文章编号:1004-0609(2016)-03-0602-08

室温大气环境下K417G合金及其表面Ni(Co)CrAlYSi涂层的磨损特性

王振生1,彭 真1,杨双双1,郭建亭2,周兰章2,谭清奇1,苏 新1

(1. 湖南科技大学 先进矿山装备教育部工程研究中心,湘潭 411201;

2. 中国科学院 金属研究所,沈阳 110016)

摘 要:研究K417G合金及其表面Ni(Co)CrAlYSi涂层在室温大气环境下的磨损特性。结果表明:K417G合金及其表面Ni(Co)CrAlYSi涂层的磨损受磨损亚表层疲劳脱层和磨损表面环境脆性的共同作用,致使其磨损率高于纯Ni的。在磨损过程中,环境脆性逐渐作用于磨损表面,磨损表面的裂纹源在γ/γ′界面以及碳化物与合金基体界面形核,裂纹既沿着γ/γ′面以及碳化物与合金基体界面扩展,又进入γ′晶粒,呈现沿晶和穿晶混合状。

关键词:K417G合金;Ni(Co)CrAlYSi涂层;Ni3Al;摩擦;磨损;环境致脆

中图分类号:TH117,TG146 文献标志码:A

镍基高温合金广泛地应用于各类军用发动机以及热成型模具、增压涡轮、烟气轮机、玻璃工业、火力发电、石油化工和冶金工业等民用装备[1-2]。由于镍基高温合金部件在磨损工况下的使用性能密切影响着装备的工作效率、可靠性和耐久性等[1-3]。因此,国内外学者对K417、IN718、IN625和IN738等镍基合金的磨损开展了研究[4-8]。研究发现,K417合金室温和高温磨损体积之比为2.64:1,K417合金的室温磨损体积还略高于不锈钢的,二者之比为1.17:1;室温下,K417微动磨损开始阶段以粘着磨损为主,摩擦因数约为1.19,稳定阶段以疲劳脱层为主,摩擦因数约为0.75[8];而高温下形成的釉质氧化膜可以减轻磨损,摩擦因数约为0.32[8]。另外,镍基高温合金部件的机加工性能很差[9-10],磨削加工容易在工件表面产生裂纹,导致工件报废。国内外学者研究磨削工艺与表层硬化等因素产生裂纹的原因[11-12],并通过调整磨削工艺参数减轻表面裂纹,但在实际生产时仍存在诸如工件裂纹等棘手的问题。

因此,针对镍基高温合金的室温磨损性能不足且容易产生裂纹的问题,本文作者研究镍基高温合金的室温磨损特性。鉴于MCrAlY(M-Ni,Co或Ni+Co)涂层作为镍基高温合金的高温防护涂层和热障涂层黏结层,已广泛应用于燃气轮机的叶片及其他热端部件[13-15];且磁控溅射和电火花沉积的NiCrAlY涂层也应用于各类热作模具的高温抗氧化耐磨涂层[16-17]。为了更全面地揭示镍基高温合金部件的微观组织与磨损裂纹之间的关系,本文作者也研究Ni(Co)CrAlYSi涂层的室温磨损特性。

1 实验

1.1 实验材料及方法

铸造镍基高温合金K417G (成分见表1)经固溶处理,线切割切取厚度为10 mm的d 80 mm的电弧离子镀和激光熔敷试样,以及10 mm×10 mm×10 mm的磨损试样。电弧离子镀和激光熔敷试样经金相砂纸逐级打磨到800号,进行喷砂(75 μm玻璃丸,湿喷)和丙酮超声清洗后,待用。选取电解Ni板和NiAl3合金作为磨损对比材料。

K417G激光熔敷试样200℃预热20min,选取粒度为45~75 μm的NiCrAlYSi和NiCoCrAlYSi粉末(见表2),采用CO2激光熔敷设备,在氩气保护下激光熔敷。输出功率4500 W,光斑d 5 mm,扫描速度12 mm/s,送粉速度4~6 g/min,搭接系数0.5。激光熔敷后的试样经300 ℃保温6 h。试样经平面磨床双面磨平后,线切割切取10 mm×10 mm×10 mm的磨损试样。

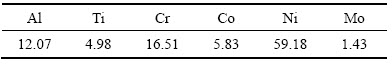

表1 K 417G合金的化学成分

Table 1 Chemical compositions of K417G alloy (mass fraction,%)

表2 Ni(Co)CrAlYSi涂层制备材料的化学成分

Table 2 Chemical compositions of Ni(Co)CrAlYSi coatings

1.2 实验设备及参数

磨损试样表面磨至1200号砂纸后(电弧离子镀试样除外),采用HRS-2M型高速磨损试验机测试摩擦磨损性能。试验条件为:室温(26 ℃)大气环境下,空气相对湿度为70%,对摩件为d 5 mm的Si3N4陶瓷球,载荷为10 N,滑动速度为0.1 m/s。摩擦系数由设备监控,NanoMap-500LS型三维接触式表面轮廓仪测磨损体积,磨损率计算公式为W=V/(FL)(式中,W为磨损率,V为磨损体积损失,F为载荷,L为滑行距离)。取3次实验的平均值。

1.3 分析设备

采用S-3400N(EDS)扫描电子显微镜观察涂层的组织形貌、磨损表面以及横截面形貌;D/max-RB型X射线衍射仪分析涂层的相组成;HV-1000型数显显微硬度计测量材料的显微硬度,加载时间为15 s,载荷为0.5 N,取5次试验结果的平均值。

2 结果与分析

2.1 K417G合金及其表面Ni(Co)CrAlYSi涂层的显微组织与硬度

图1所示为K417G合金及其表面Ni(Co)CrAlYSi涂层的组织形貌。K417G合金的组织主要由γ相、γ′相组成(γ为Ni相,γ′为Ni3(Al,Ti) 相)(见图1(a)),并含有体积分数约为2%的块状MC碳化物[18],蝶形的γ′共格镶嵌于γ基体内。结合Ni(Co)CrAlYSi涂层的XRD谱(见图2),电弧离子镀NiCrAlYSi涂层主要由γ/γ′共晶相(γ为Ni相,γ′为Ni3Al相)和Cr相组成(见图1(b)),并含有少量的NiAl相和Ni2Y相;从涂层的横截面可以看出,涂层厚度约为40 μm,组织基本致密,孔洞很少,与基体合金结合良好,界面处有一层厚约为5 μm的互扩散区(IDZ)。激光熔敷NiCrAlYSi涂层主要由γ/γ′共晶相(γ为Ni相,γ′为Ni3Al相)和Cr相组成(见图1(c)),并含有少量的Ni5Y相和AlCr2相;熔覆层与基体结合处组织形貌呈现垂直于界面方向生长的枝晶,在熔覆熔池中,由于金属结晶择优生长,通过基体散热使得在界面处温度梯度最大,使得该处的结晶方向与界面垂直;涂层与基体界面处有一层厚约15~20 μm呈冶金结合的互扩散区(IDZ),涂层内部存在弥散分布的细小气孔(见图1(d)),这是由于高温时溶解在焊接熔池中的气体在结晶和相变时,气体的溶解度突然下降而残留在焊缝金属内部形成的[19]。NiCoCrAlY涂层主要由γ/γ′共晶相(γ为Ni相,γ′为Ni3Al相)和少量的Al74Cr20Si6相构成(见图1(e)),涂层中存在较多的气孔(见图1(f)),涂层与基体界面处没有互扩散区;互扩散区有利于提高涂层与基体的结合力[20-21],没有互扩散区导致基体与NiCoCrAlY涂层界面出现少量的裂纹特征(见图1(f))。

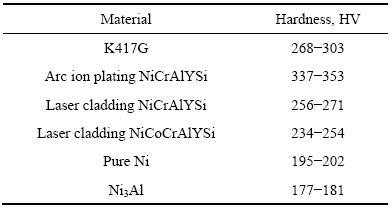

表3所列为K417G合金及其表面Ni(Co)CrAlYSi涂层的硬度。电弧离子镀NiCrAlYSi涂层的硬度最高,这跟电弧离子镀离化率高,薄膜沉积时离子所携带的能量平均值高有关[22]。激光熔敷NiCoCrAlYSi涂层的硬度最低。

2.2 K417G合金及其表面Ni(Co)CrAlYSi涂层的磨损性能

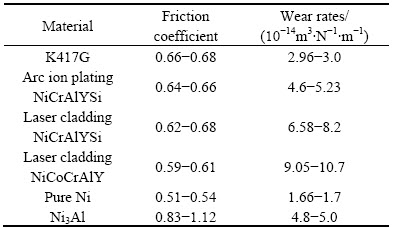

表4所列为K417G合金及其表面Ni(Co)CrAlYSi涂层的摩擦磨损性能。K417G合金、电弧离子镀NiCrAlYSi涂层、激光熔敷NiCrAlYSi涂层以及NiCoCrAlYSi涂层及的摩擦因数分别为0.66~0.68、0.64~0.66、0.62~0.68、0.59~0.61;磨损率分别为2.96×10-14~3.0×10-14、4.6×10-14~5.23×10-14、6.58× 10-14~8.2×10-14、9.05×10-14~10.7×10-14 m3/(N·m)。由图1可以发现,随着K417G合金及其表面Ni(Co)CrAlYSi涂层内部孔洞的增多以及裂纹的发生,材料的磨损率逐渐升高。纯Ni的摩擦因数为0.51~0.54,磨损率为1.66×10-14~1.7×10-14 m3/(N·m),其摩擦磨损性能明显优于经过强化的K417G合金及Ni(Co)CrAlYSi涂层的,其中,磨损率较K417G合金及Ni(Co)CrAlYSi涂层的降低了1.6~6.2倍。Ni3Al合金的摩擦因数为0.83~1.12,磨损率为4.8×10-14~ 5.0×10-14 m3/(N·m),耐磨损性能与电弧离子镀NiCrAlYSi涂层类似。

图1 K417G合金及其表面Ni(Co)CrAlYSi涂层的形貌

Fig. 1 Morphologies of K417G alloy and Ni(Co)CrAlYSi coatings deposited onto K417G alloy

图2 Ni(Co)CrAlYSi涂层的XRD谱

Fig. 2 XRD patterns of Ni(Co)CrAlYSi coatings

2.3 K417G合金及其表面Ni(Co)CrAlYSi涂层的磨损形貌与机理的分析

表3 K417G合金、Ni(Co)CrAlYSi涂层、纯Ni及Ni3Al合金的硬度

Table 3 Hardness of K417G alloy, Ni(Co)CrAlYSi coatings, pure Ni plate and Ni3Al alloy

表4 K417G合金、Ni(Co)CrAlYSi涂层、纯Ni及Ni3Al合金的摩擦磨损性能

Table 4 Friction and wear behavior of K417G alloy, Ni(Co)CrAlYSi coatings ,pure Ni plate and Ni3Al alloy

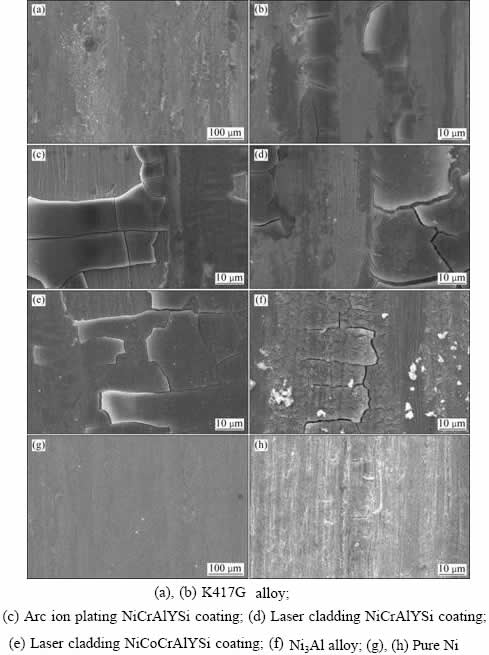

图3所示为K417G合金及其表面Ni(Co)CrAlYSi涂层磨损表面的形貌。由图3(a)可以看出,K417G合金的磨损表面主要呈现剥落和裂纹特征。由图3(b)可以看出,磨损表面呈现显著的平行和垂直于磨损方向的裂纹,剥落是以薄片形状脱离母材的,这与文献[8]观察的特征一致。电弧离子镀NiCrAlYSi涂层(见图3(c))、激光熔敷NiCrAlYSi涂层(见图3(d))和激光熔敷NiCoCrAlY涂层(见图3(e))的磨损表面形貌与K417G合金类似,剥落和裂纹特征随着K417G合金、电弧离子镀NiCrAlYSi涂层和激光熔敷NiCrAlYSi涂层的次序逐渐增强。鉴于K417G合金及其表面Ni(Co)CrAlYSi涂层,主要组成相为γ-Ni相和γ′-Ni3Al(或Ni3(Al,Ti))相,并且相对于Ni3Al合金磨损表面呈现显著的剥落、裂纹和粘着磨损的特征(见图3(f)),纯Ni的磨损表面光滑平整(见图3(g)),高倍下发现显著的犁沟特征,局部存在轻微的裂纹特征(见图3(h))。故γ′-Ni3Al(或Ni3(Al,Ti))相可能导致了K417G合金及其表面Ni(Co)CrAlYSi涂层磨损表面发生了裂纹和剥落,剥落和裂纹可能是K417G合金及其表面Ni(Co)CrAlYSi涂层室温耐磨损性能不足的主要原因。

图3 K417G合金、Ni(Co)CrAlYSi涂层、纯Ni及Ni3Al合金磨损表面的形貌

Fig. 3 Morphologies of worn surface for K417G alloy and Ni(Co)CrAlYSi coatings deposited onto K417G alloy

从K417G合金及其表面Ni(Co)CrAlYSi涂层的磨损表面横截面的形貌可以看到,裂纹主要从磨损表面和磨损亚表层萌生(见图4(a))。磨损表面亚表层存在 疲劳裂纹源的萌生和扩展(见图4(b))特征说明发生了疲劳脱层的磨损机制,这与文献[8]分析的结果一致。

萌生于磨损表面的裂纹在扩展过程中,裂纹扩展路径有直线(见图4(c))和曲线(见图4(d))两种形式,裂纹扩展方向与磨损表面的角度约为10°~20°,EDS分析发现(见图4(d)和表5),裂纹扩展路径两侧Ni与Al+Ti元素之摩尔分数比约为59:17,对比表1中合金的元素成分,说明裂纹可能是沿γ′-Ni3(Al,Ti) 相的晶内或晶界扩展的。进一步腐蚀了磨损表面后发现(见图4(e)和(f)),磨损表面上的裂纹源在γ/γ′界面以及碳化物与合金基体界面形核,既有沿着γ/γ′界面以及碳化物与合金基体界面的扩展,又出现进入γ′晶粒的穿晶扩展,呈现沿晶和穿晶混合状。磨损表面的裂纹特征(见图3)符合文献[23]中环境致脆磨损机理的特征,磨损表面与横截面的裂纹萌生与扩展形貌(见图4)符合Ni基高温合金氢脆微观机制[24-26]的特征,故其磨损机理可能存在氢引起的环境致脆。

图4 K417G合金磨损截面形貌与腐蚀后的磨损表面形貌

Fig. 4 Sectional morphologies of worn surface for K417G alloy and morphologies of worn surface after corrosion for K417G alloy

表5 K417G合金裂纹扩展区域的EDS分析结果

Table 5 EDS analysis results of crack propagation region for K417G alloy (mole fraction, %)

亚表层疲劳裂纹扩展与磨损表面裂纹扩展的相互作用,加速了裂纹的相遇重合(见图4(g)),最后使裂纹以上的材料断裂剥落,形成了“蘑菇”状的表面微观形貌(见图4(h))。这种“蘑菇”状的表面微观形貌在磨损过程中承受摩擦力和正压力的交互作用能力不足,易发生断裂剥落,导致K417G合金及Ni(Co)CrAlYSi涂层的耐磨损性能降低。另外,考虑到涂层内部存在的细小孔洞极易成为疲劳裂纹萌生的裂纹源,会加速疲劳裂纹的萌生与扩展,故随着K417G合金及其表面Ni(Co)CrAlYSi涂层内部孔洞数量的增多,材料的磨损率逐渐升高。

2.4 讨论

K417G合金及其表面Ni(Co)CrAlYSi涂层的主要组成相为γ-Ni相和γ′-Ni3Al(或Ni3(Al,Ti))相,其中,金属间化合物γ′-Ni3Al(或Ni3(Al,Ti))相作为沉淀强化相可以提高Ni基合金的高温力学性能[1]。然而Ni3Al合金在室温空气下呈现严重的环境脆性[27],且Ni3Al相可导致镍基高温合金在氢环境下发生氢脆现象[24-26]。Ni3Al在室温空气环境下呈现脆性是由于大气环境中的水汽同Ni3Al中的活性元素Al发生反应[28-30]:2Al+3H2O→Al2O3+6H,生成的原子态H在裂尖区汇集致脆,而使得合金表现出沿晶断裂倾向;且大气中的水汽只有同新鲜的Ni3Al表面反应才能生成致脆的原子态氢,而Ni3Al有对微量的原子态氢也十分敏感的特征。鉴于实验中发现,磨损2 min的Ni3Al合金磨损表面已经出现了少量的环境致脆裂纹(见图5(a)),随着实验时间的增加,环境致脆裂纹逐渐增多(见图5(b))。因而,磨损过程中材料的磨损和塑性变形不断地在磨损表面形成新鲜表面,空气中的水蒸汽在新鲜表面吸附,并不断地同Ni3Al中的活性元素Al发生反应生成的原子态H,原子态H从表面向合金内部逐渐聚集;且Ni基高温合金中晶界的碳化物是强势的氢“陷讲”[26],易聚集原子态H;当磨损接触区的循环应力超过材料的疲劳强度时,将在材料表面引发裂纹萌生,在应力作用下聚集的H在裂纹尖端聚集而导致脆化。磨损表面原子态H的逐渐生成和聚集,同时逐渐破坏了K417G合金及其表面Ni(Co)CrAlYSi涂层磨损表面的完整性,氢致脆化后的材料表面疏松,很容易被对磨件刮掉而增加材料流失量[23]。由于B和Zr可以抑制多晶Ni3Al合金的室温环境脆性[27],而K417G合金中含有微量的B和Zr,这也可能是K417G合金环境脆性特征相对较轻,磨损率相对较低的一个原因。

图5 不同磨损时间后Ni3Al合金磨损表面形貌

Fig. 5 Morphologies of worn surface for Ni3Al alloy for different time

3 结论

1) K417G合金及其表面Ni(Co)CrAlYSi涂层磨损表面呈现显著的剥落和裂纹特征导致其耐磨损性能低于纯Ni的。

2) K417G合金及其表面Ni(Co)CrAlYSi涂层的磨损受到磨损亚表层疲劳脱层机制和磨损表面环境脆性机制的共同作用。

3) 磨损过程中,环境脆性逐渐作用于磨损表面。磨损表面的裂纹源在γ/γ′界面以及碳化物与合金基体界面形核,裂纹既沿着γ/γ′界面以及碳化物与合金基体界面扩展,又进入γ′晶粒,呈现沿晶和穿晶混合状。

REFERENCES

[1] 郭建亭. 高温合金材料学(上册)[M]. 北京:科学出版社, 2010: 108-110.

GUO Jian-ting. Materials sclence and engineering for superalloys(volume 1)[M]. Beijing: Science Press, 2010: 108- 110.

[2] 敖三三, 罗 震, 单 平, 步贤政, 刘为东. Inconel 601镍基高温合金激光焊焊缝的显微组织[J]. 中国有色金属学报, 2015, 25(8): 2099-2107.

AO San-san, LUO Zhen, SHAN Ping, BU Xian-zheng, LIU Wei-dong. Microstructure of Inconel 601 nickel-based superalloy laser welded joint[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2099-2107.

[3] 沈心敏, 刘雨川, 马 纲. 航空燃气轮机摩擦学[M]. 北京: 北京航空航天大学出版社, 2008: 319-320.

SHEN Xin-min, LIU Yu-chuan, MA Gang. Tribology for aero-gas turbine engine[M]. Beijing: Beihang University Press, 2008: 319-320.

[4] STOTT F H, LIN D S, WOOD G C. The structure and mechanism of formation of the glaze oxide layers produced on nickel based alloys during wear at high temperatures[J]. Corrosion Science, 1973, 13: 449-469.

[5] HAMDY M M, WATERHOUSE R B. The fretting wear of Ti-6Al-4V and Inconel718 at elevated temperature[J]. Wear, 1981, 71: 237-248.

[6] IWABVCHI A. Fretting wear of Inconel625 at high temperature and in high vacuum[J]. Wear, 1985, 106: 163-175.

[7] KLAFFKE D, CARSTENS T, BANERJI A. Influence of grain refinement on the high temperature fretting behavior of IN738LC[J]. Wear, 1993, 160: 361-366.

[8] 徐向阳, 徐滨士, 刘文今, 刘世参, 周仲荣. K417镍基高温合金微动磨损行为的研究[J]. 航空材料学报, 2002, 22(4): 13-17.

XU Xiang-yang, XU Bin-shi, LIU Wen-jin, LIU Shi-can, ZHOU Zhong-rong. Study of fretting wear behavior of K417 nickel base superalloy[J]. Journal of Aeronautical Materials, 2002, 22(4): 13-17.

[9] 赫青山, 傅玉灿, 陈佳佳, 张 玮. 热管砂轮磨削高温合金GH4169实验研究[J]. 金刚石与磨料磨具工程, 2013, 33(4): 5-9.

HE Qing-shan, FU Yu-can, CHEN Jia-jia, ZHANG Wei. Study on heat pipe grinding wheels when grinding superalloy GH4169[J]. Diamond & Abrasives Engineering, 2013, 33(4): 5-9.

[10] 乔 阳, 艾 兴, 刘战强, 赵 军. 涂层刀具铣削粉末冶金镍基高温合金试验研究[J]. 华南理工大学学报(自然科学版), 2010, 38(8): 83-88.

QIAO Yang, AI Xing, LIU Zhan-qiang, ZHAO Jun. Experimental investigation into milling of Nickel-based powder metallurgy superalloy with coated tools[J]. Journal of South China University of Technology (Natural Science Edition), 2010, 38(8): 83-88.

[11] 任敬心, 杨茂奎, 李雅卿, 吴小玲. 镍基高温合金的磨削特征[J]. 航空学报, 1997, 18(6): 755-758.

REN Jing-xin, YANG Mao-kui, LI Ya-qin, WU Xiao-ling. Grinding characteristic of nickel-based superalloy[J]. Acta Aeronautica et Astron Autica Sinica, 1997, 18(6): 755-758.

[12] 苏旭峰. 高温合金缓进磨削烧伤机理实验研究[J]. 中国计量学院学报, 2009, 20(1): 46-50.

SU Xu-feng. On creeping grinding and crack experiment of superalloys[J]. Journal of China University of Metrology, 2009, 20(1): 46-50.

[13] JEANINE T D, DINESH K G. Protective coatings in the gas turbine engine[J]. Surface and Coatings Technology, 1994, 68/69(12): 1-9.

[14] GOWARD G W. Progress in coatings for gas turbine airfoils[J]. Surface and Coatings Technology, 1998, 108/109(10): 73-79.

[15] BRANDL W, GRABKE H J, TOMA D, KRüGER J. The oxidation behaviour of sprayed MCrAlY coatings[J]. Surface and Coatings Technology, 1996, 86/87(1): 41-47.

[16] 张 健, 郭策安, 张 罡, 郝士明. 两种NiCrAlY涂层的室温摩擦磨损性能[J]. 腐蚀科学与防护技术, 2011, 23(2): 107-110.

ZHANG Jian, GUO Ce-an, ZHANG Geng, HAO Shi-ming. Friction and wear behavior of two NiCrAlY coatings at room temperature[J]. Corrosion Science and Protection Technology, 2011, 23(2): 107-110.

[17] 张 松, 王明生, 张开祥, 张春华, 颜永根. SCH13钢表面激光熔覆CoNiCrAlY合金[J]. 焊接学报, 2010, 31(5): 49-53.

ZHANG Song, WANG Ming-sheng, ZHANG Kai-xiang, ZHANG Chun-hua, YAN Yong-gen. CoNiCrAlY alloy deposited on surface of SCH13 steel by laser cladding[J]. Transactions of the China Welding Institution, 2010, 31(5): 49-53.

[18] 肖 旋, 郭建亭, 于海朋. 固溶处理冷却速度对DZ 417G合金组织性能的影响[J]. 材料研究学报, 2006, 20(5): 533-537.

XIAO Xuan, GUO Jian-ting, YU Hai-peng. Effect of cooling rate from solution heat treatment on the microstructure and mechanical properties of superalloy DZ 417G[J]. Chinese Journal of Material research, 2006, 20(5): 533-537.

[19] 张维平, 刘文艳. 激光熔敷陶瓷涂层综述[J]. 表面技术, 2001, 30(4): 32-34, 38.

ZHANG Wei-ping, LIU Wen-yan. Progress of laser cladding about ceramic coating[J]. Surface Technology, 2001, 30(4): 32-34, 38.

[20] 徐朝政, 姜肃猛, 马 军, 宫 骏, 孙 超. 两种电弧离子镀Ni-Co-Cr-Al-Si-Y涂层的高温氧化行为[J]. 金属学报, 2009, 45(8): 964-970.

XU Chao-zheng, JIANG Su-meng, MA Jun, GONG Jun, SUN Chao. High temperature oxidation behavior of two Ni-Co-Cr-Al-Si-Y coatings deposited by arc ion plating[J]. Acta Metallurgica Sinica, 2009, 45(8): 964-970.

[21] 彭 新, 姜肃猛, 段绪海, 宫 骏, 孙 超. (MCrAIY+AlSiY)复合涂层的高温氧化行为[J]. 金属学报, 2009, 45(3): 378-384.

PENG Xin, JIANG Su-meng, DUAN Xu-hai, GONG Jun, SUN Chao. High temperature oxidation behavior of a (MCrAIY+AlSiY) composite coating[J]. Acta Metallurgica Sinica, 2009, 45(3): 378-384.

[22] 黄美东, 孙 超, 林国强, 董 闯, 闻立时. 脉冲偏压电弧离子低温沉积TiN硬质薄膜的力学性能[J]. 金属学报, 2003, 39(5): 516-520.

HUANG Mei-dong, SUN Chao, LIN Guo-qiang, DONG Chuang, WEN Li-shi. Mechanical property of low temperature deposited TiN film by pulsed biased arc ion plating[J]. Acta Metallurgica Sinica, 2003, 39(5): 516-520.

[23] 姜晓霞, 李诗卓, 李 曙. 金属的腐蚀磨损[M]. 北京: 化学工业出版社, 2003: 342-344.

JIANG Xiao-xia, LI Shi-zhuo, LI Shu. Corrosive wear of metals[M]. Beijing: Chemical Industry Press, 2003: 342-344.

[24] DOLLAR M, BERNSTEIN I M. The effect of hydrogen on deformation substructure, flow and fracture in a nickel-base single crystal superalloy[J]. Acta Metallurgica, 1988, 36: 2369-2375.

[25] CHEN P S, WILCOX R. C. Fracture of single crystals of the nickel-base superalloy PWA 1480E in hydrogen at 22 ℃[J]. Metallurgical and Materials Transactions, 1991, 22(9): 2031-2038.

[26] 何 成. 氢对GH690合金拉伸变形行为的影响[D]. 沈阳: 东北大学, 2012: 16-17.

HE Cheng. Effect of hydrogen on tensile deformation behavior of GH690 alloy[D]. Shenyang: Northeastern University, 2012: 16-17.

[27] 李玉芳. 合金元素Zr对Ni3Al力学行为的影响及韧化机制的研究[D]. 沈阳: 中国科学院金属研究所, 2004: 1-20.

LI Yu-fang. Effect of Zr on the mechanical properties of Ni3Al and ductility mechanism[D]. Shenyang: Institute of Metal Research Chinese Academy of Sciences, 2004: 1-20.

[28] GEOGE E P, LIU C T, POPE D P. Environmental embrittlement: The major cause of RT brittleness in polycrystalline Ni3Al[J]. Scripta Metallurgica, 1992, 27: 365-370.

[29] GEOGE E P, LIU C T, POPE D P. Intrinsic ductility and environmental embrittlement of binary Ni3Al[J]. Scripta Metallurgica, 1993, 28: 857-862.

[30] LIU C T. Environmental embrittlement and grain boundary fracture in Ni3Al[J]. Scripta Metallurgica, 1992, 27: 25-28.

Wear properties of K417G alloy and Ni(Co)CrAlYSi coatings deposited onto K417G under atmospheric environment at room temperature

WANG Zhen-sheng1, PENG Zhen1, YANG Shuang-shuang1, GUO Jian-ting2,

ZHOU Lan-zhang2, TAN Qing-qi1, SU Xin1

(1. Engineering Research Center of Advance Mining Equipment, Ministry of Education,

Hunan University of Science and Technology, Xiangtan 411201, China;

2. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The tribological properties of K417G superalloy and Ni(Co)CrAlYSi coatings/K417G were investigated at room temperature in atmospheric environment. The results show that the worn mechanism of both K417G superalloy and the coatings is due to interaction of environment embrittlement and fatigue delamination in subsurface stratum, which results to the higher wear rate compared with the pure nickel plate. The enviromental embrittlement gradually affect the worn surface during the process of wear. The formation of crack resource on the worn surface begins at both the interface of γ/γ′ phases and the interface of carbide and alloy. The cracks extend along both the interface of γ/γ′ phases and the interface of carbide and alloy and enter into the γ′ phase, presenting the intergranular and transgranular mixed.

Key words: K417G alloy; Ni(Co)CrAlY coatings; Ni3Al ; friction; wear; environmental embrittlement

Foundation item: Project (51101055) supported by the National Natural Science Foundation of China; Project (13JJ8015) supported by the National Natural Science Foundation of Hunan Province, China; Project (S140016) supported by Postgraduate Innovation Foundation of Hunan University of Science and Technology, China

Received date: 2015-04-19; Accepted date: 2015-11-30

Corresponding author: WANG Zhen-sheng; Tel: +86-13298538387; E-mail: zswang@imr.ac.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51101055);湖南省自然科学基金资助项目(13JJ8015);湖南科技大学研究生创新基金资助项目(S140016)

收稿日期:2015-04-19;修订日期:2015-11-30

通信作者:王振生,副教授,博士;电话:13298528387;E-mail:zswang@imr.ac.cn