高铁铝土矿直接还原-石灰烧结过程及机理研究

胡文韬1, 2,王化军1, 2,孙传尧1, 2, 3,刘欣伟1,王波1, 2

(1. 北京科技大学 金属矿山高效开采与安全教育部重点实验室,北京,100083;

2. 北京科技大学 钢铁冶金新技术国家重点实验室,北京,100083;

3. 北京矿冶研究总院 矿物加工科学与技术国家重点实验室,北京,100070)

摘要:探索基于石灰烧结的高铁铝土矿直接还原方案,并借助XRD,SEM和EDS等手段分析直接还原-石灰烧结过程中的矿物转化机理。研究结果表明:在保温过程中,由于生石灰的反应活性较低,原矿中仅有部分氧化铝矿物转化为碱溶性的铝酸钙。在剩余的氧化铝矿物中,高岭石转化为莫来石,一水硬铝石和一水软铝石转化为刚玉;刚玉和莫来石不溶于碱,造成氧化铝损失。由于石灰烧结反应温度与直接还原反应温度之间存在差异,因此,很难同步实现铝、铁矿物的高效转化。最佳条件为:预磨粒度为<0.038 mm的铝土矿质量分数为74.95%,石灰用量为19.35%,还原温度为1 400 ℃,还原时间为60 min,最佳试验指标如下:铁品位T(Fe)为71.01%,铁回收率ε(Fe)为99.5%,氧化铝溶出率ηA为61.58%。

关键词:高铁铝土矿;铁;直接还原;铝铁分离

中图分类号:TD 982 文献标志码:A 文章编号:1672-7207(2014)04-1005-08

Research on ferric bauxite direct reduction-lime sinter process and mechanism

HU Wentao1, 2, WANG Huajun1, 2, SUN Chuanyao1, 2, 3, LIU Xinwei1, WANG Bo1, 2

(1. Key Laboratory of High-Efficient Mining and Safety of Metal Mines, Ministry of Education,

University of Science and Technology Beijing, Beijing 100083, China;

2. State Key Laboratory of Advanced Metallurgy,

University of Science and Technology Beijing, Beijing 100083, China;

3. State Key Laboratory of Mineral Processing Science and Technology,

Beijing General Research Institute of Mining and Metallurgy, Beijing 100070, China)

Abstract: The investigation of ferric bauxite direct reduction method based on lime sintering technology was conducted. XRD, SEM, and EDS technology were used to reveal mineral phase transition mechanism. The results show that, with a low reactivity, only part of Al2O3 in ore is converted to alkali-soluble calcium aluminate. In the remaining alumina minerals, diaspore and boehmite are converted to corundum, while kaolinite is converted to mullite. Corundum and mullite are alkali-insouble, it results in the loss of alumina. The reaction temperature of direct reduction and lime sinter is different, so it is difficult to recover iron and alumina simultaneously. The optimum conditions are as follows: granularity of pre-grinding 74.95% (particle parameter is less than 0.038 mm), dosage of lime 19.35%, reduction temperature 1 400 ℃, reduction time 60 min. The best results are T(Fe)71.01%, ε(Fe) 99.5%, and ηA 61.58%.

Key words: ferric bauxite; iron; direct reduction; aluminum-iron separation

高铁铝土矿是重要的难选冶铝土矿资源。在优质资源日趋减少的情况下,合理开发难选冶资源,对缓解我国铝土矿和铁矿石的供需矛盾,保障矿业经济的安全发展具有重要意义[1-3]。国外高铁铝土矿大量分布于老挝、印度尼西亚、坦桑尼亚[4-5]等国境内。我国国内的高铁铝土矿资源在15亿t以上,主要分布于贵州、河南、广西、山西、重庆、海南、福建等省区[6]。近年来,直接还原工艺成为高铁铝土矿的研究热点之一。胡四春等[7]发现,保德一水硬铝石型高铁铝土矿经直接还原—磨矿—弱磁选后,精矿铁品位和回收率分别可达81.45%和60.53%。弱磁选尾矿除铁后作为铝精矿,氧化铝品位和回收率分别为60.56%和73.62%。但该方案无法脱硅,只适用于铝硅比(A/S)较高的矿石。孙娜[9]使用还原焙烧—磁选—(酸)浸出方案处理广西三水高铁铝土矿,获得了铁品位93.73%、回收率>93%的铁精矿。磁选尾渣在常温常压下以质量分数为20%的硫酸浸出,获得了84%的Al2O3浸出率。浸出液经活性炭吸附后,SiO2的脱除率可达到82.3%。朱忠平[9]研究了该过程的机理,发现磁选尾渣中的铝主要以难溶性铝硅酸钠的形式存在,解释了酸浸的必要性。但已报道的高铁铝土矿直接还原工艺侧重于回收铁,将磁选收铁后的尾矿直接作为铝精矿。而铁铝的回收过程相对独立,在回收铁后再酸浸尾渣回收氧化铝,尚未能充分利用铁铝回收条件中的共性。铝土矿烧结法是常见的铝土矿处理工艺,主要包括:碱石灰烧结法、纯碱烧结法和石灰烧结法。烧结法与直接还原法的处理温度相近,若能将二者结合,在还原气氛中保温处理高铁铝土矿,将会形成一条高铁铝土矿综合利用的新途径。本课题组综合分析了还原性气氛中高铁铝土矿和纯碱的反应性质,提出“同步转化、异步分离回收”工艺,在强还原气氛中将高铁铝土矿中的一水硬铝石、一水软铝石和一部分高岭石中的氧化铝转化为碱溶性的铝酸钙从溶液中回收,将赤铁矿和水针铁矿中的氧化铁还原为铁单质以磁选方式回收,在一次加热的基础上实现铝铁元素的同步转化和异步综合回收。回收的单质铁“压块”后可作为炼钢或铸造生产的原料,氧化铝可作为电解铝的原料。产品的市场需求大、发展前景广阔[10-12]。本文研究了预磨粒度,还原温度、保温时间、CaO用量等直接还原-石灰烧结工艺参数对粉末铁品位、回收率、氧化铝溶出率的影响,及相关的矿物转化机理,以期为高铁铝土矿的“同步转化,异步分离回收工艺”提供理论依据。

1 原材料与试验方法

1.1 原料

本次试验所用高铁铝土矿采自广西某地,化学组成如表1所示,XRD分析如图1所示,矿相照片如图2所示。

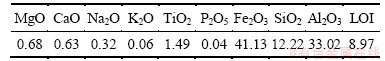

表1 广西高铁铝土矿化学组成(质量分数)

Table 1 Chemical composition of Guangxi ferric bauxite %

图1 高铁铝土矿XRD图谱

Fig. 1 XRD pattern of ferric bauxite

图2 高铁铝土矿矿相照片

Fig. 2 Mineralogical microscope photo of ferric bauxite ore

表1表明:原矿中的主要有价元素为铝和铁,主要杂质元素是硅。原矿中的磷含量较低,不需考虑单独脱磷。

图2表明:原矿中的含铝矿物主要包括一水硬铝石、一水软铝石和高岭石。含硅矿物主要为高岭石。含铁矿物为赤铁矿和少量水针铁矿。该高铁铝土矿中主要矿物的嵌布粒度较细,互相胶结,共生情况比较复杂。根据XRD所得矿物组成和表1中的化学组成计算,原矿中68.54%的氧化铝以一水硬铝石和一水软铝石形式存在。

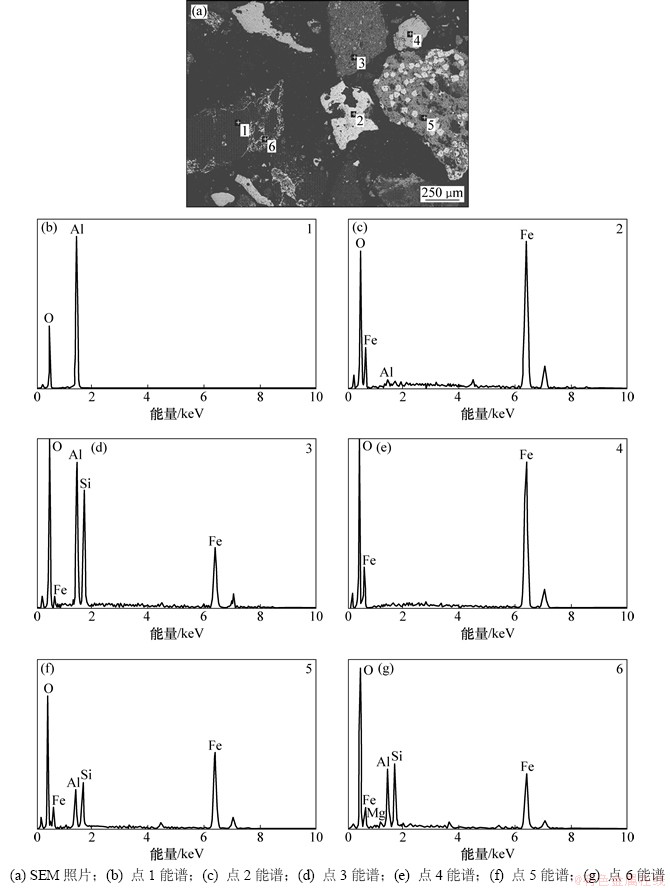

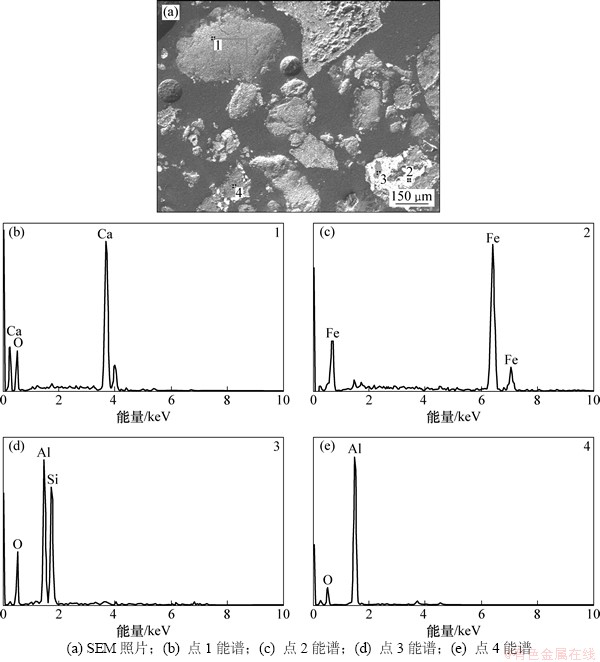

原矿中的一水硬铝石、赤铁矿和高岭石SEM照片及EDS能谱分析如图3所示。从图3所示的SEM照片和EDS能谱图可以看出:原矿中的微细粒赤铁矿与高岭石相互胶结、紧密共生,铝、铁分离困难,因此回收和获得合格铁精矿是综合利用该铝土矿的难点之一。

图3 高铁铝土矿原矿SEM照片及能谱分析结果

Fig. 3 SEM photo and EDS patterns of ferric bauxite ore

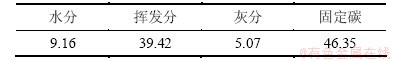

本实验所用的还原煤采自云南某地,工业分析如表2所示,灰分多元素分析如表3所示。

表2 还原煤工业分析(质量分数)

Table 2 Proximate analysis of coal adopted %

表3 煤灰分多元素分析(质量分数)

Table 3 Chemical composition of coal ash %

该褐煤挥发份高、灰分低,灰分矿物质对试验影响小,可以满足研究需要;试验所用生石灰(AR)购自国药集团化学试剂北京有限公司。

1.2 实验仪器 和分析方法

主要实验设备:XMB-70三辊四筒棒磨机;CGME-8/200箱式电阻炉;CXG-99磁选管;AR1140电子天平;XTLZ过滤机;PH050干燥箱。

分析方法:化学成分使用IRIS Intrepid II XSP型电感耦合等离子体发射光谱仪分析;XRD使用Rigaku D/MAX-rA粉晶X线衍射仪分析。

原矿及还原熟料的表面形貌采用ZEISS EVO18扫描电子显微镜及附属能谱仪分析。

1.3 实验方法

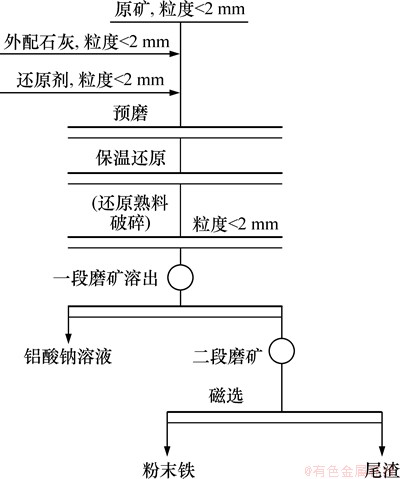

试验工艺流程如图4所示。

将原矿破碎至粒度低于2 mm,与还原煤、碳酸钙粉末、纯碱粉末混匀,并磨矿至合适粒度后高温还原。还原熟料按磨矿浓度50%磨至粒度低于0.074 mm,于75 ℃水浴中溶出并过滤出铝酸钠溶液,化验氧化铝浓度并计算氧化铝溶出率(ηA)。滤渣经二次磨矿至粒度低于0.045 mm后磁选(1 480 Gs)、干燥后得到粉末铁(颗粒状的单质铁),化验其品位,并以T(Fe)表示,计算回收率,并以ε(Fe)表示。

粉末铁回收率的计算方法:

(1)

(1)

其中:α为高铁铝土矿原矿铁品位,%;θ为粉末铁品位,%;γ为粉末铁产率,%。

氧化铝溶出率ηA的计算方法为:

(2)

(2)

图4 工艺流程图

Fig. 4 Process flow chart

其中:ρ为溶出液氧化铝的质量浓度,g/L;V为溶出液体积,L;m为试验矿样中氧化铝质量,g。

2 试验结果与讨论

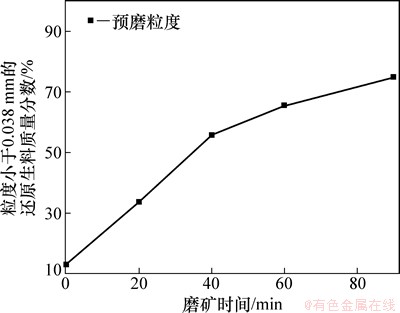

CaO热稳定性较好,参与固相反应的活性低。为了提高CaO的利用率,将-2 mm的石灰、还原煤和原矿混匀、共磨以改善颗粒间的接触条件。还原生料的磨矿曲线如图5所示。

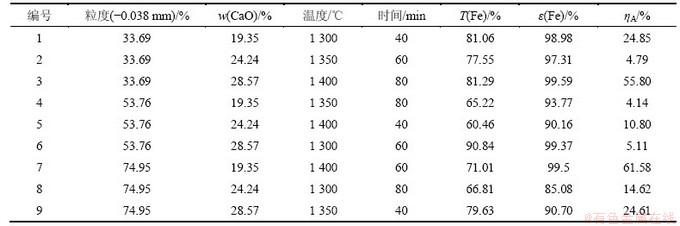

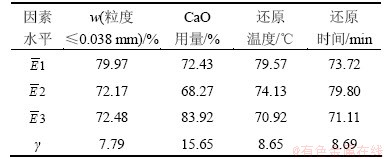

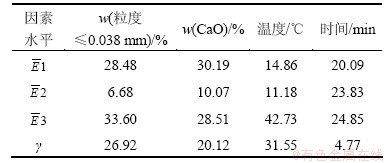

正交试验因素水平如表4所示,T(Fe), ε(Fe)和ηA极差分析如表5~7所示。

图5 石灰法生料预磨磨矿曲线

Fig. 5 Grinding curve of clinker lime direct reduction sinter process

表4 石灰法正交试验因素水平表

Table 4 Quadrature level pilot factor table of lime method

表5 T(Fe)数据极差分析

Table 5 Range analysis of T(Fe)

表6 ε(Fe)数据极差分析

Table 6 Range analysis of ε(Fe)

表7 ηA数据极差分析

Table 7 Range analysis of ηA

2.1 CaO用量对粉末铁T(Fe)的影响

金属化率、铁颗粒与熔渣之间的解离程度都是粉末铁T(Fe)的影响因素。CaO用量增加,物料的流动性提高,有利于铁颗粒与熔渣之间的解离。从表4和表5可看出:CaO用量对粉末铁T(Fe)的影响最大,表明粉末铁颗粒与熔渣之间的解离程度是影响粉末铁T(Fe)的主要因素,金属化率居于次要地位。

2.2 温度对粉末铁T(Fe)的影响

试验中发现生成的粉末铁颗粒普遍较大,且内部有夹杂,见图6(d)(表4中7#试验)。粉末铁T(Fe)随温度升高而降低,主要是因为温度升高时夹杂物含量升高。这再次表明粉末铁T(Fe)的主要影响因素是铁颗粒与熔渣之间的解离程度,而不是金属化率。因为金属化率主要取决于气氛的还原性,后者与温度与相关[7]。作为直接还原反应,表6中各条件的试验温度都比较高,对应的气氛还原性较强,故不同试验温度下金属化率差别并不显著。

2.3 还原时间对粉末铁T(Fe)的影响

从表4试验结果中看出:还原时间对粉末铁T(Fe)的影响较小,这主要是由于金属化率不是粉末铁T(Fe)的主要影响因素,且表4中各试验反应温度高,还原反应迅速发生,不同还原时间下金属化率差异不大,故还原时间的影响不显著,影响金属粉末铁T(Fe)的主要因素是铁颗粒与熔渣的解离速度。

2.4 预磨粒度对粉末铁T(Fe)的影响

预磨粒度决定了生料中含铁、铝矿物与脉石之间的单体解离度。但还原后粉末铁颗粒聚集,铁颗粒与熔渣之间的共生关系并不取决于生料中矿物的单体解离程度,而主要与铁颗粒形成过程中混入的夹杂物数量相关。故预磨粒度对粉末铁T(Fe)的影响也较小。

2.5 预磨粒度对粉末铁ε(Fe)的影响

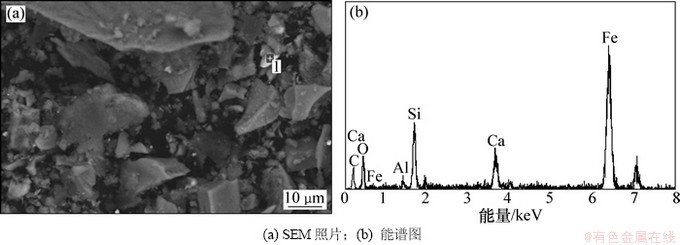

预磨粒度是粉末铁ε(Fe)的主要影响因素。预磨粒度降低,可使原矿中微细粒含铁矿物颗粒的含量提高,其还原生成的微细粒单质铁难以聚集长大,在磨矿磁选过程中容易损失于尾渣之中。故粉末铁ε(Fe)随预磨粒度的降低而逐渐降低。损失于尾渣之中的微细粒单质铁颗粒如图7所示。

图6 石灰法还原熟料扫描电镜照片

Fig. 6 SEM of reduction clinker

图7 石灰法磁选尾渣SEM照片及能谱分析结果

Fig. 7 SEM photo of magnetic separation tailings and EDS of point 1

2.6 CaO用量对粉末铁ε(Fe)的影响

CaO用量决定物料的二元碱度、软熔温度和粘度,而体系黏度较低时有利于微细粒单质铁聚集和长大[14]。因此,CaO用量对粉末铁ε(Fe)的影响可能主要体现在其对物料流动性的影响上。

2.7 还原时间对粉末铁ε(Fe)的影响

如前所述,微细粒单质铁流失于尾渣是铁元素损失的主要形式。还原时间延长有利于微细粒单质铁聚集和长大,减少流失量。但随着还原时间的进一步延长,回收率有降低趋势。这可能是因为高温下还原煤消耗较快,导致金属化率略微降低,少量非磁性铁元素损失于尾渣的缘故。但由于试验过程中粉末铁回收率普遍较高,损失于尾渣之中的铁元素量较少,在产品检查过程中并未发现尾渣中的非磁性铁,该推测尚需进一步研究证实。

2.8 还原温度对粉末铁ε(Fe)的影响

试验选取的温度较高,目的是为保证氧化铝溶出率。由于试验温度普遍超过回收铁所必需的温度,因此还原温度对粉末铁ε(Fe)的影响不显著。

2.9 还原温度对ηA的影响

由于CaO的活性较低,如图6(b)所示。反应结束后,大部分CaO仍以氧化物的形式存在。反应温度升高有利于强化CaO与Al2O3反应,增加碱溶性铝酸钙的生成量。因此,为保证氧化铝溶出,需要在较高的温度下保温。但温度过高会增加粉末铁中的夹杂物,导致粉末铁T(Fe)降低。由于铝、铁矿物转化所需的温度存在矛盾,难以同时实现铝、铁矿物的高效转化。

2.10 预磨粒度对ηA的影响

预磨粒度决定生料中矿物的单体解离程度。碱溶性的铝酸钙是固相反应的产物,预磨粒度降低有利于改善颗粒间的接触,促进固相反应发生。故预磨粒度最小时氧化铝ηA最高。

2.11 CaO用量对ηA的影响

CaO的反应活性较低,添加量较低时其对反应物的稀释作用占主导地位,故ηA随CaO用量增加而降低。虽然CaO在体系中的活度较低,但随着CaO用量的增加,固相反应系统的碱度和物料的流动性逐渐提高,有利于质量和热量传递。因而ηA随CaO用量增加先降低后提高。

2.12 还原时间用量对ηA的影响

氧化铝ηA随时间延长增长缓慢。这是因为试验选取的温度较高,高温下铝酸钙快速生成并接近最大生成量,继续延长反应时间意义不大。

综上可见:生石灰的热稳定性好,在表4中条件6之下,大部分CaO及Al2O3以氧化物的形式存在(分别见图6(a)和(e)),石灰反应活性低是碱溶性氧化铝生成量少的根本原因。提高活性主要依靠升高反应温度,但会导致铁颗粒中夹杂物含量增加,降低粉末铁T(Fe)并限制氧化铝溶出(夹杂与单质铁内部的铝酸钙无法溶出)。直接还原-石灰烧结过程中的铝、铁矿物转化所需的反应温度不一致,难以同时实现铝、铁矿物的高效转化。

3 矿物转化机理分析

直接还原-石灰烧结过程中,含铁矿物与石灰之间主要存在以下反应:

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

(7)

(7)

图6和图7中还原熟料与磁选尾渣的EDS结果表明:原矿中的含铁矿物在还原后几乎全部以单质铁形式存在。这表明还原气氛中,以铁酸钙(CaO·Fe2O3)和赤铁矿(Fe2O3)形式存在的铁元素均可以被还原,该结论与前期研究[13]相一致。且在赤铁矿还原为单质铁之前,以固相反应的形式生成铁酸盐不会影响粉末铁回收率的提高。石灰石存在时,氧化铝矿物在保温过程中主要发生以下反应:

Al2O3·H2O(一水硬铝石或一水软铝石)+CaO (8)

(8)

Al2O3·(2-x)SiO2·2H2O(高岭石)+CaO (9)

(9)

但试验表明:原矿中的氧化铝仅有61.58%转化为碱溶性的铝酸钙,其余的仍以氧化物的形式存在。而原矿中68.54%的氧化铝以一水硬铝石和一水软铝石形式存在。这表明至少有一部分一水硬铝石和一水软铝石中的氧化铝发生式(10)所示反应。

Al2O3·H2O(一水硬铝石或一水软铝石) (10)

(10)

反应生成的刚玉不溶于碱,导致氧化铝溶出率偏低。直接还原-石灰烧结反应后,部分氧化铝以硅酸盐的形式存在(图6(d))。这部分硅酸盐是原矿中的高岭石热解生成的γ-Al2O3和非晶态二氧化硅,在高温下相互作用,共同莫来石化的产物。其形成机理如式(11)和式(12)所示。

(11)

(11)

(12)

(12)

可见:原矿中一水硬铝石、一水软铝石和高岭石中的一部分氧化铝转化为碱溶性的铝酸钙,剩余的一水硬铝石、一水软铝石转化为刚玉,高岭石转化为莫来石。刚玉和莫来石不溶于碱,导致总氧化铝溶出率较低。

4 结论

(1) 高铁铝土矿与石灰烧结法的正交试验结果表明:反应活性低,是碱溶性氧化铝生成量少的根本原因。提高活性主要依靠升高反应温度,但会导致铁颗粒中夹杂物含量增加,降低粉末铁T(Fe)并限制氧化铝溶出(夹杂与单质铁内部的铝酸钙无法溶出)。直接还原-石灰烧结过程中的铝、铁矿物转化所需的反应温度不一致,难以同时实现铝、铁矿物的高效转化。试验获得的最佳条件如下:预磨粒度(<0.038 mm)的质量分数为74.95%,石灰用量为19.35%,还原温度为1 400 ℃,还原时间为60 min;获得的最佳指标为:T(Fe) 71.01%,ε(Fe) 99.5%,ηA61.58%。

(2) 原矿中的一水硬铝石、一水软铝石和高岭石中的一部分氧化铝在反应过程中转化为碱溶性的铝酸钙,剩余的一水硬铝石、一水软铝石转化为刚玉,高岭石转化为莫来石。由于刚玉和莫来石不溶于碱,导致总氧化铝溶出率较低。

参考文献:

[1] 周长春, 刘炯天, 李振,等. 中低品位铝土矿浮选柱短流程分选研究[J]. 中国矿业大学学报, 2010, 39(1): 116-120.

ZHOU Changchun, LIU Jiongtian, LI Zhen, et al. Study of short flowsheet separation with flotation column for middle low grade bauxite[J]. Journal of China University of Mining & Technology, 2010, 39(1): 116-120.

[2] Deng J, Wang Q, Yang S, et al. Genetic relationship between the emeishan plume and the bauxite deposits in western Guangxi, China: Constraints from U-Pb and Lu-Hf isotopes of the detrital zircons in bauxite ores[J]. Journal of Asian Earth Sciences, 2010, 37: 412-424.

[3] 孙德四, 陈晔, 曹飞. 细菌-矿物接触方式对铝土矿降解的影响[J]. 中国矿业大学学报, 2013, 42(1): 122-128.

SUN Desi, CHEN Ye, CAO Fei. Influence of microbe-mineral contact model[J]. Journal of China University of Mining & Technology, 2013, 42(1): 122-128.

[4] Mutakyahwa M K D, Ikingura J R, Mruma A H. Geology and geochemistry of bauxite deposits in Lushoto District, Usambara Mountains, Tanzania[J]. Journal of African Earth Sciences, 2003, 36: 357-369.

[5] Chen Q, Guan H Q, Xiong H. World aluminum industry resourcesexploration and utilization state of bauxite and alumina[J]. World Nonfeerous Metals, 2007(1): 27-28.

[6] 胡文韬, 王化军, 孙传尧, 等. 高铁铝土矿直接还原-溶出工艺研究. 北京科技大学学报, 2012, 34(5): 506-511.

HU Wentao, WANG Huajun, SUN Chuanyao, et al. Direct reduction-leaching process for high ferric bauxite[J]. Journel of University of Science and Technology Beijing, 2012: 34(5): 506-511.

[7] 胡四春, 赵恒勤, 马化龙, 等. 高铁铝土矿中温金属化焙烧-磁选工艺试验研究[J]. 轻金属, 2010(9): 6-10.

HU Sichun, ZHAO Hengqin, MA Hualong, et al. Tests on medium temperature metal-based roasting-magnetic separation of high ferrous bauxite[J]. Light Metal, 2010(9): 6-10.

[8] 孙娜. 高铁三水铝石型铝土矿中铁铝硅分离的研究[D]. 长沙: 中南大学, 2010: 1-5.

SUN Na. Study on iron-alumininm-silicon separation of high iron content gibbsite-type bauxite ores[D]. Changsha: Central South University, 2010: 1-5.

[9] 朱忠平. 高铁三水铝石型铝土矿综合利用新工艺的基础研究[D]. 长沙: 中南大学, 2011: 1-8.

ZHU Zhongping. Fundamental research on the new process of comprehensive utilization of high iron gibbsite-type bauxite ores[D]. Changsha: Central South University, 2011: 1-8.

[10] 胡文韬, 王化军, 孙传尧, 等. 还原气氛中碱石灰与高铁铝土矿间的作用机理[J].哈尔滨工程大学学报, 2013, 34(5): 662-668.

HU Wentao, WANG Huajun, SUN Chuanyao, et al. Mechanism of reaction between ferric bauxite and soda lime in the reduction atmosphere[J]. Journal of Harbin Engineering University, 2013, 34(5).

[11] 胡文韬, 王化军, 季春伶, 等. 基于直接还原的高铁铝土矿选择性富集[J]. 中南大学学报(自然科学版), 2012, 43(10): 3755-3762.

HU Wentao, WANG Huajun, JI Chunling, et al. Selective enrichment of ferric bauxite based on directreduction process[J]. Journal of Central South University (Science and Technology), 2012, 43(10): 3755-3762.

[12] 胡文韬, 王化军, 孙传尧, 等. 直接还原-烧结系统中铁颗粒聚集体的形成与金相组织研究[J]. 中南大学学报(自然科学版), 2013, 44(8).

HU Wentao, WANG Huajun, SUN Chuanyao, et al. Study on the formation progress and metallographic structure of iron grain aggregates in a reduction- sintering system[J]. Journal of Central South University (Science and Technology), 2013, 44(7).

[13] 廉树杰, 许力贤. 二元铁酸钙还原行为的研究[J]. 烧结球团, 2006, 31(4): 7-10.

LIAN Shujie, XU Lixian. Research of reduction behavior of binary calcium ferrite[J]. Sintering and Pelletizing, 2006, 31(4): 7-10.

(编辑 何运斌)

收稿日期:2013-07-16;修回日期:2013-09-09

基金项目:国家自然科学基金资助项目(51304012);中国博士后科学基金资助项目(2013M530529);钢铁冶金新技术国家重点实验室开放基金资助项目(KF13-05)

通信作者:王化军(1963-),男,内蒙古伦族人,教授,从事难选冶含铁矿物资源综合利用研究;电话:010-62332902;E-mail:wanghuajun@bjjzq.com