升高,横向的伸长率小于纵向的伸长率,这可能是由于晶粒长大速度增加所致。连铸连轧板料是单向轧制,在其他成形条件不变情况下,当成形温度小于150 ℃时,成形件均沿轧制方向开裂,特别是小于100 ℃时这种开裂现象严重,此时板料表现出强烈的各向异性,如图3(b)和4(b)所示。对交叉轧制板料来说,开裂发生在最薄弱处,最终将因材料失稳而破裂;当成形温度200 ℃时,可加工出完整的渐进成形件,此时轧制方式对渐进成形的成形性能影响较小,材料的各向异性大大减小(见图6)。

表2 不同方向和不同温度时连铸连轧板料的伸长率

Table 2 Elongation of cold-rolled sheet in different orientation of sampling at different temperatures

3.2 AZ31B薄板方形锥体的微观组织

众所周知,在冷加工变形后镁合金位错密度增加使变形体内储存了较高的能量,在后续退火过程中,其组织要发生静态回复或静态再结晶。回复或再结晶是相互竞争的过程,它们的驱动力都是变形状态下的储存能。由于镁合金的层错能比较低,在退火过程中不易发生回复现象,镁合金在高温退火过程中主要发生再结晶,因此,可以控制再结晶晶粒的形核和长大来控制晶粒的大小和分布,最终改善了镁合金的性能。

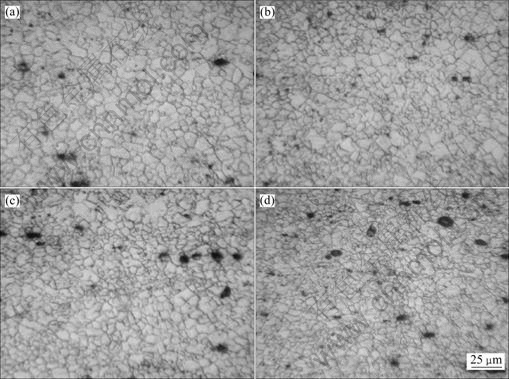

与整体成形相比,渐进成形是依靠逐次的变形累积产生整体变形。图8所示为150 ℃成形角50?时AZ31B薄板方形锥体的显微组织。从图8可以看出,在一定温度和速率下加工工具头所经过的轨迹将发生动态再结晶以及随后发生的静态再结晶两个过程。假设第n圈工具头轨迹上发生动态再结晶,随后由于在150 ℃保温一段时间发生类似静态再结晶和晶粒长大,形成的孪晶逐步消失(见图8(a));渐进成形过程与合金晶粒的尺寸关系复杂,不同于气胀、拉深等整体成形过程,在该温度下保温时间或成形时间的不同,形成的动态再结晶晶粒大小也是不同的。发生动态再结晶时间越早,那么合金原始晶粒长大机会越小,这样形成的动态再结晶晶粒越细小,那么最先形成的动态再结晶晶粒长时间处于加热状态将会发生长大(见图8(b));发生动态再结晶时间越迟,那么合金原始晶粒长大机会越大,这样形成的动态再结晶晶粒相对来说就粗大些。从成形时间角度来分析,点成形后动态再结晶晶粒在高温下停留时间越短而相对细小(见图8(c)和(d))。

因此,AZ31B镁合金热渐进成形是加工硬化、静态再结晶、动态回复和动态再结晶的复杂过程,微观组织由细小和粗大混合晶粒组成。

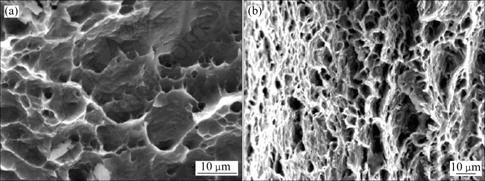

图9所示为板料渐进成形后的断口形貌。用扫描电镜对成形件破裂处断口进行了观察,断口基本上由不均匀网格状撕裂棱和大小不一,且分布不均匀的孔洞组成。局部存在一些尺寸较大,且形状不规则的孔洞,也许是板料内部存在缺陷而造成的,原则上仍是撕裂棱与韧窝共存的形貌,属于韧性断裂。

3.3 镁合金渐进成形中存在的问题

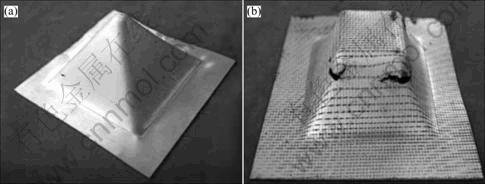

在板材数控渐进成形工艺中,由于成形工具球头的半径远小于板料尺寸,所以板料每次产生的变形仅发生在成形工具头的周围,靠逐次的变形累积产生整体的变形。成形区板料承受剪切变形,板料厚度减薄,减薄到一定程度,必然因材料失稳而破裂。图10所示为AZ31B薄板方形锥体样品的照片。根据实验得到 的数据,对镁合金渐进成形中出现破裂现象进行分析,破裂产生的主要原因如下:1) 板料毛坯本身有裂纹和夹层,如图10(a)所示,金相组织不均匀,晶粒太大,硬度不均匀等;2) 成形半锥角α大于极限半锥角,减薄量太大,金属产生破裂,如图10(b)所示;3) 被加工板料的温度不均匀,变形不均匀,晶粒大小不一。

图8 成形温度150 ℃和成形角50?时AZ31B薄板方形锥体的显微组织

Fig.8 Microstructures of AZ31B square cone sheet at forming temperature of 150 ℃ and forming angle of 50?: (a) 1 min; (b) 4 min; (c) 7 min; (d) 10 min

图9 AZ31B镁合金薄板成形后的断口形貌

Fig.9 Fractographs of AZ31 magnesium alloy sheet after forming: (a) Cross rolling; (b) Longitudinal rolling

图10 AZ31B薄板方形锥体样品的照片

Fig.10 Photos of AZ31B square cone sheet: (a) Fracture; (b) Too large forming angle

4 结论

1) AZ31B镁合金薄板在加热条件下可以实现单点渐进成形,成形极限角随着温度增加而相应增加,200 ℃时成形极限角为60?。各向异性对板料渐进成形影响较大,随温度的提高,其影响程度大大降低,250 ℃时接近最小值。

2) 板料质量对渐进成形有很大影响。渐进成形区别于其他整体成形,板料存在微小裂纹和杂夹缺陷,都将导致成形件出现孔洞或开裂。

3) 渐进成形是加工硬化、静态再结晶和动态再结晶的复杂过程,决定于板料的成形温度和成形时间。微观组织由粗细不一混合晶粒组成,决定于板料的成形温度和成形时间。

REFERENCES

[1] ZHAN M Y, LI Y Y, CHEN W P, CHEN W D. Microstructure and mechanical properties of Mg-Al-Zn alloy sheets severely deformed by accumulative roll-bonding[J]. Journal of Materials Science, 2007, 42(22): 9256-9261.

[2] HAI D V, ITOH S, SAKAI T, KAMADO S, KOJIMA Y. Experimentally and numerical study on deep drawing process for magnesium alloy sheet at elevated temperatures[J]. Materials Transactions, 2008, 49: 1101-1106.

[3] LEE M H, KIM H Y, KIN H K, KIM G D, OH S I. Non-isothermal simulation of warm circular cup deep drawing processing of an AZ31 magnesium alloy sheet[J]. Materials Transactions, 2008, 49(5): 1120-1123.

[4] YOSHIHARA S. Effect of blank holder force control in deep-drawing process of magnesium alloy sheet[J]. Journal of Materials Processing Technology, 2005, 170: 579-585.

[5] YOSHIHARA S, MACDONALD B, HASEGAWA T, KAWAHARA M, YAMAMOTO H. Design improvement of spin forming of magnesium alloy tubes using finite element[J]. Journal of Materials Processing Technology, 2004, 153: 816-820.

[6] KIM W J, PARK J D, YOON U S. Superplasticity and superplastic forming of Mg-Al-Zn alloy sheets fabricated by strip casting method[J]. Journal of Alloys and Compounds, 2008, 464(2): 197-204.

[7] 于彦东, 张凯锋, 蒋大鸣. 轧制镁合金超塑性和超塑胀形[J]. 中国有色金属学报, 2003, 13(1): 71-75.

YU Yan-dong, ZHANG Kai-feng, JIANG Da-ming. Superplasticity and superplastic bulging capability of rolled magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 71-75.

[8] HUSSAIN G, GAO L. A novel method to test the thinning limits of sheet metals in negative incremental forming[J]. International Journal of Machine Tools & Manufacture, 2007, 47: 419-435.

[9] AMBROGIO G, FILICE L, MICARI F. A force measuring based strategy for failure prevention in incremental forming[J]. Journal of Materials Processing Technology, 2006, 177: 413-416.

[10] KOPAC J, KAMPUS Z. Incremental sheet metal forming on CNC milling machine-tool[J]. Journal of Materials Processing Technology, 2005, 162: 622-628.

[11] CERRO I, MAIDAGAN E, ARANA J, RIVERO A, RODRIGUEZ P P. Theoretical and experimental analysis of the dieless incremental sheet forming process[J]. Journal of Materials Processing Technology, 2006, 177: 404-408.

[12] WONG C C, DEAN T A, LIN J. Incremental forming of solid cylindrical components using flow forming principles[J]. Journal of Materials Processing Technology, 2004, 153: 60-66.

[13] LIEVERS W B, PILKEY A K, LIOYD D J. Using incremental forming to calibrate a void nucleation model for automotive aluminum sheet alloys[J]. Acta Materialia, 2004, 52: 3001-3007.

[14] JI Y H, PARK J J. Formability of magnesium AZ31 sheet in the incremental forming at warm temperature[J]. Journal of Materials Processing Technology, 2008, 201: 354-358.

[15] AMBROGIO G, FILICE L, MANNCO G L. Warm incremental forming of magnesium alloy AZ31[J]. CIRP Annals- Manufacturing Technology, 2008, 57: 257-260.

[16] MASAAKI O, YUSUKE K, KAZUKI T. Simultaneous control of shape and properties of AZ31 magnesium alloy sheets by incremental forming[J]. Materials Transactions, 2008, 49(5): 1124-1128.

基金项目:国家自然科学基金资助项目(50774037);江苏大学资助项目(05JDG009)

收稿日期:2008-07-29;修订日期:2008-12-10

通讯作者:张青来,副教授,博士;电话:0511-88797324;E-mail: qlfzhang@sh163.net

(编辑 龙怀中)