添加Co, Ni和Mo对钛铁矿原位合成Al2O3-Ti(C,N)-Fe复合材料的影响

刘胜明,汤爱涛,赵子鹏

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:在钛铁矿原位反应合成Al2O3-Ti(C,N)-Fe复合材料的基础上,添加Co,Ni和Mo来改善Al2O3-Ti(C,N)-Fe复合材料的性能。通过物相分析、扫描电镜和力学检测手段研究不同金属添加剂对合成产物物相、组织和性能的影响。研究结果表明:添加Co和Ni以后在烧结过程中分别形成了含Co和Ni的[Fe,Co]及[Fe,Ni]固溶相,材料的硬度有所降低,抗弯强度有所提高但提高的幅度不大。Mo的添加阻碍了Ti(C,N)相的长大,细化了Ti(C,N)晶粒;在烧结过程中生成的Mo2C包覆在Ti(C,N)相的周围,改善了Ti(C,N)相与Al2O3相和Fe相的润湿性,这同时导致了材料硬度和抗弯强度升高。当Mo添加量为8%时,烧结材料的力学性能最佳,抗弯强度和硬度分别为476 MPa和19.4 GPa。

关键词:Co;Ni;Mo;钛铁矿;Al2O3-Ti(C,N)-Fe;组织;力学性能

中图分类号:TB333 文献标志码:A 文章编号:1672-7207(2014)08-2589-07

Influence of Co, Ni and Mo on microstructure and properties of Al2O3-Ti(C,N)-Fe composite by in-situ synthesis from ilmenite

LIU Shengming, TANG Aitao, ZHAO Zipeng

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: Based on the of in-situ synthesis of Al2O3-Ti(C,N)-Fe composite from ilmenite, the elements Co, Ni and Mo were added to improve the properties of Al2O3-Ti(C,N)-Fe composite. The phase, microstructure and properties were investigated by using XRD, SEM and mechanical testing means. The results show that [Fe,Co] or [Fe,Ni] solid solution phases are formed during the sintering process by adding Co or Ni, respectively. The hardness of the material decreases and the bending strength increases slightly. The addition of Mo hampers the growth of Ti(C,N) phase and refines the Ti(C,N) grains. The Mo2C phase is formed during the sintering process and clad around the Ti(C,N) phase, which improves the wetting between Ti(C,N) and Al2O3 and Fe, and increases the materials hardness and bending strength. When Mo content is 8%, the sintered materials achieve the best mechanical properties, and the values of bending strength and Vickers hardness are 476 MPa and 19.4 GPa, respectively.

Key words: Co; Ni; Mo; ilmenite; Al2O3-Ti(C,N)-Fe; structure; mechanical properties

钛铁矿资源储量大,分布广,几乎遍及全世界。因为含有丰富的铁和钛资源,钛铁矿主要用于生产二氧化钛、四氯化钛、海绵钛以及钛合金等,而其他方面的用量不大[1]。如何在保证钛白粉和海绵钛等工业应用的同时,增大其他方面的用量,开发高附加值的精细化工产品得到了人们广泛关注。目前,以钛铁矿为主要原料,原位反应合成制备TiC-Fe和Al2O3-TiC-Fe金属陶瓷复合材料已经引起了国内外学者的重视[2-7]。

碳化钛和氮化钛具有相似的结构和性能,它们之间可以形成连续固溶体Ti(C,N)。碳氮化钛是一种性能优良,用途广泛的非氧化物陶瓷材料,它具有熔点高、硬度大、耐腐蚀和抗氧化性好的特点,适用于机械化工、汽车制造和航空航天等许多领域[8-9]。Al2O3-Ti(C,N)金属陶瓷不但具有较高的硬度、耐磨性、红硬性、优良的化学稳定性、与金属间极低的摩擦因数,而且有一定的韧性和强度。与通常的硬质合金相比,在以下几个方面有明显的优势:有较高的切削速度;被加工工件有较好的表面性能;耐磨性能更优良。利用钛铁矿,在氮气气氛下通过铝热碳热原位反应合成,制备了Al2O3-TiCN-Fe复合材料。与通常的陶瓷材料一样,高硬度和高耐磨性等性能优势很明显,但是脆性高,容易断裂始终是陶瓷材料研究中面对的核心问题。本文在钛铁矿通过碳热铝热原位还原反应、采用热压工艺制备Al2O3-Ti(C,N)-Fe复合材料的基础上,添加Ni,Co和Mo金属添加剂来改善Al2O3-Ti(C,N)-Fe复合材料的性能。通过研究Ni,Co和Mo含量对钛铁矿原位反应合成Al2O3-Ti(C,N)-Fe复合材料的组织和性能的影响,寻求合适的添加剂和添加量,以便制备高性能Al2O3-Ti(C,N)-Fe复合材料。

1 实验材料及方法

实验所用原料为攀枝花所产的钛铁精矿,平均粒度为158.26 μm,其化学成分见表1;胶体石墨(颗粒粒度≤30 μm,纯度≥99.0%);铝粉(粒度75 μm,纯度≥99.0%);镍粉(粒度≤100 μm,纯度≥99.0%);钴粉(粒度≤100 μm,纯度≥99.0%);钼粉(粒度≤100 μm,纯度≥99.0%);氮气(纯度≥99.99%)。

表1 钛铁精矿的化学成分(质量分数)

Table 1 Chemical composition of ilmenite powder %

先将FeTiO3,Al粉和C粉按照摩尔比1:2:1配比称取,然后分别加入不同质量分数的金属添加剂进行配料。球磨混合均匀后干燥,然后称取15 g混合料在Φ100-Ⅱ多功能热压炉中实现合成与烧结一体化(氮气气氛,温度1400℃,保温30 min,加压30 MPa)。

烧结样品经线切割、研磨、抛光制成30 mm×3 mm×3 mm的抗弯试样备用;用X线衍射仪(Cu靶、40 kV,30 mA、波长1.540 56×10-10 m;使用单色器滤波,扫描范围为10°~90°,扫描速度为4 (°)/min)测定产物的物相组成;在带有能谱仪(EDS)的TESCAN VEGAⅡLMU型扫描电镜上进行组织观察和分析;抗弯强度在CMT-5105电子万能材料试验机上测定;硬度在HV-50A图像处理维氏硬度计上测量。

2 实验结果与讨论

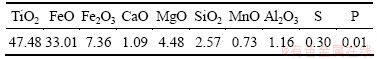

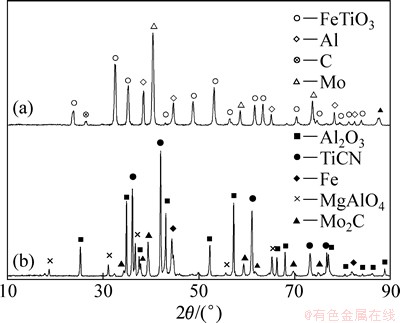

图1所示为不添加时球磨粉料以及于1 400 ℃保温30 min时,压力为30 MPa烧结合成产物的XRD图谱。球磨粉料的XRD结果表明:试样中的主要组成相为FeTiO3,Al和C,没有发现其他钛的中间氧化物TixOy,说明在球磨过程中钛铁矿与铝和碳没有发生化学反应。碳的衍射峰强度比较低,一方面是因为配料时碳的质量分数本身就比较低,另一方面是由于在有Al存在的情况下球磨时碳更容易发生无定形化,造成碳的衍射峰强度变弱[10]。经过烧结以后,合成样品的XRD结果表明:样品中的主要组成相为Al2O3,Ti(C,N),MgAl2O4和Fe相。攀枝花钛铁矿中镁含量在杂质元素中较高,在烧结产物中,镁大多以MgAl2O4的形式出现。由于杂质元素含量高(质量分数为14%左右),在烧结成型后,这些杂质部分溶解在Fe里,部分难溶的分布在相界面上,严重影响烧结材料的性能。在不添加任何添加剂时,材料的抗弯强度和硬度分别为370 MPa和16 GPa左右。

图1 不添加时球磨粉(a)以及烧结合成产物(b)的XRD图谱

Fig. 1 XRD patterns of as-milled powders (a) and sintered product (b) without additives

2.1 Co的添加对Al2O3-Ti(C,N)-Fe复合材料的影响

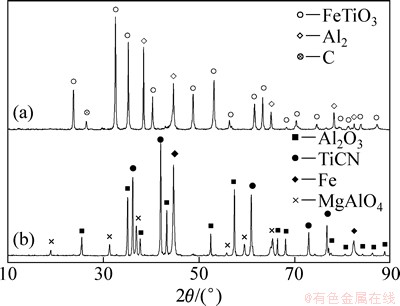

图2所示为添加Co以后球磨粉料以及1400 ℃保温30 min,压力为30 MPa烧结合成产物的XRD图谱。球磨粉料的XRD结果表明:试样中的主要组成相为FeTiO3,Al,C和Co以及微量的AlCo中间合金相。Co相在球磨后以2种形式出现:一部分Co仍以单质的形式出现,另一部分Co以AlCo中间合金的形式出现。这说明在球磨过程中Al和Co发生了机械合金化,生成了少量的AlCo中间合金相。经过烧结以后,合成样品的XRD结果表明样品中的主要组成相为Al2O3,Ti(C,N),MgAl2O4和含Co的[Fe,Co]固溶相。与不添加时相比,[Fe,Co]相的出现说明Co全部溶解在Fe里,形成了[Fe,Co]固溶相。

图2 添加Co后球磨粉(a)以及烧结合成产物(b)的XRD图谱

Fig. 2 XRD patterns of as-milled powders (a) and sintered product (b) after adding Co

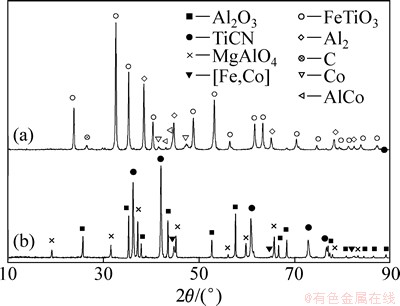

图3所示为不同Co添加量的烧结试样的3000倍背散射扫描电镜照片。通过图像中各区域颜色的区别可以判断其所含的成分,烧结体试样的显微组织中有Al2O3/MgAl2O4相(黑色区域),Ti(C,N)相(灰色区域)和[Fe,Co]相(白色区域)。当Co质量分数为4%时, Ti(C,N)均匀分布在Al2O3基体上,大部分的[Fe,Co]相分布在Ti(C,N)相中间,少部分[Fe,Co]相分布在Al2O3和Ti(C,N)之间,分布较均匀。当Co质量分数为8%时,组织分布的更加弥散,组织也有所细化。当Co质量分数为12%时,组织开始团聚,尤其是Ti(C,N)相和FeCo相。随着Co质量分数的进一步增加为16%时,Ti(C,N)相和FeCo相团聚的更加严重,形成粗大的块状组织,造成组织分布的极不均匀。可以看出随Co质量分数的增加,材料的组织逐渐变得粗大,分散也不均匀。其中当Co质量分数为8%时的组织最细,分散最均匀,因此力学性能也最好,这与力学性能测试结果一致。

图3 不同Co添加量的烧结试样的扫描电镜照片

Fig. 3 SEM photographs of sintered specimens with different Co contents

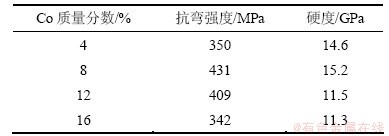

表2所示为不同Co质量分数添加时烧结材料的力学性能。当Co质量分数为4%,12%和16%时,材料的抗弯强度和硬度都偏低;当Co添加量为8%时,烧结材料的力学性能最佳,抗弯强度和硬度分别为431 MPa和15.2 GPa。与不添加时的力学性能相比,添加Co以后材料的硬度有所降低,这是由于烧结后生成的[Fe,Co]相属于金属固溶相,硬度较陶瓷材料低,造成材料的硬度降低。材料的抗弯强度有所提高,但是提高的幅度不大。Shi等[11]指出,在1 250~1 650 ℃烧结时,金属Co逐步熔化,在Al2O3和TiC颗粒表面形成薄层液相,进一步降低陶瓷颗粒间的摩擦阻力,同时,表面张力发挥作用,将陶瓷颗粒拉得更加近,形成新的致密排列结构,从而提高材料的抗弯强度。在本实验中,由组织图片可以看出:[Fe,Co]相并没有包覆在硬质相(Al2O3和Ti(C,N))的周围,大部分[Fe,Co]相分布在Ti(C,N)相中间,这样就影响了Co添加对韧性的贡献,造成抗弯强度有所提高但提高的幅度不大。

表2 不同Co添加量烧结试样的抗弯强度和硬度

Table 2 Bending strength and Vickers hardness of sintered specimen with different Co contents

2.2 Ni的添加对Al2O3-Ti(C,N)-Fe复合材料的影响

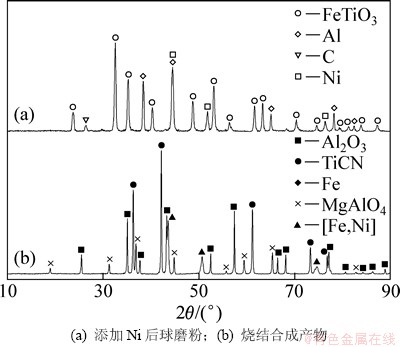

图4所示为添加Ni以后球磨粉料以及1 400 ℃保温30 min,压力为30 MPa烧结合成产物的XRD图谱。球磨粉料的XRD结果表明:试样中的主要组成相为FeTiO3,Al,C和Ni相,没有其他相的出现。这说明在球磨过程中没有发生化学反应,同时,Al和Ni也没有发生机械合金化,仍然以Ni单质的形式出现。经过烧结以后,合成样品的XRD结果表明:样品中的主要组成相为Al2O3,Ti(C,N),MgAl2O4和含Ni的[Fe,Ni]固溶相。与不添加时相比,[Fe,Ni]相的出现说明烧结以后Ni全部溶解在Fe里,形成了[Fe,Ni]固溶相。

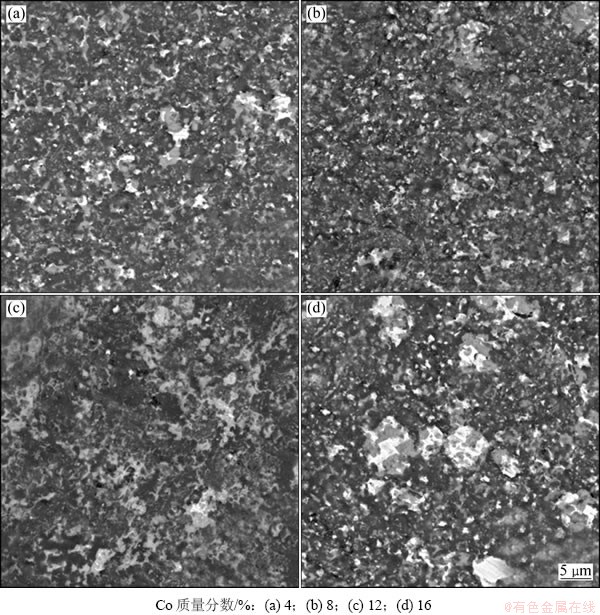

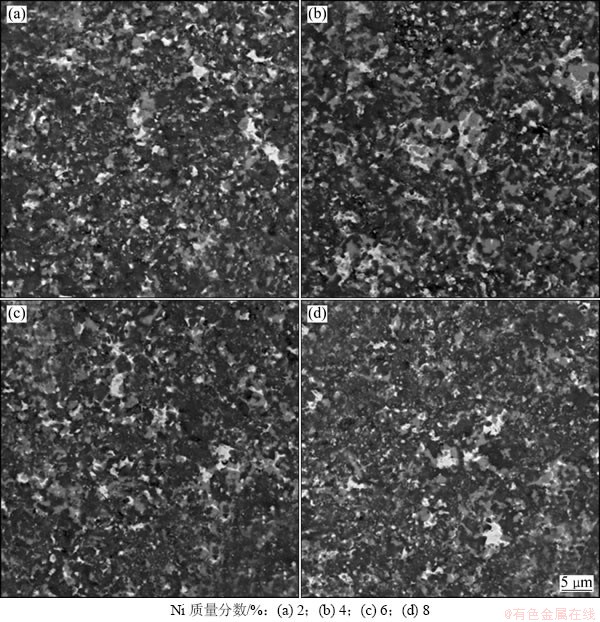

图5所示为不同Ni添加量的烧结试样的3 000倍背散射扫描电镜照片。其中白色区域为[Fe,Ni]固溶相。组织分布与添加Co时的类似,Ti(C,N)均匀分布在Al2O3基体上,大部分[Fe,Ni]固溶相分布在Ti(C,N)相中间,少部分分布在Al2O3和Ti(C,N)之间,分布较均匀。从图5可以看出:随Ni质量分数的增加,材料的组织分布没有显著变化,分散都比较均匀。

图4 添加Ni后球磨粉以及烧结合成产物的XRD图谱

Fig. 4 XRD patterns of as-milled powders and sintered product after adding Ni

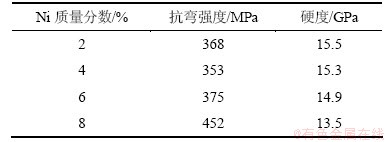

表3所示为添加不同质量分数Ni时烧结材料的力学性能。由表3可见,随着Ni质量分数的增加,材料的硬度逐渐降低。这是由于烧结后生成的[Fe,Ni]相属于金属固溶相,硬度较陶瓷材料低,造成材料的硬度降低。材料的抗弯强度随着Ni质量分数的增加整体上呈上升趋势,只是在质量分数为4%时,材料的抗弯强度出现波动,抗弯强度偏低。当Ni质量分数为8%时,烧结材料抗弯强度和硬度分别为452 MPa和13.5 GPa。

金属Ni颗粒的增韧效应主要是由于金属颗粒的塑性变形和氧化铝晶粒细化,与氧化铝热膨胀系数不匹配出现应力场。根据实验结果推断出Ni提高复合材料的断裂韧性可能存在以下几方面原因:一是添加相金属Ni属于面心立方结构,力学性能上具有较好韧性,塑性变形能力强,能吸收外部部分冲击能量;二是添加相金属Ni与复合材料基体之间的结合产生界面性能较好,颗粒部分分布在晶界上,起到阻碍了裂纹沿晶扩展作用;三是第二相金属Ni颗粒及基体颗粒均较细小,且第二相Ni颗粒能在基体中弥散分布,这有利于材料致密度提高,同时也有利于基体本身韧性的提高[12]。而在本实验中,由于合成产物中有一部分的Fe相,造成添加Ni以后与铁固溶生成了[Fe,Ni]相,而[Fe,Ni]相并没有包覆在硬质相(Al2O3和Ti(C,N))的周围,大部分[Fe,Ni]相分布在Ti(C,N)相中间,这种分布就达不到提高材料韧性的目的,造成了抗弯强度有所提高但提高幅度不大。

图5 不同Ni添加量的烧结试样的扫描电镜照片

Fig. 5 SEM photographs of sintered specimens with different Ni contents

表3 不同Ni添加量的烧结试样的抗弯强度和硬度

Table 3 Bending strength and Vickers hardness of sintered specimen with different Ni contents

2.3 Mo的添加对Al2O3-Ti(C,N)-Fe复合材料的影响

图6所示为添加Mo后的球磨粉料以及于1 400 ℃保温30 min,压力为30 MPa烧结合成产物的XRD图谱。球磨粉料的XRD结果表明:试样中的主要组成相为FeTiO3,Al,C和Mo相,没有其他相出现。这说明在球磨过程中没有发生化学反应,同时,Al和Mo也没有发生机械合金化,仍然以Mo单质的形式出现。经过烧结以后,合成样品的XRD结果表明:样品中的主要组成相为Al2O3,Ti(C,N),MgAl2O4,Fe和Mo2C相。与不添加时相比,Mo2C相的出现说明Mo在烧结过程中与碳反应,生成了Mo2C相。

图6 添加Mo后球磨粉(a)以及烧结合成产物(b)的XRD图谱

Fig. 6 XRD patterns of as-milled powders (a) and sintered product (b) after adding Mo

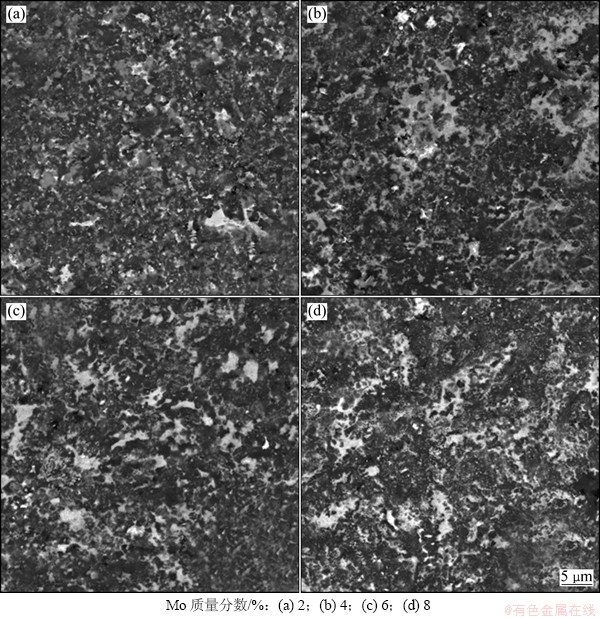

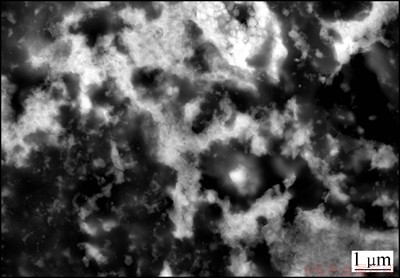

图7所示为不同Mo添加量的烧结试样的3 000倍背散射扫描电镜照片。组织分布与添加Co和Ni的类似,Ti(C,N)均匀分布在Al2O3基体上,分布较均匀。从图7可以看出:随着Mo质量分数的增加,组织中的Ti(C,N)相变得越来越亮,而Ti(C,N)相和Fe相的衬度也不再那么明显。图8所示为添加8% Mo时的10 000倍背散射扫描电镜照片。由图8可以看出:在Ti(C,N)相上有很多条纹交错分布,把Ti(C,N)相分割成很小的块状结构,包覆在Ti(C,N)相颗粒的周围。这说明Mo的添加可以抑制烧结时的碳化物晶粒长大。何林等[13-14]研究发现:Mo2C在加热过程中,1 100 ℃以下与Ti(C,N)发生固态反应生成(Mo,Ti)(C,N)固溶体;1 300 ℃时Ti(C,N)和(Mo,Ti)(C,N)颗粒溶解和沉淀在Ti(C,N)周围,开始生成(Mo,Ti)(C,N)环形相,对Ti(C,N)相起到很好的包覆作用。

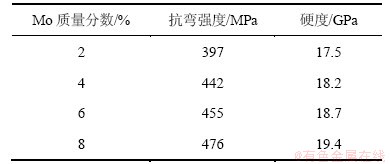

表4所示为不同Mo质量分数添加时烧结材料的力学性能。由表4可见:随着Mo质量分数的增加,材料的硬度和抗弯强度都逐渐升高,而且与不添加相比,材料的硬度和抗弯强度都得到了大幅度提高。由于烧结后生成的Mo2C相属于陶瓷相,硬度本身就比较高,对材料的硬度有一定贡献。此外,Mo的添加阻碍了Ti(C,N)相的长大,细化了Ti(C,N)晶粒;生成的Mo2C包覆在Ti(C,N)相的周围,改善了Ti(C,N)相与Al2O3相和Fe相的润湿性,提高了材料的致密度,这些都同时造成了材料硬度和抗弯强度升高。当Mo质量分数为8%时,烧结材料的力学性能最佳,抗弯强度和硬度分别为476 MPa和19.4 GPa。

表4 不同Mo添加量的烧结试样的抗弯强度和硬度

Table 4 Bending strength and Vickers hardness of sintered specimen with different Mo contents

图7 不同Mo添加量的烧结试样的扫描电镜照片

Fig. 7 SEM photographs of sintered specimen with different Mo contents

图8 添加量为8%Mo的烧结试样扫描电镜照片

Fig. 8 EBSD photographs of sintered specimen with 8% Mo

3 结论

(1) 添加Co后,在球磨以后大部分的Co仍以单质的形式出现,另一小部分Co和Al发生了机械合金化,生成了少量的AlCo中间合金相;经过烧结以后,Co全部溶解在Fe里,形成了含Co的[Fe,Co]固溶相。随Co质量分数的增加,材料的组织逐渐变粗大,分散不均匀。其中Co质量分数为8%时的组织最细,分散最均匀。当Co质量分数为8%时,烧结材料的力学性能最佳,抗弯强度和硬度分别为431 MPa和15.2 GPa。

(2) 添加Ni以后在烧结过程中与Fe形成了含Ni的[Fe,Ni]固溶相,而[Fe,Ni]相并没有包覆在硬质相(Al2O3和Ti(C,N))的周围,大部分[Fe,Ni]相分布在Ti(C,N)相中间,这种分布达不到提高材料韧性的目的,造成了抗弯强度有所提高但是提高的幅度不大。随Ni质量分数的增加,反应合成材料的硬度降低,抗弯强度整体上呈现上升的趋势。当Ni质量分数为8%时,烧结材料抗弯强度和硬度分别为452 MPa和13.5 GPa。

(3) 添加Mo以后在烧结过程中生成了Mo2C相,Mo2C相属于陶瓷相,硬度本身就比较高,对材料的硬度有一定的贡献。此外,Mo的添加阻碍了Ti(C,N)相的长大,细化了Ti(C,N)晶粒;生成的Mo2C包覆在Ti(C,N)相的周围,改善了Ti(C,N)相与Al2O3相和Fe相的润湿性,提高了材料的致密度,这些都同时造成了材料硬度和抗弯强度升高。当Mo质量分数为8%时,烧结材料的力学性能最佳,抗弯强度和硬度分别为476 MPa和19.4 GPa。

参考文献:

[1] 杨佳, 李奎, 汤爱涛. 钛铁矿资源综合利用现状与发展[J]. 材料导报, 2004, 18(8): 44-46.

YANG Jia, LI Kui, TANG Aitao, et al. Comprehensive utilization of ilmenite resources: Present status and future prospects[J]. MaterialsReview, 2004, 18(8): 44-46.

[2] Wang Y M, Yuan Z F, Guo Z C, et al. Reduction mechanism of natural ilmenite with graphite[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 962-968.

[3] Razavi M, Rahimipour M R. Effect of mechanical activation on syntheses temperature of TiC reinforced iron-based nano-composite from ilmenite concentrate[J]. Ceramics International, 2009, 35(8): 3529-3532.

[4] Willis P E, Welham N J, Kerr A. Ambient temperature formation of an alumina-titanium carbide-metal ceramic[J]. Journal of the European Ceramic Society, 1998, 18: 701-708.

[5] Kerr A, Welham N J, Willis P E. Low temperature mechanochemical formation of titanium carbonitride[J]. Nanostructured Materials, 1999, 11(2): 233-239.

[6] Zou Z G, Wu Y, Yin C Q, et al. Preparation of Fe-Al intermetallic/TiC-Al2O3 ceramic composites from ilmenite by SHS[J]. Journal of Wuhan University of Technology (Materials Science), 2007, 22: 706-709.

[7] Razavi M, Rajabi Zamani A H, Rahimipour M R, et al. Synthesis of Fe-TiC-Al2O3 hybrid nanocomposite via carbothermal reduction enhanced by mechanical activation[J]. Ceramics International, 2011, 37(2): 443-449.

[8] 李江, 潘裕柏, 宁金威. 氧化铝陶瓷低温烧结的研究现状与发展前景[J]. 中国陶瓷, 2001, 37(5): 41-45.

LI Jiang, PAN Yubai, NING Jinwei. Low temperature sintering of alumina ceramics[J]. China ceramics, 2001, 37(5): 41-45.

[9] 仇启缘, 赵维新, 傅志刚. 陶瓷刀具的推广应用[J]. 硬质合金, 1991, 8(1): 44-48.

QIU Qiyuan, ZHAO Weixin, FU Zhigang. The promotion and application of ceramic tool[J]. Cemented Carbide, 1991, 8(1): 44-48.

[10] Wang Z Q , Liu X F , Zhang J Y , et al. Reaction mechanism in an Al-TiO2-C system for producing in situ Al(TiC+Al2O3) composite[J]. Journal of Materials Science, 2004, 39: 667-669.

[11] Shi R X, Li J, Wang D Z, et al. Mechanical properties and thermal shock resistance of Al2O3-TiC-Co composites[J]. Materials Engineering and Performance, 2009, 18(4): 414-419.

[12] 李合琴, 何晓雄, 曹闰. 纳米Ni-20Fe颗粒增韧Al2O3复合材料的力学性能与磁性能[J]. 复合材料学报, 2006, 23(3): 103-107.

LI Heqin, HE Xiaoxiong, CAO Run, et al. Mechanical and magnetic properties of nano-Ni-20Fe toughening alumina-based nanocomposites[J]. Acta Material Compositae Sinica, 2006, 23(3): 103-107.

[13] 何林, 黄传真, 刘玉先, 等. Ti( C, N)基金属陶瓷的力学性能与显微结构的研究[J]. 硅酸盐学报, 2003, 31(3): 324-328.

HE Lin, HUANG Chuanzhen, LIU Yuxian, et al. Microstructure and mechanical properties of Ti( C, N)-based cermets[J]. Journal of The Chinese Ceramic Society, 2003, 31(3): 324-328.

[14] Yang J K, Lee H C. Microstructural evolution during the sintering of a Ti(C, N)-Mo2C-Ni alloy[J]. Materials Science & Engineering A, 1996, 209: 213-217.

(编辑 何运斌)

收稿日期:2013-08-01;修回日期:2013-10-27

基金项目:国家高技术研究发展计划(“863”计划)资助项目(2008AA031101);重庆大学研究生创新基金资助项目(CDJXS10131161)

通信作者:汤爱涛(1963-),女,四川渠县人,教授,博士生导师,从事计算机在材料科学中的应用、镁合金材料、复合材料研究;电话:023-65106120;E-mail:tat@cqu.edu.cn