文章编号:1004-0609(2015)-01-0171-08

等离子体辅助球磨活化Al2O3合成AlN

戴乐阳1, 3,张宝剑1,林少芬1,刘志杰2,王文春2

(1. 集美大学 轮机工程学院 福建省船舶与海洋工程重点实验室,厦门 361021;

2. 大连理工大学 材料改性教育部重点实验室,大连 116024;

3. Department of Materials Science and Engineering, North Carolina State University, Raleigh 27695, USA)

摘 要:利用介质阻挡放电等离子体辅助球磨和普通球磨分别对Al2O3粉末进行活化,研究等离子体辅助球磨活化Al2O3合成AlN的碳热还原反应机制。结果表明:等离子体辅助球磨40 h的Al2O3粉末,在N2气氛中于1400 ℃下保温4 h可以完成碳热还原反应,全部转化为AlN。经等离子体辅助球磨后,Al2O3的碳热还原反应符合气相反应机制,等离子体辅助球磨活化大大降低Al2O3的后续反应温度,辅助球磨40 h后的Al2O3合成AlN的反应激活能下降到371.5 kJ/mol。等离子体的协同效应促使辅助球磨中Al2O3晶体产生更严重的晶格畸变,这是激活Al2O3并促进碳热还原反应的一个重要因素。

关键词:Al2O3;等离子体辅助球磨;活化;碳热还原反应;AlN

中图分类号:TG174 文献标志码:A

Synthesis of AlN from Al2O3 activated by plasma assisted ball milling

DAI Le-yang1, 3, ZHANG Bao-jian1, LIN Shao-fen1, LIU Zhi-jie2, WANG Wen-chun2

(1. Fujian Provincial Key Laboratory of Naval Architecture and Ocean Engineering,

Institute of Marine Engineering, Jimei University, Xiamen 361021, China;

2. Key Laboratory of Materials Modification, Ministry of Education,

Dalian University of Technology, Dalian 116024, China;

3. Department of Materials Science and Engineering, North Carolina State University, Raleigh 27695, USA)

Abstract: The synthesis mechanism of AlN by Al2O3 powders through carbothermic reduction reaction was investigated, in which the Al2O3 powders was activated by plasma assisted ball milling (PM) or by conventional ball milling (CM). The results indicate that Al2O3 powders activated by plasma assisted ball milling for 40 h can be converted to AlN totally through carbothermic reduction reaction when annealed at 1400 ℃ for 4h in N2. It is gas reaction mechanism for the carbothermic reduction reaction of Al2O3 powders after plasma assisted ball milling. The subsequent reaction temperature of Al2O3 powders is reduced significantly because the reaction activation energy decreases to 371.5 kJ/mol after plasma assisted ball milling for 40 h. A lot of lattice distortions are generated in Al2O3 grain due to the cooperation of plasma and ball milling, which is an important factor for promoting the carbothermic reduction reaction of Al2O3 powders activated by plasma assisted ball milling.

Key words: Al2O3; plasma assisted ball milling; activation; carbothermic reduction reaction; AlN

AlN作为一种综合性能优良的功能陶瓷,在诸多领域具有广阔的应用前景,如何制备高纯度、低成本的超细AlN粉至今仍是人们所关注的一个热点[1-2]。Al2O3碳热还原法是商用AlN粉的主要制备方法之一,该法生产的AlN粉纯度较高、烧结性好,但存在合成温度高,反应时间长的缺点,因此,对该方法的改进一直是诸多研究人员致力的方向[3-4]。另外,对Al2O3碳热还原合成AlN的反应机制也存在不同的看法[5-6],值得深入探索。

高能球磨是目前制备先进材料的一个重要技术[7]。由于球磨导致粉体破碎细化,粉体的比表面积也随之不断增加,并产生大量的晶体缺陷,因此,球磨后粉体的反应活性得以增强[8]。高能球磨的这种机械力活化效应对降低粉体的后续反应条件极为有利,其活化效应及引发的后续反应模式也被广泛研究[9-10]。刘新宽等[6]研究搅拌式高能球磨后Al2O3的碳热还原反应,发现反应温度有明显降低,他们认为球磨导致Al2O3储藏能的增加不能解释反应温度的降低,是球磨后Al2O3的碳热还原反应机制发生了变化,先形成的中间相AlON对反应起到促进作用,降低AlN的开始生成温度。

介质阻挡放电等离子体辅助高能球磨作为一种利用外加物理能场辅助高能球磨的新技术[11],在新材料制备领域开始崭露头角[12]。由于等离子体辅助球磨时产生的温度热爆效应、电子脉冲效应和活性基团激活效应,等离子体辅助球磨比普通球磨具有更高的粉体细化效率和更独特的合金化机制,这在金属粉末的细化及碳化物的合成方面已得以验证[13-14]。

本文作者利用介质阻挡放电等离子体辅助高能球磨Al2O3粉末,研究等离子体辅助球磨活化Al2O3碳热还原反应合成AlN的反应机制。通过计算Al2O3合成AlN的反应激活能,定量分析等离子体辅助球磨活化Al2O3粉末对合成AlN反应的促进作用,并研究球磨影响Al2O3碳热还原反应的关键因素以及等离子体在球磨过程中的协同作用机理。

1 实验

实验用Al2O3和石墨原料粉末均由国药集团化学试剂有限公司出品,Al2O3的纯度为99.99%,石墨粉的纯度≥99.85%。球磨在自制的等离子体辅助振动球磨装置[11]上进行,球磨机的振动频率为25 Hz,振幅为10 mm双振幅,球粉比为50:1,球磨罐及磨球均为不锈钢材质。Al2O3粉末的装粉与取粉在手套箱中进行,手套箱中为0.1 MPa的高纯氮气,这样保证辅助球磨时的放电气体为0.1 MPa的高纯氮气。等离子体辅助球磨时(Plasma assisted ball milling,PM),等离子体电源放电参数为放电电压30 kV,放电频率为8 kHz。为了与普通球磨的机械力活化效果对比,在其他球磨参数相同的情况下,关闭等离子体放电电源,进行没有等离子体辅助的普通球磨(Conventional ball milling,CM)。为了减少高能球磨引入的铁污染,在试验前用普通球磨工艺预先球磨Al2O3粉末20 h,使得球磨罐内壁和磨球上包覆一层Al2O3。

对球磨时间为10、20、30和40 h的Al2O3进行取粉,将这些不同球磨时间的Al2O3粉末分别与未经球磨的石墨粉按1:0.8的质量比混合,在玛瑙研钵中搅拌均匀后,利用ZT-50-20型真空碳管炉在流量100 mL/min的流动氮气中进行保温热处理,保温温度分别为1200、1300、1400和1600 ℃,保温时间均为4 h。利用马弗炉对热处理产物进行除碳处理,除碳工艺为在空气中600 ℃保温4 h。

采用日立S-4800型场发射扫描电镜(SEM)对粉末进行形貌观察。采用Bruker D8衍射仪(XRD,Cu Kα)分析球磨过程中及热处理后粉末的物相构成,并利用Voigt方法计算辅助球磨和普通球磨不同时间后Al2O3的晶粒尺寸和晶格畸变。采用Labsys Evo同步热分析仪对上述Al2O3+石墨混合粉末进行差热-热重测试(DSC-TG),测试时氮气流量为100 mL/min,升温速率分别为5、15和25 K/min。

2 结果与分析

2.1 球磨过程中Al2O3粉末的形貌演变

图1所示为Al2O3原料粉末的SEM像。由图1可以看出,原始Al2O3粉体呈无规则形态,粒度比较均匀,平均粒径在1 μm左右。

图1 Al2O3原始粉末的SEM像

Fig. 1 SEM image of Al2O3 powder un-milled

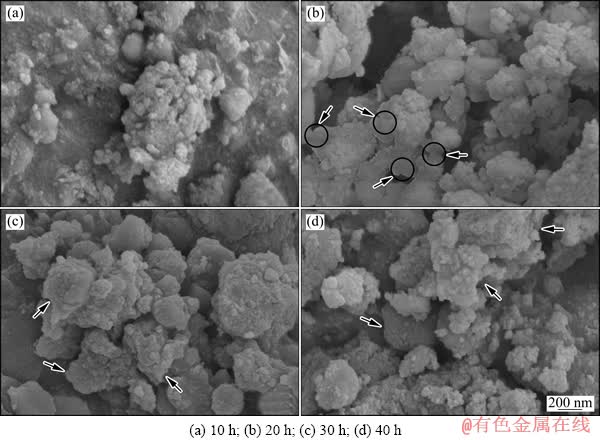

图2 辅助球磨不同时间后Al2O3粉末的SEM像

Fig. 2 SEM images of PM Al2O3 powder milled for different times by PM

图2所示为辅助球磨不同时间后Al2O3粉体的微观形貌。从图2可见,辅助球磨至10 h时,Al2O3颗粒已经被细化到100 nm左右,细小的Al2O3颗粒互相团聚,形成一些比较致密的大粉体;辅助球磨至20 h时,部分Al2O3粉体呈现出明显的片状形貌,如图2(b)中箭头所指。Al2O3的属于脆性材料,这种片状形貌不可能是Al2O3颗粒被磨球撞击后自身发生塑性形变而形成。仔细观察这些层片状的Al2O3粉体,可见其轮廓清晰,表面光滑,片与片之间呈现出熔化后冷凝搭接的迹象。由此可以推断,在辅助球磨时,等离子体中的大量高能粒子与Al2O3粉体发生碰撞,进行能量传递。同时,由于Al2O3为介电材料,在辅助球磨的放电等离子体气氛中,Al2O3粉体能够积蓄大量荷电粒子,这进一步提高了Al2O3粉体的储能,导致Al2O3粉体温度迅速上升,甚至超过其熔点诱发“热爆”[13]。当这些熔化或因“热爆”飞溅的Al2O3颗粒被低温的钢球击中,粉体发生急剧冷却形成片状形貌。辅助球磨至30h时,Al2O3粉末呈团聚趋势,团聚体为层状结构,但构成团聚体的层片表面不再光滑,上面布满了大量的一次颗粒,尺寸在50~100 nm左右。这是因为随着辅助球磨时间的增加,等离子体协同作用的温度效应进一步增强,Al2O3粉体的熔化微区增多,在钢球的撞击和冷凝作用下,更多的Al2O3粉体形成片状形貌,如图2(c)中箭头所指。且由于Al2O3粉体被急冷,其熔化微区表面结晶生成大量细小的Al2O3一次颗粒。在钢球的撞击和混合作用下,这些细小的粉体相互堆叠在一起,逐渐形成层状结构的团聚体。继续辅助球磨至40 h,Al2O3粉末仍呈层状结构的团聚体形态,形貌与30 h的相差不大,如图2(d)中箭头所指。但随着球磨机械剪切力和摩擦力的累积,粉末团聚体的尺寸更小,这些粉末团聚体上的一次颗粒也被细化到50 nm左右。

图3所示为普通球磨不同时间后Al2O3粉末的SEM像。由图3可看出,当普通球磨10 h时,Al2O3一次颗粒粒径分布较宽,约为200~500 nm,Al2O3粉末呈类球状团聚体形态;球磨到20 h时,Al2O3粉末的形貌和粒径没有发生明显的变化;当球磨至30 h,部分Al2O3颗粒被进一步细化至100 nm左右;继续球磨到40 h时,Al2O3粉体出现明显的冷焊,Al2O3颗粒粒径分布范围更宽,此时团聚体尺寸也呈增大趋势,部分团聚体达到15 μm左右。由此可以认为,当普通球磨至40 h时,Al2O3颗粒基本达到破碎和冷焊的动态平衡。

2.2 球磨后Al2O3粉末的物相分析

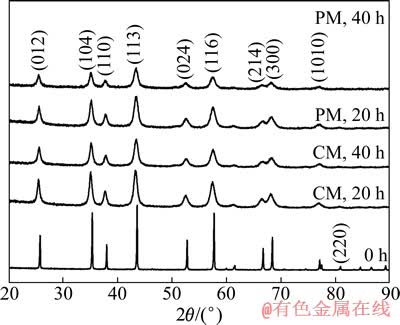

图4所示为辅助球磨和普通球磨不同时间后Al2O3的XRD谱。由图4可见,随着球磨时间的延长,两种方式球磨中Al2O3各个衍射峰均发生宽化和矮化,但Al2O3的晶型没有发生变化,仍为Rhombohedral晶型。通常导致X射线衍射峰发生宽化是因为晶粒细化导致应力释放引起的线形宽化、微观畸变引起的线形宽化以及实验条件引起的线形宽化。由于本研究中实验都是在相同条件下完成,可以认为实验条件导致衍射峰的宽化相同,因此,图4中各个衍射峰的宽化主要由Al2O3的晶粒细化以及颗粒的微观畸变导致的结构缺陷和晶格应力造成。

图3 普通球磨不同时间后Al2O3粉末的SEM像

Fig. 3 SEM images of CM Al2O3 powder milled for different times by CM

图4 辅助球磨和普通球磨不同时间后Al2O3粉末的XRD谱

Fig. 4 XRD patterns of Al2O3 powder milled for different times by PM and CM

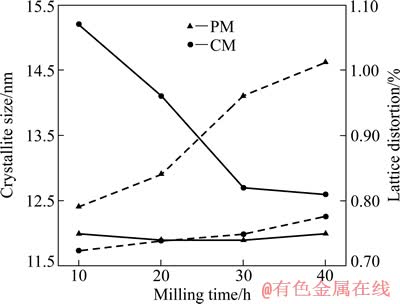

图5所示为利用Voigt方法计算辅助球磨和普通球磨不同时间后Al2O3的晶粒尺寸和晶格畸变。由图5可见,随着球磨时间的增加,两种方式球磨中Al2O3的晶粒尺寸都呈减小趋势,但在球磨的初始阶段,辅助球磨的晶粒细化速率就远高于普通球磨的。球磨至10 h时,辅助球磨Al2O3粉末的晶粒尺寸已经达到12 nm左右,继续球磨晶粒尺寸没有发生明显变化。而普通球磨要到30 h,Al2O3粉末的晶粒尺寸才接近12.5 nm。这说明在等离子体的协同作用下,辅助球磨的晶粒细化能力相比普通球磨提前了近20 h。另一方面,随着球磨时间的增加,Al2O3晶体的晶格畸变程度均呈不断增大的趋势,但辅助球磨导致的Al2O3晶格畸变值的增加幅度明显高于普通球磨的,且随着球磨时间的延长,两种方式球磨产生的晶格畸变的差距进一步增大。在球磨40h时,两种球磨方式中Al2O3被细化到相近的晶粒尺寸(约为12 nm),此时普通球磨中的Al2O3的晶格畸变不再有明显增大,但等离子体辅助球磨Al2O3粉末的畸变程度仍呈现出较大幅值的上升。

图5 辅助球磨和普通球磨不同时间后Al2O3粉末的晶粒尺寸和晶格畸变

Fig. 5 Crystallite size and lattice distortion of Al2O3 powder milled for different times by PM and CM

普通球磨时,Al2O3粉末被钢球强烈地撞击,内部形成大量结构缺陷,微观形变加大。经过钢球反复的冲击碾磨,Al2O3粉末发生晶格松弛并最终破碎。随着球磨时间的增加,粉末粒度不断细化,生成大量亚微米粒子,应力得以释放,导致X射线衍射峰发生宽化。但是当球磨进行到一定时间后,Al2O3晶粒已经非常细小,此时单一机械球磨的破碎能力越来越小,最终破碎效果与焊合作用达到平衡,晶粒尺寸和晶格畸变趋于平稳。而辅助球磨过程中,等离子体的存在大大地增加了Al2O3的晶格畸变程度,这与等离子体所产生的温度效应以及高能粒子轰击效应密切有关。等离子体的这些协同效应大大增强了辅助球磨中对Al2O3粉末的能量输入,且随着粉末的不断细化,粉末的比表面积不断增大,粉末接受等离子体能量的输入效应也不断增强。

2.3 球磨后Al2O3粉末的热处理产物分析

将辅助球磨和普通球磨不同时间后的Al2O3粉末分别与未经球磨的石墨混合后进行不同温度的保温热处理,通过XRD检测发现:在1200 ℃保温时,两种方式球磨不同时间的Al2O3均没有转化为AlN;当保温温度在1300℃时,所有球磨后Al2O3的热处理产物中均有AlN相出现。这说明经球磨活化后,Al2O3开始合成AlN的反应温度在1200~1300 ℃之间。

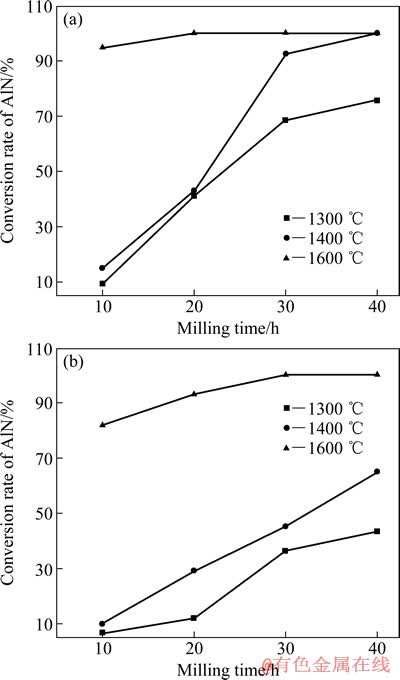

图6所示为利用RIR参考强度比法对辅助球磨和普通球磨不同时间的Al2O3在不同温度热处理后的AlN转化率的半定量计算结果。由图6可见,无论是普通球磨还是辅助球磨Al2O3粉末,在相同的保温温度下,随着球磨时间的增加,AlN的产率均不断提高;而在相同的球磨时间下,随着反应温度提高,Al2O3的转化率也在提高。这说明随着球磨时间的延长, Al2O3粉末的反应活性随之增加,温度的升高也将促进反应的完成。但就两种球磨方式比较而言,相同条件下辅助球磨Al2O3粉末的AlN转化率要显著高于普通球磨的。例如在1400 ℃保温4 h时,辅助球磨40 h的Al2O3粉末全部参与反应,AlN的转化率为100%;而此条件下普通球磨40 h的Al2O3粉末的转化率只有65%左右。在1600 ℃下保温4 h时,普通球磨需要30 h,Al2O3粉末的转化率才基本达到100%;而辅助球磨只需10 h左右,Al2O3就可以完全转化为AlN。这说明辅助球磨对Al2O3粉末的激活能力远远高于普通球磨的。

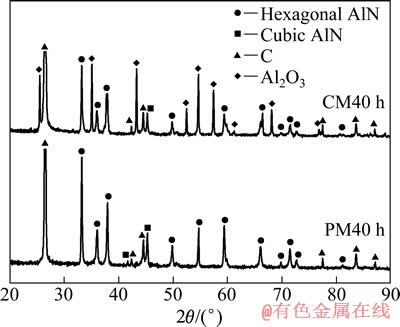

图7所示为辅助球磨和普通球磨40 h的Al2O3粉末在1400 ℃时热处理产物的XRD谱。由图7可见,在1400 ℃保温时,辅助球磨40 h的Al2O3全部转化为AlN,合成的AlN中以六方结构为主,同时还存在一定量的立方结构AlN。这种立方AlN是一种不稳定的相结构,它在更高温度下将会转变成六方AlN[15]。而普通球磨40 h的样品中除了合成的六方及立方AlN相,仍有显著的Al2O3残余。由于石墨的添加量大于反应所需的化学计量,在两种样品的热处理产物中均有残余C的衍射峰。

图6 辅助球磨和普通球磨不同时间的Al2O3在不同温度热处理后的AlN转化率

Fig. 6 Conversion rate of AlN from PM (a) and CM (b) Al2O3 powders for different times after annealing at different temperatures

图7 辅助球磨和普通球磨40 h的Al2O3粉末在1400 ℃时热处理产物的XRD谱

Fig. 7 XRD patterns of production from PM and CM Al2O3 powders for 40 h after annealing at 1400 ℃

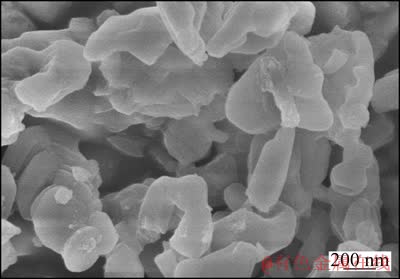

图8所示为辅助球磨40 h的Al2O3在1400 ℃合成的AlN经除碳后的SEM像。由图8可见,合成的AlN粉末呈不规则的片状颗粒,粒径在500 nm左右。

图8 辅助球磨40 h的Al2O3在1400 ℃合成AlN的SEM像

Fig. 8 SEM image of AlN gained from PM Al2O3 powder for 40 h after annealing at 1400 ℃

2.4 辅助球磨活化Al2O3的碳热还原反应机理

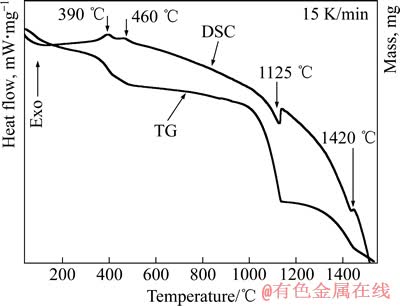

图9所示为辅助球磨40 h的Al2O3粉末与石墨混合后的DSC-TG测试结果,升温速率为15K/min。由图9可见,DSC曲线首先在390 ℃和460 ℃连续出现两个放热峰,对应的TG质量损失曲线出现一个较小的质量损失,这是由于混合粉末中吸附有少量的空气,当加热到390~460 ℃时,部分石墨被氧化成CO或CO2逸出,从而造成质量损失。当温度升高到1125 ℃,DSC曲线出现第一个吸热峰,与之对应的TG曲线有较大的质量损失。随后,在1420 ℃时,DSC曲线出现第二个吸热峰,TG曲线有微弱的质量损失与之对应。由此可见,辅助球磨后的Al2O3,其合成AlN的碳热还原反应是分步进行的,其反应机制与气相反应模型[5]相吻合。

反应式(1)~(3)是Al2O3碳热还原反应的气相反应模型步骤:

Al2O3(s)→Al2O/Al2O2/Al(g) (1)

Al2O(g)+C+N2→2AlN+CO(g) (2)

图9 辅助球磨40 h的Al2O3粉末与石墨混合后的DSC-TG曲线

Fig. 9 DSC-TG curves of mixture of Al2O3 powder PM for 40 h and graphite un-milled

2Al(g)+N2→2AlN (3)

1125 ℃时,辅助球磨活化的Al2O3首先蒸发分解成气态的铝及铝的低价态氧化物(反应式(1)),造成较大程度的质量损失。随着温度的升高,这一步反应在持续进行,TG曲线出现持续质量损失。当温度达到1420 ℃时,第一步反应生成的气态铝及铝的低价态氧化物再发生氮化反应,转化成AlN(反应式2和反应 式(3))。

黄莉萍等[5]的研究发现,在气相反应模型中,只有温度高于1650 ℃时,Al2O3固体表面上各反应物蒸气压才足以推动反应的进行,获得接近完全氮化的产物,该温度远高于辅助球磨40 h后Al2O3的开始合成AlN的反应温度。

这是由于经过辅助球磨后,Al2O3粉末表现出与标准状态的粉末明显不同的性质,如晶粒细小、晶格畸变严重,这导致Al2O3粉末熔点下降、表面能升高和表面活性增大等,Al2O3在低温时即可发生蒸发分解而促进反应进行,从而大幅降低反应发生所需的温度。从热力学角度而言,这就降低反应过程所需的反应热。利用积分法计算图9中两个吸热峰的面积估算其对应的反应热,得到1125 ℃吸热峰对应的反应热为245.82 J/g,1420 ℃吸热峰对应的反应热为57.43 J/g。

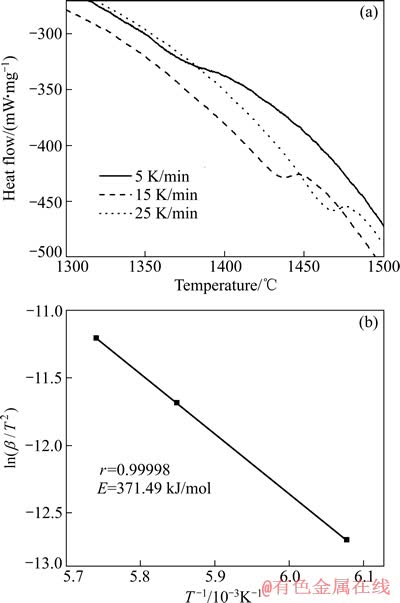

图10所示为不同升温速率下辅助球磨40 h 的Al2O3粉末与石墨混合后的DSC测试结果,以及根据Kissinger法得到的ln (β/T2)-1/T的关系图。图中T为对应的峰值温度(1645.4、1709.6、1741.6 K),β为加热速率(5、15、25 K/min),摩尔气体常数R取值为8.3145 J/(Kmol)。对ln (β/T2)-1/T 的关系进行拟合得到一条直线,该直线的斜率即为反应的激活能。经计算,辅助球磨40 h后,Al2O3合成AlN的反应激活能为371.5 kJ/mol。刘新宽等[16]的研究表明,未经球磨的Al2O3合成AlN的反应激活能为529 kJ/mol,而普通球磨后Al2O3的反应激活能为457 kJ/mol。由此可见,辅助球磨更大程度地降低了Al2O3合成AlN所需的反应激活能。

图10 利用Kissinger法计算辅助球磨40 h的Al2O3碳热还原反应的激活能

Fig. 10 Energy of carbothermic reduction reaction calculated by Kissinger method of PM Al2O3 powders for 40 h

2.5 等离子体协同作用的机理分析

对比两种方式球磨40 h后Al2O3粉末的晶粒尺寸和晶格畸变(见图5),可见两种方式球磨40 h后Al2O3的晶粒尺寸大致相当,但辅助球磨导致的晶格畸变程度远远大于普通球磨的,因此,辅助球磨高效激活Al2O3粉末的一个重要原因是等离子体协同球磨作用导致Al2O3粉体产生了更大的晶格畸变。

辅助球磨时,球磨罐内为0.1 MPa的N2气,当实施介质阻挡放电时,被解离的N2气氛中会产生大量高能态的荷电粒子以及光辐射[17],这些高能量、高密度的粒子会对粉体表面产生碰撞和轰击。当具有数十电子伏特的激发态粒子轰击粉末表面时,入射粒子与晶格原子在固体表面层内引起一连串碰撞,这些碰撞将导致晶格原子的振动或移动。这些高能粒子有可能被粉体表面复合,也有可能注入表面内部把它们的动能传递给晶格原子。随着辅助球磨时间的增加,Al2O3粉体承受入射粒子的密度增加,晶体内大量的晶格原子将处于一种不稳定的状态。与此同时,介电性质的Al2O3粉末内部蓄能的增加导致粉体温度急剧升高,甚至产生局部熔化。当低温钢球频繁地剪切冲击到这些熔化或半熔化状态的Al2O3粉体时,Al2O3晶体内部更容易形成位错、空位和晶界等缺陷,从而产生更大的晶格畸变,并生成大量细小的微晶颗粒。因此,辅助球磨对Al2O3粉体的活化作用远远大于普通球磨的,进而有效降低反应激活能,降低后续反应温度。

3 结论

1) 与普通球磨相比,辅助球磨获得的Al2O3晶粒尺寸更小,晶格畸变更大,其晶格畸变程度随辅助球磨时间的延长一直呈明显的增大趋势。

2) 将球磨后的Al2O3粉末进行碳热还原反应,辅助球磨40 h的Al2O3在1400 ℃保温4 h可以完全转化为AlN;而在相同条件下,普通球磨的转化率只有65%。

3) 辅助球磨后Al2O3粉末的碳热还原反应符合气相反应模型,其中氮化反应的激活能下降至371.5 kJ/mol,反应温度大大降低。

4) 在辅助球磨中,等离子体产生的热效应和高能粒子轰击效应大大促进了Al2O3的晶格畸变,这是辅助球磨活化Al2O3反应粉体的一个重要原因。

REFERENCES

[1] ROUNAGHI S A, ESHGHI H, KIANI R A R, VAHDATI K J, SAMADI K M, SCUDINO S, ECKERT J. Synthesis of nanostructured AlN by solid state reaction of Al and diaminomaleonitrile[J]. Journal of Solid State Chemistry, 2013, 198: 542-547.

[2] WANG H P, YANG Q H, JIA G H, LEI R S, WANG S F, XU S Q. Influence of yttrium dopant on the synthesis of ultrafine AlN powders by CRN route from a sol-gel low temperature combustion precursor[J]. Advanced Powder Technology, 2014, 25(1): 450-456.

[3] MOLISANI A L, YOSHIMURA H N. Low-temperature synthesis of AlN powder with multicomponent additive systems by carbothermal reduction-nitridation method[J]. Materials Research Bulletin, 2010, 45(6): 733-738.

[4] CHU Ai-min, QIN Ming-li, Rafi-ud-din, JIA Bao-rui, LU Hui-feng, QU Xuan-hui. Citric acid-assisted combustion- carbothermal synthesis of well-distributed highly sinterable AlN nanopowders[J]. Journal of the American Ceramic Society, 2012, 95(8): 2510-2515.

[5] 黄莉萍, 黄熊璋, 符锡仁, 沈宝珍. 氮化铝粉末的制备[J]. 硅酸盐学报, 1986, 14(3): 332-338.

HUANG Li-ping, HUANG Xiong-zhang, FU Xi-ren, SHEN Bao-zhen. Preparation of aluminum nitride powder[J]. Journal of the Chinese Ceramic Society, 1986, 14(3): 332-338.

[6] 刘新宽, 马明亮, 席生歧, 周敬恩, 王渠东, 丁文江. 氧化铝碳热还原反应机制及其热力学[J]. 中国有色金属学报, 2000, 10(S1): s46-s49.

LIU Xin-kuan, MA Ming-liang, XI Sheng-qi, ZHOU Jing-en, WANG Qu-dong, DING Wen-jiang. Mechanism and thermodynamics of carbothermal reduction of alumina[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(S1): s46-s49.

[7] ZHANG D L. Processing of advanced materials using high-energy mechanical milling[J]. Progress in Materials Science, 2004, 49(3/4): 537-560.

[8] ANDR B, COULET M V, ESPOSITO P H, RUFINO B, DENOYEL R. High-energy ball milling to enhance the reactivity of aluminum nanopowders[J]. Materials Letters, 2013, 110: 108-110.

B, COULET M V, ESPOSITO P H, RUFINO B, DENOYEL R. High-energy ball milling to enhance the reactivity of aluminum nanopowders[J]. Materials Letters, 2013, 110: 108-110.

[9] XU D, TANG D M, JIAO L, YUAN H M, ZHAO G P, CHENG X N. Effects of high-energy ball milling oxide-doped and varistor ceramic powder on ZnO varistor[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1423-1431.

[10] 吴彩霞, 朱世根, 马 俊, 张梅琳. 高能球磨制备纳米WC-MgO粉末的反应模式及判据[J]. 中国有色金属学报, 2009, 19(3): 411-418.

WU Cai-xia, ZHU Shi-gen, MA Jun, ZHANG Mei-lin. Reaction mode and criterion of nanocomposite WC-MgO powders prepared by high-energy ball milling[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 411-418.

[11] 朱 敏, 戴乐阳, 曹 彪, 曾美琴, 欧阳柳章, 童燕青, 李 北. 一种等离子体辅助高能球磨方法: 中国发明专利ZL200510036231.9[P]. 授权日期: 2007-08-29.

ZHU Min, DAI Le-yang, CAO Biao, ZENG Mei-qin, OUYANG Liu-zhang, TONG Yan-qiang, LI Bei. A method of high-energy ball milling assisted by plasma: Chinese patent ZL200510036231.9[P]. 2007-08-29.

[12] SUN W, HU R Z, LIU H, ZENG M Q, YANG L C, WANG H H, ZHU M. Embedding nano-silicon in graphene nanosheets by plasma assisted milling for high capacity anode materials in lithium ion batteries[J]. Journal of Power Sources, 2014, 268: 610-618.

[13] DAI L Y. Behavior of Fe powder during high-energy ball milling cooperated with dielectric barrier discharge plasma[J]. Acta Metallurgica Sinica. (English Letters), 2013, 26(1): 63-68.

[14] DAI L Y, LIN S F, CHEN J F, ZENG M Q, ZHU M. A new method of synthesizing of ultrafine vanadium carbide by dielectric barrier discharge plasma assisted milling[J]. International Journal of Refractory Metals and Hard Materials, 2012, 30(1): 48-50.

[15] WANG J, WANG W L, DING P D, YANG Y X, FANG L, ESTEVE J, POLO M C, SANCHEZ G. Synthesis of cubic aluminum nitride by carbothermal nitridation reaction[J]. Diamond and Related Materials, 1999, 8: 1342-1344.

[16] 刘新宽, 马明亮, 席生岐, 周敬恩, 王渠东, 丁文江. 机械力活化合成纳米晶氮化铝研究[J]. 硅酸盐学报, 2000, 28(5): 468-471.

LIU Xin-kuan, MA Ming-liang, XI Sheng-qi, ZHOU Jing-en, WANG Qu-dong, DING Wen-jiang. Study on mechanical activation synthesis of nano-crystal aluminium nitride[J]. Journal of the Chinese Ceramic Society, 2000, 28(5): 468-471.

[17] NIE D X, WANG W C, YANG D Z, SHI H C, HUO Y, DAI L Y. Optical study of diffuse Bi-directional nanosecond pulsed dielectric barrier discharge in nitrogen[J]. Spectrochimica Acta A, 2011, 79: 1896-1903.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51177008);福建省自然科学基金资助项目(E1310036,2013J01202)

收稿日期:2014-05-13;修订日期:2014-08-28

通信作者:戴乐阳,教授,博士;电话:13850065983;E-mail:daileyang@jmu.edu.cn