文章编号:1004-0609(2016)-01-0050-10

镍基粉末高温合金原始颗粒边界形成及组织演化特征

秦子珺1, 2,刘琛仄1, 2,王 子1, 2,何国爱1, 2,

刘 锋1, 2,黄 岚1, 2,江 亮1, 2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中南大学 粉末冶金研究院,长沙 410083)

摘 要:采用等离子旋转电极(PREP)法制备高温合金粉末,通过热等静压(HIP)和热挤压(HE)进行固结成型,对制备的粉末及HIP、HE态合金内部和表面显微组织进行表征,探索镍基高温合金原始颗粒边界(PPB)的组成、形成机制及组织演化特征。结果表明:合金在粉末态已发生元素偏析,粉末表层有细小的富Al氧化物颗粒,且颗粒表面有Zr、C、O元素的富集层;合金PPB主要为连续的大尺寸 相、MC型碳化物、Al2O3和富Zr的氧化物颗粒;PPB形成机制是在温度场的作用下,碳化物、

相、MC型碳化物、Al2O3和富Zr的氧化物颗粒;PPB形成机制是在温度场的作用下,碳化物、 相和氧化物易于在结合面析出,合金经热挤压后,原始颗粒边界上大的

相和氧化物易于在结合面析出,合金经热挤压后,原始颗粒边界上大的 相完全消失,连续的PPB被破碎,形成含MC碳化物和少量氧化物的沿挤压方向竖状排列的小颗粒,此时,合金已完成动态再结晶。

相完全消失,连续的PPB被破碎,形成含MC碳化物和少量氧化物的沿挤压方向竖状排列的小颗粒,此时,合金已完成动态再结晶。

关键词:镍基高温合金;粉末冶金;等离子旋转电极制粉;热等静压;热挤压;原始颗粒边界

中图分类号:V256 文献标志码:A

粉末冶金高温合金在热等静压过程中,在粉末颗粒与颗粒之间会出现明显的由连续的第二相颗粒组成的网状边界,称为粉末原始颗粒边界(Prior particle boundry, PPB),直接影响粉末冶金高温合金的工艺性能和力学性能,粉末的微结构组织特性直接决定PPB的形成和严重程度,从而影响高温合金服役性能。因此,研究镍基高温合金粉末的微结构组织特性,在理论上和实际上都有重要意义[1-4]。

PPB的形成一直是冶金材料学者关注的热点和难点。通常认为PPB是由沿合金原始粉末颗粒边界析出的碳化物或碳氧化物构成的网状组织,而这些碳化物或碳氧化物是在热等静压(Hot isostatic pressing, HIP)或挤压工艺前的加热过程中形成的[5-8]。有研究指出[9],PPB是来源于由宏观偏析和表面吸附引起的表面脏化:氩气雾化法制备的René95粉末表面有富含Nb、Ti的碳化物和含Zr的氧化物。另有文献指出[10-11],粉末冶金高温合金成形时,在压坯原始颗粒边界(PPB)会形成脆性的析出相,这种析出相主要是碳化物和氧化物。原始颗粒边界的析出相十分稳定,一般来说碳化物和氧化物的固溶线温度较高,会阻碍热等静压时金属颗粒间的扩散和连接,且在随后的热处理中很难消除,导致粉末冶金高温合金沿原始颗粒边界断裂,降低合金的力学性能。有研究对高温合金粉末进行了表征,指出原始粉末表面无明显析出相[12],但其所用方法相对简单,仅用扫描电镜(SEM)观测了粉末表面形貌。为了理清粉末特性对粉末冶金高温合金原始颗粒边界组成和形成机制的影响,对高温合金粉末的表征还有待进一步开展。

本文作者拟通过对PREP工艺制造的FGH96的粉末和热等静压及热挤压后的合金进行表征和计算,从源头上探讨粉末冶金高温合金原始颗粒边界的成因及组织演化特征。FGH96合金是我国研制出的第二代粉末高温合金,该合金是对美国René88DT合金进行相关的成分优化研制成功的。该种合金的抗拉强度低于第一代,但蠕变强度、裂纹扩展抗力以及损伤容限等性能大幅提高,最高使用温度可达 750 ℃,适合制造推重比10以上的发动机涡轮盘[13-16]。因此,选用FGH96这一性能较好、应用较广的合金进行深入研究,分析其原始粉末的形貌及组合,以期为减少热等静压过程中原始粉末颗粒边界的产生提供理论与实验依据。

1 研究方法

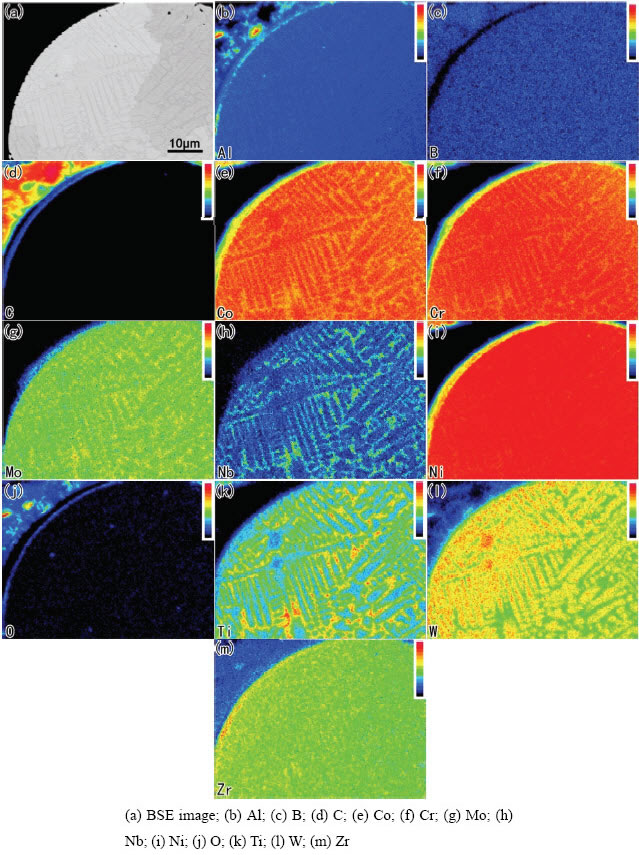

本实验中采用FGH96的名义成分制备镍基高温合金,实验所用的FGH96合金的名义化学成分和采用光谱分析法得到的实际化学成分如表1所列。其材料制备的工艺路线如下:真空感应熔炼→PREP法制粉→筛分→混装→包套→热等静压→热挤压。为研究原始颗粒边界的形成及演化特征,本实验中分别分析合金粉末态、热等静压态和热挤压态3种不同加工状态的样品。实验粉末由钢铁研究总院制备。

采用俄歇电子能谱仪(AES)和能谱仪(EDS)对合金粉末表面元素进行了分析,利用电子探针X射线显微分析仪(EPMA)对合金粉末态剖面的元素偏析情况进行了表征。并分析了热等静压态合金PPB组成元素的分布特征,结合Thermo-Calc软件计算分析原始颗粒边界的形成机制。利用金相显微镜(OM)、SEM、EPMA和电子背散射衍射(EBSD)等方式分析热挤压消除破碎PPB的机制。

2 结果与讨论

2.1 粉末分析

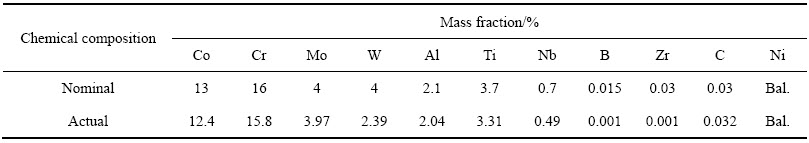

为了分析热等静压合金PPB中碳化物、氧化物的来源,本实验中对粉末态合金进行了表征和分析。图1所示为PREP工艺制备的FGH96合金粉末表面的AES能谱成分分析结果。图1(b)、(c)、(d)所示为溅射

时间0、1.5、10 min的AES谱。图1(e)所示为合金元素成分随粉末沿颗粒表面到内部的深度的变化曲线。图1(f)所示为图1(e)中元素摩尔分数为0~30%、溅射时间为0~4 min区间的放大图。从图中可以看出,C元素含量随着粉末溅射深度的增加急剧下降,说明粉末表面的C主要为空气中吸附的C元素;O元素的含量随着溅射时间的增加,先增加后减小,说明粉末表面含有O元素。

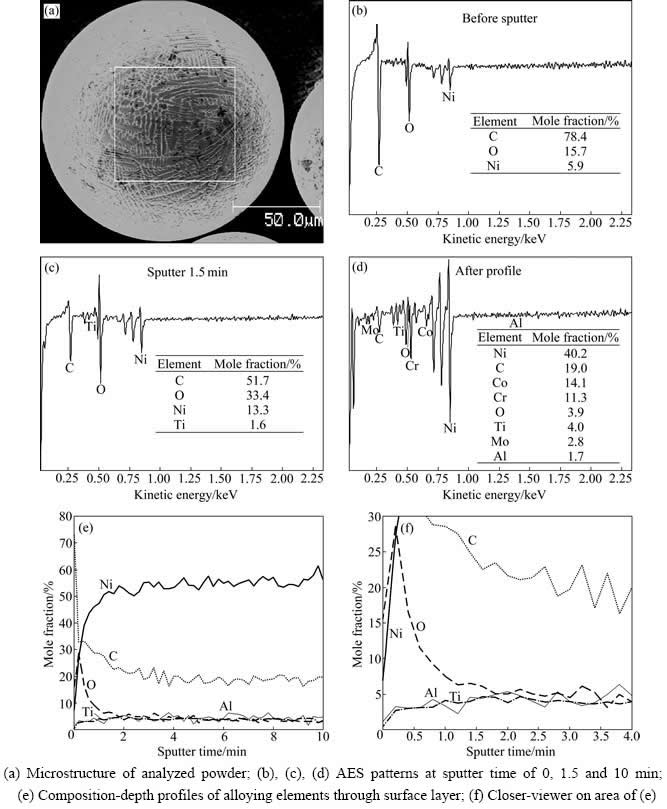

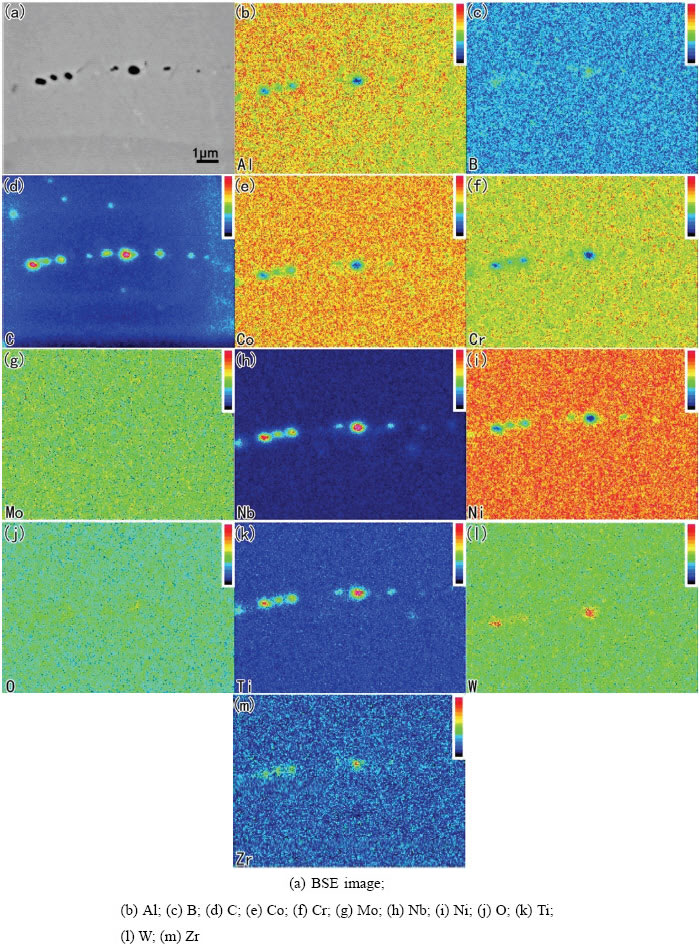

为了进一步探究原始颗粒边界处C、Ni、Ti、O、Al这5种元素的分配形式,本文作者运用EDS和EPMA分别对合金的粉末进行了分析。粉末(如图2(a)所示)表面含有如图上白色箭头所指的白色颗粒。对这些白色颗粒进行EDS分析,其典型的EDS图谱如图2(b)所示,其元素含量(质量分数,%)为Ni 41.4、O 13.0、 Cr 12.5、Al 12.2、Co 9.9、W 3.6、Mo 3.4、Ti 3.0。与合金元素成分相比较而言,该白色颗粒物中Al和O的元素含量明显偏高,因此该白色颗粒可能为含有Al的氧化物。之后对粉末表面多个白色颗粒进行EDS分析,其结果均与图2结果相似,未发现其余元素的富集情况。

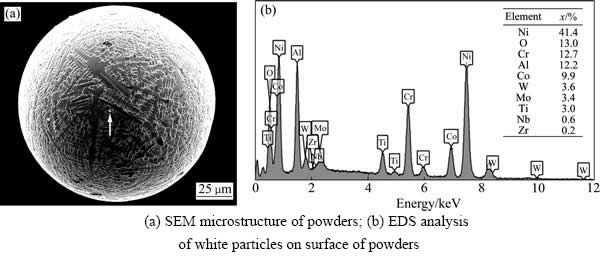

为了直观地反应整个粉末表面的元素偏析情况,考虑到粉末表面碳化物或者氧化物可能以质点的方式存在,相比于整个粉末颗粒体积较小,故对其剖面的1/4圆进行面扫描,其结果如图3所示。合金添加的所有元素及O元素的结果如图3((b)~(m))所示,每张图谱右上角为其对应含量,元素含量越高,图中所对应的位置的颜色越偏红色(见网络电版);元素含量越低,图中所对应的位置的颜色越偏蓝色。可以明显的看出,粉末表面有O的富集,且在含量较高处同时有Al的富集,即粉末表面有大量富Al的氧化物质点;同时,C、Zr元素也在粉末表面有富集现象,即粉末颗粒表面存在明显的C、O、Zr元素富集层。

2.2 热等静压态PPB组成及形成机制

表1 FGH96高温合金的化学成分

Table 1 Chemistry composition of FGH96 superalloy

图1 PREP FGH96合金粉末的颗粒表面及一定深度的AES能谱及其合金元素成分—深度分布曲线

Fig. 1 AES patterns on particle surface of FGH96 superalloy powders and its composition-depth profiles of alloying elements through surface layer

图2 FGH96高温合金粉末表面颗粒元素EDS分析

Fig. 2 EDS analysis of precipitates on surface of FGH96 superalloy powders

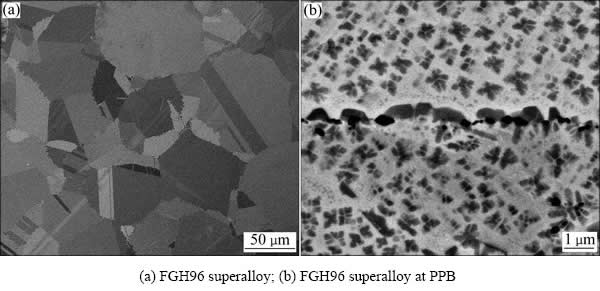

热等静压态合金的扫描电镜的背散射电子(SEM-BSE)照片如图4所示。从低倍的显微组织照片(图4(a))可以发现,HIP态合金已经几乎完全致密化,截面为近圆形,可以清晰地看到原始颗粒边界。从原始颗粒边界区域的放大图(见图4(b))可以看出,原始颗粒边界处至少存在两种类型的析出相(偏黑色颗粒和偏灰色颗粒)。其中偏灰色析出相和基体相有相同的衬度,推测其与基体具有同样的组成和结构。

图3 FGH96粉末颗粒1/4剖面BSE像和元素偏析

Fig. 3 BSE image (a) and corresponding element map distributions ((b)~(m)) of FGH96 powder mapped by EPMA

图4 热等静压态合金的显微组织

Fig. 4 Microstructures of as-HIPed superalloys

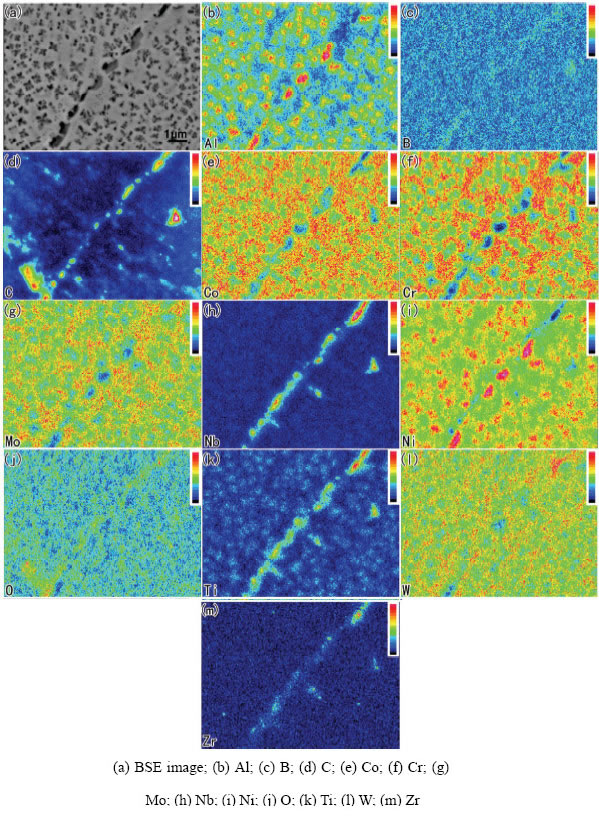

采用EPMA对热等静压态的FGH96合金样品PPB处进行了分析,其结果如图5所示。图5(a)所示为EPMA采集处的BSE照片。由于外界的氧会带入合金中,因此,本实验中对合金添加的所有元素和氧元素进行EPMA的图谱采集,结果如图5(b)~(m)所示。分析各元素的聚集情况可以发现,原始颗粒过界主要存在Al、C、Nb、Ni、Ti、O和Zr这6种元素的富集。根据富集区域形状可知,Al、Ni和Ti的富集区域相同,即此区域的元素种类与基体相同;C、Nb和Ti的富集区域相同;O、Al和Zr的富集区域相同。因此,热等静压态FGH96高温合金原始颗粒边界处至少存在3种不同的析出相:一种为大颗粒的富Ni、Al和Ti的析出相,即 相;第二种为分布在大颗粒析出相间隙的富Ti和Nb的碳化物;第三种为少量的富Al和Zr的氧化物。

相;第二种为分布在大颗粒析出相间隙的富Ti和Nb的碳化物;第三种为少量的富Al和Zr的氧化物。

目前,普遍认为原始颗粒边界的形成机理要结合外因和内因一同分析[5,10]。影响PPB形成的外因主要可以由制粉、成型固化及运输储运过程几个方面论述。内因主要从快速凝固过程中元素偏析,表面结构和析出相特性等方面论述。但他们的关于原始颗粒边界形成机制的讨论只是一种猜测,比如:他们认为在粉末近表面层中存在较高饱和度的碳;在粉末颗粒表面上有MC′型的亚稳碳化物;原始粉末表面存在着Ti、Al、Zr和C等 相和MC型碳化物形成元素的偏析层。但这些结果在本研究过程中均未发现。

相和MC型碳化物形成元素的偏析层。但这些结果在本研究过程中均未发现。

图5 热等静压态FGH96合金PPB处的BSE像和元素偏析

Fig. 5 BSE image (a) and corresponding element map distributions ((b)~(m)) of FGH96 as-HIPed alloy map by EPMA

由用Thermo-Calc热力学软件得到的FGH96合金的热力学平衡相图可知[17],合金在600~1400 ℃区间可能析出相有 、MC、M23C6、M3B2、MB2C3、μ相、σ相及P相。从本研究中对原始颗粒边界处的析出相的表征结果看来,PPB处已有

、MC、M23C6、M3B2、MB2C3、μ相、σ相及P相。从本研究中对原始颗粒边界处的析出相的表征结果看来,PPB处已有 相、MC型碳化物相及氧化物的析出,其它相(如M23C6、M3B2、MB2C3、μ相、σ相及P相)未在PPB处析出。

相、MC型碳化物相及氧化物的析出,其它相(如M23C6、M3B2、MB2C3、μ相、σ相及P相)未在PPB处析出。

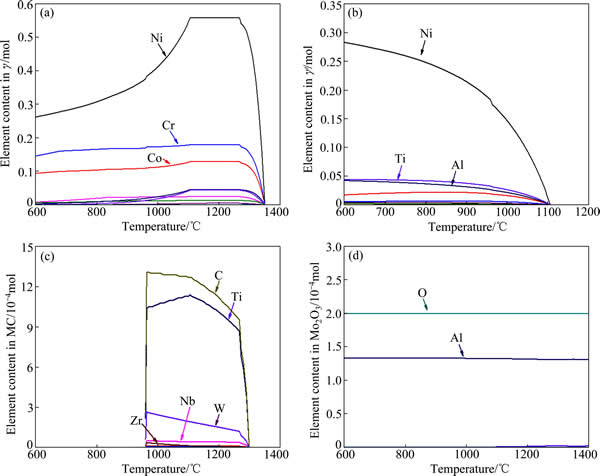

用Thermo-calc热力学计算软件 基体相、

基体相、 相、MC型碳化物相和M2O3型氧化物相中各元素的含量,其结果如图6所示。基体相的主要成分为Ni、Cr、Co,

相、MC型碳化物相和M2O3型氧化物相中各元素的含量,其结果如图6所示。基体相的主要成分为Ni、Cr、Co, 相的主要成分为Ni、Ti、Al,MC型碳化物的主要成分为C、Ti、Nb、W、Zr,M2O3型氧化物的主要成分为Al和O,说明氧化物为Al2O3。另外,本研究结果发现,原始颗粒边界处还存在富Zr的氧化物,但由于Thermo-Calc数据库中没有这种相,故暂未考虑其存在。此外,其它的相的类型和它所包含的元素成分都与本研究的检测结果一致,说明运用热力学的方法可以预测原始颗粒边界所处包含的相。

相的主要成分为Ni、Ti、Al,MC型碳化物的主要成分为C、Ti、Nb、W、Zr,M2O3型氧化物的主要成分为Al和O,说明氧化物为Al2O3。另外,本研究结果发现,原始颗粒边界处还存在富Zr的氧化物,但由于Thermo-Calc数据库中没有这种相,故暂未考虑其存在。此外,其它的相的类型和它所包含的元素成分都与本研究的检测结果一致,说明运用热力学的方法可以预测原始颗粒边界所处包含的相。

图6所示为基体和原始颗粒边界析出相中所包括的元素的绝对含量,而前文EPMA所表征的元素的含量是其相对含量,因此,本研究中运用Thermo-Calc软件计算了 、

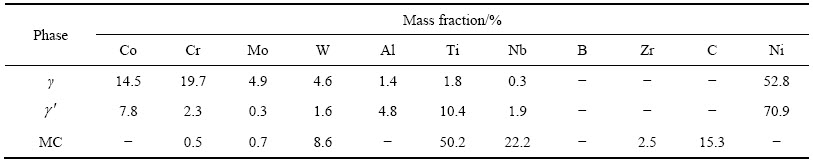

、 和MC相在1000 ℃下各元素的含量,其结果如表2所示。其中,

和MC相在1000 ℃下各元素的含量,其结果如表2所示。其中, 中Ni、Al、Ti元素含量比γ基体相中的高,MC型碳化物中C、Ti、Nb、W、Zr的含量比基体中的高,由于W和Zr的含量偏低,在EPMA谱中W和Zr的富集也同样不明显。因此,Thermo-Calc计算得到的结果与前文中的表征结果吻合。

中Ni、Al、Ti元素含量比γ基体相中的高,MC型碳化物中C、Ti、Nb、W、Zr的含量比基体中的高,由于W和Zr的含量偏低,在EPMA谱中W和Zr的富集也同样不明显。因此,Thermo-Calc计算得到的结果与前文中的表征结果吻合。

在粉末结合界面上,由于原子束缚力弱,原子迁移阻力小,元素的扩散速率较高,这也就加速了原始颗粒边界析出相在粉末结合界面上形成。文献计算结果表明[18],第二相在结合界面析出所需要的临界形核功,相较于晶内和自由表面是最小的。同时,粉末表面偏析有大量的Ti、Nb、Al、Zr和C等碳化物和 相形成元素,这些元素在粉末表面固溶度为PPB析出相在HIP过程中析出提供了足够的驱动力。综合以上各种因素可以看出,PPB的形成由粉末表面固有原子结构和成分组元特性决定,在HIP高温高压过程中形成。

相形成元素,这些元素在粉末表面固溶度为PPB析出相在HIP过程中析出提供了足够的驱动力。综合以上各种因素可以看出,PPB的形成由粉末表面固有原子结构和成分组元特性决定,在HIP高温高压过程中形成。

图6 由Thermo-Calc软件计算得到的FGH96高温合金中 基体、

基体、 相、MC型碳化物相及M2O3型氧化物相中各元素的含量

相、MC型碳化物相及M2O3型氧化物相中各元素的含量

Fig. 6 Element contents of γ (a),  (b), MC carbide (c) and M2O3 oxide (d) in FGH96 superalloy calculated by Thermo-Calc software

(b), MC carbide (c) and M2O3 oxide (d) in FGH96 superalloy calculated by Thermo-Calc software

2.3 热挤压态PPB组成及消除机制

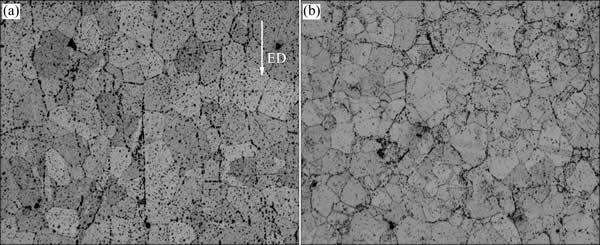

为研究HIP态的P/M镍基高温合金经热挤压(HEX)后显微组织的变化以及PPB的破碎情况,本文作者采用金相显微镜对热挤压态的高温合金的组织进行了观察,其结果如图7所示。经热挤压后,在合金纵截面上都出现了沿挤压方向的竖状黑色条纹,横截面上则有分散的小黑点。

图8所示为采用EPMA表征小颗粒集中的区域,所有合金添加元素及氧元素的分布如图所示。比较图中大部分黑色小颗粒的位置,可以发现其上富集了C、Nb、O、Ti、W、Zr这6种元素,其中C、Nb和Ti 3种元素的富集现象最为明显,W元素次之,而O、Zr元素的富集相对较少。从对热等静压状样品的分析结果来看,这些小颗粒主要为富Nb、Ti、W的碳化物和富Zr的氧化物。因此,在热挤压过程中,受挤压过程中的机械力作用和高温的温度场作用,热等静压态中分布在原始颗粒边界处的析出相的连续性被破坏了,大的 相消失、其它小颗粒离散地分布在基体中。而这些小颗粒是热等静压态的原始颗粒边界的遗留组织(碳化物、氧化物)。

相消失、其它小颗粒离散地分布在基体中。而这些小颗粒是热等静压态的原始颗粒边界的遗留组织(碳化物、氧化物)。

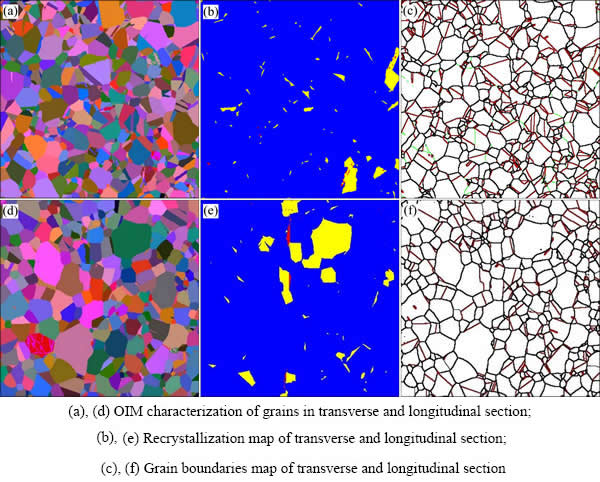

图9(a)和9(d)所示分别为合金横截面和纵截面内部晶粒取向EBSD图。从图中取向颜色的多样性可以发现热挤压后的合金并无织构。图9(b)和9(e)所示为热挤压态合金横截面和纵截面内部晶粒再结晶图。测量得到,热挤压态合金的横截面的再结晶分数为97.0%,不完全再结晶分数为2.9%,变形态分数为0.1%。纵截面的再结晶分数为91.8%,不完全再结晶分数为7.9%,变形态分数为0.3%。图9(c)和图9(f)所示分别为热挤压态合金横截面和纵截面内部晶粒晶界图,其中黑色线条代表大于15°的晶界;红色线条代表Σ3孪晶晶界。热挤压态合金横截面的孪晶分数为22.4%,其纵截面的孪晶分数为20.9%。用EBSD图像分析软件计算其平均晶粒大小,得到HEX态合金横截面的平均晶粒尺寸为14.8 μm,纵截面的平均晶粒尺寸为17.1 μm。

表2 Thermo-Calc软件计算得到FGH96合金γ、 和MC相在1000 ℃下各相的成分

和MC相在1000 ℃下各相的成分

Table 2 Phase composition of γ,  and MC carbide in FGH96 superalloy at 1000 ℃ measured by Thermo-Calc software

and MC carbide in FGH96 superalloy at 1000 ℃ measured by Thermo-Calc software

图7 热挤压态镍基粉末高温合金的显微组织

Fig. 7 Microstructures of as-HEXed superalloy longitudinal section of FGH96 allloy (a) and it’s transverse section (b)

图8 热挤压态的FGH96合金的BSE像和元素偏析

Fig. 8 BSE image (a) and corresponding element map distributions ((b)~(m)) of FGH96 as-HEXed alloy map by EPMA

3 结论

1) 合金在粉末态已发生元素偏析,粉末表层形成一些细小而富Al的氧化物,且颗粒表面有Zr、C、O元素的富集层。

2) 合金原始颗粒边界主要由连续的大尺寸 相,MC型碳化物颗粒、少量的Al2O3和富Zr的氧化物颗粒构成。

相,MC型碳化物颗粒、少量的Al2O3和富Zr的氧化物颗粒构成。

3) 原始颗粒边界析出相的形成机制是在温度场的作用下,碳化物、 相和氧化物易于在结合界面析出,因此选择在PPB处析出。

相和氧化物易于在结合界面析出,因此选择在PPB处析出。

4) 经热挤压后,PPB上的大的 相都完全消失,连续的PPB已被破碎,合金界面上形成了由未溶于基体的原始颗粒边界的遗留组织(MC型碳化物和少量氧化物)所构成的沿挤压方向的竖状排列的小颗粒,合金经热挤压后已完成动态再结晶。

相都完全消失,连续的PPB已被破碎,合金界面上形成了由未溶于基体的原始颗粒边界的遗留组织(MC型碳化物和少量氧化物)所构成的沿挤压方向的竖状排列的小颗粒,合金经热挤压后已完成动态再结晶。

图9 热挤压态FGH96 合金的EBSD表征

Fig. 9 EBSD analysis of as-HEXed FGH96 alloy

REFERENCES

[1] 李慧英, 胡本芙, 章守华. 原粉末颗粒边界碳化物的研究[J]. 金属学报, 1987, 23(2): B90-B94.

LI Hui-ying, HU Ben-fu, ZHANG Shou-hua. Study of previous powder-particle boundary[J]. Acta Metallurgica Sinica, 1987, 23(2): B90-B94.

[2] GAROSSHEN T. Influence of alloy chemistry on carbide precipitation in a nickel base superalloy[J]. Metallurgical and Materials Transactions A, 1986, 17(11): 2075-2077.

[3] QIU C, ATTALLAH M, WU X, ANDREWS P. Influence of hot isostatic pressing temperature on microstructure and tensile properties of a nickel-based superalloy powder[J]. Materials Science and Engineering A, 2013, 564: 176-185.

[4] LIU C Z, LIU F, HUANG L, JIANG L. Effect of hot extrusion and heat treatment on microstructure of nickel-base superalloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2544-2553.

[5] 马文斌, 刘国权, 胡本芙, 贾成厂. 镍基粉末高温合金 FGH96中原始粉末颗粒边界的形成机理[J]. 金属学报, 2013, 49(10): 1248-1254.

MA Wen-bin, LIU Guo-quan, HU Ben-fu, JIA Cheng-chang. Formation of previous particle boundary of nickel base PM superalloy FGH96[J]. Acta Metallurgica Sinica, 2013, 49(10): 1248-1254.

[6] 刘建涛, 张义文. FGH96 合金粉末的俄歇分析及预热处理[J]. 中国有色金属学报, 2012, 22(10): 2797-2804.

LIU Jian-tao, ZHNAG Yi-wen. AES analysis and pre-heat treatment of FGH96 superalloy powders[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2797-2804.

[7] MA W B, LIU G Q, HU B F, HU P H, ZHANG Y W. Study of metallic carbide (MC) in a Ni-Co-Cr-based powder metallurgy superalloy[J]. Metallurgical and Materials Transactions A, 2014, 45(1): 208-217.

[8] ZHANG L, LIU H S, HE X B, RAFI U D, QU X H, QIN M L, LI Z, ZHANG G Q. Thermal evolution behavior of carbides and γ′ precipitates in FGH96 superalloy powder[J]. Materials Characterization, 2012, 67(0): 52-64.

[9] YANG W H, MAO J, WANG W X, ZOU J W, ZHOU R F. Effects of heat treatment on prior particle boundary precipitation in a powder metallurgy nickel base superalloy[J]. Advanced Performance Materials, 1995, 2(3): 269-279.

[10] 赵军普, 陶 宇, 袁守谦, 贾 建, 韩寿波. 粉末冶金高温合金中的原始颗粒边界(PPB)问题[J]. 粉末冶金工业, 2010, 20(4): 43-49.

ZHAO Jun-pu, TAO Yu, YUAN Shou-qian, JIA Jian, HAN Shou-bo. The problem of prior particle boundary precipitation in P/M superalloys[J]. Powder Metallurgy Industry, 2010, 20(4): 43-49.

[11] 张 莹, 刘明东, 孙志坤, 张译文. 颗粒间断裂在P/M镍基高温合金低周疲劳断口上的特征[J]. 中国有色金属学报, 2013, 23(4): 987-996.

ZHANG Ying, LIU Ming-dong, SUN Zhi-kun, ZHANG Yi-wen. Characteristics of inter-particle rupture on LCF fractograph of P/M nickel-based superalloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 987-996.

[12] 马文斌, 刘国权, 胡本芙, 张义文, 刘建涛. 粉末高温合金 FGH96中的原始粉末颗粒边界及其对合金拉伸断裂行为的影响[J]. 粉末冶金材料科学与工程, 2013, 18(1): 1-7.

MA Wen-bin, LIU Guo-quan, HU Ben-fu, ZHANG Yi-wen, LIU Jian-tao. Prior particle boundary and its effect on tensile properties of PM FGH96 superalloy[J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(1): 1-7.

[13] 王淑云, 李惠曲, 谭 勇, 杨洪涛. 热等静压FGH96合金热处理过程的组织[J]. 新技术新工艺, 2008, (11): 103-105.

WANG Shu yun, LI Hui qu, TAN Yong, YANG Hong-tao. Microstructure evolution behavior of HIP FGH96 alloy during heat treatment process[J]. New Technology & New Process, 2008(11): 103-105.

[14] TILEY J, VISWANATHAN G B, SRINIVASAN R, BANERJEE R, DIMIDUK D M, FRASER H L. Coarsening kinetics of γ′ precipitates in the commercial nickel base superalloy René 88 DT[J]. Acta Materialia, 2009, 57(8): 2538-2549.

[15] VISWANATHAN G B, SAROSI P M, HENRY M F, WHITIS D D, MILLIGAN W W, MILLS M J. Investigation of creep deformation mechanisms at intermediate temperatures in René 88 DT[J]. Acta Materialia, 2005, 53(10): 3041-3057.

[16] ZHANG M J, LI F G, WANG S Y, LIU C Y. Effect of powder preparation technology on the hot deformation behavior of HIPed P/M nickel-base superalloy FGH96[J]. Materials Science and Engineering A, 2011, 528(12): 4030-4039.

[17] LIU Chen-ze, LIU Feng, HUANG Lan, JIANG Liang. Effect of hot extrusion and heat treatment on microstructure of nickel-base superalloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 2544-2553.

[18] 杨万宏, 俞克兰, 赖和怡, 颜鸣皋. 一种高温合金粉末预处理后表面的分析[J]. 航空材料学报, 1993, 13(1): 22-29.

YANG Wan-hong, YU Ke-lan, LAI He-yi, YAN Ming-gao. Surface analysis of a PHTed superalloy powder[J]. Journal of Aeronautical Materials, 1993, 13(1): 22-29.

Formation and microstructure evolution of precipitation on prior particle boundaries in P/M nickel-base superalloys

QIN Zi-jun1, 2, LIU Chen-ze1, 2, WANG Zi1, 2, HE Guo-ai1, 2, LIU Feng1, 2, HUANG Lan1, 2, JIANG Liang1, 2

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Research Institute of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The superalloys powders were prepared by plasma rotating electrode processing (PREP). The powder was consolidated by hot isostatic pressing (HIP) and hot extrusion (HE). The microstructures of powders, as-HIPed and as-HEXed alloys were examined. The constitution, formation mechanism and the microstructure evolution of PPB during the hot extrusion were studied. The results show that some small size oxides enriched with Al and a layer of Zr, O, C concentrate on the surface of powder. The PPB is stracture of  phases, MC carbides and Al2O3, Zr enriched oxides particles. The PPB formation mechanism is that, under the effect of temperature field, carbides,

phases, MC carbides and Al2O3, Zr enriched oxides particles. The PPB formation mechanism is that, under the effect of temperature field, carbides,  precipitates and oxides are more ready to precipitate at bonding interface. After hot extrusion, the big

precipitates and oxides are more ready to precipitate at bonding interface. After hot extrusion, the big  phases at PPB are gone and continuous PPB is broken. These particles aligned along extrusion direction are the remains of PPB (MC type carbides and trace amounts of oxides), and the dynamic recrystallization occurs during hot extrusion.

phases at PPB are gone and continuous PPB is broken. These particles aligned along extrusion direction are the remains of PPB (MC type carbides and trace amounts of oxides), and the dynamic recrystallization occurs during hot extrusion.

Key words: nickel-based superalloys; powder metallurgy; plasma rotating electrode processing; hot isostatic pressing; hot extrusion; prior particle boundry

Foundation item: Project (2012AA03A514) supported by the National High-tech Research and Development Programm of China; Projects (51401242, 61271356, 51205031) supported by the National Natural Science Foundation of China; Project (2015zzts031) supported by the Doctoral-Independent Exploration and Innovation of Central South University, China

Received date: 2015-03-20; Accepted date: 2015-10-25

Corresponding author: LIU Feng; Tel: +86-731-88830937; E-mail: liufengehe@126.com

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2012AA03A514);国家自然科学基金资助项目(51401242, 61271356, 51205031);研究生自主探索项目(2015zzts031)

收稿日期:2015-03-20;修订日期:2015-10-25

通信作者:刘 锋,副教授,博士;电话:0731-88830937;E-mail: liufengehe@126.com