文章编号:1004-0609(2007)07-1155-05

非晶55Mg35Ni10Si块体的制备及力学性能

孙 蔚

(浙江工贸职业技术学院,温州 325003)

摘 要:利用机械合金化方法制备55Mg35Ni10Si三元非晶合金粉末,以该非晶粉末为基础材料,采用真空热压法制备55Mg35Ni10Si非晶块体,利用显微硬度测试等手段考察其力学性能。DSC和XRD分析表明,粉体和块体材料中均出现一个明显的放热峰,结合高分辨电子显微镜观察证明,真空热压后块体材料总体上仍以非晶相为主并含少量纳米晶,而块体材料的晶化峰温度要略低于非晶粉末。力学性能测试表明,块体材料的显微硬度为7 834~8 048 MPa,且随载荷的增加而下降,与传统晶态材料的硬度—载荷依赖关系相似。块体材料的断口呈山峦状,没有明显塑性形变的特征,断裂裂纹扩展沿压痕对角线呈放射状。

关键词:非晶合金;机械合金化;力学性能

中图分类号:TB 31; TB 303 文献标识码:A

Fabrication and mechanical properties of

bulk amorphous 55Mg35Ni10Si alloy

SUN Wei

(Zhejiang Industry and Trade Polytechnic, Wenzhou 325003, China)

Abstract: Powders of 55Mg35Ni10Si amorphous alloy were prepared by mechanical alloying method. Using the mechanically alloyed powders as row material, bulk amorphous 55Mg35Ni10Si alloy was prepared by vacuum thermal consolidation. The mechanical properties of bulk material were characterized by micro-hardness. It is found that exothermic peaks appear at the DSC curves of both the powder and bulk material. In combination with the HRTEM examination, it is demonstrated that the bulk material mainly consists of amorphous phase together with some nano-crystals. In addition, the crystallization peak temperature of bulk material shifts toward low temperature compared with that of the corresponding powders. The micro-hardness of bulk material varies between 7 834 MPa and 8 048 MPa and decreases with increasing applied load, being in agreement with that of the normal crystalline materials. The fracture surface shows a mountain-like morphology without obvious plastic deformation features and the cracks propagate along the diagonal lines of the indentation.

Key words: amorphous alloys; mechanical alloying; mechanical properties

随着航空航天技术及汽车工业的发展,对低密度、高比强度、耐腐蚀轻质材料的需求愈显迫切。由于镁合金是工程金属中密度最小的材料之一,而且具有良好的力学性能、可压铸性、焊接性能及可再生性等,因此在轻质结构中具有广泛的应用前景。但是,工程镁合金目前还存在一些明显的不足,如较低的塑性和耐腐蚀性能等。因此,进一步提高镁合金的综合性能是提高其服役行为、扩大其应用范围的关键因素。目前,在工程上主要采取细化晶粒的方法提高镁合金的力学性能,如通过快速凝固、变质、再结晶、喷射共沉积及剧烈塑性变形等[1-7]。最新的研究表明[7-10],非晶态镁基合金因具有无定形原子结构,兼有一般金属

和玻璃特征,呈现出独特的物理化学特性。通过适当控制微观结构,有望获得更高的强度和延性[8]。例如,Mg-Ni-Y和Mg-Cu-Y非晶合金的抗拉强度高达800 MPa,是传统晶态镁合金的两倍[9-10],Mg-Ca-Al和Mg-Ca-Ni合金的强度虽比Mg-Ni-Y和Mg-Cu-Y合金的低,但因其密度小,比强度仍然很高[7]。快速凝固的85Mg12Zn3Ce合金中,微结构含有非晶和晶态两种组织,具有更高的抗拉强度和塑性[8]。镁基非晶合金不存在晶界、位错和层错等结构缺陷,也没有成分偏析和第二相析出,这种组织和成分的均匀性使之具备抗局部腐蚀的先决条件[11],加上非晶态镁合金自身活性较高,能在表面迅速形成均匀的钝化膜,所以抗腐蚀性能优良,其中Mg-Ca-Al、Mg-Y-Al和Mg-Y-M的耐腐蚀性能十分优异。此外,还可以利用非晶晶化的特征,制备出纳米晶或非晶加纳米晶双相结构,使其性能进一步提高。因此,通过非晶化或先非晶后晶化的途径,是一种很有前途的强化镁合金的方法。

在众多非晶合金的制备工艺中,机械合金化是一种较适合制备镁基非晶粉体的工艺,其有效性已被实验所证实[3-4]。在已报道的镁基非晶粉体材料中,Mg-Ni-Si三元系合金不仅具有很强的非晶形成能力,而且具有很高的晶化温度[12],这为利用粉末冶金技术制备块体非晶材料提供了有利条件。但目前相关的研究报道很少,具体制备参数、微结构特征及性能特点也很少公布。因此,本文作者试图在机械合金化制备Mg-Ni-Si三元系非晶粉体的基础上,重点探索粉末冶金法制备非晶块体材料的工艺原理,并对各种制备条件下材料的微结构及力学性能进行考察,为块体镁基非晶材料的制备提供技术基础。

1 实验

原料选用纯度均为99.9%的Mg、Ni和Si粉,粉末粒径分别为180、35和44 mm。将3种粉末按照55Mg35i10Si的化学计量比称量,充分混合后放入真空球磨罐中,同时加入磨球,球料比为20?1。然后密封并抽真空,再注入高纯氩气(99.999%)。球磨过程在Rethsch mill(PM400)行星式球磨机上进行,球磨时间为68 h。将球磨好的粉料装入不锈钢圆柱形模具,在真空热压机上经真空热压获得非晶块体,压制时压力为300 MPa,真空度为10-3 Pa。样品尺寸为d10 mm×4 mm。样品密度采用称重法测量,压制后样品相对密度为92.6%,符合粉末冶金工艺对湿密度的要求[6]。烧结温度为(350±1) ℃、保持时间为5 h。材料微结构分别采用X射线衍射(XRD)、X射线能谱(EDS)、场发射扫描电镜(FE-SEM)和高分辨电镜(HRSEM)等进行表征,力学性能用显微维氏硬度测量。

众所周知,材料硬度与其他物理性能之间存在一定的内在联系,例如硬度和抗拉强度都是反映材料抵抗塑性变形的能力。因此两者具有一定的对应和正比关系,在一定程度上可用硬度反映材料的力学性能。而且硬度测试方法简单、没有破坏性,对脆性材料而言,还可以通过硬度测试间接了解材料的韧性及断裂特征[6]。根据所研究材料的特点,本实验选用显微 维氏硬度对材料的力学性能进行表征,计算方法 如下[13]:

GPa (1)

GPa (1)

式中 F为施加的载荷,2a为压痕对角线长度。测试显微硬度所用载荷一般小于10 N,所产生的压痕需通过显微镜来观察和测量。

首先将样品表面研磨,然后用1 mm的金刚石研磨膏抛光。测量时,分别施加不同的载荷,保持时间均为30 s,随后在显微镜下测量压痕对角线长度。为使所测硬度值具有代表性,每个样品都选取5个以上的区域进行测量,最后取该5个区域硬度的平均值作为材料的硬度值。

2 结果与讨论

2.1 55Mg35Ni10Si块体非晶材料的微结构特征

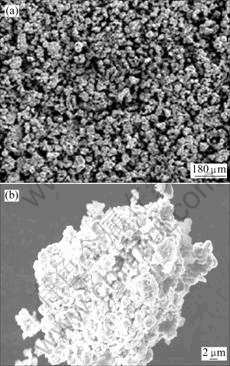

图1所示为热压前合金粉末的颗粒形貌。由图可以看出,粉末颗粒为细小的球形,尺寸约30~60 mm,呈均匀分布。

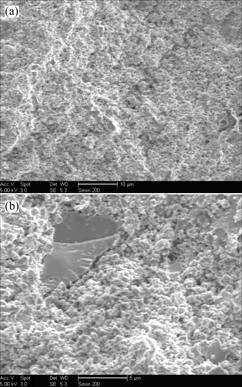

图2所示为热压后块体材料的断口形貌。由图2(a)可以看到,断口呈山峦状,没有明显塑性形变产生的韧窝。进一步观察发现,有一些粗大颗粒存在,如图2(b)所示。EDS检测证明这些颗粒是SiO2,其形成应该是制备过程中Si被氧化的结果。

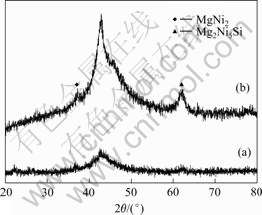

由图3所示的XRD谱可见,对于真空热压后的块体材料来说,非晶相的宽包状峰比热压前粉体材料要尖窄一些,同时还有一些新衍射峰出现。经分析可知,这些新相分别为MgNi2和Mg2Ni5Si。这些相的出现可能与热压保温过程中55Mg35i10Si的部分分解及重新化合有关,也可能与合金化球磨过程中残留的Mg、Ni和Si在保温过程中发生的化学反应有关。其产生原因有待进一步研究。

图1 热压前合金粉末颗粒的形貌

Fig.1 Morphologies of alloy powder before thermal consolidation: (a) Overall morphology; (b) Microscopic morphology

图2 350 ℃真空热压块体材料的断口形貌

Fig.2 Fractographs of bulk specimens consolidated at 350 ℃ in vacuum under varied magnifications

图3 55Mg35Ni10Si非晶粉体和真空热压后块体材料的XRD谱

Fig.3 XRD patterns of amorphous 55Mg35Ni10Si powders(a) and corresponding thermally consolidated bulk specimen(b)

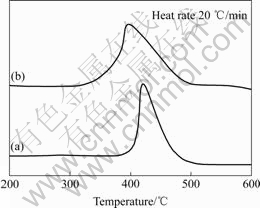

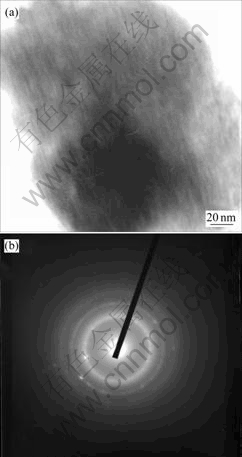

从图4所示的DSC曲线可以看到,在粉体和块体材料中均出现一个明显的放热峰,这说明真空热压后材料总体上仍以非晶相为主,放热峰的出现应该起因于非晶相的晶化放热。一般来说,在压制非晶粉体的过程中,高应力使原子间的扩散受到抑制,从而使非晶的晶化温度有所提高[14]。但是,从图4所示的放热峰来看,块体非晶合金的晶化峰温要比非晶粉末低。这可能是本实验所采用的压制压力(300 MPa)还不足以抑制组元之间原子的扩散运动,另外,因粉体中含有少量纳米晶(见图3),它们在真空热压及加热处理过程中极易生长,使非晶块体的热稳定性下降,故使DSC曲线的放热峰向低温方向移动。图5所示为块体非晶材料的HRSEM照片,这进一步验证了块体材料由非晶相和少量纳米晶组成。

图4 55Mg35i10Si非晶粉体和真空热压后块体材料的DSC曲线

Fig.4 DSC spectra of amorphous 55Mg35Ni10Si powders(a) and corresponding thermally consolidated bulk specimen(b)

图 5 块体55Mg35Ni10Si非晶合金的明场透射图(a)及相应的选区衍射图(b)

Fig.5 Bright field image (a) and corresponding diffraction pattern in selected zone (b) for bulk amorphous 55Mg35Ni10Si specimen

2.2 55Mg35Ni10Si块体非晶材料的力学性能

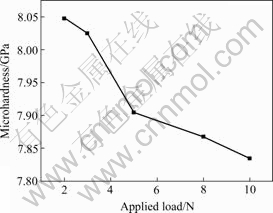

图6所示为350 ℃、300 MPa、真空热压5 h所得55Mg35i10Si块体非晶样品显微硬度的测试结果。可以看出,随载荷增加,材料硬度下降,与传统晶态材料的硬度—载荷依赖关系是一致的[15]。对于本实验所研究的块体55Mg35i10Si块体非晶合金来说,这一变化可能与加载不同时材料的弹性响应有关。由于压痕对角线长度与载荷之间存在Meyer法则,载荷越小,与Meyer法则吻合得就越好[14]。这是因为载荷较小时,卸载过程中材料内部产生的弹性恢复形变所占比例较大,残余塑性形变较小即压痕较小,所以反应出硬度值就比较高。从图6可以看出,施加载荷从2 N增加到5 N时,显微硬度从8 048 MPa迅速下降到7 900 MPa左右,而载荷从5 N增加到10 N时,显微硬度的下降趋势明显减慢,这与在Zr基大块非晶中所观察到的现象相似。

图6 块体55Mg35i10Si非晶显微硬度随载荷的变化

Fig.6 Dependence of microhardness on loading for bulk amorphous 55Mg35Ni10Si specimen

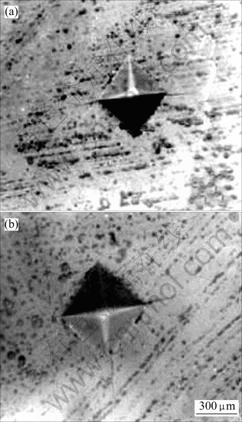

图7所示为载荷为5 N和10 N时的压痕形貌。可以看出,载荷较小时,在压痕对角线方向出现细微裂纹;而当载荷增加到10 N后,裂纹变宽,并以压痕对角线为起点向周围扩展,说明裂纹扩展是以散射方式进行的。

图7 载荷分别为5 N(a)和10 N(b)时的压痕形貌

Fig.7 Indentations under loading 5 N(a) and 10N(b), respectively

3 结论

1) 通过真空热压得到的块体非晶材料,在相组成以非晶为主,但其晶化峰温度比与之相应的粉体材料的有所下降。这可能与压制时所加的压力较小,尚不足以抑制组元之间的原子扩散运动,以及非晶粉体中已有的少量纳米晶有关。这些纳米晶在真空热压过程中极易生长,因此导致块体非晶材料热稳定性下降。

2) 显微硬度测试表明,随施加载荷增加,55Mg35Ni10Si非晶块体的显微硬度下降,该变化趋势与传统晶态材料相同。对微观压痕观察发现,沿压痕对角线方向出现了细微裂纹,呈散射扩展方式。

REFERENCES

[1] Suryanarayana C. Mechanical alloying and milling[J]. Prog in Mater Sci, 2001, 46: 1-184.

[2] Feng A H, Ma Z Y. Enhanced mechanical properties of Mg-Al-Zn cast alloy via friction stir processing[J]. Scripta Materialia, 2006, 56: 397-400.

[3] Wang W H, Dong C, Shek C H. Bulk metallic glasses[J]. Mater Sci Eng R, 2004, R44: 45-89.

[4] Inoue A. Stabilization of metallic supercooled liquid and bulk amorphous alloys[J]. Acta Materialia, 2000, 48: 279-306.

[5] Hufnagel T C. Preface to the viewpoint set on mechanical behavior of metallic glasses[J]. Scripta Materialia, 2006, 54: 317-319.

[6] Perez P, Eddahbi M, Garces G, Sommer F, Adeva P. Mechanical properties of crystallised amorphous Mg-23.5Ni(wt.%) alloy[J]. Scripta Materialia, 2004, 50: 1039-1043.

[7] Lewandowski J J, Shazly M, Nouri A S. Intrinsic and extrinsic toughening of metallic glasses[J]. Scripta Materialia, 2006, 54: 337-341.

[8] Watanabe H, Mukai T, Mabuchi M, Higashi K. Superplastic deformation mechanism in powder metallurgy magnesium alloys and composites[J]. Acta Materialia, 2001, 49: 2027-2037.

[9] Seidel M, Echkert J, Zueco-Rodrigo E, Schultz L. Mg-based amorphous alloys with extended supercooled liquid region produced by mechanical alloying[J]. J Non-Cryst Solids, 1996, 205/207: 514-517.

[10] Schlorke N, Weiss B, Echert J, Schultz L. Properties of Mg-Y-Cu glasses with nanocrystalline particles[J]. Nanostructured Mater, 1999, 12: 127-130.

[11] Tang M B, Zhao D Q, Pan M X, Wang W H. Binary Cu-Zr bulk metallic glasses[J]. Chinese Phys Lett, 2004, 21: 901-903.

[12] Ozaki K, Nishio T, Matsumoto A, Kobayashi K. Preparing Mg-Ni-Si amorphous powders by mechanical alloying and consolidation by pulsed current sintering[J]. Mater Sci Eng A, 2004, A375/377: 857-860.

[13] Soifer Y M, Kobelev N P, Brodova I G, Manukhin A N, Korin E, Soifer L. Internal friction and the Young's modulus change associated with amorphous to nanocrystalline phase transition in Mg-Ni-Y alloy[J]. Nanostructured Mater, 1999, 12: 875-878.

[14] Su S Y, He Y, Shiflet G J, Poon S J. Formation and properties of Mg-based metallic glasses in Mg-TM-X alloys (TM≡Cu or Ni; X≡Sn, Si, Ge, Zn, Sb, Bi or In)[J]. Mater Sci Eng A, 1994, A185: 115-121.

[15] Gennari F C, Urretavizcaya G, Andrade-Gamboa J J, Meyer G. New Mg-based alloy obtained by mechanical alloying in the Mg-Ni-Ge system[J]. J Alloys Comp, 2003, 354: 187-192.

(编辑 龙怀中)

基金项目:国家“十五”科技攻关计划资助项目(2003BA310A03-1)

收稿日期:2007-01-24;修订日期:2007-06-13

通讯作者:孙 蔚,副教授;电话:0577-88311700;E-mail: sunwei@mail.zjitc.net