铝熔炼炉炉衬组合的优化模拟

王计敏1,闫红杰1,周孑民1,李世轩2,贵广臣2

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 苏州新长光热能科技有限公司,江苏 苏州,215008)

摘要:为了减少炉衬的热损失和节约投资成本,针对铝熔铸行业广泛使用的反射式铝熔炼炉,以三层平壁炉衬结构为研究对象,计算分析隔热方式对炉衬传热影响。以经济厚度法为依据,推导出炉衬的经济厚度计算公式,并通过编程实现炉衬组合的计算机优化。同时以蓄热式铝熔炼炉热平衡测试为例,建立铝熔炼炉数学模型,运用计算流体力学软件FLUENT对炉窑工作制度为40周的优化前后的炉衬组合进行仿真。结果表明:炉衬组合的计算机优化结果可获得比较理想的经济效益:炉墙采用40 mm黏土质浇注料+300 mm硅藻土砖+120 mm硅酸铝纤维毡;炉顶采用220 mm普通耐火混凝土+150 mm黏土质浇注料+80 mm硅酸铝纤维毡;炉底采用200 mm高铝质浇注料+300 mm硅藻土砖+50 mm黏土质浇注料。

关键词:铝熔炼炉;炉衬;数值模拟;优化组合

中图分类号:TF806.31 文献标志码:A 文章编号:1672-7207(2012)04-1523-09

Numerical simulation and optimizing combination of aluminum melting furnace linings

WANG Ji-min1, YAN Hong-jie1, ZHOU Jie-min1, LI Shi-xuan2, GUI Guang-chen2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Suzhou Longray Thermal Technology Co. Ltd., Suzhou 215008, China)

Abstract: In order to reduce heat loss and save cost, three-tier slab was simplified for furnace linings of widely-used reverberatory aluminum melting furnace in aluminum casting industry. Heat transfer analysis of different heat-insulating mode on furnace lining was carried out. Based on economic thickness method, the calculation formulae of economic thickness for furnace linings were introduced, and furnace linings were optimized by computer programming. On this basis, a three dimensional mathematical model of aluminum melting furnace was developed based on heat balance test of regenerative aluminum melting furnace. Furnace linings before and after optimization with 40-week working system were simulated by CFD software FLUENT. The results show that ideal economic effect is obtained by optimization as follows: furnace side with 40 mm clay castables, 300 mm diatomite brick and 120 mm alumino-silicate fiber felts; furnace top with 220 mm refractory concrete, 150 mm clay castables and 80 mm alumino-silicate fiber felts; furnace bottom with 200 mm high-alumina castable, 300 mm diatomite brick and 50 mm clay castables.

Key words: aluminum melting furnace; lining; numerical simulation; optimizing combination

能源与环境问题给铝加工行业的快速发展带来限制性影响,节能降耗和减少排放是企业技术进步和可持续发展的必然选择。熔铸是铝及铝合金加工的先头工序,而熔炼炉是熔铸厂必不可少的设备,其主要作用是向铸造机提供铝液。目前,我国铝加工行业冶金炉的主要问题是热效率低,能耗高。全行业的平均热效率约为32%,与工业发达国家的56%相比约低24%,其中熔炼炉为热效率19.5%。熔炼炉中热量消耗基本上可以分解为物料熔化潜热和吸收的热量、烟气带走的热量、炉体散热、炉渣带走热等几个部分,其中仅仅用于产品吸收的热量是有效能量。为应对能源形势的严峻挑战,熔炼炉节能降耗是发展的必然趋势。熔炼炉节能与炉衬耐火材料的技术进步、窑炉技术设计和施工密切相关。文献[1-5]对炉窑炉衬的温度场进行传热分析,以达到减少炉体热损失的目的。杨尚宝 等[6]通过对高炉炉衬破损的实际调查,建立炉体状态模型来实现对高炉操作的指导。结合磨损节点分析模型,以数学模型和理化模型为基础,Parra等[7]对高温冶金过程中炉衬的磨损和腐蚀现象进行了数值解析。Gruber等[8]对高炉炉衬的热应力行为进行了有限元仿真,为炉衬的优化选择提供技术支持。由于电磁搅拌长时间的使用而使铝液渗入到炉衬中,Takahashi等[9]对炉衬中电磁力的损失进行了数值模拟。本文作者从隔热方式对炉衬传热影响的角度出发,以炉衬的经济厚度法为依据,通过编程实现炉衬组合的计算机优化,同时以蓄热式铝熔炼炉热平衡测试为基础,建立铝熔炼炉数学模型,运用计算流体力学软件FLUENT对优化前后的炉衬组合进行炉衬仿真分析,为优化熔炼炉炉衬耐火材料组合和研究耐火节能一体化结构以及发展新型节能型耐火材料提供技术依据。

1 隔热方式对炉衬传热的影响

在进行炉衬传热计算时,为简化计算,针对铝熔炼炉的实际情况,假定[10-11]:

(1) 炉衬为一维稳态导热,即热流量不随时间而变化,且热量只沿等温面的法线方向传递。

(2) 各层材料的导热系数为常数,并等于每层材料两侧壁温的平均温度下的导热系数。

(3) 各层之间的接触良好,两层的接触面上具有相同的温度。

(4) 2S/d1≤1(d1为炉窑内径,S为炉衬厚度),将圆筒壁简化处理为平壁。

根据以上假设,炉体的散热损失q1和炉衬的蓄热损失q2为[11]

(1)

(1)

式中:Thot为炉衬热面热力学温度,依据铝熔炼炉热平衡测试结果,取1 173 K;T0,Ti为分别为耐火材料初始和终止温度;Tf为环境温度;Si为耐火材料厚度;hout为炉外壁综合对流换热系数;λi为耐火材料导热系数;ρi为耐火材料密度;cp0和cpi分别为耐火材料初始和终止比热。炉衬的热损失与炉窑的热惰性系数成正比,因此,要减少炉窑的热损失,在满足使用温度和工作条件的情况下,应选用热惰性系数低的材料[5]。常用铝熔炼炉筑炉材料的主要性能参考文献[12-18]。

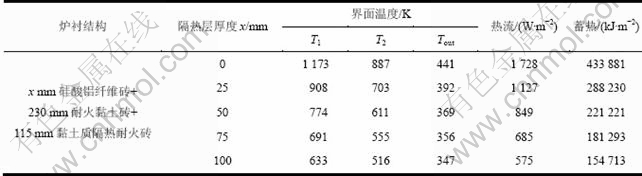

表1和表2分别为通过传热计算得到的炉墙冷面和热面加强隔热的作用效果。从表1和2可以看出,在炉衬材料相同的情况下,外隔热时,随着隔热的加强,其外壁温度逐渐降低,散热损失显著降低,但由于炉衬的平均温度升高,炉墙蓄热损失逐渐增加。而在内隔热时,散热和蓄热都随着强化隔热而降低。在相同的厚度情况下,外隔热的散热损失比内隔热小,而蓄热损失比内隔热大。

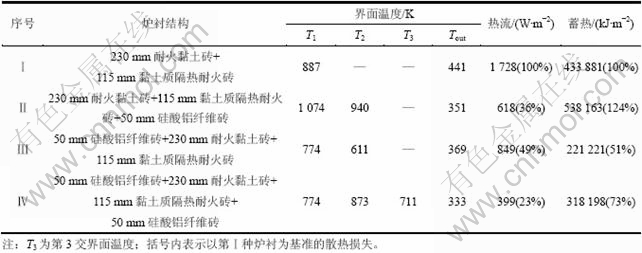

炉衬内隔热和外隔热的传热计算效果对比如表3所示。第Ⅰ种炉衬由耐火黏土砖和黏土质隔热耐火砖组成。第Ⅱ种情况为炉衬外隔热,表面温度由441 K降至351 K,与第Ⅰ种情况相比,散热损失降低了64%,但由于隔热效果好,炉衬平均温度升高,界面温度由887 K升到1 074 K,而使蓄热损失增加了24%。因此在采用外隔热时,必须考虑炉衬的耐火度是否适应的问题。第Ⅲ种情况为炉衬内隔热,与第Ⅰ种情况相比,散热和蓄热损失分别减少了51%和49%。第Ⅳ种情况为炉衬内外同时隔热,与第Ⅰ种情况相比,散热损失降低77%,蓄热损失降低27%。从炉窑的作业方式看,工业炉窑可分为连续作业和周期作业2种类型,对于连续作业的炉窑,蓄热损失仅是开炉升温阶段一次蓄热,而散热则是长期的,其总量远大于蓄热量,因此连续作业的炉窑炉衬应考虑使用外隔热结构,但这会导致炉衬温度升高,因而对炉衬的安全使用问题需加以注意。对于周期作业的炉窑,蓄热损失占总损失比例较大,因此周期作业的炉窑炉衬应采用内隔热结构,以减少蓄热损失。另外,有些周期工作制度的炉窑,虽然是周期性的,但其周期很长,炉窑在稳定态下工作时间远大于非稳态工作时间,即蓄热损失远比散热损失小的周期工作的炉窑,也应按连续作业炉窑设计。本文研究的铝熔炼炉熔炼周期约为5 h,装料时间约为15 min,因此应按周期作业炉窑设计炉衬。

表1 炉墙冷面加强隔热的作用效果

Table 1 Effect of cold wall with heat insulation

表2 炉墙热面加强隔热的作用效果

Table 2 E ffect of hot wall with heat insulation

表3 炉衬隔热效果对比

Table 3 Comparisons of heat transfer for heat insulation on furnace linings

2 炉衬组合的优化

2.1 炉衬材料经济厚度的计算

炉衬耐火材料的选择与计算是炉窑设计及节能改造的重要内容之一,不仅关系到炉窑初期投资,也对炉窑热工性能有直接影响。目前对炉衬厚度计算方法主要有3种:允许最大热损失法、外表面允许最高温度法、经济厚度法[11, 19],前两种方法仅仅考虑炉衬允许最大热损失或炉衬外表面最高温度,没有考虑炉衬材料价格及热量价格,计算出的厚度并不十分合理,而经济厚度法则综合考虑炉衬热损失费用和材料投资费用,使此2项费用之和最小,因此计算出的炉衬厚度更符合实际。众所周知,炉衬越厚,散热损失越小,蓄热损失和材料投资越大。不同炉衬材料组合也存在不同的热损失,因此存在着一个最佳炉衬材料组合及炉衬经济厚度,以三层平壁炉衬结构为研究对象,其最佳经济厚度由式(2)确定。

(2)

(2)

式中:i=1,2,3;Si为炉衬各层不同材料的厚度;λi各层材料的导热系数;Ci为各层材料单位投资(包括初投资和施工安装维修费)费用;M为平均年投资分摊率;N为年工作时间;τ为炉窑操作周期;q1为散热损失;q2为蓄热损失;Cq为热量价格;hout炉外壁综合对流换热系数;j为利率;n为炉衬寿命;T2*和T3*分别为二层和三层炉衬材料最高连续使用温度。

式(2)为多变量函数条件极值问题。利用松弛变量法和拉格朗日乘数法可以求出各层炉衬的经济厚度Si*,使Ct为最小。假设铝熔炼炉的热效率为40%,炉衬的使用寿命为3 a(120周),炉窑的工作制度有3种典型类型,即40周连续作业,144 h连续作业和16 h连续作业[20]。天然气按市场价格计算,则热量价格Cq为1.58×10-7 元/J[21]。各层经济厚度为:

(3)

(3)

式中,ΔT1=T1-T2*,ΔT2=T2*-T3*,ΔT3=T3*-Tf;λ1,λ2,λ3分别为各层材料在平均温度

时的导热系数。

时的导热系数。

2.2 炉衬组合的计算机优化

铝熔炼反射炉用耐火材料要求具有抗铝液及镁蒸气的渗入,且有优良的抗磨损和抗热冲击性能等。一般来说,与铝液接触的炉衬,采用高铝质耐火材料,如果需要熔炼高纯度铝时,考虑熔渣的酸性特性,则使用莫来石砖或刚玉砖。不接触铝液的炉衬,一般采用黏土砖、黏土质耐火浇注料或耐火可塑料。炉顶采用耐热混凝土结构以提高炉衬的整体性和气密性。炉衬设计原则[14]:带灰缝的耐火砖、硅藻土砖砌体的水平尺寸为116 mm的倍数,垂直尺寸为68 mm的倍数。炉墙设计总的原则是轻质、重质料的复合炉墙,其厚度分别为40~200 mm和200~300 mm。炉顶衬体用的材料,与炉墙的基本相同或同一档次,其衬体材料也是轻质、重质料复合使用,厚度分别为50~150 mm和200~250 mm。

在铝熔炼炉原有炉衬组合的基础上,依据炉衬设计原则及炉衬传热分析,炉衬材料选取如下:炉墙由耐火黏土砖(A1)、硅藻土砖(B1)、硅酸铝纤维毡(C1)和黏土质浇注料(D1)组成;炉顶由普通耐火混凝土(A2)、黏土质浇注料(B2)和硅酸铝纤维毡(C2)组成;炉底由高铝砖(A3)、黏土质浇注料(B3)、硅藻土砖(C3)和高铝质浇注料(D3)组成。

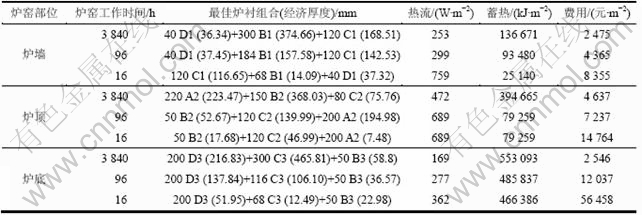

炉衬组合的计算机优化过程[22]如图1。由于炉衬及其厚度的排列组合较多,全局变量的数量超过编译器允许最大值,因此程序中采用临时文件的方法解决这一问题。优化结果如表4所示。从表4可以看出:式(3)所计算出的经济厚度与炉衬组合的计算机优化结果有较大的差距,这主要与式(3)中的T2*和T3*有关,即第二层和第三层炉衬材料的最高连续使用温度,式(3)中假设它们分别为1 073 K和673 K,但从炉衬组合优化所选用材料性能[12-18]来看,显然并不完全符合。因此,铝熔炼炉炉衬组合的计算机优化结果更加真实合理。

图1 炉衬优化设计程序框图

Fig.1 Optimizing procedure of aluminum melting furnace linings

表4 铝熔炼炉炉衬优化结果

Table 4 Optimizing results of aluminum melting furnace linings

3 铝熔炼炉炉衬的数值模拟

3.1 模型的建立及实现

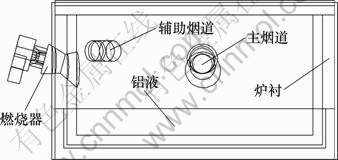

本文研究的铝熔炼炉呈圆筒形状,铝液位于熔炼炉下部,侧部安装有蓄热式燃烧器,如图2所示。工作时,其中一个燃烧器用作主烟道,其烟气流量占总流量的80%,另一部分烟气则从辅助烟道流出。本文不考虑燃烧器间的换向,只研究单个烧嘴的燃烧现象。

模型假设[23-24]:

(1) 结合铝熔炼过程及其特点,根据工程实际,假设铝液不运动,界面无波动,忽略铝液表面的化学反应,只考虑铝液与周边空气的辐射和对流换热,不考虑铝液过热度。

图2 铝熔炼炉几何模型(包括炉衬)

Fig.2 Geometry model of aluminum melting furnace with linings

(2) 铝液上表面均匀覆盖一层Al2O3,且氧化充分完全,氧化层厚度和发射率分别假设为5 mm和0.33。

数学模型包括连续性方程、动量方程、能量方程以及化学组分守恒方程,另外还有湍流模型、燃烧反应模型以及辐射模型等。湍流模型采用广泛使用的标准k-ε模型;使用非预混燃烧模型来模拟天然气和空气的燃烧反应;P-1模型用来模拟炉壁、炉气及铝液之间的辐射换热。吸收系数假设符合介于简化模型和完全模型之间的WSGGM模型。流固耦合界面处,采用式(4)描述:

(4)

(4)

式中:λA为铝液的导热系数;h为局部对流换热系数;Tg为炉气温度;Tb为炉壁温度;Tw为耦合面温度;ε1为炉气对铝液的系统发射率;ε2为炉壁对铝液的系统发射率;σ为Stefan-Boltzmann常数。

炉衬为变物性传导方程,即

(5)

(5)

式中:ρ为炉衬密度;cp,Ln为炉衬比热容;λ为炉衬导热系数;T为炉衬温度。

(1) 炉内向炉衬传热边界。对于炉内的传热过程涉及了传热学的三类边界条件,其数学描述为

,

,

,

,

(6)

(6)

式中:T(z)为炉内衬温度分布;q(z)为炉内向炉衬传递的热流;hin为炉气与炉衬间的综合换热系数;Tx,in为内衬表面温度;Tg为炉气温度。

(2) 炉衬外壁传热边界。

(7)

(7)

式中:hout为炉外壁综合对流换热系数;Tx,out为外衬表面温度。

不考虑液相区域中对流现象,则对于固相区域和液相区域来说,热流均以热传导方式传递,由于存在潜热,其支配导热过程的能量方程如下[25]:

(8)

(8)

式中:fL为液相率;L为熔化潜热;cp,Al为铝液比热容;ρA为铝液密度。

由式(8)可见,处理潜热项的关键在于求得液相率fL随温度的变化规律。假设熔化潜热在固液两相区内呈线性释放,采用等价比热法对潜热进行处理[26]:

(9)

(9)

式中:c1为固态铝比热容;c2为液态铝比热容;TS为固相温度;TL为液相温度;L为熔化潜热。

由于熔化温度区间内的导热过程不但要受相变潜热的影响,而且还要受本身组成改变所引起的物理特性变化的影响,所以两相区物性参数为:

(10)

(10)

式中:xL为液相物性参数;xm为两相区物性参数。

铝液的初始条件:TAl|τ=0=300 K;空气质量进口边界条件:Mair-inlet=1.871 kg/s,Tair-inlet=823 K,fair-inlet=0;天然气成分可按标准天然气成分计,其速度进口边界条件:Unatural-gas-inlet=43.195 m/s,Tnatural-gas-inlet=300 K,fnatural-gas--inlet=1;主烟道和辅助烟道分别为自由出流边界条件:Omain-flue=0.8,Osecondary-flue=0.2。铝液和Al2O3等的物性参数参考文献[23]。炉衬材料物性参数参考文献[12-18]。运用FLUENT UDF和FLUENT Scheme混合编程实现燃烧量的改变、液相率的计算、铝液物性参数改变和保存指定时刻结果文件等。当液相率达到100%时,保存结果文件并退出FLUENT。

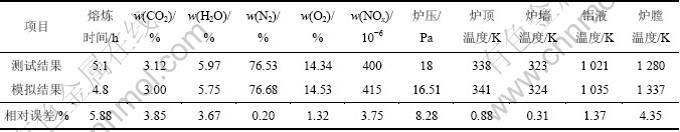

3.2 模型验证

由于燃烧器和炉体的尺寸悬殊较大,采用多块网格结构。考虑计算资源紧张性和计算结果准确性,对网格数和时间步长进行无关性检验,最终选取的网格数为977 259,时间步长为1 s。为了验证模型的可靠性和准确性,对某厂的35 t蓄热式铝熔炼炉进行了热平衡测试和数值模拟。模拟结果和测试结果的对比列于表5。从表5可以看出,数值模拟结果和测试结果基本一致,模型较好地反映了铝熔炼炉燃烧熔炼状况。

3.3 铝熔炼炉炉衬的仿真分析

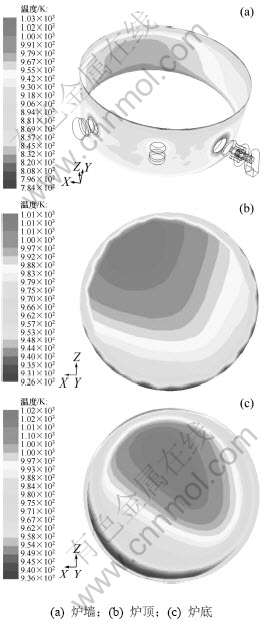

以炉窑工作制度为40周的炉衬组合计算机优化结果为例,运用计算流体力学软件FLUENT进行仿真计算。炉衬耐火材料的损坏与热负载引起的温度热应力有关,因此炉衬的温度分布是炉窑设计重要因素。从图3可以看出,燃烧器和烟道部位温度较高,应使用致密的高氧化铝质的耐火砖防止炉衬由于长期的高温冲蚀而损坏。炉衬温度的高温区域与火焰和烟气有关:由于受到高温烟气的影响,与燃烧器对面的炉墙区域温度较高;炉顶温度较高区域位于高温烟气回流的始端;由于火焰的温度较高,且速度也较大,所以铝液面较高温度区域位于和火焰接触面下方。而假设铝液内传热方式仅有导热,故炉底的温度与铝液面的温度分布相对应。

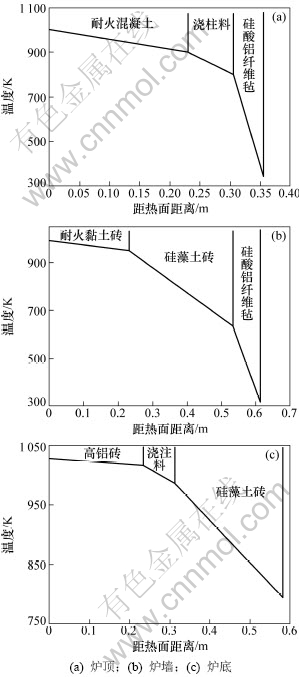

通过对炉衬中心处的截面温度分布分析,得到结果如图4。其中,炉顶部位耐火混凝土的工作温度为899~1 000 K,温度差为101 K;黏土质浇注料的工作温度为802~899 K,温度差为97 K;硅酸铝纤维毡的工作温度为340~802 K,温度差为462 K。由于炉墙及炉底部位的耐火材料不同于炉顶,故温度梯度有所不同。炉墙耐火黏土砖的工作温度为950~992 K,温度差为42 K;硅藻土砖的工作温度为634~950 K,温度差为316 K;硅酸铝纤维毡的工作温度在320~634 K,温度差为314 K。炉底高铝砖的工作温度在1 016~1 027 K之间,温度差为11 K;黏土质浇注料的工作温度在986~1 016 K之间,温度差为30 K;硅藻土砖的工作温度在793~986 K,温度差为193 K。由此可知,炉墙炉底和炉顶的温度下降速率由大到小依次为保温层、隔热层和耐火层。温度梯度较大将产生较大的温差应力,这是造成炉衬损坏的主要原因。

表5 模拟和测试结果对比

Table 5 Comparisons of simulation results and test values for aluminum melting furnace

图3 铝熔炼炉不同部位炉衬温度分布

Fig.3 Temperature distribution for different parts of aluminum melting furnace linings

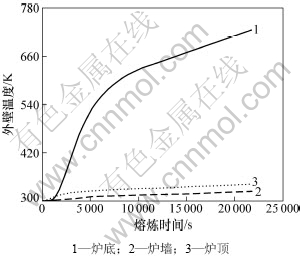

从图5可以看出:炉底温度远大于炉墙温度和炉顶温度,这与该铝熔炼炉采用实炉底结构和炉底炉衬的物性参数有关。当液相率达到某值,燃烧量开始随液相率线性减小,炉膛温度开始降低,故炉体外壁温度开始缓慢上升。随着燃烧量降低达到到稳定值,炉体外壁温度又开始线性升高。

图4 铝熔炼炉不同部位炉衬温度梯度

Fig.4 Temperature gradient for different parts of aluminum melting furnace linings

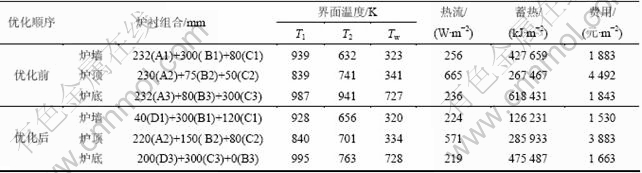

表6所示为铝熔炼炉炉衬工作制度为40周的优化前后仿真结果比较。从表6可见:优化前总费用为8 218 元/m2,而优化后总费用为7 076元/m2,节约了1 142 元/m2,表明炉衬组合的计算机优化是成功的,可获得比较理想的经济效益。由于炉顶外壁温度高于炉墙外壁温度,所以炉顶散热损失大于炉墙散热损失。

表6 铝熔炼炉炉衬优化前后仿真结果

Table 6 Simulation results for aluminum melting furnace linings of before and after optimization with 40-week working system

图5 炉体外壁温度与熔炼时间的变化关系

Fig.5 Relationship between outer wall temperature and melting time

4 结论

(1) 以经济厚度法为依据,通过编程实现炉衬组合的计算机优化,得到了不同工作制度下的炉窑不同部位的最佳炉衬组合。并以蓄热式铝熔炼炉热平衡测试为基础,建立铝熔炼炉数学模型,运用计算流体力学软件FLUENT对炉窑工作制度为40周的优化前后的炉衬组合进行仿真,结果分析表明炉衬组合的计算机优化结果是成功的,可获得比较理想的经济效益。

(2) 在炉衬材料相同的情况下,外隔热时,随着隔热的加强,其外壁温度逐渐降低,散热损失显著降低,炉墙蓄热损失逐渐增加。而在内隔热时,散热和蓄热都随着强化隔热而降低。因此,连续作业的炉窑炉衬应采用外保温结构,降低散热损失,而对于周期作业的炉窑炉衬则采用内保温结构,减少蓄热损失。另外,可采用热惰性系数低的材料来减少炉窑的惰性,即减少散热损失和蓄热损失。

(3) 炉衬的温度分布是炉窑设计重要因素,炉衬的高温区域与火焰和烟气有关,燃烧器和烟道等部位温度较高,应使用致密的高氧化铝质的耐火砖。无论炉墙还是炉底、炉顶,炉衬温度梯度由大到小依次为保温层、隔热层和耐火层。

参考文献:

[1] 王寿增, 顾静, 苗蔚, 等. 工业窑炉中几种炉衬耐火材料结构的传热分析[J]. 稀有金属材料与工程, 2009, 38(S2): 1259-1262.

WANG Shou-zeng, GU Jing, MIAO Wei, et al. Heat transfer analysis of several industrial furnace lining refractory structures[J]. Rare Metal Materials and Engineering, 2009, 38(S2): 1259-1262.

[2] 张卫军, 吴雪琦, 陈海耿, 等. 宝钢4号高炉炉衬温度场数学模型及分析[J]. 东北大学学报: 自然科学版, 2006, 27(10): 1122-1125.

ZHANG Wei-jun, WU Xue-qi, CHEN Hai-geng, et al. Mathematical model of temperature field for Baosteel new No.4 blast furnace lining and heat transfer analysis[J]. Journal of Northeastern University: Natural Science, 2006, 27(10): 1122-1125.

[3] 关丽坤, 王春香. 转炉炉衬温度场的有限元分析[J]. 工业加热, 2004, 33(6): 14-16.

GUAN Li-kun, Wang Chun-xiang. FEM analysis of temperature field for BOF lining[J]. Industrial Heating, 2004, 33(6): 14-16

[4] 姚俊峰, 梅炽, 任鸿九, 等. 卧式转炉炉衬温度场的数值模拟[J]. 中国有色金属学报, 2000, 10(4): 546-550.

YAO Jun-feng, MEI Chi, REN Hong-jiu, et al. Numerical simulation of temperature field in lining of horizontal converter[J]. The Chinese Journal of Nonferrous Metal, 2000, 10(4): 546-550.

[5] 赵荣新. 熔铝炉设计和炉衬材料的改进[J]. 轻合金加工技术, 1999, 27(4): 14-18.

ZHAO Rong-xin. Design of aluminum melting furnaces and improvement on lining materials[J]. Light Alloy Fabrication Technology, 1999, 27(4): 14-18.

[6] 杨尚宝, 杨天钧, 窦庆和, 等. 高炉炉衬破损调查与炉体状态模型的建立[J]. 钢铁, 1998, 33(6): 9-12.

YANG Shang-bao, YANG Tian-jun, DOU Qing-he, et al. Investigation of erosion of blast furnace lining and establishment of a model for blast furnace lines[J]. Iron and Steel, 1998, 33(6): 9-12.

[7] Parra R, Verdeja L F, Barbes M F. Furnace lining analysis and design by mathematical and physicochemical modeling[C]// International Symposium on Sulfide Smelting. Warrendale: TMS, 2006: 561-575.

[8] Gruber D, Andreev K, Harmuth H. FEM simulation of the thermomechanical behaviour of the refractory lining of a blast furnace[J]. Journal of Materials Processing Technology, 2004, 155(156): 1539-1543.

[9] Takahashi K, Maruyama M, Ishikawa N. Simulation for loss of electromagnetic stirring force due to the penetrated aluminum into the furnace lining[C]//Light Metals. Warrendale: TMS, 2007: 49-58.

[10] 华泽錞, 张德信, 高捷. 工业炉耐热炉衬[M]. 北京: 化学工业出版社, 2007: 15-32.

HUA Ze-chun, ZHANG De-xin, GAO Jie. Industrial furnace linings[M]. Beijing: Chemistry Industry Press, 2007: 15-32.

[11] 韩小良. 炉衬耐火材料经济厚度计算[J]. 工业加热, 2000, 29(1): 43-46.

HAN Xiao-liang. Economic thickness calculation of furnace linings[J]. Industrial Heating, 2000, 29(1): 43-46.

[12] 吴德荣, 杨泽耒, 周家骅. 工业炉及其节能[M]. 北京: 机械工业出版社, 1990: 290-325.

WU De-rong, YANG Ze-lei, ZHOU Jia-hua. Industrial furnace and energy saving[M]. Beijing: Machinery Industry Press, 1990: 290-325.

[13] 梅炽. 有色冶金炉设计手册[M]. 北京: 冶金工业出版社, 2000: 250-291.

MEI Chi. Non-ferrous metallurgical furnace handbook[J]. Beijing: Metallurgy Industry Press, 2000: 250-291.

[14] 王秉铨. 工业炉设计手册[M]. 北京: 机械工业出版社, 1996: 280-341.

WANG Bing-quan. Industrial furnace handbook[M]. Beijing: Machinery Industry Press, 1996: 280-341.

[15] 李红霞. 耐火材料手册[M]. 北京: 冶金工业出版社, 2007: 766-810.

LI Hong-xia. Refractories handbook[M]. Beijing: Metallurgy Industry Press, 2007: 766-810.

[16] 刘麟瑞, 林彬荫. 工业窑炉用耐火材料手册[M]. 北京: 冶金工业出版社, 2001: 10-35.

LIU Lin-rui, LIN Bin-yin. Handbook of industrial furnace refractories[M]. Beijing: Metallurgy Industry Press, 2001: 10-35.

[17] 中国建材在线.材料市场价[DB/OL]. [ 2010.11.29].http://www.jc.net.cn.

China building materials online. Material price[DB/OL]. [ 2010.11.29].http://www.jc.net.cn.

[18] 中国预算网.炉窑砌筑工程定额[DB/OL]. [ 2010.11.29].http://www.yusuan.com.

China budget network. Quota of brick works for industrial furnaces[DB/OL]. [ 2010.11.29].http://www.yusuan.com.

[19] 陈福有, 李广志. 工业炉炉墙经济厚度的确定[J]. 本钢技术, 2001, 40(7): 8-10.

CHEN Fu-you, LI Guang-zhi. Economic thickness of industrial furnace[J]. Bengang Technology, 2001, 40(7): 8-10.

[20] 胡景川. 炉衬材料合理组合的研究[J]. 能源工程, 1983, 3(1): 33-37.

HU Jing-chuan. Rational combination of furnace linings[J]. Energy Engineering, 1983, 3(1): 33-37.

[21] 刘宝庆, 陈磊, 于江美. 铝合金熔炼热工学分析及能耗效益对比[J]. 节能, 2006, 285(4): 17-18.

LIU Bao-qing, CHEN Lei, YU Jiang-mei. Thermal analysis and energy efficiency comparisons of aluminum melting[J]. Energy Conservation, 2006, 285(4): 17-18.

[22] 卢开澄, 卢华明. 组合数学[M]. 北京: 清华大学出版社, 2002: 1-64.

LU Kai-cheng, LU Hua-ming. Combinatorics[M]. Beijing: Tsinghua University Press, 2002: 1-64.

[23] Nieckele A O, Naccache M F, Gomes M S P. Numerical modeling of an industrial aluminum melting furnace[J]. Journal of Energy Resources Technology, 2004, 126(1): 72-81.

[24] Alchalabi R, Meng F, Peel A. Furnace operation optimization via enhanced bath circulation: technologies for production increase and dross reduction[C]//Light Metals. Warrendale: TMS, 2002: 739-746.

[25] 张仁远. 相变材料与相变储能技术[M]. 北京: 科学出版社, 2009: 199-349.

ZHANG Ren-yuan. PCM and latent thermal energy storage[M]. Beijing: Science Press, 2009: 199-349.

[26] 许光明, 李兴刚, 崔建忠. 液固相铝-不锈板复合轧制温度场的模拟计算[J]. 钢铁研究学报, 2000, 12(4): 19-22.

XU Guang-ming, LI Xin-gang, CUI Jian-zhong. Simulation of temperature field for liquid-solid composite rolling of stainless steel/aluminum[J]. Journal of Iron and Steel Research, 2000, 12(4): 19-22.

(编辑 赵俊)

收稿日期:2011-04-28;修回日期:2011-07-16

基金项目:湖南省自然科学基金资助项目(07JJ4016);中南大学博士生创新基金资助项目(2009bsxt022)

通信作者:闫红杰(1977-),男,河南永城人,教授,从事热工设备仿真与优化研究;电话:13873102530;E-mail:s-rfy@mail.csu.edu.cn