DOI: 10.11817/j.issn.1672-7207.2016.10.008

780 MPa级热镀锌冷轧双相钢断裂过程的原位观察

宇文龙1, 2,李声慈1,康永林1

(1. 北京科技大学 材料科学与工程学院,北京,100083;

2. 首钢技术研究院,北京,100043)

摘要:制备780 MPa级热镀锌冷轧双相钢,并对其组织性能进行测试分析;采用原位拉伸实验观察裂纹的萌生及扩展行为。研究结果表明:实验钢经热处理后获得铁素体+马氏体的双相组织;抗拉强度为789 MPa,屈强比为0.56,伸长率为23%,具有较好的力学性能;裂纹可以在铁素体内部或在铁素体-马氏体两相界上萌生;裂纹在扩展过程中遇到硬相马氏体岛时,会沿着马氏体岛的边缘绕过;铁素体产生的塑性变形能够减弱裂纹附近的局部应力集中,减缓裂纹扩展。双相钢的断口形貌是韧窝型,断裂形式属于塑性断裂。

关键词:双相钢;断裂;原位观察;裂纹扩展

中图分类号:TG142.1 文献标志码:A 文章编号:1672-7207(2016)10-3341-06

In-situ observation of fracture process for 780 MPa grade galvanized cold rolled dual phase steel

YU Wenlong1, 2, LI Shengci1, KANG Yonglin1

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China; 2. Technical Research Institute, Shougang Co. Ltd., Beijing 100043, China)

Abstract: 780 MPa grade galvanized cold rolled dual-phase steel was trial-produced, the microstructure and mechanical properties were tested. In-situ tensile test method was used to observe the crack initiation and propagation behavior. The results show that the dual phase steel consisting of ferrite + martensite shows a tensile strength of 789 MPa, a yield ratio of 0.56, and an elongation of 23%. Cracks may derive from internal ferrite or ferrite-martensite phase boundary. When the cracks encounters hard martensite island during the expansion process, it will bypass the martensite and propagate along the edge of the islands. The plastic deformation near the crack of ferrite can weaken the local stress concentration, thus slowing crack growth. The final fracture pattern is plastic fracture, and the fracture morphology is a dimple pattern.

Key words: dual phase steel; fracture; in-situ observation; crack propagation

双相钢由于具有高强度、低屈强比、高初始加工硬化速率等特点,成为新一代深冲型汽车用先进高强钢;据超轻汽车车身—先进汽车技术项目(ULSAB- AVC)预计,未来汽车上双相钢用量可达80%[1-3]。双相钢一般用于需高强度、高的抗碰撞吸收能且有一定成形要求的汽车零件,如车轮、保险杠、悬挂系统及其加强件等[4]。目前,LUO等[5-10]研究了双相钢的合金成分、微观组织、力学性能和热处理工艺,对推动双相钢的发展起到了积极作用。双相钢在使用过程中难免会出现裂纹,一般是根据断口和金相来分析裂纹的扩展,但这种方法不能直接连续地追踪裂纹的发展。本文作者在实验室中制备780 MPa级冷轧热镀锌双相钢,分析其微观组织和力学性能,并通过原位拉伸实验观察分析双相钢的裂纹形成及扩展行为。

1 实验材料与方法

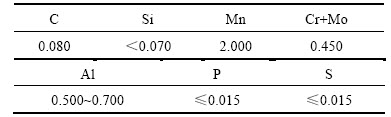

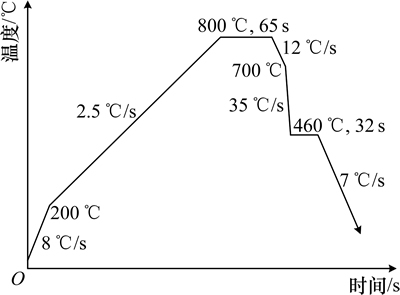

在低碳低硅的条件下,通过添加Mn,C和Mo等合金元素设计了DP780热镀锌双相钢的化学成分,如表1所示。添加约2% Mn不仅增加了实验钢的加工窗口温度,而且解决了低碳固溶强化不足的问题[11]。Mo和Cr增加了钢的淬透性,同时也是良好的固溶强化元素。Al元素在细化晶粒同时还可以提高钢的焊接性。采用真空冶炼炉冶炼后,对铸坯进行锻造,然后在1 250 ℃保温1 h。将坯料在四辊热轧机上轧制到4.0 mm厚,开轧温度1 150 ℃,终轧温度为870 ℃,水冷至660 ℃,模拟卷取空冷至室温。经过酸洗后,将热轧板冷轧至1.5 mm厚,冷轧压下率为62.5%。采用线切割截取长度×宽度为220 mm(轧向)×70 mm的冷轧板在连续退火实验机上进行实验,具体工艺路线如图1所示。

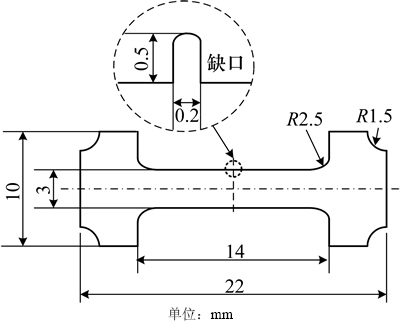

在装有拉伸装置的CS3400型扫描电镜上进行原位拉伸实验。为了保证试样能够被拉断且方便追踪裂纹扩展,试样中间切开1个缺口,具体尺寸如图2所示,试样长度方向为轧向。试样经抛光后,用体积分数为4%的硝酸酒精腐蚀,然后在扫描电镜下拉伸,观察裂纹的起源与扩展过程。拉伸速率为0.1 mm/s,随时可暂停拉伸以拍摄组织照片。计算机自动记录载荷与位移数据。试样拉断后采用扫描电镜观察断口形貌。

表1 实验钢的主要化学成分(质量分数)

Table 1 Main chemical composition of investigated steels %

图1 连续退火工艺路线

Fig. 1 Continuous annealing process of tested steel sheet

图2 原位拉伸试样尺寸

Fig. 2 Specimen geometry for in-situ tensile test

2 结果与分析

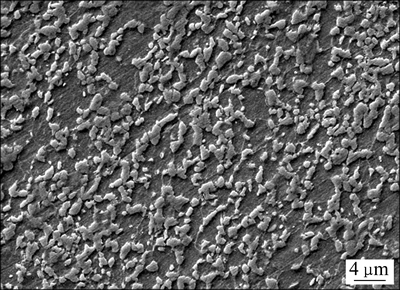

2.1 双相钢的微观组织

在连退处理后的钢板上采用线切割截取长度×宽度为10 mm×10 mm的金相试样,经过机械磨抛后,用体积分数为4%的硝酸酒精溶液侵蚀,然后在扫描电镜下观察组织,如图3所示。由图3可以看出:实验钢的组织主要由铁素体和马氏体构成,马氏体呈岛状均匀分布在铁素体基体上,马氏体岛边缘清晰。冷轧后的钢板在两相区加热得到铁素体+奥氏体,快冷后奥氏体转变为马氏体,得到铁素体+马氏体的双相组织。通过ImageTool软件测得,马氏体体积分数约为39%。从图3还发现:有的马氏体岛存在亮白色边圈,这是由于Mn通过铁素体或沿铁素体晶界扩散时,在奥氏体岛的周围形成了高Mn的边圈,使得奥氏体岛的边部比中心有更高的淬透性,从而在冷却过程中形成了高锰的马氏体边圈及中心部分形成的渗碳体加铁素体的聚合体[12]。

图3 DP780钢的SEM组织形貌

Fig. 3 SEM micrograph of DP780 steel

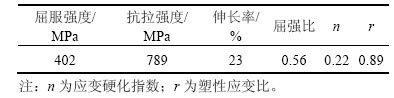

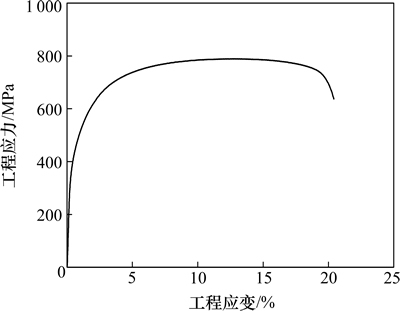

2.2 双相钢的力学性能

表2所示为通过单向拉伸测得DP780双相钢的力学性能,图4所示为工程应力-应变曲线。从图4可以看出:热镀锌双相钢发生连续屈服,无屈服平台;屈服强度较低,屈强比低,而且有较宽的延伸区,有利于冲压成形。双相钢在连续退火快冷过程中,会发生马氏体相变,体积膨胀诱发周围铁素体内产生大量的可动位错,在较低应力下位错源就被激活,从而表现出连续屈服,可以避免成形零件表面起皱。两相区热处理过程中,铁素体中的碳氮化合物大量溶解或部分溶解,快冷过程只能以极小的颗粒析出,因此,位错线将切过粒子而不发生弯曲,明显减弱了原来的强化效应[13]。此外,缓冷过程由于取向附生铁素体的析出,大量C和Mn 元素进一步向剩余奥氏体中转移,铁素体基体得到净化。由于以上2个因素使得双相钢具有低的屈服强度[12, 14]。

2.3 断裂过程的原位观察

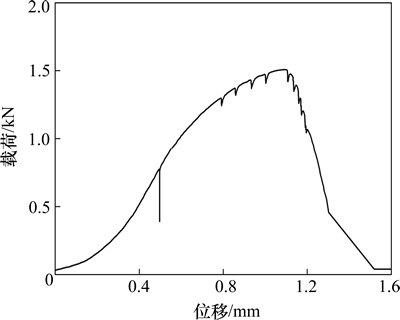

通过原位拉伸实验,可以直接连续地追踪观察裂纹的萌生和扩展以及伴随的形变行为[15]。图5所示为拉伸位移与载荷的关系。图中曲线上的突变点表示停止加载,进行拍照。

表2 DP780钢的力学性能

Table 2 Mechanical properties of the DP780 steel sheets

图4 DP780钢的工程应力-应变曲线

Fig. 4 Engineering stress-strain curves of DP780 steel

图5 原位拉伸过程的载荷-位移曲线

Fig. 5 Curve of force-displacement during in-situ tensile test

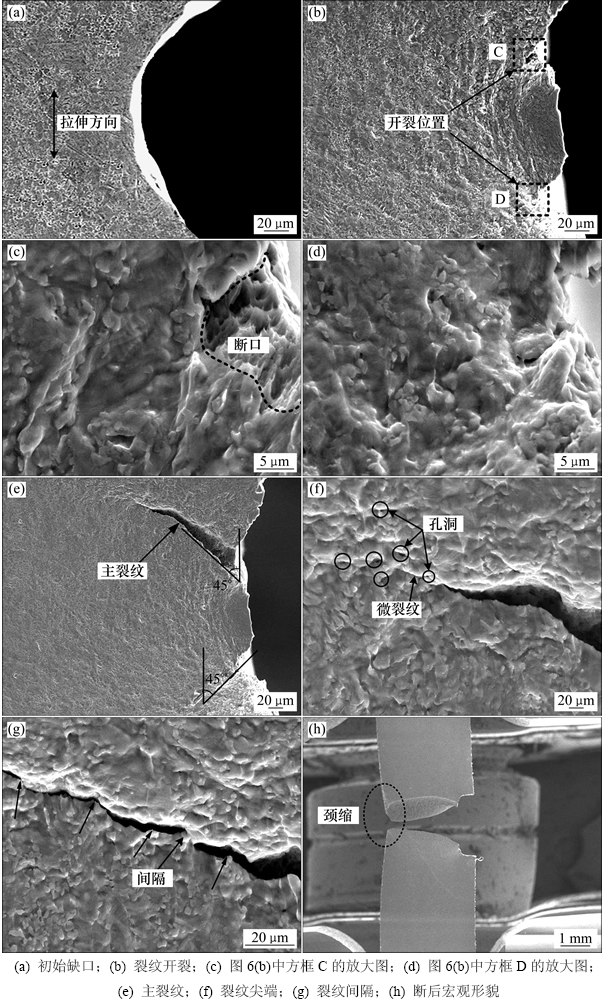

图6(a)所示为初始缺口的形状(位移ΔL=0 mm),缺口加工质量较好,没有明显缺陷。拉伸初始阶段外应力较小,缺口处并未产生明显裂纹;当ΔL=0.791 mm时,载荷约为1 300 N,缺口底部才开始产生明显开裂,如图6(b)所示,图中的方框C和D的放大图分别如图6(c)和6(d)所示。经分析发现裂纹起源机制有多种:铁素体相变形被拉断,铁素体和马氏体相界面开裂。从图6(c)还可以观察到韧窝型断口。当拉应力达一定程度后,在材料内位错塞积造成应力集中,出现局部不协调变形,从而产生孔洞。随着变形程度不断增大,相邻的孔洞贯通直至出现微裂纹,从而实现了裂纹的开裂[16]。但是,直到ΔL=1.136 mm(图6(e))拍照前,开裂处的裂纹并未发生明显扩展,说明钢的塑性较好。随着加载的进行,载荷越来越大。当ΔL=1.136 mm时,其中一个开裂位置迅速发展成主裂纹,另一开裂位置在之后的加载过程中变化不大,后续主要跟踪主裂纹的扩展。裂纹扩展初期,扩展方向与拉伸方向成45°,这是由于该方向剪应力最大。

在应力场的作用下,裂纹尖端会产生塑性区,内应力最大处会萌生新的微裂纹或微孔洞,如图6(f)所示(ΔL=1.159 mm)。微裂纹或微孔洞可能在铁素体内部或在铁素体—马氏体两相界上萌生。铁素体内的微裂纹是应力增大时局部塑性变形产生应力集中导致的;铁素体和马氏体两相之间的性能差异致晶界之间结合力减弱,同时两相变形抗力不等,在外加应力作用下,因变形程度不同产生附加应力导致产生裂纹[17]。微裂纹或微孔会在外应力作用下不断增殖增大,间隔断裂后贯通连接而向前扩展;微裂纹的形成使材料内部增加了新的应力集中并在微裂纹端部产生较集中的塑性变形,这又加速了新的微孔开裂、长大及与微裂纹的连结。主裂纹继续向前扩展时,也会与其尖端的微裂纹相互连接而继续向前扩展。当裂纹扩展到第二相马氏体岛时,会沿着马氏体岛的边缘绕过并不从其中穿过,如图6(g)中箭头(ΔL=1.160 mm)所示。继续拉伸试样直至断裂,ΔL>1.500 mm,如图6(h)所示,试样产生了颈缩现象。从上述可知:马氏体与铁素体界面有利于微裂纹的形成,铁素体产生的塑性变形能够减弱裂纹附近的局部应力集中,减缓裂纹扩展。

图6 双相钢中裂纹的扩展

Fig.6 Crack propagation in DP780 steel

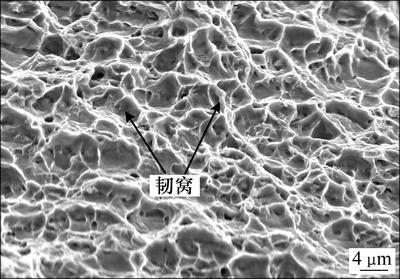

试样拉断后,切取断口在扫描电镜下观察断口形貌,如图7所示。由图7可知:断口微观形态的主要特征是韧窝。韧窝是由一些大小不等的圆形或椭圆形的凹坑组成,在拉伸过程中硬相马氏体被从拉长的软相铁素体拔出而形成韧窝。综合断口形貌和上述试样断裂过程分析,可以判断本实验双相钢的断裂形式属于塑性断裂,铁素体断裂形式主要是微孔相连的塑性方式。

图7 DP780双相钢的断口形貌

Fig. 7 Fracture morphology of DP780 steel

3 结论

1) 试制的双相钢经800 ℃保温,缓冷至700 ℃后快速冷却,在460 ℃下过时效处理32 s,其屈服强度为402 MPa,抗拉强度为789 MPa,伸长率为23 %,综合力学性能优良。

2) 微裂纹可在铁素体内部或两相界上萌生,在外应力作用下繁殖长大;当裂纹扩展到第二相马氏体岛时,会沿着马氏体岛的边缘绕过;铁素体产生的塑性变形能够使裂纹尖端的局部应力集中得以释放,减缓裂纹扩展。

3) 在断裂过程中,铁素体被拉长,硬相马氏体被从铁素体拔出而形成韧窝;双相钢的断裂形式属于塑性断裂。

参考文献:

[1] 康永林, 陈贵江, 朱国明, 等. 新一代汽车用先进高强钢的成形与应用[J]. 钢铁, 2010, 45(8): 13-19.

KANG Yonglin, CHEN Guijiang, ZHU Guoming, et al. Forming technology and application of new generation advanced high strength steel for automobile[J]. Iron Steel, 2010, 45(8): 13-19.

[2] 康永林. 现代汽车板工艺及成形理论与技术[M]. 北京: 冶金工业出版社, 2009: 230-237.

KANG Yonglin. Theory and technology of processing and forming for advanced automobile steel sheets[M]. Beijing: Metallurgical Industry Press, 2009: 230-237.

[3] LI Shengci, KANG Yonglin, KUANG Shuang. Effects of microstructure on fatigue crack growth behavior in cold-rolled dual phase steels[J]. Material Science Engineering A, 2014, 612: 153-161.

[4] 李国彬, 赵征志, 罗青, 等. 780 MPa级冷轧双相钢的组织与性能研究[J]. 金属热处理, 2009, 34(9): 11-14.

LI Guobin, ZHAO Zhengzhi, LUO Qing, et al. Microstructure and properties of 780 MPa grade cold rolled dual-phase steel[J]. Heat Treatment of Metals, 2009, 34(9): 11-14.

[5] LUO Juanjuan, SHI Wen, HUANG Qunfei, et al. Heat treatment of cold-rolled low-carbon Si-Mn dual phase steels[J]. Journal of Iron and Steel Research International, 2010, 17(1): 54-58.

[6] 朱国明, 邝霜, 陈贵江, 等. 马氏体对C-Si-Mn冷轧双相钢屈服特性的影响[J]. 材料工程, 2011(4): 66-70.

ZHU Guoming, KUANG Shuang, CHEN Guijiang, et al. Effect of martensite on yield characteristics of cold rolled C-Si-Mn dual phase steel[J]. Journal of Materials Engineering, 2014(4): 66-70.

[7] GUNDUZ S. Effect of chemical composition, martensite volume fraction and tempering on tensile behavior of dual phase steels[J]. Materials Letters, 2009, 63: 2381-2383.

[8] PIERMAN A P, BOUAZIZ O, PARDOEN T, et al. The influence of microstructure and composition on the plastic behaviour of dual-phase steels[J]. Acta Materialia, 2014, 73: 298-311.

[9] GHAHERI A, SHAFYEI A, HONARMAND M. Effects of inter-critical temperatures on martensite morphology, volume fraction and mechanical properties of dual-phase steels obtained from direct and continuous annealing cycles[J]. Materials Design, 2014, 62: 305-319.

[10] MENG Qingge, LI Jun, WANG Jian, et al. Effect of water quenching process on microstructure and tensile properties of low alloy cold rolled dual-phase steel[J]. Materials Design, 2009, 30: 2379-2385.

[11] 米振莉, 潘殿军, 江海涛. 700 MPa冷轧低合金超高强钢的典型连续退火工艺[J]. 工程科学学报, 2015, 37(2): 185-189.

MI Zhenli, PAN Dianjun, JIANG Haitao. Typical continuous annealing technology of cold-rolled 700 MPa ultra-high strength low-alloy steel[J]. Chinese Journal of Engineering, 2015, 37(2): 185-189.

[12] 张增良, 宋仁伯, 程知松, 等. 800 MPa级冷轧双相钢的工艺与组织性能研究[J]. 上海金属, 2007, 29(5): 160-163.

ZHANG Zengliang, SONG Renbo, CHENG Zhisong, et al. Research on processing microstructures and properties of 800 MPa cold rolling dual phase steel[J]. Shanghai Metals, 2007, 29(5): 160-163.

[13] GUO Enyu, WANG Mingyue, JING Tiao, et al. Temperature- dependent mechanical properties of an austenitic–ferritic stainless steel studied by in situ tensile loading in a scanning electron microscope(SEM)[J]. Materials Science & Engineering A, 2013, 580: 159-168.

[14] 金光灿, 赵爱民, 赵征志, 等. 800 MPa冷轧热镀锌双相钢组织性能及其织构演变[J]. 材料工程, 2010(9): 40-44.

JIN Guangcan, ZHAO Aimin, ZHAO Zhengzhi, et al. Microstructure and property of 800 MPa cold rolled hot dip galvanized dual phase steel and its texture evolution[J]. Journal of Materials Engineering, 2010(9): 40-44.

[15] 宇文龙, 李声慈, 杨乐, 等. 连续退火工艺对冷轧双相钢组织与性能的影响[J]. 金属热处理, 2015, 40(1): 79-82.

YU Wenlong, LI Shengci, YANG Le, et al. Effect of continuous annealing process on microstructure and properties of cold rolled dual-phase steel[J]. Heat Treatment of Metals, 2015, 40(1): 79-82.

[16] LI Shengci, ZHU Guoming, KANG Yonglin. Effect of substructure on mechanical properties and fracture behavior of lath martensite in 0.1C-1.1Si-1.7Mn steel[J]. Journal of Alloys and Compounds, 2016, 675: 104-115.

[17] SAJAD Z, REZA J N, MASOUD A. The sources of the micro stress and strain inhomogeneity in dual phase steels[J]. Materials Science and Engineering A, 2016, 674: 384-396.

(编辑 赵俊)

收稿日期:2015-10-11;修回日期:2016-02-06

基金项目(Foundation item):国家自然科学基金资助项目(U1460101);国家高技术研究发展计划(863计划)项目(2013AA031601)(Project(U1460101) supported by the National Natural Science Foundation of China;Project(2013AA031601) supported by the National High Technology Research and Development Program(863 Program) of China)

通信作者:康永林,教授,博士生导师,从事汽车用高强钢的研究;E-mail:kangylin@ustb.edu.cn